Audi A6 Typ 4G: Rear Final Drive, Removing and Installing

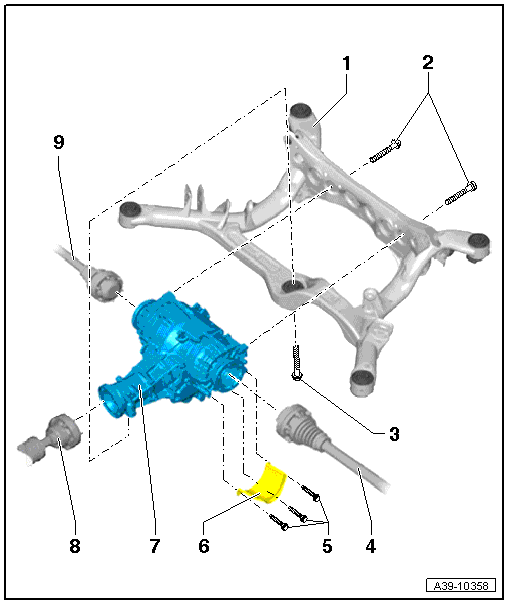

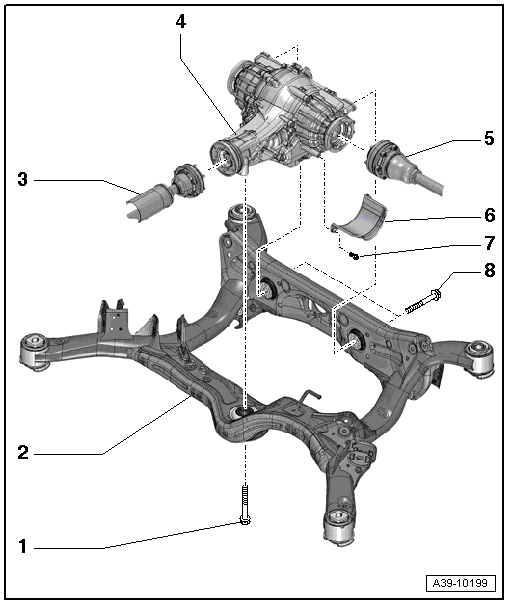

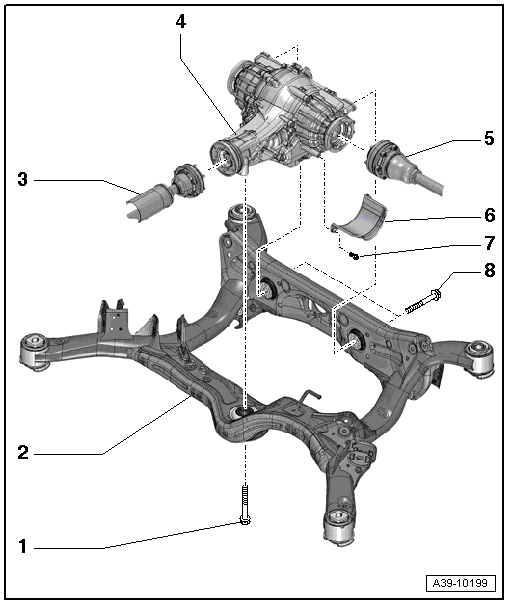

Overview - Rear Final Drive, Audi A4, A5 Coupé/Sportback/Cabriolet, A6, A7

1 - Subframe

- Removing and installing.

2 - Bolt

- 95 Nm

3 - Bolt

- 55 Nm

4 - Left Drives Axle

- Removing and installing.

5 - Bolt

- 20 Nm

6 - Heat Shield

7 - Rear Final Drive

- Removing and installing. Refer to → Chapter "Rear Final Drive, Removing and Installing, Audi A4, A5 Coupé/Sportback/Cabriolet, A6, A7".

- Additional work after replacing the rear final drive. Refer to → Chapter "Rear Final Drive, Additional Work after Replacing".

8 - Driveshaft

- Removing and installing. Refer to → Chapter "Driveshaft Bolted on Transmission Side, Removing and Installing".

9 - Right Drive Axle

- Removing and installing.

