Audi A6 Typ 4G: Peripheral Camera System, Calibrating

Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6-, Installing and Aligning

Special tools and workshop equipment required

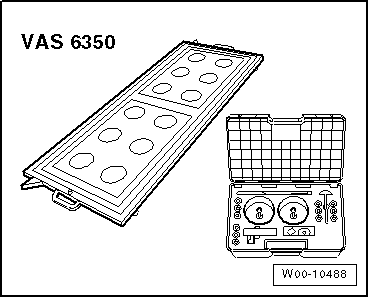

- Calibration Tool -VAS6350-

- Peripheral Camera Calibration Device -VAS6350/6-

- Vehicle Diagnostic Tester

After performing service work on the vehicle, it may be necessary to calibrate the peripheral camera system. In detail, this is the case after:

- Replacing one or more cameras

- Replace Peripheral Camera Control Module -J928- (all cameras need to be calibrated)

- Repair work on components in which a camera is installed or that influence the component location of the camera

- After suspension adjustments

- When adjusting the overlap range of the individual cameras

All cameras must be calibrated if the Peripheral Camera Control Module -J928- is replaced.

Calibration Requirements

- The camera lens must be clean. Cleaning

- Check the camera images on the Front Information Display Control Head -J685-. Replace the camera if the images are unclear because the camera has been damaged. Check the mount for the camera if the image is low.

- Make sure both exterior rearview mirrors are folded out.

- The vehicle must be standing on a firm and level surface.

- There must be enough clearance around the vehicle (at least 2 meters).

- If the vehicle has an air suspension, turn on "Auto" and drive the vehicle at "standard vehicle height" onto Vehicle Diagnostic Tester.

- The parking brake must be set.

- The steering wheel must be in the 0 position and the wheels must be straight.

- All doors and the rear lid must be closed.

- No one should be in the vehicle.

- The vehicle must not be loaded (curb weight).

- Connect the battery charger.

- Ignition switched on.

- The system is active and is displayed on the Front Information Display Control Head -J685-.

- Do not move the vehicle during the calibration process.

Calibrate the cameras in the following sequence:

- Front Peripheral Camera -R243-

- Rear Peripheral Camera -R246-

- Left Peripheral Camera -R244-

- Right Peripheral Camera -R245-

The Calibration Tool -VAS6350- consists of the following parts:

- Calibration field

- Calibration Tool - Wheel Center Mountings -VAS6350/1-

- Calibration Tool - Spacing Laser -VAS6350/2-

- Calibration Tool - Linear Laser -VAS6350/3-

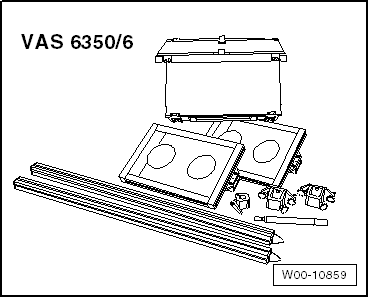

The Night Vision Calibration Tool -VAS6350/6- is comprise of the following components:

- Left Post With Plate -VAS6350/6-1-

- Right Post With Plate -VAS6350/6-2-

- Left Post Mount -VAS6350/6-3-

- Right Post Mount -VAS6350/6-4-

- Peripheral Camera Calibration Device - Guide Pin -VAS6350/6-5-

- Line Laser Mount -VAS6350/6-6-

Overview Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6-

The Left Post With Plate -VAS6350/6-1- and Right Post With Plate -VAS6350/6-2- must be vertical.

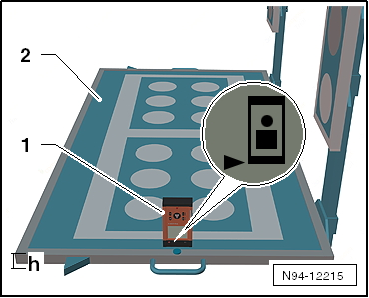

- Move the calibration field on the Calibration Tool -VAS6350-into a horizontal position.

