Audi A6 Typ 4G: Driveshaft on Transmission or Rear Final Drive, Removing and Installing

Driveshaft on Transmission, Removing and installing, Driveshaft Bolted on Transmission Side

Special tools and workshop equipment required

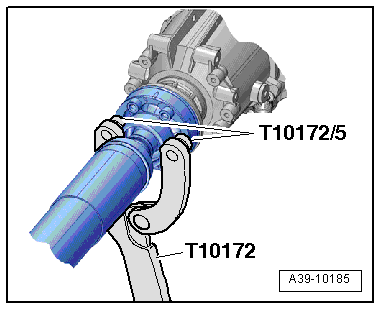

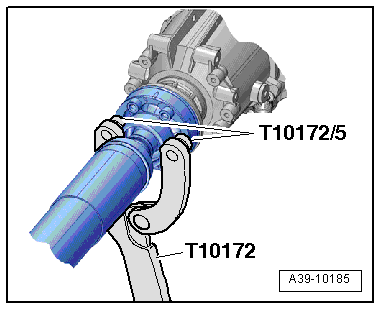

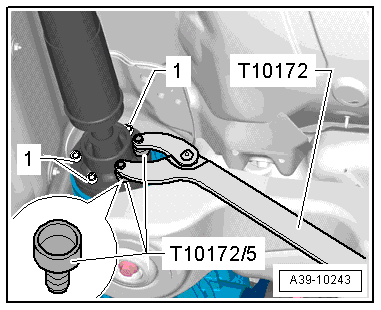

- Counterhold - Kit - Multiple Use -T10172- with adapters

- Counterhold - Kit - Adapter 5 -T10172/5- (M8 Bolts)

- Counterhold - Kit - Adapter 6 -T10172/6- (M10 Bolts)

- High Temperature Grease -G 000 633-

Remove the Driveshaft

- Note the instructions. Refer to → Chapter "Overview - Driveshaft, Bolts On Transmission Side".

- A two-column workshop hoist should be used when working on the driveshaft.

Note

Note

Do not bend the flex joint in the front exhaust pipe more than 10º or it will be damaged.

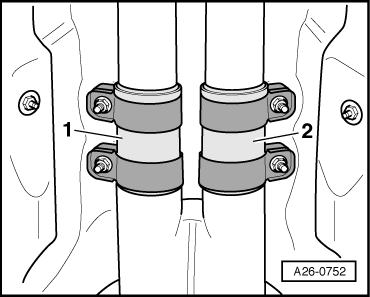

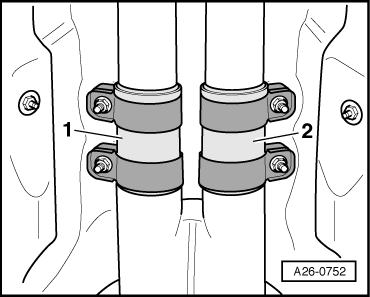

- Loosen the clamping sleeves -1 and 2- and disconnect the exhaust system.

- Tie the front exhaust pipe(s) to the underbody.

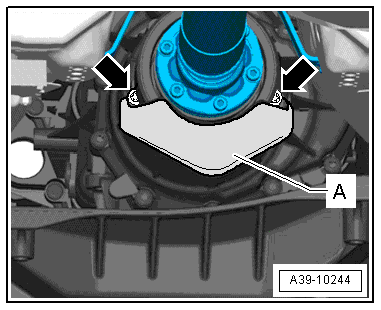

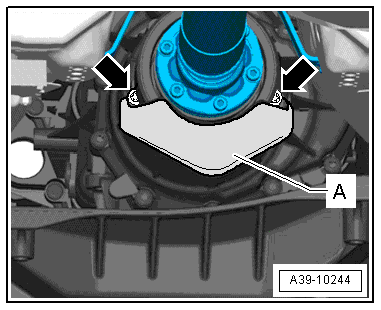

- Remove the heat shield -A- from the transmission -arrows-, if applicable.

