Audi A6 Typ 4G: Fiber-Optic Cables, Repairing

Caution

Caution

Do not bend the fiber-optic cable too much. The bending radius must be no less than 25 mm.

Fiber optic cables must not be routed over sharp edges.

The fiber-optic cable must not be dirty or touched with bare fingers.

Fiber optic cables may not be heated.

It is not permitted to twist together 2 fiber optic cables or one fiber optic cable with a copper wire.

Protect the connector and the connection box from dust. Place the cap on the trunk.

Determine Position of the Error

Special tools and workshop equipment required

- Vehicle Diagnostic Tester

Procedure

It is very difficult to find the exact location of the problem. Replace the damaged fiber-optic cable and lay a new wire parallel to the defective fiber-optic cable.

Note

Note

- Via the "Guided Fault Finding" it can be determines which component of the fiber-optic cable is damaged.

- A fiber-optic cable that needs repair is represented by a "yellow" color.

- Perform in the "Off-board Diagnostic Information System Service" the "Ring break diagnosis" function in the Vehicle Diagnostic Tester.

- Remove the affected components.

- Disconnect the connector from the components.

- Assemble the fiber-optic cable:

Fiber-Optic Cable, Preparing with the Fiber-Optic Conductor Repair Set -VAS6223A-

Special tools and workshop equipment required

- Fiber Optic Repair Set -VAS6223B-

- Hose Cutting Pliers -VAS6228-

Checking Remaining Cut Indicator

- Start by checking remaining cut indicator:

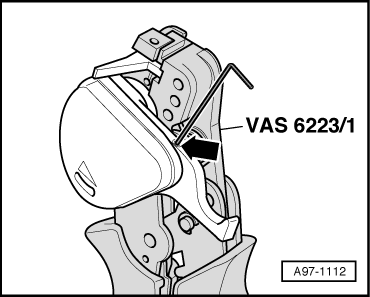

- The Fiber-Optic Repair Set - Pliers -VAS6223/1- cutting device can perform approximately 1260 cuts. The blade is rotated for each further cut.

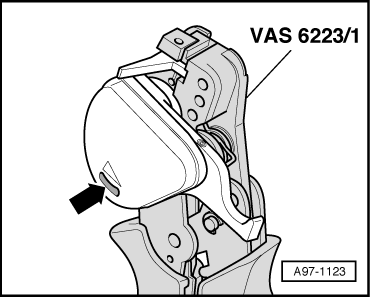

- The remaining cut indicator -arrow - displays the last 150 cuts available.

- Once no further cuts are available, the blade is blocked. It must be replaced. Refer to the Operating Instructions that come with Fiber-Optic Repair Set - Pliers -VAS6223/1-.

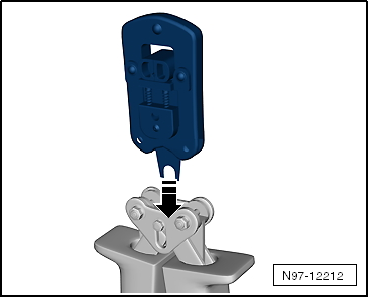

Fiber-Optic Repair Set - Pliers -VAS6223/1- Preparing

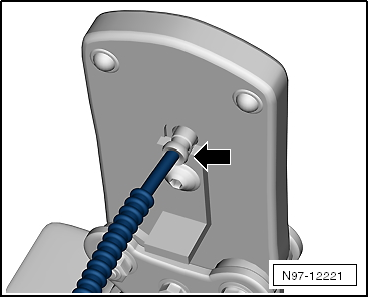

- Release the transport safety device on the cutter by loosening the bolt -arrow-.

Fiber Optic Cable, Cutting to Length

- Establish length of fiber optic cable required.