Rear Final Drive, Removing and Installing, Audi A4, A5 Coupé/Sportback/Cabriolet, A6, A7

Follow the general repair information. Refer to → Chapter "General Repair Information".

Pay attention to the safety precautions. Refer to → Chapter "Safety Precautions and Test Procedures".

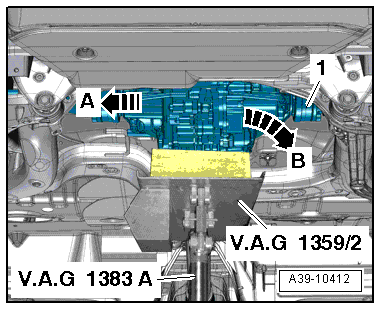

Special tools and workshop equipment required

- Engine and Gearbox Jack -VAS6931- with Universal Transmission Support -VAG1359/2-

- Tensioning Strap -T10038-

- Counterhold - Kit - Multiple Use -T10172- with Counterhold - Kit - Adapter 5 -T10172/5-

Removing

- Place the vehicle on a lift.

- Remove the wheel hubcap from the left rear wheel. On alloy wheels, remove the cap using the puller in the vehicle tool kit.

- Remove the rear wheels.

Note

Note

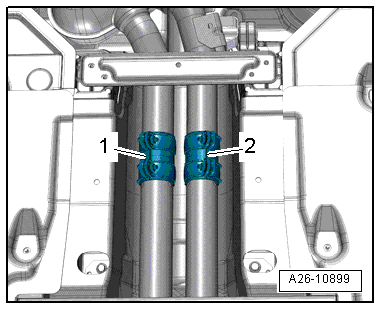

Do not bend the flex joint in the front exhaust pipe more than 10º or it will be damaged.

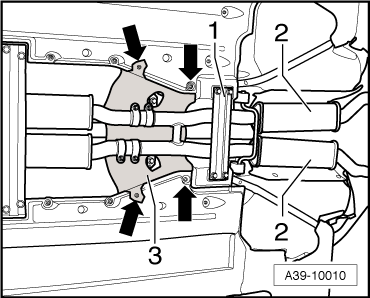

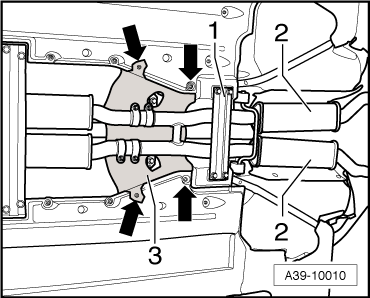

- Loosen the clamping sleeves -1 and 2- and disconnect the exhaust system.

- Attach the front exhaust pipe on the underbody side.

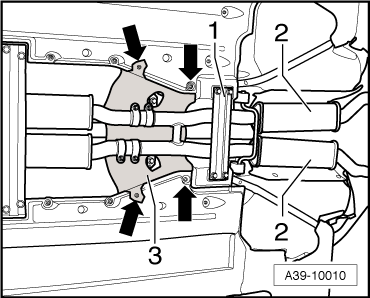

- Remove the rear crossbrace -1- if equipped. Refer to →Body Exterior;

- Remove the rear section of the exhaust system -2-.

Note

Note

A second technician is needed to help remove the rear section of the exhaust system.

- Remove the driveshaft. Refer to → Chapter "Driveshaft Bolted on Transmission Side, Removing and Installing".

