Audi A6 Typ 4G: Horn

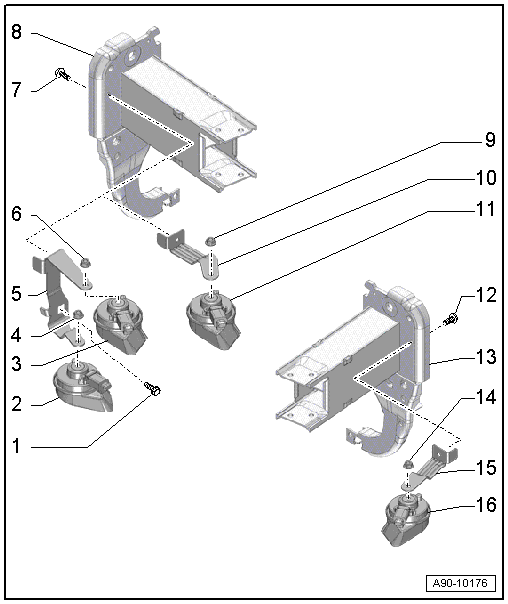

Overview - Horn

1 - Screw

- Tightening specification: Refer to → Body Exterior; Rep. Gr.63; Front Bumper; Overview - Impact Member

2 - High Tone Horn -H2-

- For vehicles with a TDI engine

- Removing and installing. Refer to → Chapter "High Tone Horn -H2-/Low Tone Horn -H7-, Removing and Installing".

3 - Low Tone Horn -H7-

- For vehicles with a TDI engine

- Removing and installing. Refer to → Chapter "High Tone Horn -H2-/Low Tone Horn -H7-, Removing and Installing".

4 - Nut

- 11 Nm

5 - Bracket

- For signal horns

- Removing and installing. Refer to → Chapter "Mount for Horns, Removing and Installing".

6 - Nut

- 11 Nm

7 - Screw

- 8 Nm

8 - Right Impact Member Mount

9 - Nut

- 11 Nm

10 - Bracket

- For the right horn

- Removing and installing. Refer to → Chapter "Mount for Horns, Removing and Installing".

11 - High Tone Horn -H2-

- For vehicles with a gasoline engine

- Removing and installing. Refer to → Chapter "High Tone Horn -H2-/Low Tone Horn -H7-, Removing and Installing ".

12 - Screw

- 8 Nm

13 - Left Impact Member Mount

14 - Nut

- 11 Nm

15 - Bracket

- For the left horn

- Removing and installing. Refer to → Chapter "Mount for Horns, Removing and Installing".

16 - Low Tone Horn -H7-

- For vehicles with a gasoline engine

- Removing and installing. Refer to → Chapter "High Tone Horn -H2-/Low Tone Horn -H7-, Removing and Installing ".

Special Tools

Special tools and workshop equipment required

- Fiber-Optic Repair Set - Connector Protective Caps -VAS6223/9- from Fiber-Optic Repair Set -VAS6223B-

- Head-Up Display Calibration Board - Audi A6 -VAS6657-

- Calibration Board - Head-Up Display -VAS6658-