Audi A6 Typ 4G: Center Differential

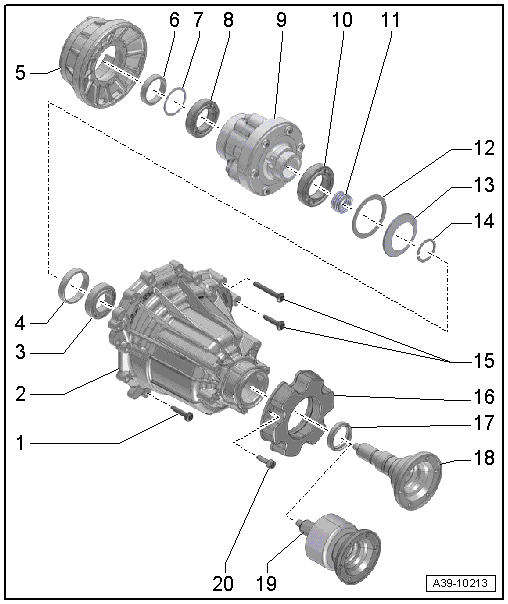

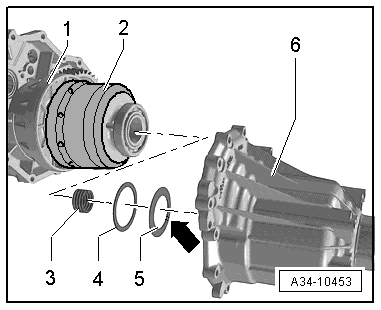

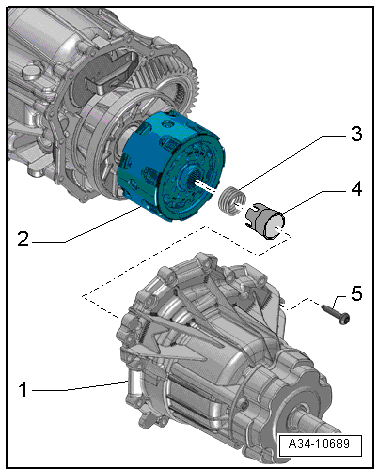

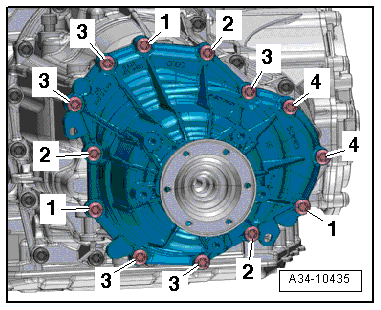

Overview - Center Differential Housing

Overview - Center Differential Housing, Bolted Driveshaft

The Center Differential Housing Can Also be Removed and Installed With The Transmission Installed. Refer to → Chapter "Center Differential Housing, Removing and Installing, Bolted Driveshaft".

1 - Bolt

- Aluminum bolts

- Quantity 11

- Replacing

- Tightening specification and sequence. Refer to → Fig. "Tightening Specification and Sequence, Center Differential Housing - Bolted Driveshaft"

2 - Housing

- For the center differential

- Refer to → Chapter "Center Differential Housing, Removing and Installing, Bolted Driveshaft"

3 - Ball Bearing

- For the flange shaft

- Refer to → Chapter "Rear Flange Shaft, Seal and Ball Bearing, Removing and Installing"

4 - Spacer Sleeve

- Removing and installing. Refer to → Chapter "Rear Flange Shaft, Seal and Ball Bearing, Removing and Installing".

5 - Gear Carrier

- Installed position: The tab must fit into the opening in the transmission intermediate housing

6 - Spacer Sleeve

7 - Shim

8 - Ball Bearing

- for the center differential

9 - Center Differential

10 - Ball Bearing

- For the center differential

11 - Pressure Spring

12 - Shim

13 - Plate Spring

- Installed position: The side curved outward faces the shaft seal -17-

14 - Locking Ring

- For the flange shaft

- Removing and installing. Refer to → Chapter "Rear Flange Shaft, Seal and Ball Bearing, Removing and Installing".

15 - Bolt

- Steel bolts

- Quantity: 2

- Replacing

- Tightening specification and sequence. Refer to → Fig. "Tightening Specification and Sequence, Center Differential Housing - Bolted Driveshaft"

16 - Balance Weight

- Installed depending on the version

17 - Shaft Seal

- Refer to → Chapter "Rear Flange Shaft, Seal and Ball Bearing, Removing and Installing"

18 - Rear Flange Shaft

- without vibration damper

- Allocation. Refer to the Parts Catalog.

- Removing and installing. Refer to → Chapter "Rear Flange Shaft, Seal and Ball Bearing, Removing and Installing".

19 - Rear Flange Shaft

- With vibration damper

- Allocation. Refer to the Parts Catalog.

- Removing and installing. Refer to → Chapter "Rear Flange Shaft, Seal and Ball Bearing, Removing and Installing".