- Remove the bolts for attaching the driveshaft to the transmission by counterholding with the Counterhold - Multiple Use -T10172A- and with the Counterhold - Kit - Adapter 5 -T10172/5-.

- Secure the driveshaft to the underbody.

Install the Driveshaft

Install in reverse order of removal. Note the following:

- Remove the old, dry High Temperature Grease from the CV joint and the driveshaft flange. Fill with the exact same amount of new High Temperature Grease.

- The threads in the flange shaft on the transmission must be cleaned of locking fluid residue. They can be cleaned with a thread tap. If the threads are not clean, the bolts will break off when they are being installed.

- Always replace the bolts for driveshaft (self-locking bolts).

- Check the driveshaft seal on the transmission flange for damage (bent, rubber layer worn off). Replace the damaged seal.

- Install the driveshaft and the new CV joint bolts.

- Tighten the bolts on the front driveshaft. Tightening specification. Refer to -item 5-.

- Use the Counterhold - Kit - Multiple Use -T10172- with Counterhold - Kit - Adapter 5 -T10172/5-.

- Tighten the heat shield -A- to the transmission -arrows-. Tightening Specification. Refer to → Fig. "Driveshaft Heat Shield - Tightening Specification".

- Assemble the exhaust system and align it without tension. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

Drive Shaft, Removing and Installing from Rear Final Drive

Special tools and workshop equipment required

- Counterhold - Kit - Multiple Use -T10172-

- Counterhold - Kit - Adapter 5 -T10172/5- (M8 Bolts)

- Counterhold - Kit - Adapter 6 -T10172/6- (M10 Bolts)

- High Temperature Grease -G 000 633-

- Pay attention to the notes. Refer to → Chapter "Overview - Driveshaft, Bolts On Transmission Side".

- A two-column workshop hoist should be used when working on the driveshaft.

Drive Shaft, Removing from Rear Final Drive

- Disconnect the exhaust system at the clamping sleeves -1 and 2-.

- Tie the front exhaust pipe(s) to the underbody.

Note

Note

- Do not bend the flex joint in the front exhaust pipe more than 10º or it will be damaged. Tie up the front exhaust pipes on the body and to the side.

- A second technician is needed to help remove the rear section of the exhaust system.

- Remove the rear section of the exhaust system. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

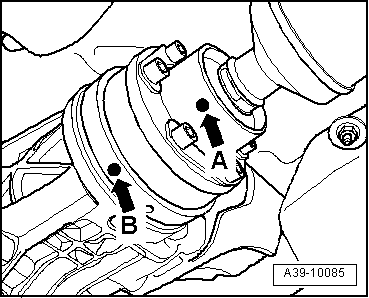

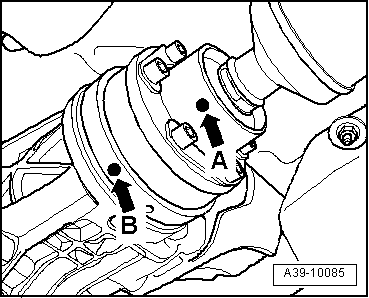

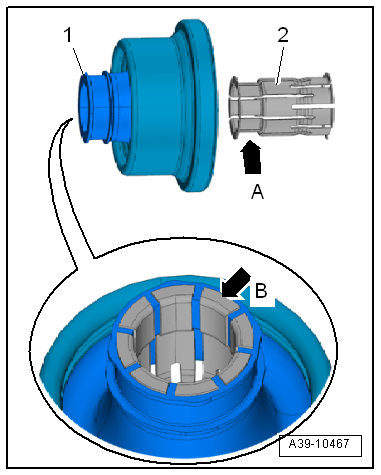

- Check whether there is a color marking on the driveshaft and at flange/driveshaft on the rear final drive -arrow A and arrow B-.

- If one of these markings is no longer visible (for example -arrow A- on the driveshaft), then make a mark for the missing colored dot in color.

- The mark on the driveshaft -arrow A- and on the rear final drive -arrow B- are on one line.