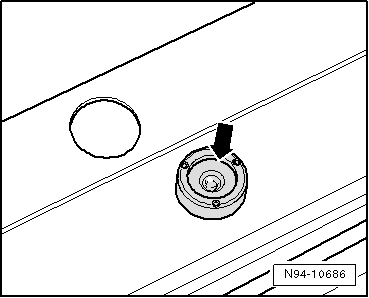

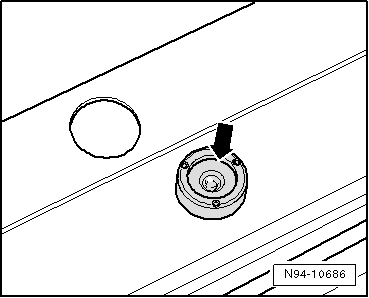

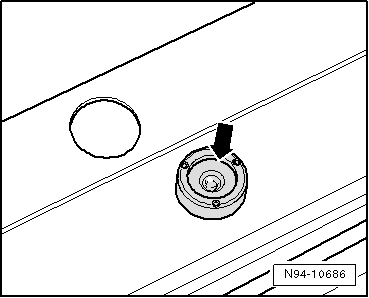

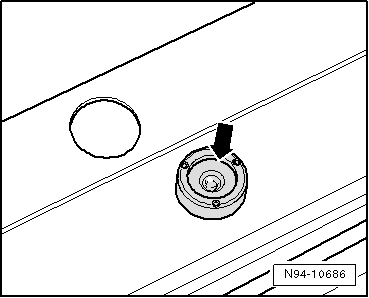

- To do so, twist plastic feet under the calibration field of the Calibration Tool -VAS6350- so that air bubble in level is located exactly in the center of the indicator -arrow-

WARNING

WARNING

Make sure light does not reflect off the Peripheral Camera Calibration Device -VAS6350/6-.

Reflections affect the camera and may make it impossible to perform the calibration.

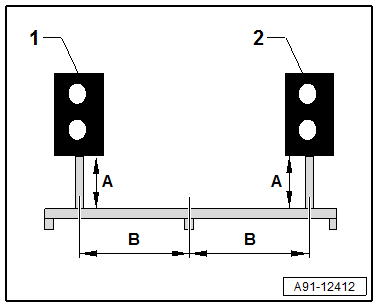

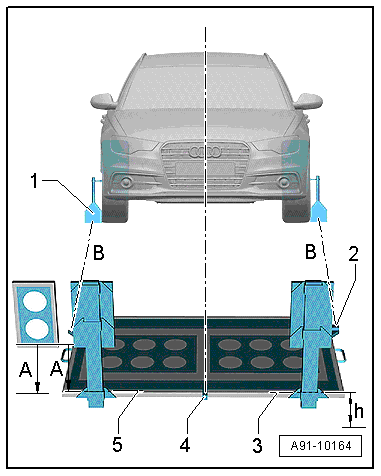

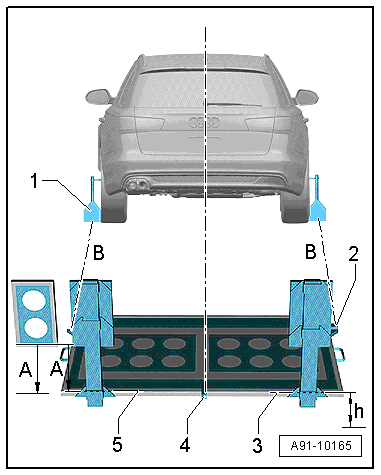

- Set the Left Post With Plate -VAS6350/6-1--1- and the Right Post With Plate -VAS6350/6-2--2- on both sides to the dimension -B- 77.5 of the scale on the Calibration Device -VAS6350-.

- Adjust the height of the Left Post With Plate -VAS6350/6-1--1- and Right Post With Plate -VAS6350/6-2--2- so that dimension -A- is 150 mm between the lower edge of the black measuring field (not of the aluminum frame!) and the surface of the Calibration Device -VAS6350- calibration field.

The corners on the outside of the Calibration Tool -VAS6350- calibration field must always be flush with the outer edge of the black line on the measuring field when performing distance measuring.