20 - Bolt

- 20 Nm +90º

- Replacing

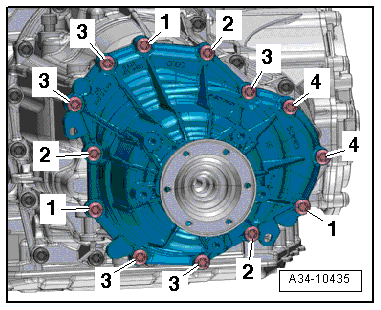

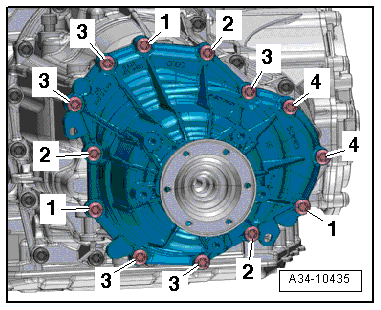

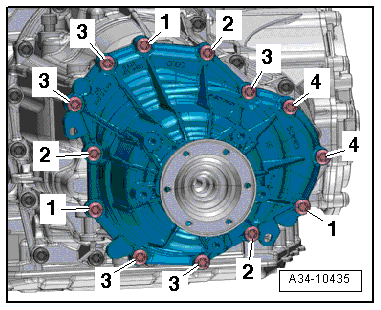

Tightening Specification and Sequence, Center Differential Housing - Bolted Driveshaft

- Tighten the bolts in eight steps as follows:

.png)

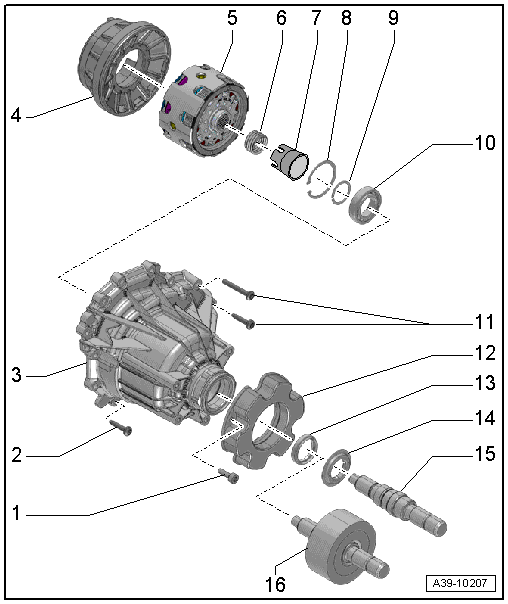

Overview - Center Differential Housing, Attached Driveshaft

The Center Differential Housing Can Also be Removed and Installed with the Transmission Installed. Refer to → Chapter "Center Differential Housing, Removing and Installing, Bolted Driveshaft".

1 - Bolt

- 20 Nm +90º

- Replacing

2 - Bolt

- Replacing

- Aluminum bolts

- Quantity 11

- Tightening specification and sequence. Refer to → Fig. "Tightening Specification and Sequence, Center Differential Housing - Attached Driveshaft"

3 - Housing

- For the center differential

4 - Gear Carrier

- Installed position: The tab must fit into the opening in the transmission intermediate housing

5 - Center Differential

6 - Pressure Spring

7 - Assembly Sleeve

- Does not have to be installed again

8 - Locking Ring

- For the transmission output shaft ball bearing with splines

- Removing and installing. Refer to → Chapter "Transmission Output Shaft with Splines, Seal and Ball Bearing, Removing and Installing".

9 - Locking Ring

- For the transmission output shaft with splines

- Removing and installing. Refer to → Chapter "Transmission Output Shaft with Splines, Seal and Ball Bearing, Removing and Installing".

10 - Ball Bearing

- For the transmission output shaft with splines

11 - Bolt

- Replacing

- Steel bolts

- Quantity: 2

- Tightening specification and sequence. Refer to → Fig. "Tightening Specification and Sequence, Center Differential Housing - Attached Driveshaft"

12 - Balance Weight

- Installed depending on the version

13 - Shaft Seal

- Replace on vehicles with vibration damper. Refer to → Chapter "Transmission Output Shaft with Splines, Seal and Ball Bearing, Removing and Installing".

- Replace on vehicles without vibration damper. Refer to → Chapter "Transmission Output Shaft Seal, Replacing, Transmission Output Shaft with Splines without Vibration Damper"

14 - Dust Ring

- Replace after removing

15 - Transmission Output Shaft with Splines without Vibration Damper

- Allocation. Refer to the Parts Catalog.

- Removing and installing. Refer to → Chapter "Transmission Output Shaft with Splines, Seal and Ball Bearing, Removing and Installing".

16 - Transmission Output Shaft with Splines and Vibration Damper

- Allocation. Refer to the Parts Catalog.

- Removing and installing. Refer to → Chapter "Transmission Output Shaft with Splines, Seal and Ball Bearing, Removing and Installing".

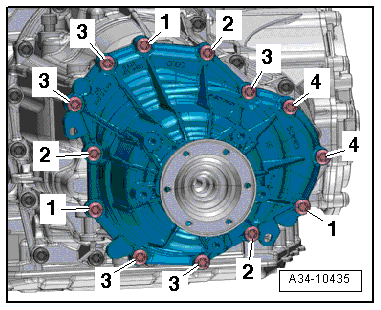

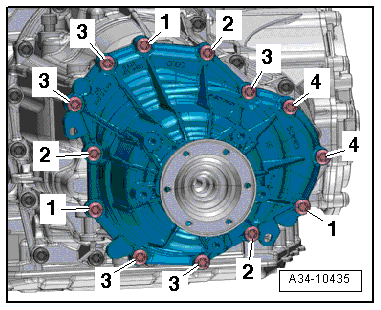

Tightening Specification and Sequence, Center Differential Housing - Attached Driveshaft

- Tighten the bolts in eight steps as follows:

.png)

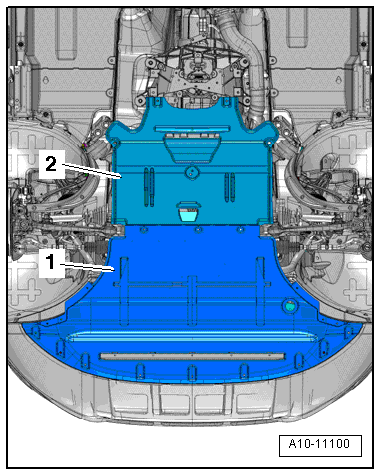

Center Differential Housing, Removing and Installing

Center Differential Housing, Removing and Installing, Bolted Driveshaft

Special tools and workshop equipment required

- Used Oil Collection and Extraction Unit -SMN372500-

- Sealant. Refer to the Parts Catalog.