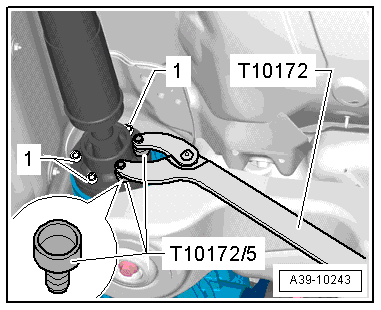

- Remove the bolts -1- (quantity: 6) from the rear CV joint.

- Counterhold with Counterhold - Kit - Multiple Use -T10172- and Counterhold - Kit - Adapter 5 -T10172/5- or Counterhold - Kit - Adapter 6 -T10172/6-.

- Remove the driveshaft from the rear final drive and move it to the side of the subframe.

Install the Driveshaft on the Rear Final Drive

Install in reverse order of removal. Note the following:

- Remove the old, dry High Temperature Grease from the CV joint and the driveshaft flange. Fill with the exact same amount of new High Temperature Grease.

- The threads in the flange shaft on the rear final drive must be cleaned of locking fluid residue. They can be cleaned with a thread tap. If the threads are not clean, the bolts will break off when they are being installed.

- After removing the driveshaft from the rear final drive, do not install the additional balance washer (thicker washer) that may be between the backing plate and the bolt.

- Always replace the bolts for driveshaft (self-locking bolts).

- Check the driveshaft seal on the rear final drive flange for damage (bent, rubber layer worn off) and replace if damaged. Replace the damaged seal.

- Position the driveshaft on the rear final drive while paying attention to the installation position:

- The dots on the driveshaft -arrow A- and on the rear final drive -arrow B- must line up.

- Maximum difference between the markings: 30º.

- Insert and tighten the new bolts -1- for the driveshaft. Follow the tightening sequence. Refer to → Fig. "Driveshaft to Rear Final Drive - Tightening Specification and Sequence".

- Install the rear section of the exhaust system. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

Boot, Replacing

Boot, Replacing, Driveshaft Connected on Transmission Side

Special tools and workshop equipment required

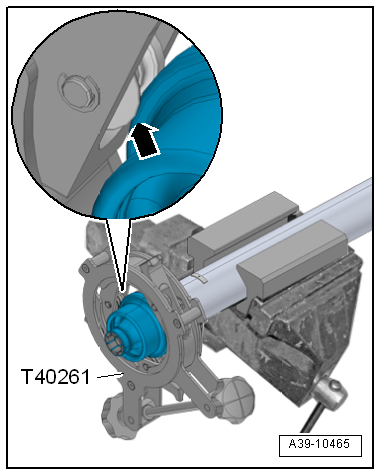

- Flanging Tool -T40261-

- Hose Clamp -23 to 35 mm Diameter-

Procedure

- Remove the driveshaft. Refer to → Chapter "Driveshaft, Removing and Installing, Driveshaft Connected on Transmission Side".

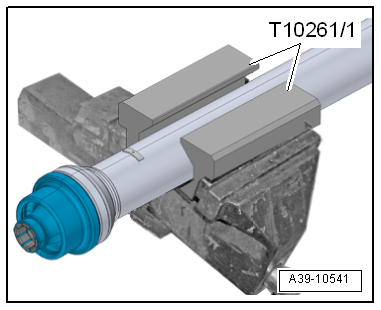

- Clamp the driveshaft with the Flanging Tool - Protective Jaws -T40261/1- into the vise, as shown in the illustration.

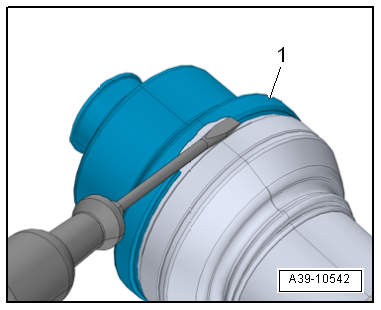

- Carefully loosen the metal sleeve flanging -1- from the driveshaft joint at one place with a screwdriver.

- The surface on the driveshaft joint must not be damaged.