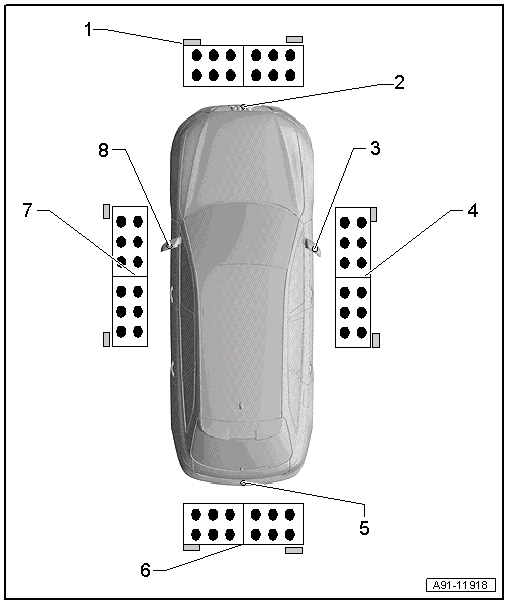

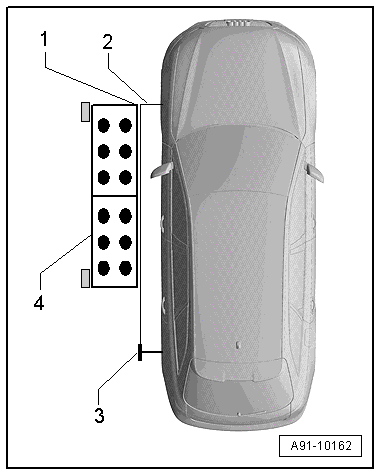

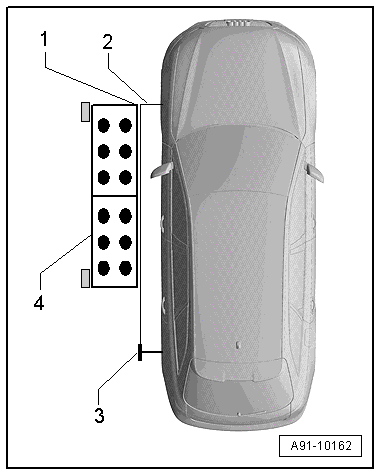

Layout of Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6-

1 - Positioning the Front Peripheral Camera -R243- for calibrating

2 - Front Peripheral Camera -R243-

- Calibrating. Refer to → Chapter "Rear Peripheral Camera -R246-, Calibrating".

3 - Right Peripheral Camera -R245-

- Calibrating. Refer to → Chapter "Left Peripheral Camera -R244-/Right Peripheral Camera -R245-, Calibrating".

4 - Positioning the Right Peripheral Camera -R245- for calibrating

5 - Rear Peripheral Camera -R246-

- Calibrating. Refer to → Chapter "Rear Peripheral Camera -R246-, Calibrating".

6 - Positioning the Rear Peripheral Camera -R246- for calibrating

7 - Positioning the Left Peripheral Camera -R244- for calibrating

8 - Left Peripheral Camera -R244-

- Calibrating. Refer to → Chapter "Left Peripheral Camera -R244-/Right Peripheral Camera -R245-, Calibrating".

WARNING

WARNING

Make sure light does not reflect off the Peripheral Camera Calibration Device -VAS6350/6-.

Reflections affect the camera and may make it impossible to perform the calibration.

Front Peripheral Camera -R243- Calibrating

Special tools and workshop equipment required

- Calibration Tool -VAS6350-

- Peripheral Camera Calibration Device -VAS6350/6-

- Vehicle Diagnostic Tester

The Front Peripheral Camera -R243- is installed in the bumper cover between the Audi rings (between Night Vision System Camera -R212- and Garage Door Opener Control Module -J530-).

- Setup requirements.

- Install and align the Calibration Tool -VAS6350- with Peripheral Camera Calibration Device - VAS6350/6-. Refer to → Chapter "Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6-, Installing and Aligning".

- Connect the Vehicle Diagnostic Tester.

Setting up the calibration device

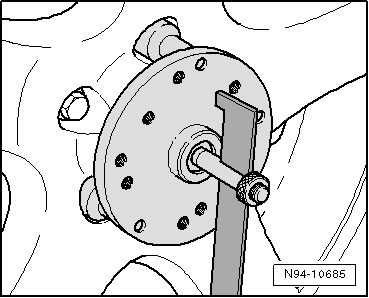

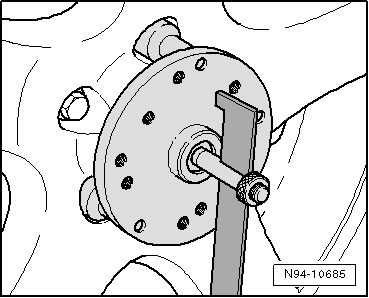

Calibration Tool - Wheel Center Mountings -VAS6350/1- installing:

- Check the dimension of the holes.

- Equip the Calibration Tool - Wheel Center Mountings -VAS6350/1- appropriately.

- To do so, secure three wheel bolt adapters in the hole circle to each Calibration Tool - Wheel Center Mountings -VAS6350/1-.

- Place the paddle on both Calibration Tool - Wheel Center Mountings -VAS6350/1- and secure them using a clamping screw.

- Place the Calibration Tool - Wheel Center Mountings -VAS6350/1- onto the wheel bolts on the rear wheels.

The Calibration Tool - Wheel Center Mountings -VAS6350/1- are positioned by the "O rings" in the adapters and held in place.

Note

Note

Attach the Calibration Tool - Wheel Center Mountings -VAS6350/1- onto the wheels so that any installed "anti-theft" wheel mounting bolts are not connected to the Calibration Tool - Wheel Center Mountings -VAS6350/1-.