Removing with Transmission Installed

It is possible to remove the center differential housing with the transmission still installed.

- Perform the vehicle-specific preliminary work. Refer to → S tronic Transmission; Rep. Gr.39; Center Differential.

Removing with the Transmission Removed

- Secure the transmission on the Engine And Transmission Holder -VAS6095-. Refer to → Chapter "Securing on Engine and Transmission Holder".

Continuation for a Removed or Installed Transmission

- Place the Used Oil Collection and Extraction Unit -SMN372500- under the transmission.

- Remove the bolts -1 through 4- and carefully remove the center differential housing. The transmission fluid (MTF) will leak out while doing this.

Caution

Caution

Danger of damaging the center differential.

- Carefully and slowly pull center differential housing off of transmission toward rear. Otherwise the center differential can fall out of the transmission.

- A center differential that has fallen out may not be installed.

- Remove the pressure spring -3-, shim(s) -4- and plate spring -5-.

- Pull the center differential -2- toward the rear.

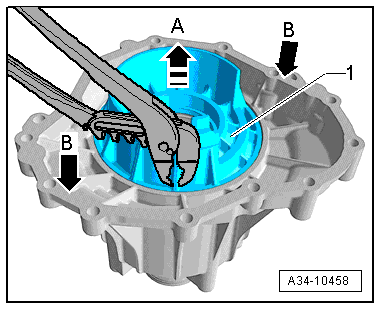

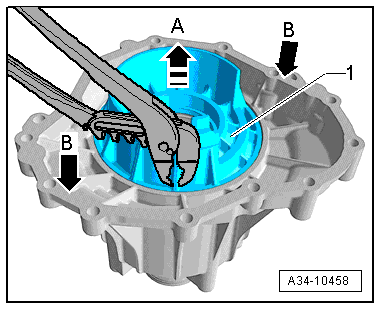

If the gear carrier -1- remains in the center differential housing, proceed as follows:

Caution

Caution

Danger of damaging the sealing surface on the center differential housing.

Use a hammer to hit the housing on several places.

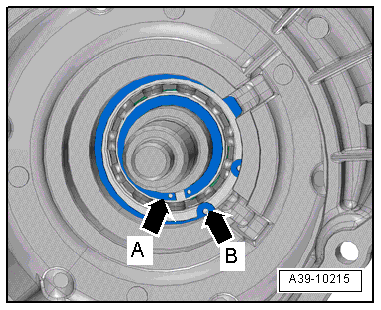

- Hold the gear carrier -1- by one of the side ribs with pliers and remove it in direction of -arrow A-.

- Using a Rubber Hammer, tap the housing on alternating sides -arrows B-.

Installing

Install in reverse order of removal. Note the following:

- Tightening specifications. Refer to → Chapter "Overview - Center Differential Housing, Bolted Driveshaft".

Note

Note

Replace the bolts for the center differential housing.

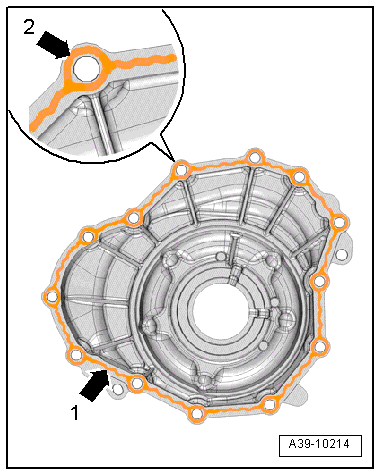

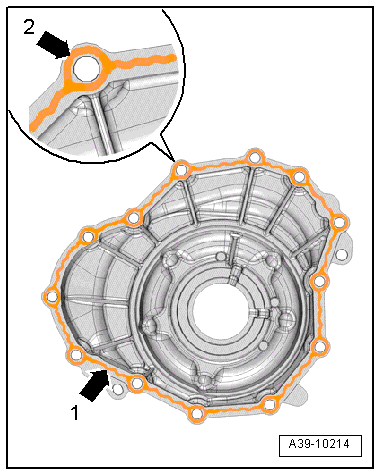

- Clean both housing separating surfaces thoroughly. They must be free of oil and grease.

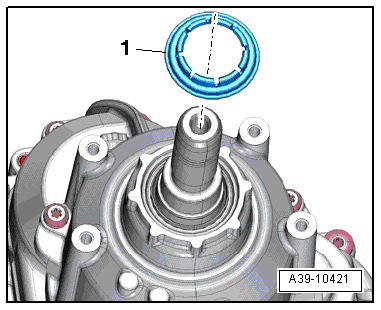

- Apply a bead sealant -arrow 1- evenly and not too thick on the housing surfaces; sealant. Refer to the Parts Catalog.

- Place a sealing ring round each bolt hole to prevent contact corrosion -arrow 2-.

- Coat the gear carrier surfaces with transmission fluid (MTF).

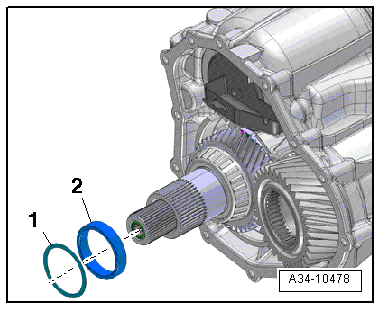

- Make sure the spacer sleeve -2- and the shim -1- are mounted on the output shaft.