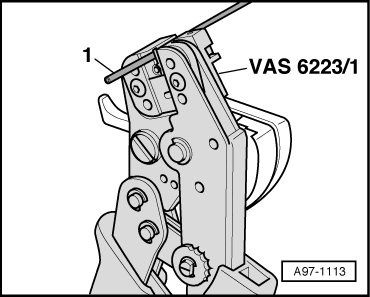

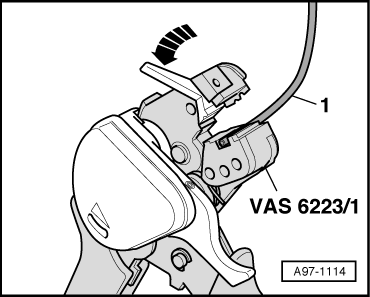

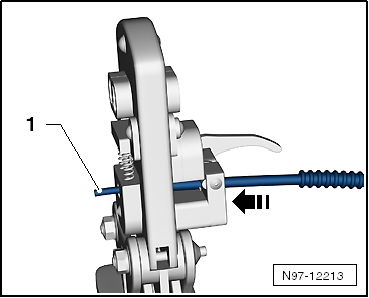

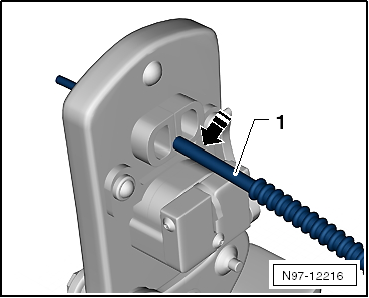

- Open Fiber-Optic Repair Set - Pliers -VAS6223/1- and insert fiber-optic cable -1- into trimming station.

- Close cutting tool to cut fiber optic cable to length.

Stripping

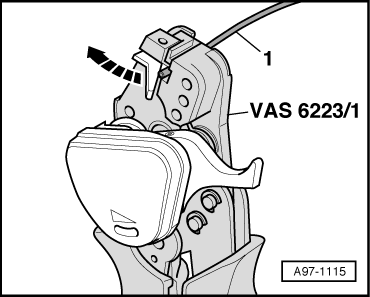

- Open the Fiber-Optic Repair Set - Pliers -VAS6223/1-.

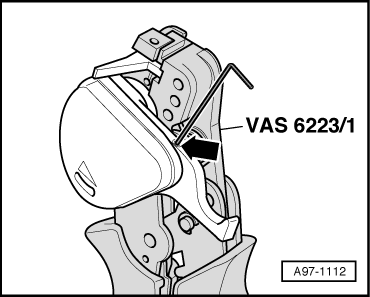

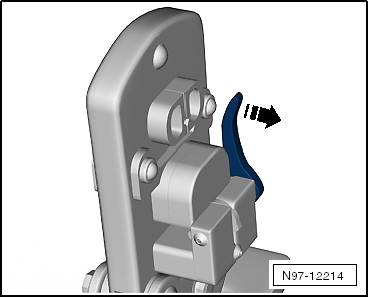

- Stripping lever must be in lower position -arrow-.

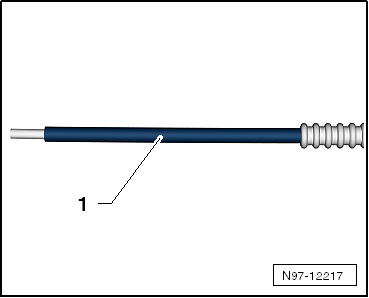

- Place the fiber optic cable -1- in the stripping point.

- The end of the fiber-optic cable must be flush with the rear side of the cutting pliers.

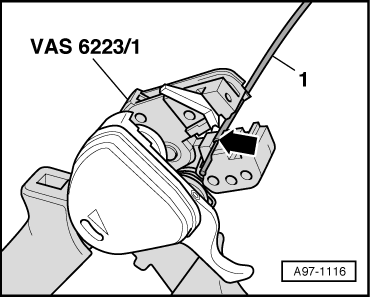

- Close Fiber-Optic Repair Set - Pliers -VAS6223/1- until stop and keep closed.

- Lift the stripping lever -arrow- upward.

- Open the cutting tool and take out the fiber-optic cable -1-.

- Detach the separated section of the insulation from the fiber-optic cable.