- Adjust the paddle with aid of lock bolts so that they move freely just above the floor. Make sure that the paddle is easily accessible.

Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6- orientation

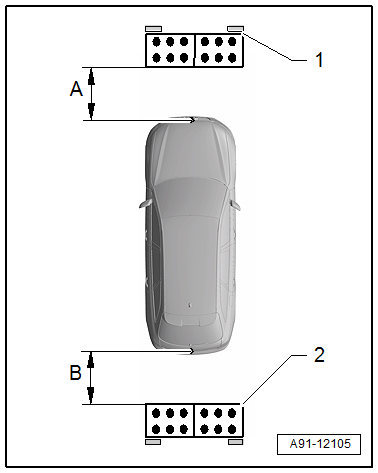

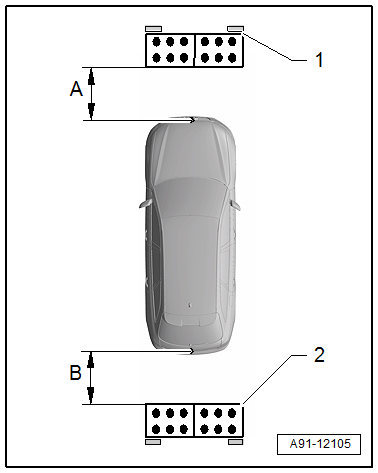

- Position the Calibration Tool -VAS6350- with the Night Vision Calibration Tool -VAS6350/6--1- at a distance of between 400 mm and 600 mm -dimension A- in front of the vehicle in the center (in front of the front bumper trim).

- Bring the Calibration Tool -VAS6350- with Night Vision Calibration Tool -VAS6350/6- into a horizontal position.

- To do so, twist plastic feet under the calibration field of the Calibration Tool -VAS6350- so that air bubble in level is located exactly in the center of the indicator -arrow-

WARNING

WARNING

Make sure light does not reflect off the Peripheral Camera Calibration Device -VAS6350/6-.

Reflections affect the camera and may make it impossible to perform the calibration.

- Attach the Calibration Tool - Linear Laser -VAS6350/3--4- to the Night Vision Calibration Tool -VAS6350/6- to the center of the location provided.

- Switch on the Calibration Tool - Linear Laser -VAS6350/3--4- and align the calibration field of the Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6- so that the laser beam points at the front of the vehicle, in the center just above the Audi rings.

- Make sure the Audi rings are exactly in the center. Correct the laser beam accordingly.

Distance measurement:

- Switch on the Calibration Tool - Spacing Laser -VAS6350/2-.