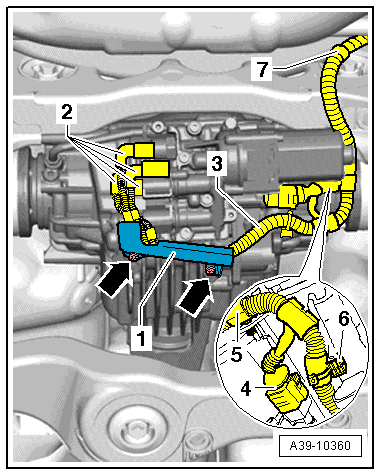

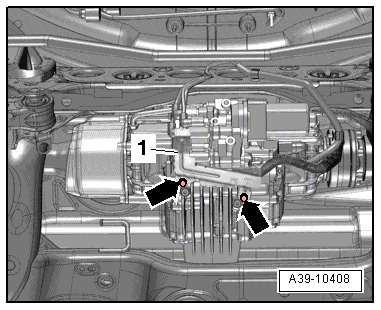

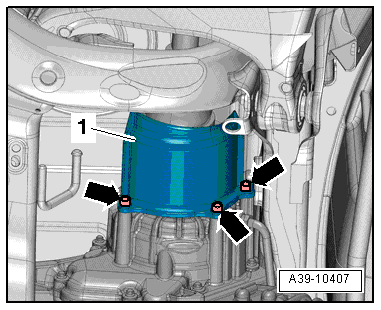

- Remove the left drive axle heat shield -A- from the rear final drive -arrows-.

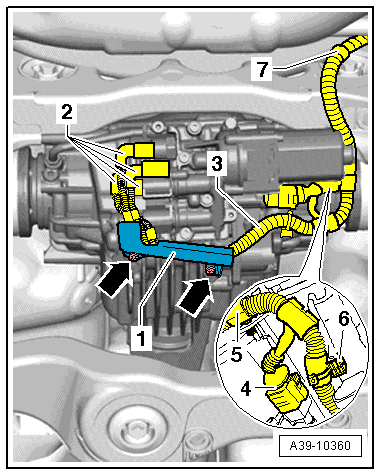

- Remove the bolts -arrows- and remove the bracket -1- from the rear final drive.

Note

Note

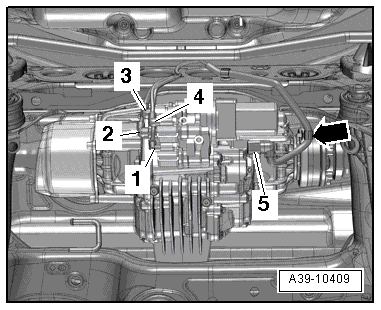

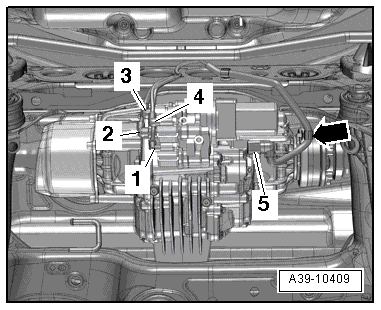

Mark the connectors -2- for the Oil Pressure/Temperature Sensor and on the Clutch Valves.

- Disconnect the connectors -2- from the Oil Pressure/Temperature Sensor and the Clutch Valves.

- Disconnect the connector -4- from the All Wheel Drive Pump -V415-.

- Unclip the wiring harness -3- from the final drive and the subframe and tie it up -5 through 7-.

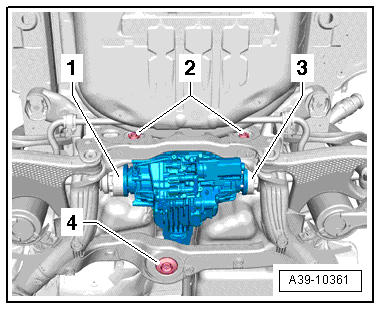

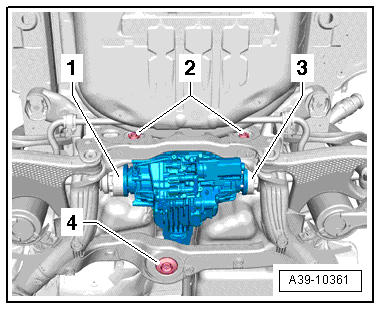

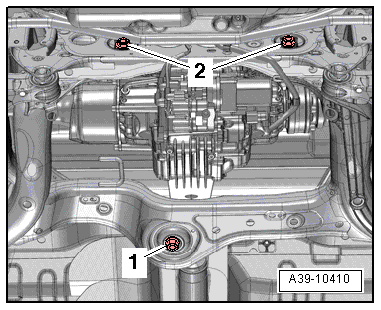

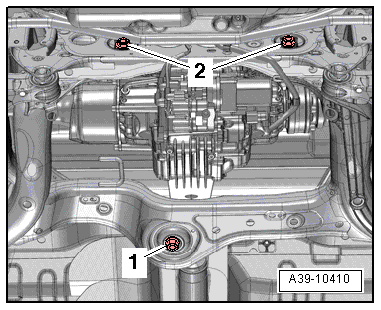

- Remove the left -1- and right -3- drive axles from the final drive.