Precision Cutting (production of optical end face)

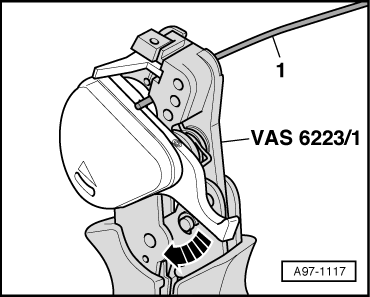

- Slide the fiber-optic cable -1- into the cutting station.

- The insulation must make contact with the cutting point stop -arrow-.

- Close the Fiber-Optic Repair Set - Pliers -VAS6223/1-.

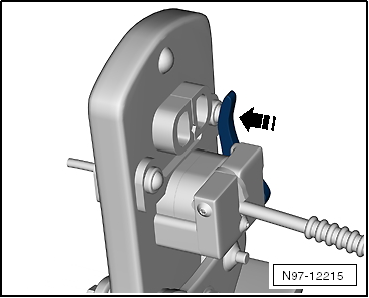

- Press the cutting unit down -arrow-.

- Open Fiber-Optic Repair Set - Pliers -VAS6223/1- and remove fiber-optic cable -1-.

Note

Note

The fiber-optic cable should only be placed on a completely clean surface.

Transport Protection, Activating

- Close the Fiber-Optic Repair Set - Pliers -VAS6223/1-.

- Tighten the hex socket bolt -arrow- for the transport safety device on the cutter.

Attaching Brass Pin Contact to Fiber-Optic Cable

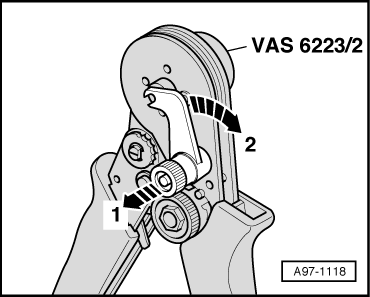

- Open securing lever on Fiber-Optic Repair Set - Crimping Pliers -VAS6223/2--arrow 1- and -arrow 2-.

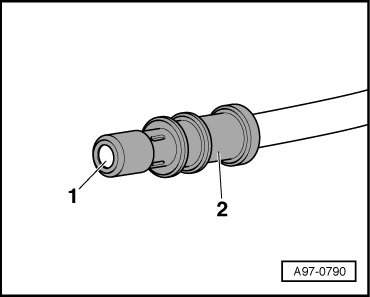

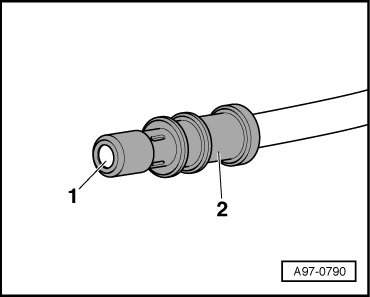

- Insert brass pin contact -1- in the mount.

- Close the safety lever on the Fiber-Optic Repair Set - Crimping Pliers -VAS6223/2--arrow-.

- Slide the fiber optic cable -2- into the brass pin contact -1- as far as spring-loaded stop.

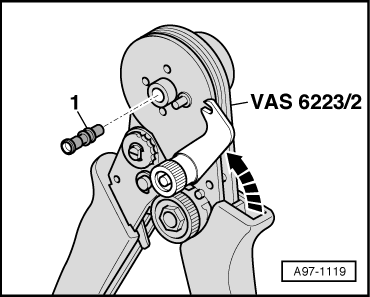

- Slide fiber-optic cable further in up to fixed stop and close Fiber-Optic Repair Set - Crimping Pliers -VAS6223/2-.

- Open the crimping pliers for fiber-optic cable and remove the fiber-optic cable with the brass pin contact.

Caution

Caution

Do not bend the fiber-optic cable too much. The bending radius must be no less than 25 mm.