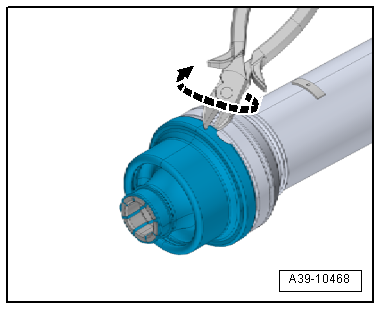

- Open the rest of the metal sleeve flanging -arrow- with a side cutter.

- Remove the old boot with the metal sleeve from the driveshaft joint.

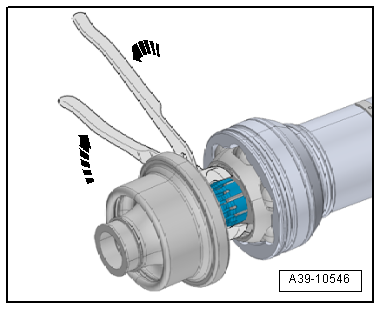

- Break the support ring with the water pump pliers -arrows- and remove the boot with the metal sleeve.

Note

Note

The inside of the joint and the balls remain in the driveshaft joint.

- Wipe away any excess grease.

- Grease the driveshaft joint with grease from the installation kit.

Note

Note

Fill with the same amount of grease, that has been clean off plus the amount that remains in the old boot.

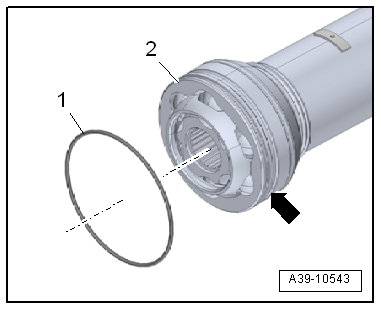

- Clean the sealing surface -arrow- on the driveshaft joint -2-.

- If there are scratches left behind after removing the old boot, smooth them out.

- Insert a new O-ring -1- in the groove.

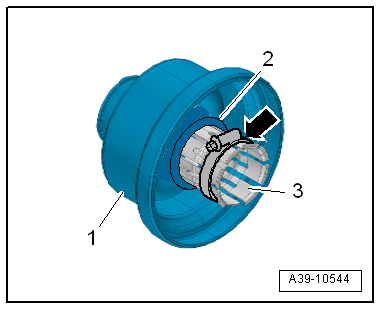

- Install the support ring -2- in the boot opening -1-.

- Direction of installation: the depression -arrow A- is slid into the boot.

- The guides for the support ring -arrow B- must be visible on the edge of the boot opening.

- Fold the boot -2- inward inside the metal sleeve -1-.

- Slide the hose clamp -arrow- onto the open guides for the support ring -3- as shown in the illustration.

- The end of the support ring must be freed up.

- Tighten the hose clamp -2- until the support ring guides -1- are able to be inserted into the groove -3- of the inside of the joint.

- Loosen the hose clamp -2- and remove.

- The support ring guides must catch on the inside of the groove -arrow-.

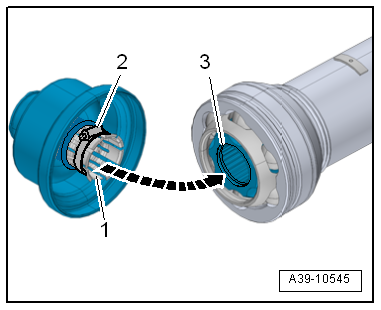

- Slide the metal sleeve for the boot all the way onto the joint.

- Attach the Flanging Tool -T40261- to the metal sleeve so that the guide roller stops -arrow- are touching the edge of the metal sleeve.

- Flange the metal sleeve by turning the Flanging Tool -T40261- back and forth.

- The turning angle must be at least 90º when turning it back and forth.

- While turning it back and forth, turn the hand wheel for the Flanging Tool -T40261-.

- The flanging is finished when the hand wheel for the Flanging Tool -T40261- can only be turned if a lot of force is used.