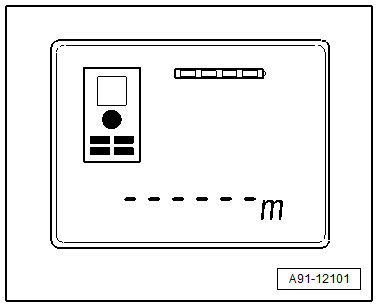

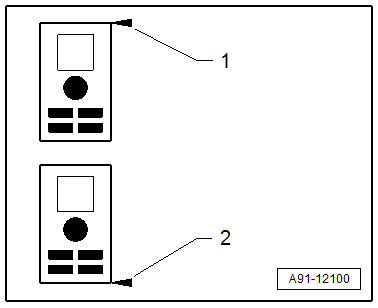

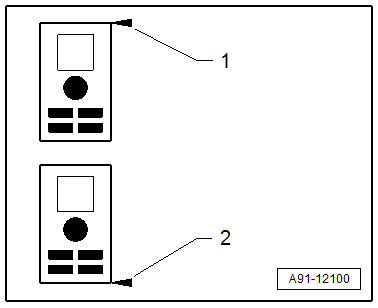

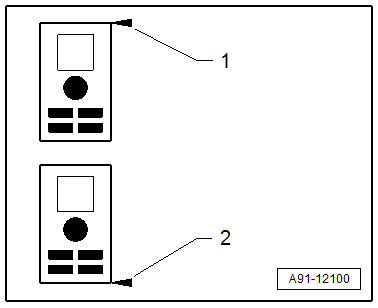

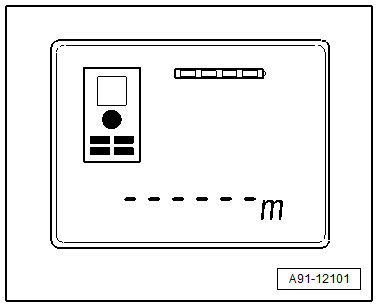

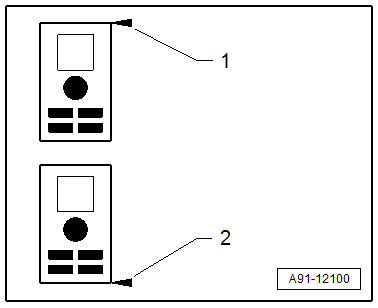

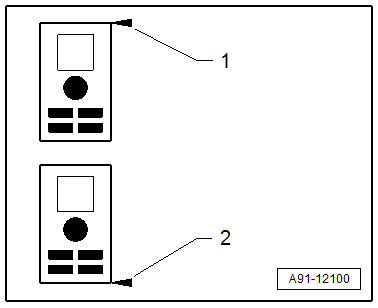

The following display appears:

The display shows how to stop the Calibration Tool - Spacing Laser -VAS6350/2-. Press the corresponding button.

1 - Attach with front edge

2 - Attach with rear edge

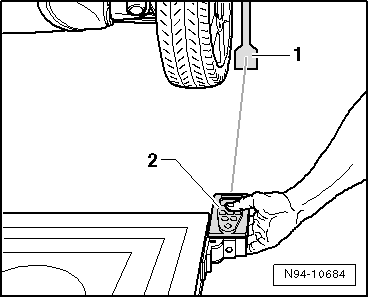

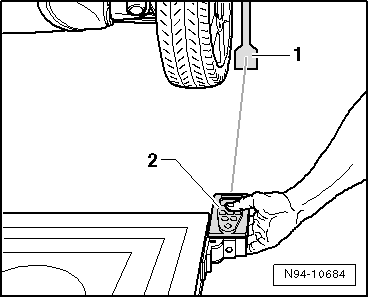

- Hold the Calibration Tool - Spacing Laser -VAS6350/2--2- flush in the bracket on one side of the Calibration Tool -VAS6350- calibration field (with rear edge). To do so, the Calibration Tool - Spacing Laser -VAS6350/2--2- must sit securely on the bracket.

- Press the measuring button briefly.

The laser turns on.

- Make sure that laser beam from Calibration Tool - Spacing Laser -VAS6350/2--2- hits lower, enlarged part of paddle -1-.

If this is not the case, paddles must be corrected accordingly via clamping screws on the Calibration Tool - Wheel Center Mountings -VAS6350/1-.

- Use one hand to secure the Calibration Tool - Spacing Laser -VAS6350/2- in the bracket on the calibration field Calibration Tool -VAS6350- while the laser beam is visible on the paddle.

- Then press the measuring button for distance measurement briefly.

- Repeat this measurement on the other side of the Calibration Tool -VAS6350- calibration field in the same way for the rear wheel.

The distance value must be the same on both sides.

If values are not identical:

- Align the Calibration Tool -VAS6350- with the Peripheral Camera Calibration Device -VAS6350/6- long enough so that both sides are identical.

Pay attention when aligning the Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6- that the Calibration Tool - Linear Laser -VAS6350/3- from the Peripheral Camera Calibration Device -VAS6350/6- strikes the center of the Audi rings and the indicator of the level remains centered. Adjust if necessary.

- Make note of the distance dimension measured.

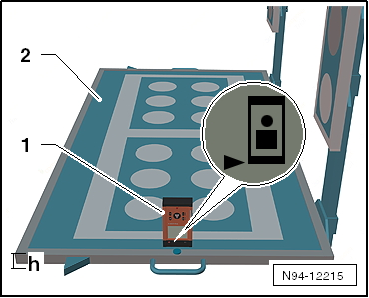

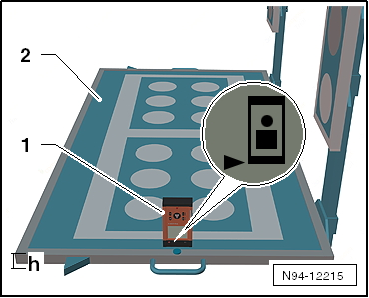

Dimension measurement -h-:

- Measure the height of the Calibration Tool -VAS6350--2- calibration field, dimension -h-, from the surface of the Calibration Tool -VAS6350--2- calibration field (not the aluminum frame) down to the floor. Measure the hole in the Calibration Tool -VAS6350--2- calibration field.

Make sure the Calibration Tool - Spacing Laser -VAS6350/2--1- is adjusted correctly (attach with front edge).

The display shows how to stop the Calibration Tool - Spacing Laser -VAS6350/2-. Press the corresponding button.

1 - Attach with front edge

2 - Attach with rear edge

Dimension -h- and the distance dimension must now be entered into the Vehicle Diagnostic Tester in "millimetres".