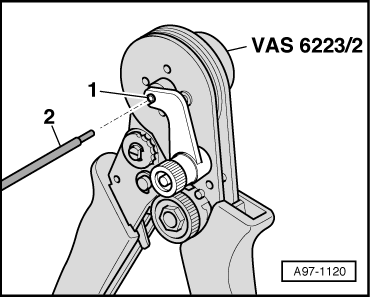

- Make sure the brass pin contact -2- is secured correctly on the fiber-optic cable -1-.

- Four crimp points must be visible at the brass connection pin.

- The brass pin contact must not be able to be removed by hand from the fiber-optic cable.

- The front surface of the fiber-optic cable is 0.01 to 0.1 mm behind the brass pin contact (visual check).

Note

Note

- Connector couplings are available for connecting the fiber-optic cables. Refer to Parts Catalog.

- For installing the new fiber optic cable in the wiring harness connector. Refer to → Chapter "Fiber-Optic Cable, Disconnecting from Wiring Harness Connector".

Corrugated Tube, Install on Fiber Optic Cable.

- Cut the corrugated tube to the appropriate length.

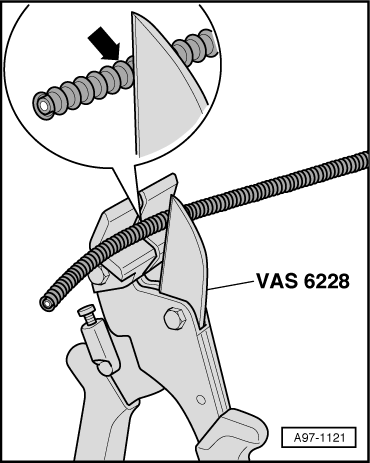

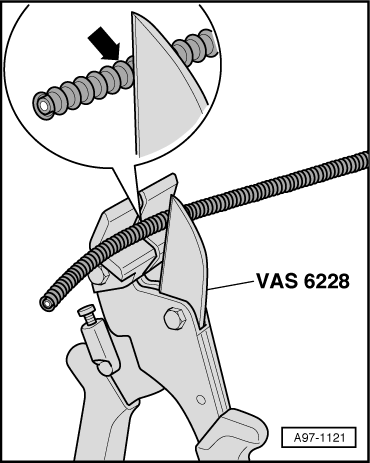

- Use the Hose Cutting Pliers -VAS6228- or a sharp knife for cutting.

- The corrugated tube must not be cut through using a side cutter under any circumstances

- The corrugated tube must be cut on the wave peak -arrow-, not in the wave trough.

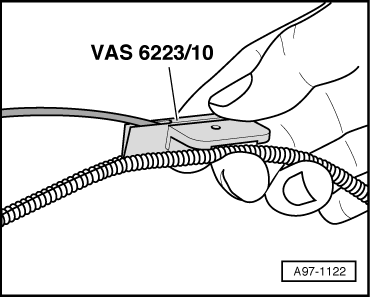

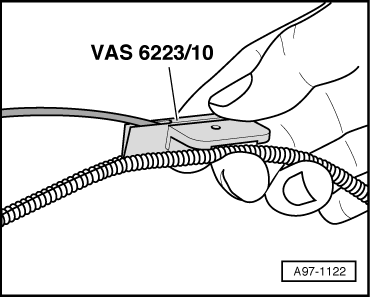

- Guide fiber-optic cable into Fiber-Optic Repair Set - Tube Tool -VAS6223/10- as shown in illustration.

- Position the crimping pliers for fiber-optic cable at the slot on the corrugated tube.

- Slide the crimping pliers for fiber-optic cable along the slot on the circumference of the corrugated tube. The fiber optic cable is then routed in the corrugated tube.

Fiber-Optic Cable, Preparing with the Fiber-Optic Conductor Repair Set -VAS6223A-

Special tools and workshop equipment required

- Fiber-Optic Conductor Repair Set -VAS6223A-

- Hose Cutting Pliers -VAS6228-

- Vehicle Diagnostic Tester

Caution

Caution

Do not bend the fiber-optic cable too much. The bending radius must be no less than 25 mm.

