Audi A6 Typ 4G: Gear Oil

Gear Oil Drain and Inspection Plugs Overview

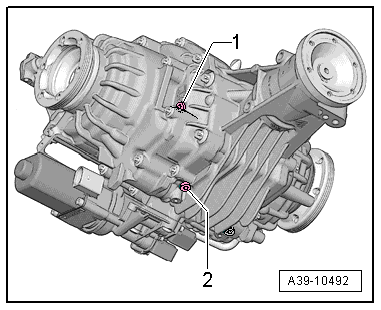

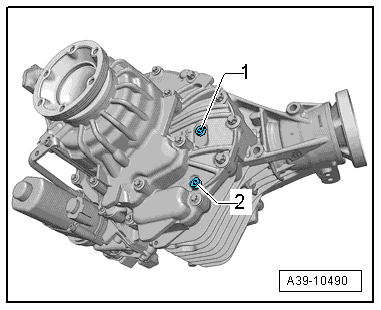

Gear Oil Drain and Inspection Plugs Overview, 0BE, 0BF

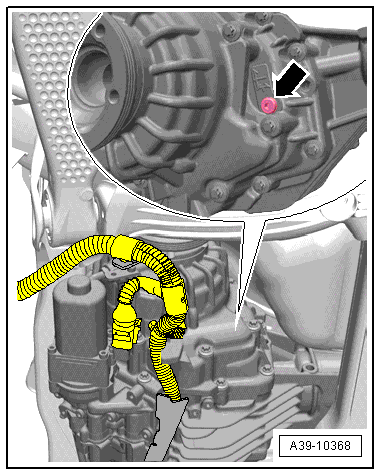

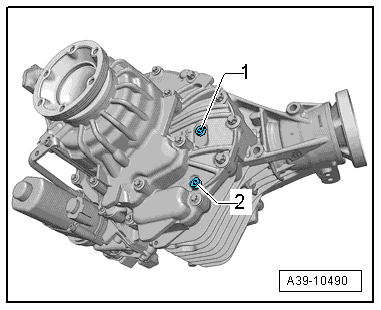

Gear Oil Drain Plug on Rear Final Drive 0BF

1- Check plug for gear oil

- Tightening Specification -item 23-.

- Always replace.

2- Gear oil drain plug

- Tightening Specification -item 17-.

- Always replace.

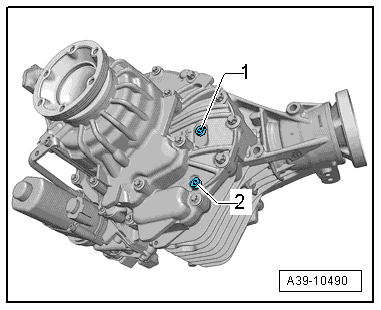

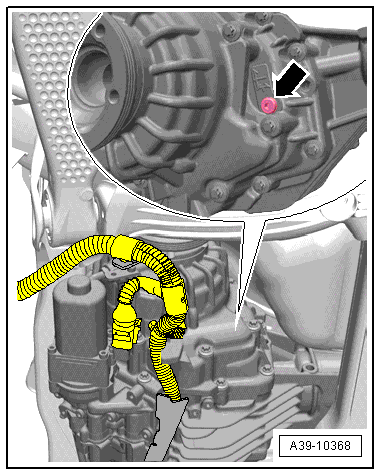

Gear Oil Drain Plug on Rear Final Drive 0BE

1- Check plug for gear oil

- Tightening Specification -item 23-.

- Always replace.

2- Gear oil drain plug

- Tightening Specification -item 17-.

- Always replace.

Gear Oil, Checking Level

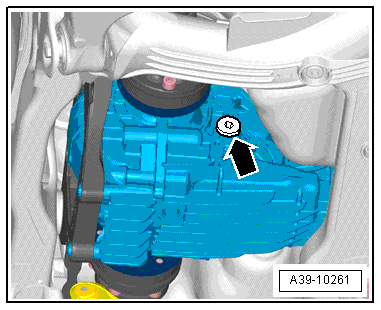

Gear Oil, Checking Level, 0BC

Special tools and workshop equipment required

- Drip Tray

- Remove the plug to check the transmission fluid level -arrow-.

The oil level is correct when the rear final drive is filled up to the lower edge of the oil fill hole.

- Refer to the Parts Catalog for the correct transmission fluid specification.