Performing calibration

Vehicle Diagnostic Tester is attached.

- Select the Diagnostic mode and start the diagnostics.

- Select the tab test plan.

- Select select individual tests and choose the following sequence.

- Body

- Electrical Equipment

- 01 - OBD-capable systems

- 6C - peripheral camera control module | J928

- 6C - peripheral camera control module, functions

- 6C - Calibration, (Repair Group 91)

From here the Vehicle Diagnostic Tester advances the calibration procedure forward.

WARNING

WARNING

Make sure light does not reflect off the Peripheral Camera Calibration Device -VAS6350/6-.

Reflections affect the camera and may make it impossible to perform the calibration.

Left Peripheral Camera -R244-/Right Peripheral Camera -R245-, Calibrating

Special tools and workshop equipment required

- Calibration Tool -VAS6350-

- Peripheral Camera Calibration Device -VAS6350/6-

- Vehicle Diagnostic Tester

The Left Peripheral Camera -R244-/Right Peripheral Camera -R245- are installed inside the left and right exterior mirrors.

The following describes calibrating the Left Peripheral Camera -R244-. Calibrating the Right Peripheral Camera -R245- is identical.

- Setup requirements.

- Install and align the Calibration Tool -VAS6350- with Peripheral Camera Calibration Device - VAS6350/6-. Refer to → Chapter "Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6-, Installing and Aligning".

- Connect the Vehicle Diagnostic Tester.

Setting up the calibration device

Calibration Tool - Wheel Center Mountings -VAS6350/1- installing:

- Check the dimension of the holes.

- Equip the Calibration Tool - Wheel Center Mountings -VAS6350/1- appropriately. Use spacer pieces.

- To do so, secure three wheel bolt adapters in the hole circle to each Calibration Tool - Wheel Center Mountings -VAS6350/1-.

- Place the paddle on both Calibration Tool - Wheel Center Mountings -VAS6350/1- and secure them using a clamping screw.

- Place the Wheel Center Mounting -VAS6350/1- onto the wheel bolts on the front wheels.

The Calibration Tool - Wheel Center Mountings -VAS6350/1- are positioned by the "O rings" in the adapters and held in place.

Note

Note

Attach the Calibration Tool - Wheel Center Mountings -VAS6350/1- onto the wheels so that any installed "anti-theft" wheel mounting bolts are not connected to the Calibration Tool - Wheel Center Mountings -VAS6350/1-.

- Position the equipped Calibration Tool -VAS6350- with the Peripheral Camera Calibration Device -VAS6350/6--4- near the vehicle.

- Adjust the paddle -2- with a clamping screw so that it moves freely and easily just over the Calibration Tool -VAS6350--4- calibration platform.

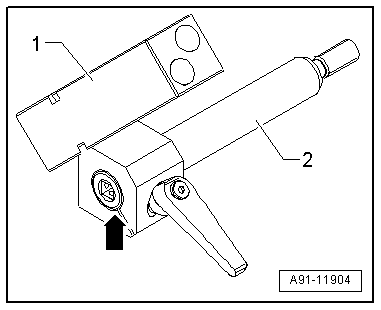

Installing the Calibration Tool - Linear Laser -VAS6350/3-:

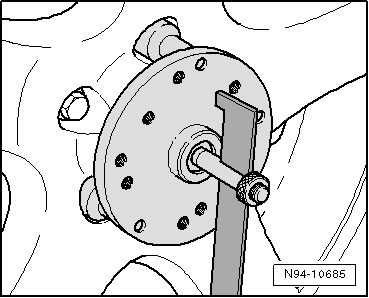

- Install the Guide Pin -VAS6350/6-5--2- all the way using the 3/8" fine toothed ratchet on the left rear wheel and install the Line Scan Laser Mount -VAS6350/6-6- together with the Left Post Mount -VAS6350/3--1-.

- Slide the Line Scan Laser Mount -VAS6350/6-6- so that the outer edge of the Guide Pin -VAS6350/6-5- is flush with the outer edge of the laser housing -arrow-. Tighten the clamping lever.

Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6- orientation

- Switch on the Calibration Tool - Linear Laser -VAS6350/3--3- and adjust the laser beam forward toward the Calibration Tool - Wheel Center Mountings -VAS6350/1--2- such that a line appears on the Calibration Tool -VAS6350--4- calibration field.

- Adjust the Calibration Tool -VAS6350--4- calibration field such that the outer edge of the black line on the Calibration Tool -VAS6350--4- calibration field is exactly on the laser beam.