- Loosen the bolts -2- approximately three turns.

- Remove the bolt -4-.

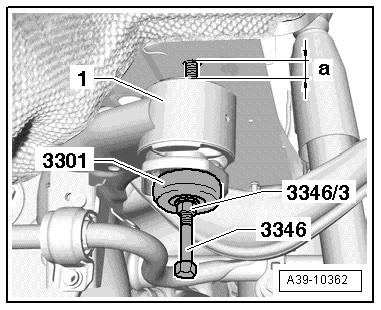

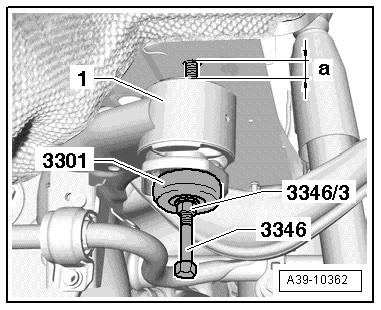

Lower the subframe -1- at the rear as follows:

- Remove the right rear bolt that connects the subframe to the body.

- Install the Bearing Installer - Control Arm -3346- with Control Arm Bearing Installer - Nut -3346/3- and Bearing from the Subframe Bushing Tool Kit -3301-.

- Then remove the left rear bolt that connects the subframe to the body.

- Lower the subframe to dimension -a- = 40 mm. While doing so counterhold the Bearing Installer - Control Arm -3346- and turn the Control Arm Bearing Installer - Nut - 3346/3- counter-clockwise.