- Install the plug -arrow- and tighten it.

Tightening specification 30 Nm.

Gear Oil, Checking Level, 0BE, 0BF

Test requirement

- Gear oil temperature: 10 ºC to 60 ºC (50º to 140 ºF)

- The rear final drive must be in the installed position.

- The vehicle must be level.

- Gear oil plug overview. Refer to → Chapter "Gear Oil Drain and Inspection Plugs Overview, 0BE, 0BF".

Special tools and workshop equipment required

- Drip Tray

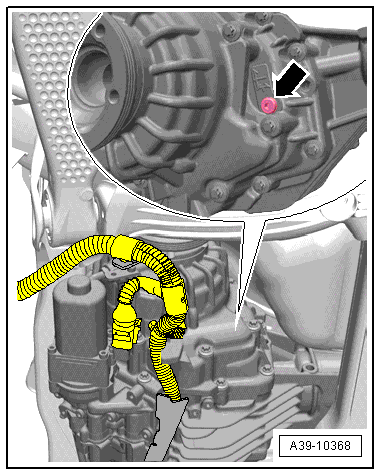

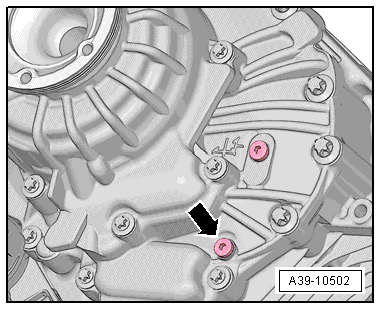

Rear Final Drive 0BF

- Remove the gear oil check plug -arrow-, located on the right side of the final drive.

Rear Final Drive 0BE

- Remove the gear oil check plug -1-.

Continuation for All Rear Final Drives

- The oil level is correct when the rear final drive is filled up to the lower edge of the oil fill hole.

- Refer to the Parts Catalog for the correct transmission fluid specification.

- If necessary fill the gear oil.

- Install the gear oil inspection plug -arrow- and tighten. Tightening specification: -item 23-.

Gear Oil, Draining and Filling

Gear Oil, Draining, 0BE, 0BF

Special tools and workshop equipment required

- Drip Tray

Rear Final Drive 0BF

- Remove the gear oil check plug -arrow-.

Note

Note

- Gear oil plug overview. Refer to → Chapter "Gear Oil Drain and Inspection Plugs Overview, 0BE, 0BF".

- Removing the gear oil check plug allows the gear oil to drain faster.

- Remove the drain plug -arrow- and drain the gear oil.

Rear Final Drive 0BE

- Remove the gear oil check plug -1-.

Note

Note

- Gear oil plug overview. Refer to → Chapter "Gear Oil Drain and Inspection Plugs Overview, 0BE, 0BF".

- Removing the gear oil check plug allows the gear oil to drain faster.

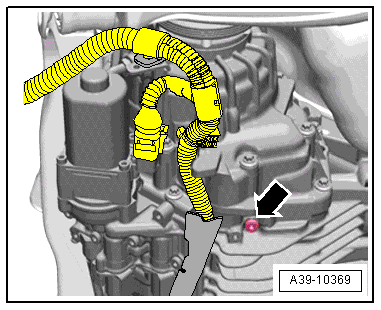

- Remove the drain plug -arrow- and drain the gear oil.

Continuation for All Rear Final Drives

- Install the new drain plug -arrow- and tighten it. Tightening Specification -item 17-.