- Coat both outer ring surfaces on the gear carrier slightly with transmission fluid (MTF).

- Insert the gear carrier.

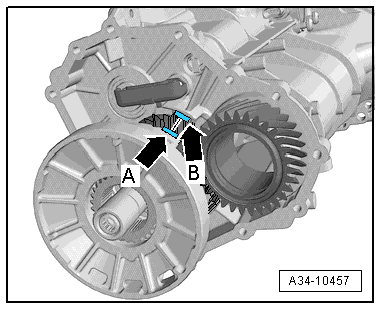

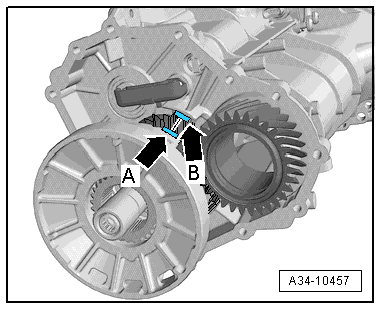

- Installed position: The tab on the gear carrier -arrow A- must fit into the opening in the transmission intermediate housing -arrow B-.

- Place the center differential -2- on the transmission -1-.

- Install the pressure spring -3- into the center differential.

- Attach the plate spring -5- and shim(s) -4- in the center differential housing -6- with a little grease.

- Plate spring installation location: The side rounded on the outside faces the flange shaft.

- Press the center differential housing centrally on until it makes contact with the transmission intermediate housing and hold it securely.

- Tighten the center differential housing bolts. Refer to → Fig. "Tightening Specification and Sequence, Center Differential Housing - Bolted Driveshaft".

- Install the transmission. Refer to → S tronic Transmission; Rep. Gr.34; Transmission, Removing and Installing; Transmission, Installing.

Note

Note

Check the vehicle data label or the designation on the rear final drive itself to determine which one is installed in the vehicle. Then select the correct rear final drive repair manual.

- Install the (attached) driveshaft. Refer to → Rear Final Drive 0BC, 0BD, 0BE, 0BF; Rep. Gr.39; Description and Operation

- Fill with transmission fluid (MTF). Refer to → S tronic Transmission; Rep. Gr.39; Transmission Fluid; Transmission Fluid, Draining and Filling

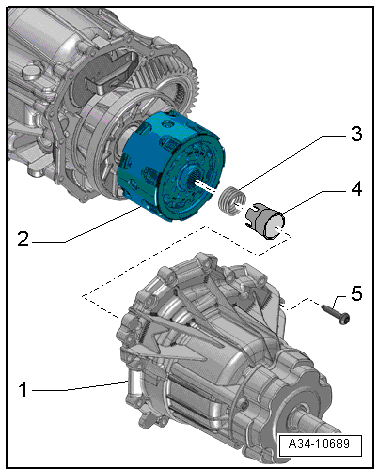

Center Differential Housing, Removing and Installing, Attached Driveshaft

Special tools and workshop equipment required

- Used Oil Collection and Extraction Unit -SMN372500-

- Sealant. Refer to the Parts Catalog.

Removing with Transmission Installed

It is possible to remove the center differential housing with the transmission still installed.

- Perform the vehicle-specific preliminary work. Refer to → S tronic Transmission; Rep. Gr.39; Center Differential

Removing with the Transmission Removed

- Secure the transmission on the Engine And Transmission Holder -VAS6095-. Refer to → Chapter "Securing on Engine and Transmission Holder".

Continuation for a Removed or Installed Transmission

- Place the Used Oil Collection and Extraction Unit -SMN372500- under the transmission.

- Remove the bolts -1 through 4- and carefully remove the center differential housing. The transmission fluid (MTF) will leak out while doing this.

Caution

Caution

Danger of damaging the center differential.

- Carefully and slowly pull center differential housing off of transmission toward rear. Otherwise the center differential can fall out of the transmission.

- A center differential that has fallen out may not be installed.

- Remove the guide sleeve -4- and pressure spring -3-.

- Pull the center differential -2- toward the rear.

If the gear carrier -1- remains in the center differential housing, proceed as follows:

Caution

Caution

Danger of damaging the sealing surface on the center differential housing.

Use a hammer to hit the housing carefully on several places.

Note

Note

In this case the center differential is pulled off together with the center differential housing.

- Hold the gear carrier -1- by one of the side ribs with pliers and remove it in direction of -arrow A-.

- Using a Rubber Hammer, tap the housing on alternating sides -arrows B-.

Installing

Install in reverse order of removal. Note the following:

- Tightening specifications. Refer to → Chapter "Overview - Center Differential Housing".

Note

Note

Replace the bolts for the center differential housing.

- Clean both housing separating surfaces thoroughly. They must be free of oil and grease.

- Apply a bead sealant -arrow 1- evenly and not too thick on the housing surfaces; sealant. Refer to the Parts Catalog.

- Place a sealing ring round each bolt hole to prevent contact corrosion -arrow 2-.

- Coat the gear carrier surfaces with transmission fluid (MTF).

- Coat both outer ring surfaces on the gear carrier slightly with transmission fluid (MTF).

- Insert the gear carrier.

- Installed position: The tab on the gear carrier -arrow A- must fit into the opening in the transmission intermediate housing -arrow B-.

- Place the center differential -2- on the transmission -1-.

- Mount the guide sleeve -4- on the center differential.

- Install the pressure spring -3- into the center differential.

- Press the center differential housing centrally on until it makes contact with the transmission intermediate housing and hold it securely.

- Tighten the center differential housing bolts. Refer to → Fig. "Tightening Specification and Sequence, Center Differential Housing - Bolted Driveshaft".