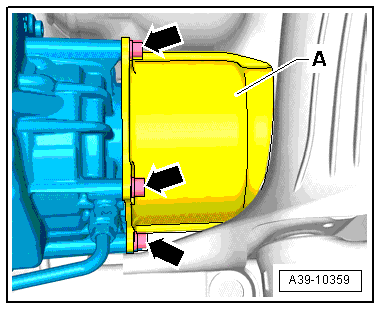

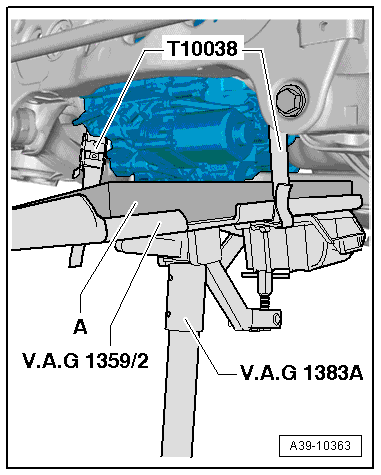

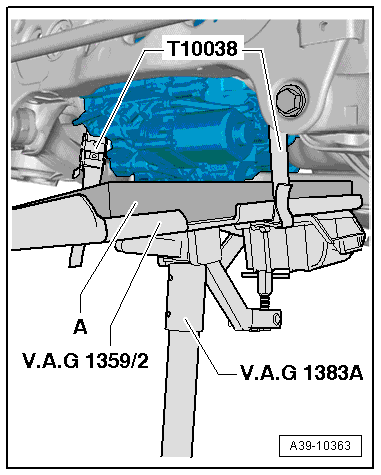

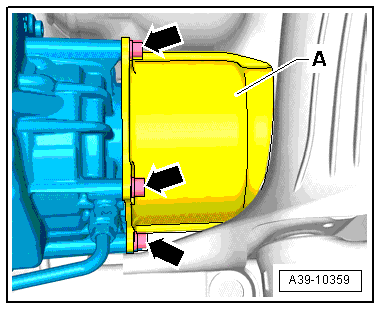

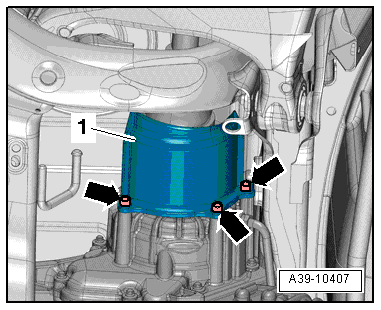

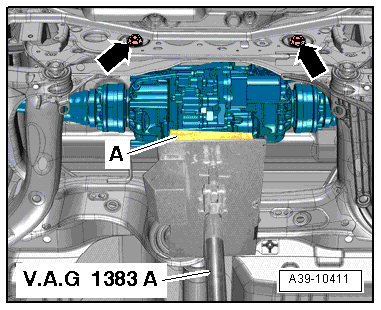

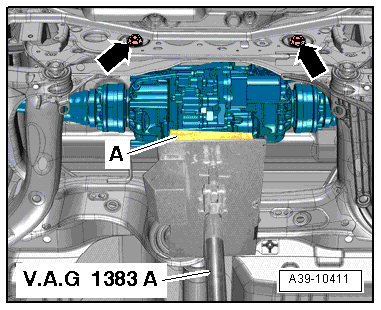

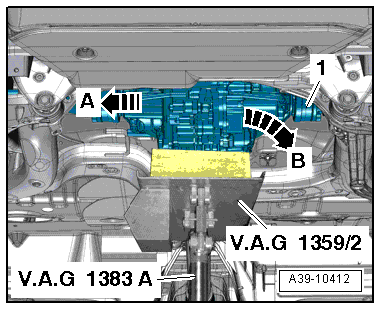

- Position the Engine and Gearbox Jack -VAS6931- with the Universal Transmission Support -VAG1359/2- and a corresponding rubber or hard foam mat -A- under the rear final drive.

Caution

Caution

The rubber or hard foam mat is needed to protect the Clutch Valves on the rear final drive from getting damaged.

Use a Tensioning Strap -T10038- to secure the rear final drive from falling.

- Remove the two rear bolts that connect the rear final drive to the subframe.

- A second technician must help with the next steps in removing the final drive.

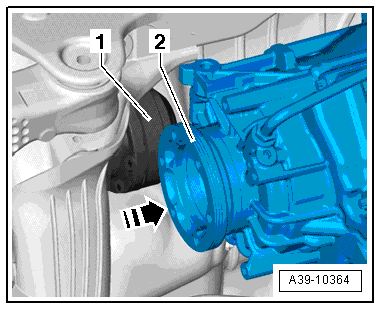

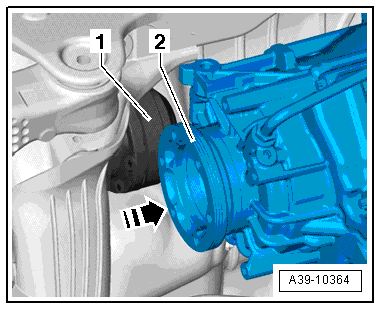

- A second technician must now push the rear final drive in direction of -arrow- toward the right side of the vehicle.

- Then guide the left drive axle -1- upward and out of the final drive flange shaft -2-.

- Guide the right drive axle out and tilt the final drive toward the rear and downward.

- Carefully lower the final drive together with a second technician. Pay attention to the subframe.

WARNING

WARNING

- Do not raise or lower the vehicle when the Engine and Gearbox Jack -VAS6931- is underneath it.

- Do not leave the Engine and Gearbox Jack -VAS9631- under the vehicle longer than necessary.

Installing

Install in reverse order of removal. Pay attention to the following:

WARNING

WARNING

Malfunctions on the rear final drive.

If the rear final drive was replaced, additional work is necessary. Refer to → Chapter "Rear Final Drive, Additional Work after Replacing".

- Carefully raise the rear final drive using the Engine and Gearbox Jack -VAS9631- and, with a second technician, position it on the subframe in its installed position.

-A- = rubber or hard foam mat

Caution

Caution

The rubber or hard foam mat is needed to protect the Clutch Valves on the rear final drive from getting damaged.

Use a Tensioning Strap -T10038- to secure the rear final drive from falling.