- Adjust the Calibration Tool -VAS6350--4- calibration field relative to the outer edge of the black line -1- so that it lines up exactly with the free-hanging paddle on the Calibration Tool - Wheel Center Mountings -VAS6350/1--2-.

- Bring the Calibration Tool -VAS6350- with Night Vision Calibration Tool -VAS6350/6- into a horizontal position.

- To do so, twist plastic feet under the calibration field of the Calibration Tool -VAS6350- so that air bubble in level is located exactly in the center of the indicator -arrow-

WARNING

WARNING

Make sure light does not reflect off the Peripheral Camera Calibration Device -VAS6350/6-.

Reflections affect the camera and may make it impossible to perform the calibration.

- Measure the height of the Calibration Tool -VAS6350--2- calibration field, dimension -h-, from the surface of the Calibration Tool -VAS6350--2- calibration field (not the aluminum frame) down to the floor. Measure the hole in the Calibration Tool -VAS6350--2- calibration field.

Make sure the Calibration Tool - Spacing Laser -VAS6350/2--1- is adjusted correctly (attach with front edge).

The display shows how to stop the Calibration Tool - Spacing Laser -VAS6350/2-. Press the corresponding button.

1 - Attach with front edge

2 - Attach with rear edge

Dimension -h- and the distance dimension must now be entered into the Vehicle Diagnostic Tester in "millimetres".

Performing calibration

Vehicle Diagnostic Tester is attached.

- Select the Diagnostic mode and start the diagnostics.

- Select the tab test plan.

- Select select individual tests and choose the following sequence.

- Body

- Electrical Equipment

- 01 - OBD-capable systems

- 6C - peripheral camera control module | J928

- 6C - peripheral camera control module, functions

- 6C - Calibration, (Repair Group 91)

From here the Vehicle Diagnostic Tester advances the calibration procedure forward.

WARNING

WARNING

Make sure light does not reflect off the Peripheral Camera Calibration Device -VAS6350/6-.

Reflections affect the camera and may make it impossible to perform the calibration.

Rear Peripheral Camera -R246-, Calibrating

Special tools and workshop equipment required

- Calibration Tool -VAS6350-

- Peripheral Camera Calibration Device -VAS6350/6-

- Vehicle Diagnostic Tester

The Rear Peripheral Camera -R246- is installed in the rear lid handle button.

- Setup requirements.

- Install and align the Calibration Tool -VAS6350- with Peripheral Camera Calibration Device - VAS6350/6-. Refer to → Chapter "Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6-, Installing and Aligning".

- Connect the Vehicle Diagnostic Tester.

Setting up the calibration device

Calibration Tool - Wheel Center Mountings -VAS6350/1- installing:

- Check the dimension of the holes.

- Equip the Calibration Tool - Wheel Center Mountings -VAS6350/1- appropriately. Use spacer pieces.

- To do so, secure three wheel bolt adapters in the hole circle to each Calibration Tool - Wheel Center Mountings -VAS6350/1-.

- Place the paddle on both Calibration Tool - Wheel Center Mountings -VAS6350/1- and secure them using a clamping screw.

- Place the Calibration Tool - Wheel Center Mountings -VAS6350/1- onto the wheel bolts on the rear wheels.

The Calibration Tool - Wheel Center Mountings -VAS6350/1- are positioned by the "O rings" in the adapters and held in place.

Note

Note

Attach the Calibration Tool - Wheel Center Mountings -VAS6350/1- onto the wheels so that any installed "anti-theft" wheel mounting bolts are not connected to the Calibration Tool - Wheel Center Mountings -VAS6350/1-.

- Adjust the paddle with aid of lock bolts so that they move freely just above the floor. Make sure that the paddle is easily accessible.

Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6- orientation

- Position the Calibration Tool -VAS6350- with the Night Vision Calibration Tool -VAS6350/6--1- at a distance of between 400 mm and 600 mm -dimension B- in the rear of the vehicle in the center (in behind of the rear bumper trim).

Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6- orientation

- Move the calibration field on the Calibration Tool -VAS6350-into a horizontal position.

- To do so, twist plastic feet under the calibration field of the Calibration Tool -VAS6350- so that air bubble in level is located exactly in the center of the indicator -arrow-

WARNING

WARNING

Make sure light does not reflect off the Peripheral Camera Calibration Device -VAS6350/6-.

Reflections affect the camera and may make it impossible to perform the calibration.

- Attach the Calibration Tool - Linear Laser -VAS6350/3--4- to the Calibration Tool -VAS6350- to the center of the location provided.

- Switch on the Calibration Tool - Linear Laser -VAS6350/3--4- on the calibration field of the Calibration Tool -VAS6350- and align the entire Calibration Tool -VAS6350- with Peripheral Camera Calibration Device -VAS6350/6- so that the laser beam of the Calibration Tool - Linear Laser -VAS6350/3- hits the center of vehicle rear above the Audi rings.