- Install the transmission. Refer to → S tronic Transmission; Rep. Gr.34; Transmission, Removing and Installing; Transmission, Installing

Note

Note

Check the vehicle data label or the designation on the rear final drive itself to determine which one is installed in the vehicle. Then select the correct rear final drive repair manual.

- Install the (attached) driveshaft. Refer to → Rear Final Drive 0BC, 0BD, 0BE, 0BF; Rep. Gr.39; Description and Operation

- Fill with transmission fluid (MTF). Refer to → S tronic Transmission; Rep. Gr.39; Transmission Fluid; Transmission Fluid, Draining and Filling

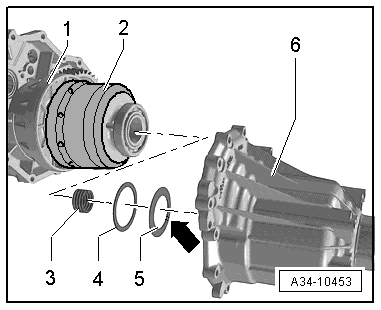

Center Differential Housing, Servicing

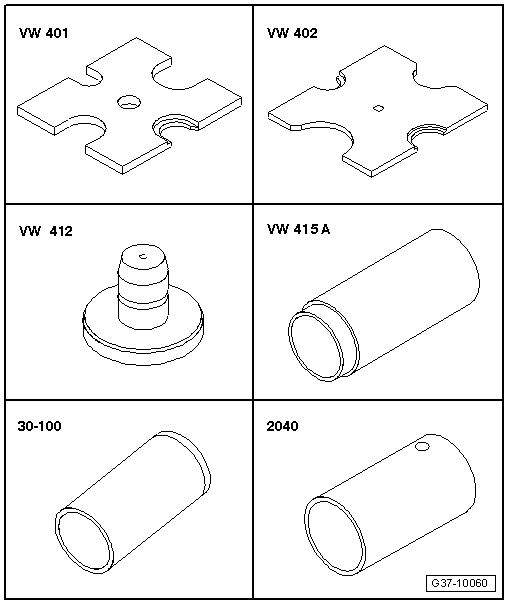

Rear Flange Shaft, Seal and Ball Bearing, Removing and Installing

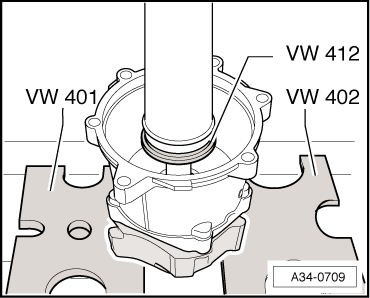

Special tools and workshop equipment required

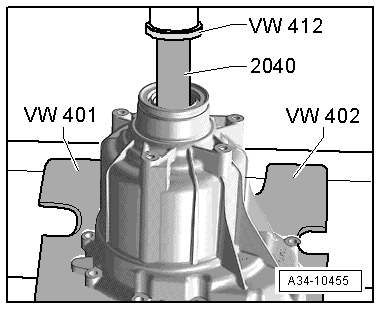

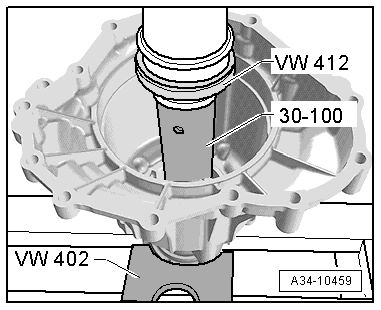

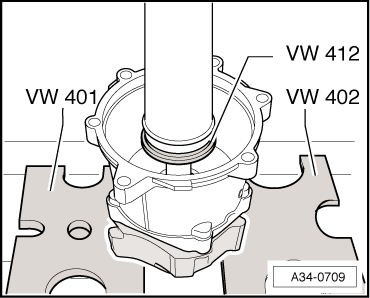

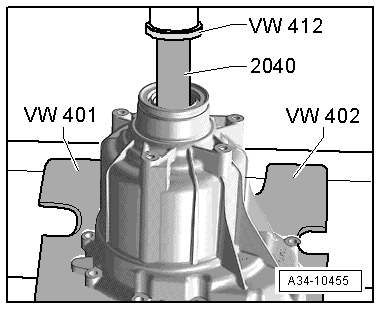

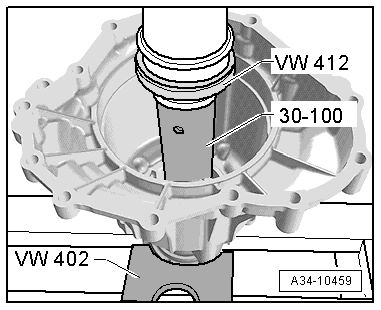

- Press Plate -VW401-

- Press Plate -VW402-

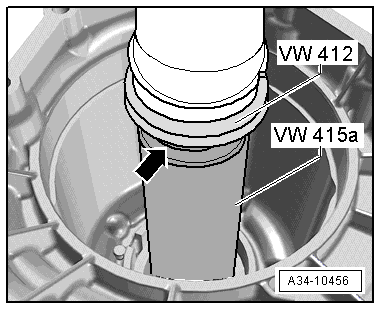

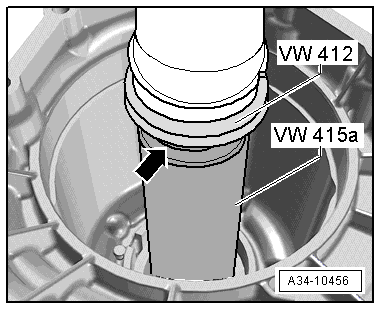

- Press Piece - Multiple Use -VW412-

- Press Piece - 60mm - VW415A-

- Press Piece - Press Tube -30-100-

- Press Piece - Front Control Arm -2040-

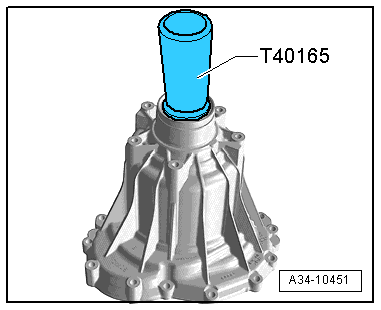

- Seal Installer - Cardan Flange -T40165-

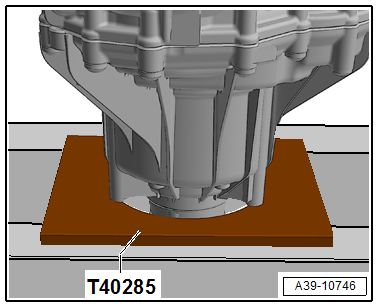

- Plate -T40285- for vehicles with torsional vibration damper or without vibration damper

- Grease. Refer to the Parts Catalog.

Procedure

- Remove the center differential housing. Refer to → Chapter "Center Differential Housing, Removing and Installing, Bolted Driveshaft".

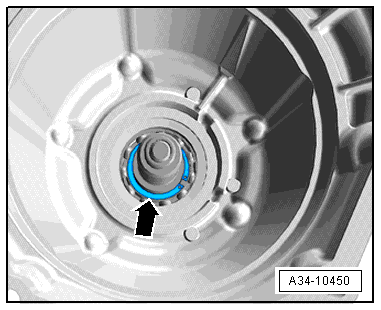