Fiber optic cables must not be routed over sharp edges.

The fiber-optic cable must not be dirty or touched with bare fingers.

Fiber optic cables may not be heated.

It is not permitted to twist together 2 fiber optic cables or one fiber optic cable with a copper wire.

Protect the connector and the connection box from dust. Place the cap on the trunk.

Mount Tool Head for the Fiber-Optic Repair Set - Pliers -VAS6223/1-.

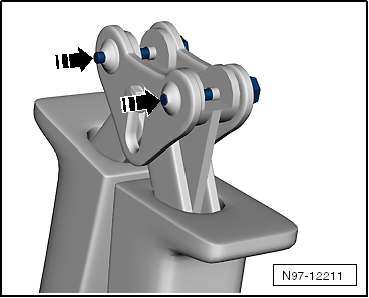

- Remove the locking pin -arrows-.

- Remove the tool set -arrow- and pull the locking pin back.

Fiber Optic Cable, Cutting to Length

- Establish length of fiber optic cable required.

- Open the Fiber-Optic Repair Set - Pliers and lay the fiber-optic cable -1- in the mount.

- Close the Fiber-Optic Repair Set - Pliers to cut the fiber-optic cable lengths.

Stripping

- Open the Fiber-Optic Repair Set - Pliers -VAS6223/1-.

- Position the wire stripper in the lower position -arrow-.

- Insert fiber-optic cable into the stripping station.

- The end of the fiber-optic cable must be flush with the rear side of the cutting pliers.

- Close the Fiber-Optic Repair Set - Pliers until the stop and keep closed.

- Bend the wire stripper upward -arrow- and remove the fiber-optic cable.

Precision Cutting (production of optical end face).

- Push the fiber-optic cable -1- into the cutting station.

- Insulation must make contact with cutting point stop.

- Close the Fiber-Optic Repair Set - Pliers -VAS6223/1- and remove the wire.

- Visually inspect the wire -1- to make sure that it was cut correctly and that there are no burrs on the front surface.

Note

Note

- Fiber-optic cable is only to be placed on an absolutely clean surface or held in hand.

- Use the cap if there is a risk of the fiber-optic cable surface becoming dirty.

Attaching Brass Pin Contact to Fiber-Optic Cable.

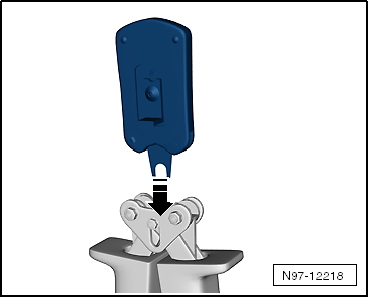

- Change tool head -arrow-.

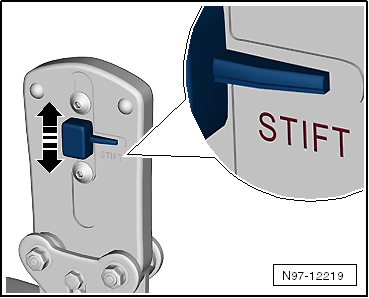

- Slide the safeguard on the Fiber-Optic Repair Set - Pliers-arrow- so that the word "Stift" (pin) is legible.

- Insert a brass pin contact -1- in the mount.

- Close the securing lever on the Fiber-Optic Repair Set - Pliers-arrow-.

- Insert the fiber-optic cable into the brass pin contact -arrow- all the way up to the threaded stop and then close the Fiber-Optic Repair Set - Pliers.

- Open the fiber-optic cable pliers and remove the fiber-optic cable along with the brass contact pin.

Caution

Caution

Do not excessively bend or kink the fiber-optic cables (minimum bending radius 25 mm).

- Make sure the brass pin contact -2- is secured properly on the fiber-optic cable -1-.

- 4 crimped points must be visible on the brass connecting pin.

- The brass pin contact must not be able to be removed by hand from fiber-optic cable.

- The front surface of the fiber-optic cable is 0.01 to 0.1 mm behind the brass pin contact (visual check).