- Install the right drive axle into the final drive flange shaft.

- A second technician must now push the rear final drive in direction of -arrow- toward the right side of the vehicle.

- Install the left drive axle -1- into the final drive flange shaft -2-.

- Install the bolts -2- that connect the rear final drive to the subframe hand-tight.

Note

Note

For better illustration the Engine and Gearbox Jack -VAS6931- with the Universal Transmission Support -VAG1359/2- are not shown.

- Tighten the bolt -4- to the tightening specification -item 3- and then the bolts -2- to the tightening specification -item 2-.

- Remove the Engine and Gearbox Jack -VAS6931- from under the final drive.

- Attach the left -1- and right -3- drive axles.

Attach the subframe -1- to the body in the rear as follows:

- First turn the Control Arm Bearing Installer - Nut -3346/3- clockwise until the subframe touches the body. While doing this, counterhold the Bearing Installer - Control Arm -3346-.

- Then install the left rear bolt that connects the subframe to the body and tighten it to the tightening specification.

- Remove the Bearing Installer - Control Arm -3346- and install the right rear bolt that attaches the subframe to the body and tighten it to the tightening specification.

- Attach the left drive axle heat shield -A- to the rear final drive -arrows--item 5-.

- Install the wiring harness -3- to the final drive and subframe -5 through 7-.

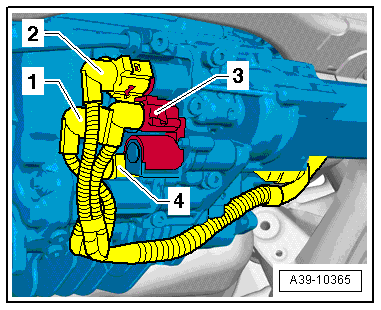

- Connect the connectors -4 and 2-. Pay attention to the marks made during the removal, that identify the allocation to the Oil Pressure/Temperature Sensor and which connectors go to the Clutch Valves.

Caution

Caution

Risk of damaging the wiring harness.

Make sure the wiring harness -3- does not get pinched when installing the bracket -1- to the rear final drive.

- Position the bracket -1- on the final drive and tighten the bolts -arrows- to the tightening specification.

Note

Note

- Allocation for the Oil Pressure/Temperature Sensor and Clutch Valves connectors:

- -1- = Oil Pressure/Temperature Sensor 2 -G640- Connector

- -2- = Oil Pressure/Temperature Sensor -G437- Connector

- -3- = All Wheel Drive Clutch Valve 2 -N446- Connector

- -4- = All Wheel Drive Clutch Valve -N445- Connector

- Install the driveshaft. Align the markings and follow the tightening sequence. Refer to → Chapter "Driveshaft Bolted on Transmission Side, Removing and Installing".

- Check the gear oil in rear final drive. Refer to → Chapter "Gear Oil Level in Rear Final Drive 0BF and 0BE, Checking".

- Check the ATF inside the rear final drive. Refer to → Chapter "ATF Level in Rear Final Drive 0BF and 0BE, Checking".

- Install the rear section of the exhaust system and align it so it is free of tension.

- If equipped, remove the rear crossmember. Refer to →Body Exterior;

- Install the rear wheels and tighten. Refer to →Wheel and Tire Guide;

- If the rear final drive was replaced, additional work is necessary. Refer to → Chapter "Rear Final Drive, Additional Work after Replacing".

Overview - Rear Final Drive, RS 5

1 - Bolt

- 55 Nm

2 - Subframe

- Overview. Refer to →Suspension, Wheels, Steering;

3 - Driveshaft

- Overview. Refer to → Chapter "Overview - Driveshaft, Mounted On Transmission Side".

4 - Rear Final Drive

- Removing and installing. Refer to → Chapter "Rear Final Drive, Removing and Installing RS 5".

- Additional work after replacing the rear final drive. Refer to → Chapter "Rear Final Drive, Additional Work after Replacing".