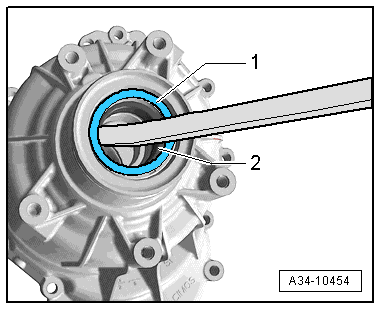

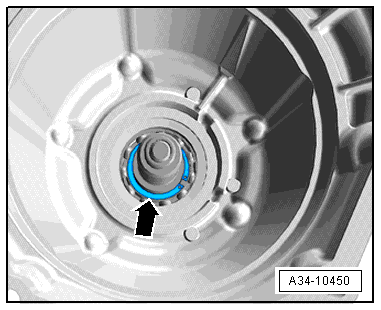

- Remove the circlip -arrow-.

Transmission with Bolted Vibration Damper

- Remove the flange shaft by positioning the center differential housing so the flange shaft does not touch the Press Plate -VW401- and Press Plate -VW402-.

Transmission with Torsional Vibration Damper or without Vibration Damper

- Remove the flange shaft by allowing the housing for the center differential to rest on the Plate -T40285-.

All Transmissions

Note

Note

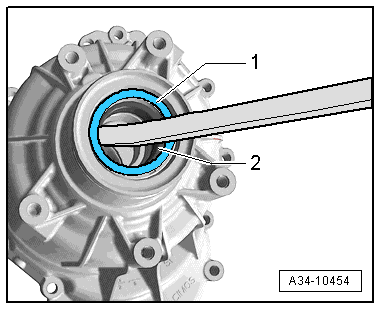

Ignore item -2-.

- Pry out the shaft seal -1-.

- Remove the flange shaft ball bearing and spacer sleeve if necessary.

- Installing the flange shaft ball bearing.

- The shoulder on the Press Piece - 60mm -VW415A--arrow- faces the Press Piece - Multiple Use -VW412-.

- The press in the spacer sleeve -item 4- using the Press Piece - 60mm -VW415A-.

- Lightly oil the outer circumference on the shaft seal and then install it all the way using the Seal Installer - Cardan Flange -T40165-.

- Installed position: Open side of shaft seal faces transmission.

- Fill the space between the sealing- and dust lip half way with sealing grease. Refer to the Parts Catalog.

- Install the flange shaft.

- Install the flange shaft into the center differential housing from underneath.

- Position the housing and flange shaft on the Press Plate -VW402- under the shop press.

- Press in the bearing inner race using the Press Piece - Press Tube -30-100- on the flange shaft.

- Install a new circlip -arrow- on the flange shaft.

- Install the center differential housing. Refer to → Chapter "Center Differential Housing, Removing and Installing, Bolted Driveshaft".

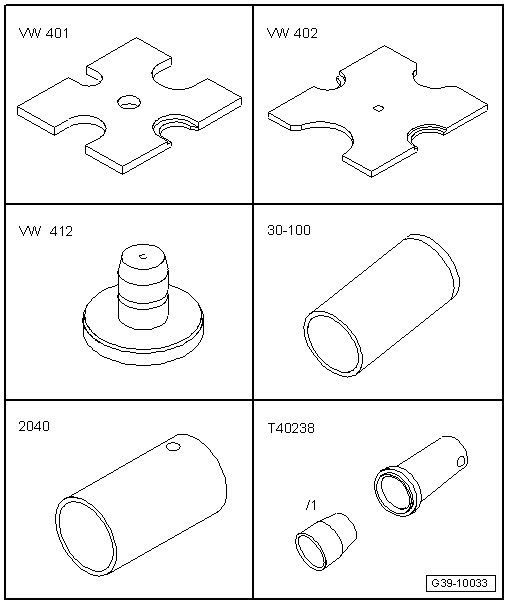

Transmission Output Shaft with Splines, Seal and Ball Bearing, Removing and Installing