Note

Note

- Connector couplings are available for connecting the fiber-optic cables. Refer to Parts Catalog.

- To install the new fiber optic cable in wiring harness connector. Refer to → Chapter "Fiber-Optic Cable, Disconnecting from Wiring Harness Connector".

Corrugated Tube, Install On Fiber Optic Cable

- Cut corrugated tube to appropriate length.

- Use the Hose Cutting Pliers -VAS6228- or a sharp knife for cutting.

- The corrugated tube must not be cut through using a side cutter under any circumstances

- The corrugated tube must be cut on the wave peak -arrow-, not in the wave trough.

- The corrugated tube must audibly engage in the fiber-optic cable housing when installing.

- Guide the fiber-optic cable into the Fiber-Optic Repair Set - Tube Tool -VAS6223/10- as shown.

- Position corrugated tube assembly pliers on slot on the tube.

- Position crimping pliers for fiber-optic cable at slot of corrugated tube. The fiber optic cable is then routed in the corrugated tube.

Fiber-Optic Cable, Disconnecting from Wiring Harness Connector

Removing

- Unplug connector for fiber optic cable from appropriate control unit.

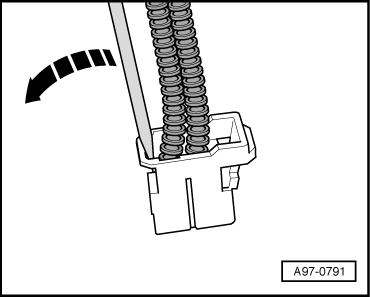

- Release the catch in the fiber optic cable connector in direction of -arrow-.

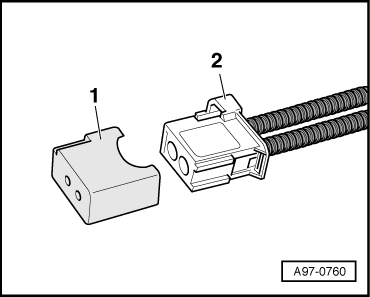

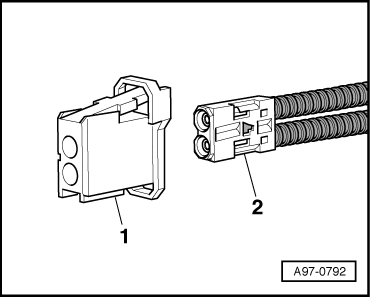

- Pull the fiber optic cable basic module -2- out of connector housing -1-.

Caution

Caution

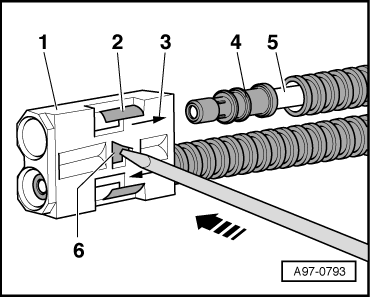

- Make colored dots to mark assignment of the fiber optic cable -5- to the corresponding sockets in the base module -1-.

- Note the arrows -3- for allocation on the base module "IN" and "OUT".

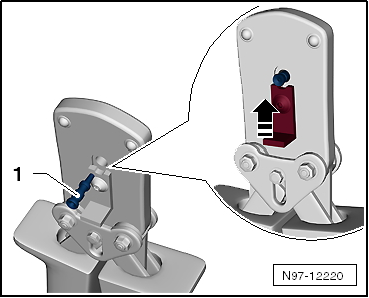

- Release the secondary catch -6- (blue pin) using a small screwdriver -arrow-.

- Release the catch -2- and remove the fiber-optic cable -5- with brass connector pin -4- from the base module -1-.

Installing

Install in reverse order of removal. Note the following:

Note

Note

- Cover the open connector -2- for the fiber-optic cable using the Fiber-Optic Repair Set - Connector Protective Caps -VAS6223/9--1-.

- The protective cap prevents contamination of or mechanical damage to end face of fiber optic cable which would impair signal transmission.

- Install fiber optic cable in line with markings.