5 - Drive Axle

- Overview. Refer to →Suspension, Wheels, Steering;

6 - Heat Shield

7 - Bolt

- 20 Nm

8 - Bolt

- 95 Nm

- Quantity: 2

Rear Final Drive, Removing and Installing RS 5

Special tools and workshop equipment required

- Engine and Gearbox Jack -VAS6931-

Removing

- Remove the rear crossmember -1-. Refer to →Body Exterior; Rep. Gr.66.

Note

Note

A second technician is needed to remove the exhaust system rear section.

- Remove the exhaust system rear section -2-.

- Remove the driveshaft from the rear final drive. Refer to → Chapter "Driveshaft, Removing and Installing from Rear Final Drive".

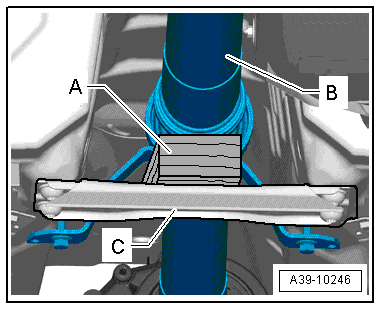

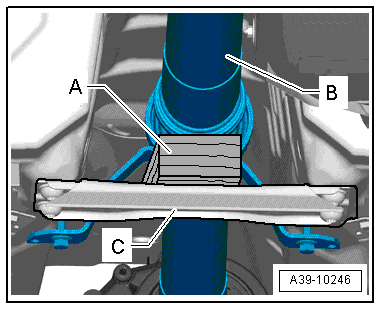

- Place a wooden block -A- (approximately 40 mm high) on the rear crossmember -C- to support the driveshaft -B-.

Note

Note

The driveshaft can be bent all the way to the center joint without force. Bending the joint forcibly all the way can damage the center joint and/or the protective boot.

- Remove the bolts -arrows- and the left drive axle heat shield -1-.

- Remove the left and right drive axle from the rear final drive. Refer to →Suspension, Wheels, Steering; Rep. Gr.42.

- Remove the bolts -arrows-, and remove the wire protective plate.

- Disconnect the connectors -1 through 5- and free up the wiring harness -arrow-.

- Remove the bolt -1- and loosen the bolt -2-.

- Place the Engine and Gearbox Jack -VAS6931- and a wooden block -A- on the mounting plate under the rear final drive and secure.

Note

Note

Make sure the engine and transmission jack mounting plate does not make contact with the fuel tank.

- Remove the bolts -arrows-.

- Push the rear final drive to the left -arrow A-.

- Move the right drive axle -1- upward.

- To loosen the left flange shaft from the drive axle, the rear final drive must first be lowered to the right -arrow B-.

- Secure the rear final drive with a strap and continue lowering with the Engine and Gearbox Jack -VAS6931-.

Installing

Install in reverse order of removal. At the same time note the following:

WARNING

WARNING

Malfunctions on the rear final drive.

If the rear final drive was replaced, additional work is necessary. Refer to → Chapter "Rear Final Drive, Additional Work after Replacing".

- Tightening specifications. Refer to → Chapter "Overview - Rear Final Drive, RS 5".

- Attach the drive axles to the rear final drive. Refer to →Suspension, Wheels, Steering; Rep. Gr.40.

- Install the driveshaft.

- Install the exhaust system. Refer to →Engine Mechanical; Rep. Gr.26 and align free of tension.

- Remove the rear crossmember. Refer to →Body Exterior; Rep. Gr.66.

- Check the ATF inside the rear final drive. Refer to → Chapter "ATF Level in Rear Final Drive 0BF and 0BE, Checking".

- Check the gear oil level in the rear final drive. Refer to → Chapter "Gear Oil Level in Rear Final Drive 0BF and 0BE, Checking".

- If the rear final drive was replaced, additional work is necessary. Refer to → Chapter "Rear Final Drive, Additional Work after Replacing".

Overview - Rear Final Drive, Audi A8

1 - Bolt

- 55 Nm

2 - Subframe

- Overview. Refer to →Suspension, Wheels, Steering; Rep. Gr.42.

3 - Driveshaft

- Overview. Refer to → Chapter "Overview - Driveshaft, Mounted On Transmission Side".

4 - Rear Final Drive

- Removing and installing. Refer to → Chapter "Rear Final Drive, Removing and Installing, A8".