Special tools and workshop equipment required

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Multiple Use -VW412-

- Press Piece - Press Tube -30-100-

- Press Piece - Front Control Arm -2040-

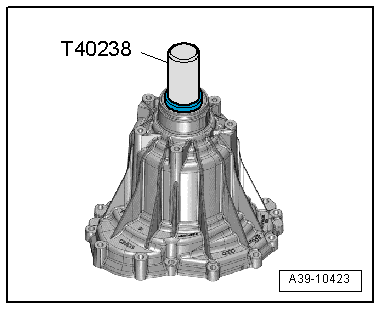

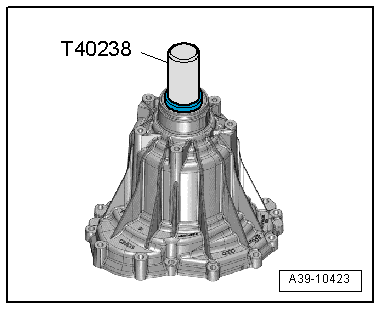

- Seal Installer - Output Shaft -T40238-

- Grease. Refer to the Parts Catalog.

Procedure

- Remove the center differential housing. Refer to → Chapter "Center Differential Housing, Removing and Installing".

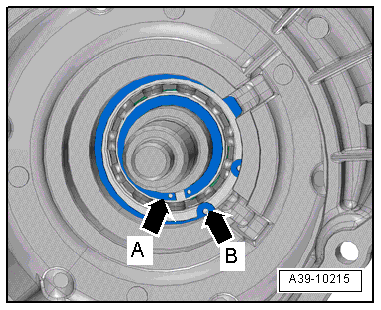

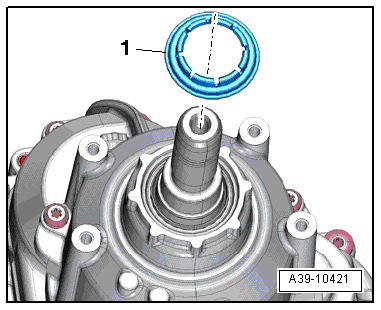

- Remove the circlip -arrow A-.

- Remove the locking ring -arrow B- as well if the ball bearing is also being removed.

Transmission Output Shaft With Splines without Vibration Damper:

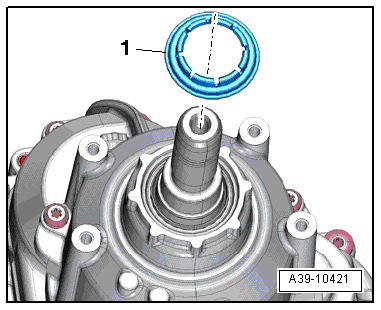

- Pry off the dust ring -1-.

Note

Note

The dust ring cannot be removed without destroying it.

- Position the center differential housing so that the transmission output shaft with splines does not touch the thrust plates Press Plate -VW401- and Press Plate -VW402- and remove the transmission output shaft with splines.

Transmission Output Shaft With Splines and Vibration Damper:

- Position the center differential housing so that the vibration damper does not touch the thrust plates Press Plate -VW401- and Press Plate -VW402- and remove the transmission output shaft with splines.

All:

- Pry out the shaft seal -1-.

Note

Note

Ignore item -2-.

- Remove the transmission output shaft ball bearing with splines, if necessary.

- Install the transmission output shaft ball bearing.

- The shoulder on the Press Piece - 60mm -VW415A--arrow- faces the Press Piece - Multiple Use -VW412-.

- Coat the seal on the outer circumference lightly with oil and then install it all the way in using Seal Installer - Output Shaft -T40238-.

- Installed position: Open side of shaft seal faces transmission.

- Fill the space between the sealing- and dust lip half way with sealing grease. Refer to the Parts Catalog.

- Install the transmission output shaft into the center differential housing as follows:

- Attach the vibration damper (if equipped) to the center differential housing. Tightening specification. Refer to → Chapter "Overview - Center Differential Housing".

- Install the transmission output shaft with splines into the center differential housing from underneath.

- Position the housing and transmission output shaft on the Press Plate -VW402- under the shop press.

- Mount the Press Plate - 30-100- on the ball bearing inner race.

- Install the transmission output shaft.

- Mount the new locking ring -arrow A- for the transmission output shaft with splines and -arrow B- for the ball bearing.

Transmission Output Shaft with Splines without Vibration Damper:

- Install a new dust ring -1-.

All:

- Install the center differential housing. Refer to → Chapter "Center Differential Housing, Removing and Installing".

Transmission Output Shaft Seal, Replacing

Transmission Output Shaft Seal, Replacing, Transmission Output Shaft with Splines without Vibration Damper

Special tools and workshop equipment required

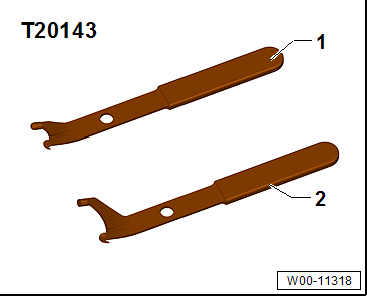

- Puller - Crankshaft/Power Steering Seal -T20143/1-

- Seal Installer - Output Shaft -T40238-

- Grease. Refer to the Parts Catalog.

Procedure

The Transmission Is Installed.

It is possible to replace the transmission output shaft seal with the transmission installed.

Note

Note

Check the vehicle data label or the designation on the rear final drive itself to determine which one is installed in the vehicle. Then select the correct rear final drive repair manual.