- Make sure the Audi rings are centered on the rear. Correct the laser beam accordingly.

Distance measurement:

- Switch on the Calibration Tool - Spacing Laser -VAS6350/2-.

The following display appears:

The display shows how to stop the Calibration Tool - Spacing Laser -VAS6350/2-. Press the corresponding button.

1 - Attach with front edge

2 - Attach with rear edge

- Hold the Calibration Tool - Spacing Laser -VAS6350/2--2- flush in the bracket on one side of the Calibration Tool -VAS6350- (attach with rear edge). The Calibration Tool - Spacing Laser -VAS6350/2--2- must sit securely on the bracket.

- Press the measuring button briefly.

The laser turns on.

- Make sure that laser beam from Calibration Tool - Spacing Laser -VAS6350/2--2- hits lower, enlarged part of paddle -1-.

If this is not the case, paddles must be corrected accordingly via clamping screws on the Calibration Tool - Wheel Center Mountings -VAS6350/1-.

- Use one hand to secure the Calibration Tool - Spacing Laser -VAS6350/2- in the bracket on the Calibration Tool -VAS6350- while the laser beam is visible on the paddle.

- Then press the measuring button for distance measurement briefly.

- Repeat this measurement on the other side of the Calibration Tool -VAS6350- in the same way for the rear wheel.

The distance value must be the same on both sides.

If values are not identical:

- Align the Calibration Tool -VAS6350- long enough so that both sides are identical.

Pay attention when aligning the calibration field of the Calibration Tool -VAS6350-, that the Calibration Tool - Linear Laser -VAS6350/3- from the Calibration Tool -VAS6350- strikes the center of the Audi rings and the indicator of the level remains centered. Adjust if necessary.

- Make note of the distance dimension measured.

Dimension measurement -h-:

- Measure the height of the Calibration Tool -VAS6350--2- calibration field, dimension -h-, from the surface of the Calibration Tool -VAS6350--2- calibration field (not the aluminum frame) down to the floor. Measure the hole in the Calibration Tool -VAS6350--2- calibration field.

Make sure the Calibration Tool - Spacing Laser -VAS6350/2--1- is adjusted correctly (attach with front edge).

The display shows how to stop the Calibration Tool - Spacing Laser -VAS6350/2-. Press the corresponding button.

1 - Attach with front edge

2 - Attach with rear edge

Dimension -h- and the distance dimension must now be entered into the Vehicle Diagnostic Tester in "millimeters".

Performing calibration

Vehicle Diagnostic Tester is attached.

- Select the Diagnostic mode and start the diagnostics.

- Select the tab test plan.

- Select select individual tests and choose the following sequence.

- Body

- Electrical Equipment

- 01 - OBD-capable systems

- 6C - peripheral camera control module | J928

- 6C - peripheral camera control module, functions

- 6C - Calibration, (Repair Group 91)

From here the Vehicle Diagnostic Tester advances the calibration procedure forward.

WARNING

WARNING

Make sure light does not reflect off the Peripheral Camera Calibration Device -VAS6350/6-.

Reflections affect the camera and may make it impossible to perform the calibration.

Special Tools

Special tools and workshop equipment required

- Radio Removal Tool -T10057-

- Torque Wrench 1783 - 2-10Nm -VAG1783-

- Fiber-Optic Repair Set -VAS6223B-

- Fiber-Optic Repair Set - Connector Protective Caps -VAS 6223/9-.

- Calibration Tool -VAS6350-

- Peripheral Camera Calibration Device -VAS6350/6-

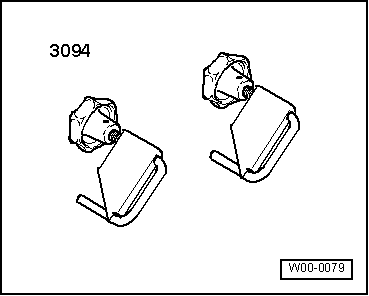

- Hose Clamps - Up To 25mm -3094-

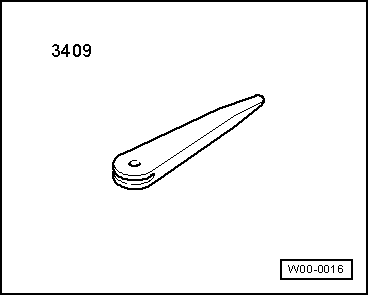

- Trim Removal Wedge -3409-

Revision History

DRUCK NUMBER: A005A000421

.png)

.png)