- Additional work after replacing the rear final drive. Refer to → Chapter "Rear Final Drive, Additional Work after Replacing".

5 - Drive Axle

- Overview. Refer to →Suspension, Wheels, Steering; Rep. Gr.42.

6 - Heat Shield

7 - Bolt

- 20 Nm

8 - Bolt

- 95 Nm

Rear Final Drive, Removing and Installing, A8

Special tools and workshop equipment required

- Engine and Gearbox Jack -VAS6931-

Removing

- Remove the rear crossmember -1-. Refer to →Body Exterior; Rep. Gr.66.

Note

Note

A second technician is needed to remove the exhaust system rear section.

- Remove the exhaust system rear section -2-. Refer to →Engine Mechanical; Rep. Gr.26.

- Remove the driveshaft from the rear final drive. Refer to → Chapter "Driveshaft, Removing and Installing from Rear Final Drive".

- Place a wooden block -A- (approximately 40 mm high) on the rear crossmember -C- to support the driveshaft -B-.

Note

Note

The driveshaft can be bent all the way to the center joint without force. Bending the joint forcibly all the way can damage the center joint and/or the protective boot.

- Remove the bolts -arrows- and the left drive axle heat shield -1-.

- Remove the left and right drive axle from the rear final drive. Refer to →Suspension, Wheels, Steering; Rep. Gr.42.

- Disconnect the connectors -1 through 5- and free up the wiring harness -arrow-.

- Remove the bolt -1- and loosen the bolt -2-.

- Place the Engine and Gearbox Jack -VAS6931- and a wooden block -A- on the mounting plate under the rear final drive and secure.

Note

Note

Make sure the engine and transmission jack mounting plate does not make contact with the fuel tank.

- Remove the bolts -arrows-.

- Push the rear final drive to the left in direction of -arrow A-.

- Move the right drive axle -1- upward.

- To loosen the left flange shaft from the drive axle, the rear final drive must first be lowered to the right -arrow B-.

- Secure the rear final drive with a strap and continue lowering with the Engine and Gearbox Jack -VAS6931-.

Installing

Install in reverse order of removal. At the same time note the following:

WARNING

WARNING

Malfunctions on the rear final drive.

If the rear final drive was replaced, additional work is necessary. Refer to → Chapter "Rear Final Drive, Additional Work after Replacing".

- Tightening specifications. Refer to → Chapter "Overview - Rear Final Drive, Audi A8".

- Attach the drive axles to the rear final drive. Refer to →Suspension, Wheels, Steering; Rep. Gr.40.

- Install the drive axle.

- Install the exhaust system.

- Remove the rear crossmember.

- Check the gear oil level in the rear final drive. Refer to → Chapter "Gear Oil Level in Rear Final Drive 0BF and 0BE, Checking".

- Check the ATF inside the rear final drive. Refer to → Chapter "ATF Level in Rear Final Drive 0BF and 0BE, Checking".

- If the rear final drive was replaced, additional work is necessary. Refer to → Chapter "Rear Final Drive, Additional Work after Replacing".

Rear Final Drive, Additional Work after Replacing

WARNING

WARNING

Malfunctions on the rear final drive.

If the rear final drive was replaced, the following additional work is necessary.

- Bleed the hydraulic control module using the Vehicle Diagnostic Tester.

- Program the rear final drive on the All Wheel Drive Control Module -J492- use the Vehicle Diagnostic Tester.

The additional work can only be performed when the rear final drive is replaced.

Procedure

- Connect the Vehicle Diagnostic Tester and switch on the ignition.

- On the Vehicle Diagnostic Tester select the function 22 - Control Module, Replacing under Guided Functions in the directory 22 - Rear Final Drive, Replacing.

- Follow the instructions given by the Vehicle Diagnostic Tester exactly.

"Adapt" the new rear final drive to the All Wheel Drive Control Module -J492- with the Vehicle Diagnostic Tester.

Note

Note

A system check will take place when the function 22 - Rear Final Drive Replacing is complete. If malfunctions appear, then use "Guided Fault Finding" to correct them.

Tightening Specification

.png)