- Remove the (attached) driveshaft. Refer to → Rear Final Drive 0BC, 0BD, 0BE, 0BF; Rep. Gr.39; Removal and Installation

Transmission Removed

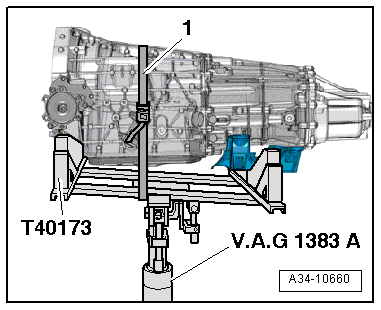

- Secure the transmission to the Gearbox Support -T40173- using a tension strap -1-.

or

- Secure the transmission on the Engine And Transmission Holder -VAS6095-. Refer to → Chapter "Securing on Engine and Transmission Holder".

Continuation for a Removed or Installed Transmission

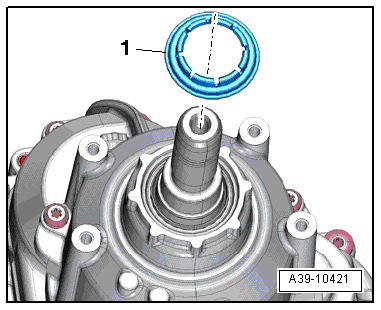

- Pry off the dust ring -1-.

Note

Note

The dust ring cannot be removed without destroying it.

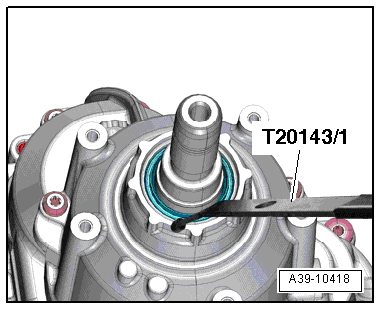

- Shaft Seal, Transmission Output Shaft with Splines, Removing

- Clean the running and sealing surface.

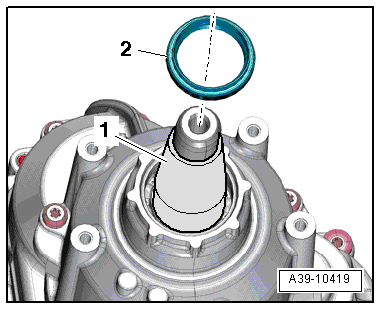

- Coat outer edge of seal with gear oil.

- Mount the Seal Installer - Output Shaft -T40238/1- item -1- on the transmission output shaft with splines.

- Fill the space between the sealing- and dust lip half way with sealing grease. Refer to the Parts Catalog.

- Install the shaft seal -2-.

- Installed position: The open side of the seal faces the transmission housing.

- Install the shaft seal all the way around evenly using Seal Installer - Output Shaft -T40238-. Do not bend the seal.

- Install a new dust ring -1-.

- Install the transmission. Refer to → S tronic Transmission; Rep. Gr.34; Transmission, Removing and Installing; Transmission, Installing

Continuation for an Installed Transmission

Note

Note

Check the vehicle data label or the designation on the rear final drive itself to determine which one is installed in the vehicle. Then select the correct rear final drive repair manual.

- Install the (attached) driveshaft. Refer to → Rear Final Drive 0BC, 0BD, 0BE, 0BF; Rep. Gr.39; Description and Operation

- Fill with transmission fluid (MTF). Refer to → S tronic Transmission; Rep. Gr.39; Transmission Fluid; Transmission Fluid, Draining and Filling

Transmission Output Shaft Seal, Replacing, Transmission Output Shaft with Splines with Vibration Damper

The transmission output shaft with splines on vehicles with a vibration damper must be removed in order to replace the transmission output shaft seal with splines.

Special Tools

Special tools and workshop equipment required

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Multiple Use -VW412-

- Press Piece - Press Tube -30-100-

- Press Piece - Front Control Arm -2040-

- Seal Installer - Output Shaft -T40238-

- Grease. Refer to the Parts Catalog.

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Multiple Use -VW412-

- Press Piece - 60mm -VW415A-

- Press Piece - Press Tube -30-100-

- Press Piece - Front Control Arm -2040-

- Used Oil Collection and Extraction Unit -SMN372500-

- Puller - Crankshaft/Power Steering Seal -T20143/1-

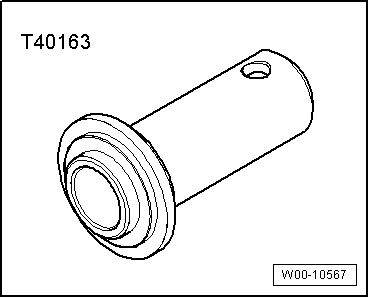

- Seal Installer - Flange Shaft -T40163-

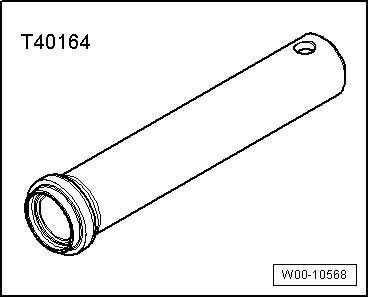

- Seal Installer - Flange Shaft -T40164-

- Seal Installer - Cardan Flange -T40165-

- Plate -T40285- for vehicles with torsional vibration damper or without vibration damper

- Bearing/Bushing Installer - Multiple Use -VW295A-

- Press Piece - 42mm -VW516-

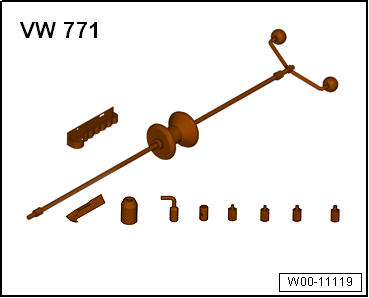

- Slide Hammer Set -VW771-

- Lifting Eyebolt -3368-