Gear Oil, Filling, 0BF

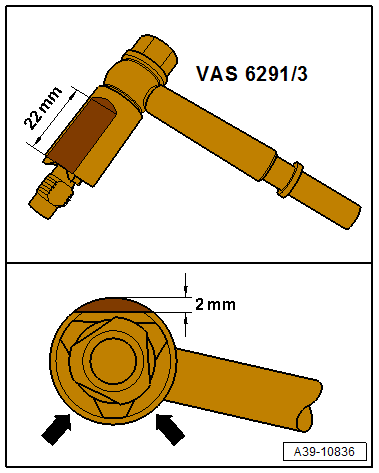

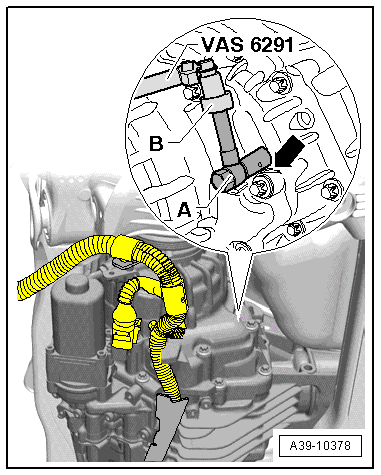

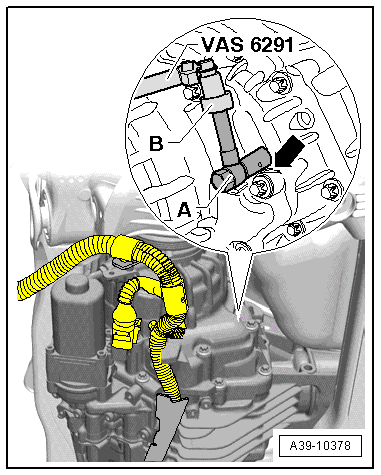

Special tools and workshop equipment required

- Charging Device For Haldex Coupling 2 -VAS6291- or Charging Device For Haldex Coupling 2 -VAS6291A-

- Charging Device For Haldex Coupling 2 - Adapter 3 -VAS6291/3- (rework if necessary. Refer to → Fig. "Depending on the version the spacer tube from the Charging Device For Haldex Coupling 2 - Adapter 3 -VAS6291/3- can line up on the housing rib on the final drive.".)

- Drip Tray

Depending on the version the spacer tube from the Charging Device For Haldex Coupling 2 - Adapter 3 -VAS6291/3- can line up on the housing rib on the final drive.

- Grind the adapter spacer tube as shown, opposite the side holes -arrows-.

Gear Oil, Filling

- The rear final drive must be in the installed position.

- The vehicle must be level.

- Gear oil plug overview. Refer to → Chapter "Gear Oil Drain and Inspection Plugs Overview".

- The gear oil drain plug is installed and tightened. Tightening specification. Refer to -item 17-.

- Oil specifications. Refer to the Parts Catalog.

- Lift the vehicle.

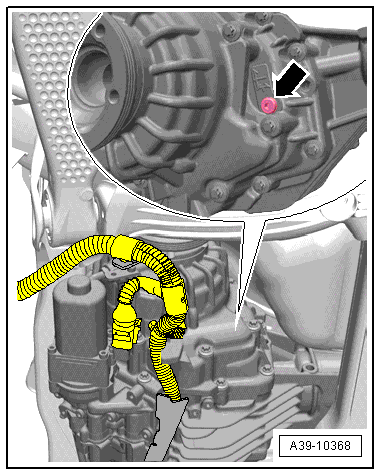

- Remove the gear oil check plug -arrow-.

- Disconnect the adapter -A- and elbow -B-.

- Install in the adapter -A- all the way.

Caution

Caution

Risk of damaging the fluid filler hole threads.

- Do not install the adapter -A- at an angle.

- The sanded side on the adapter -A- must point to the housing rib -arrow-.

- Attach the elbow -B- to the adapter -A-.

- Route the hose over the right drive axle.

- The hose must not sag. It must be routed over the right rear wheel.

- Lower the vehicle.

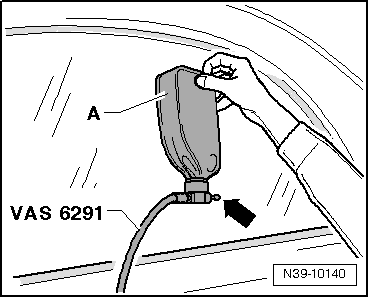

- Make sure that the valve -arrow- is closed.

- Install the oil container -A- on the Charging Device For Haldex Coupling 2 -V-.

- Open the valve -arrow- and hold the oil container as shown.

The rear final drive will not be filled.

- When at the correct filling of the rear final drive oil drips between the adapter -A- and the final drive housing -arrow-.

- Lift the vehicle.

- If oil leaks from adapter -A-, set down the fluid container (for example, on a tool cart).

A portion of the excess oil runs back into the oil container.

- If no more oil runs back, remove the Charging Device For Haldex Coupling 2 -VAS6291A-.

- The oil level is correct when the rear final drive is filled up to the lower edge of the oil fill hole.

- If necessary fill the gear oil again.

- Install the new gear oil check plug -arrow- and tighten. Tightening specification. Refer to -item 23-.