Audi A6 Typ 4G: Hydraulic Control Unit, Removing and Installing

Hydraulic Control Unit, Removing and Installing, 0BE, 0BF

Note

Note

- Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- Pay attention to the safety precautions. Refer to → Chapter "Safety Precautions".

Removing

- The ignition is off.

- Place the vehicle on a lift.

- Lower the back section of the exhaust system just a little and secure it. If necessary remove the back section of the exhaust system. Refer to → Engine Mechanical, Fuel Injection and Ignition; Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

Note

Note

A second technician is needed to help remove the rear section of the exhaust system.

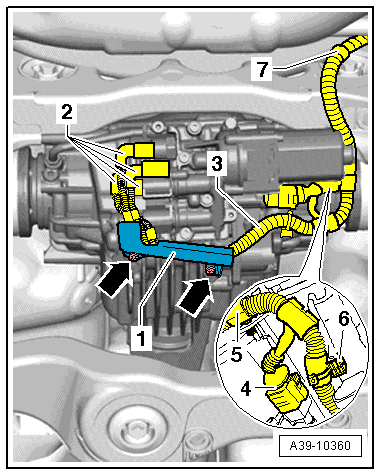

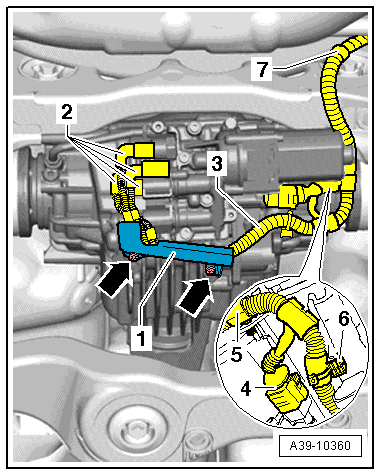

- If equipped, remove the screws -arrows- and remove the wiring harness bracket -1- from the rear final drive.

Note

Note

Mark the Oil Pressure/Temperature Sensor and the Clutch Valves connectors -2-.

- Disconnect the connectors -2- from the Oil Pressure/Temperature Sensor and the Clutch Valves.

- Disconnect the connector -4- from the All Wheel Drive Pump -V415-.

- Unclip the wiring harness -3- from the final drive and the subframe and tie it up -items 5 through 7-.

- Place the Drip Tray under the rear final drive.

- Drain the ATF from the rear final drive. Refer to → Chapter "ATF, Draining and Filling".

- Drain the gear oil from the rear final drive. Refer to → Chapter "Gear Oil, Draining, 0BE, 0BF".

- Remove the All Wheel Drive Pump -V415-. Refer to → Chapter "All Wheel Drive Pump -V415-, Removing and Installing".

Note

Note

The All Wheel Drive Pump -V415- must be removed in order to loosen and tighten the nut on the right line to the hydraulic control unit.

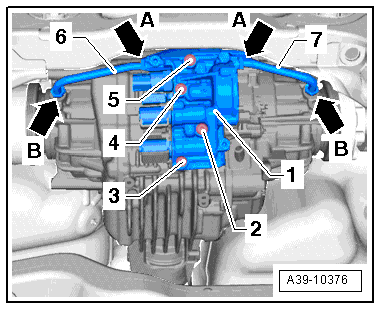

- Loosen the left -6- and right -7- lines to the hydraulic control unit -1- one turn -arrows A- and remove them from the chambers -arrows B-.

- Remove the screws -2 through 5- and remove the hydraulic control unit -1- with the seal.

Installing

Note

Note

Follow all safety precautions exactly when replacing the hydraulic control unit. Install the "old" sensors again if possible. Refer to → Chapter "Safety Precautions and Test Procedures"

Conditions:

- Replace the seal between the hydraulic control unit -1- and the final drive housing.

- The centering pins -item 18- must be installed inside the housing for the hydraulic control unit.

- The left -6- and right -7- lines must be installed loosely when attaching the hydraulic control unit -1-.

Attach the hydraulic control unit -1- to the rear final drive as follows:

First install the lines -6 and 7- into the chambers hand-tight -arrows B-.

Then install the screws -2 through 5- hand-tight. One screw -2- has a permanent seal on the head. Coat the thread with Sealing Compound -D 176 501 A1-.

Tighten the M8 x 30 screws -2 through 5- to the tightening specification in the sequence: -4, 2, 5 and 3-.

Tighten the nuts -A arrows- and -B arrows- on the left -6- and right -7- lines to the tightening specification.

- Install the All Wheel Drive Pump -V415-. Refer to → Chapter "All Wheel Drive Pump -V415-, Removing and Installing".

- Install the wiring harness -3- to the final drive and subframe -items 5 through 7-.

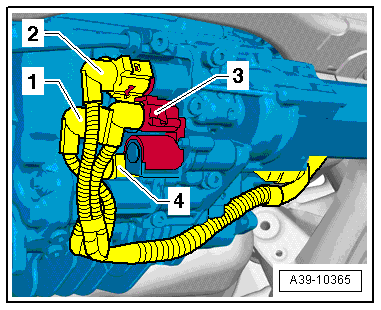

- Connect the connectors -4 and 2-. Pay attention to the marks made during the removal, that identify the allocation to the Oil Pressure/Temperature Sensor and which connectors go to the Clutch Valves.

- If equipped, position the wiring harness bracket -1- on the rear final drive and tighten the bolts -arrows- to the tightening specification. Make sure the wiring harness -3- does not get pinched.

Note

Note

- Allocation for the Oil Pressure/Temperature Sensor and Clutch Valves connectors:

- -1- = Oil Pressure/Temperature Sensor 2 -G640- Connector

- -2- = Oil Pressure/Temperature Sensor -G437- Connector

- -3- = All Wheel Drive Clutch Valve 2 -N446- Connector

- -4- = All Wheel Drive Clutch Valve -N445- Connector

- Fill the rear final drive with gear oil and then check the level. Refer to → Chapter "Gear Oil, Checking Level, 0BE, 0BF".

- Fill the ATF in the rear final drive and check the ATF level. Refer to → Chapter "ATF Level, Checking, 0BE, 0BF".

- Install the rear section of the exhaust system and align it so it is free of tension. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

Hydraulic Control Unit, Disassembling and Assembling

Hydraulic Control Unit, Disassembling and Assembling, 0BE, 0BF

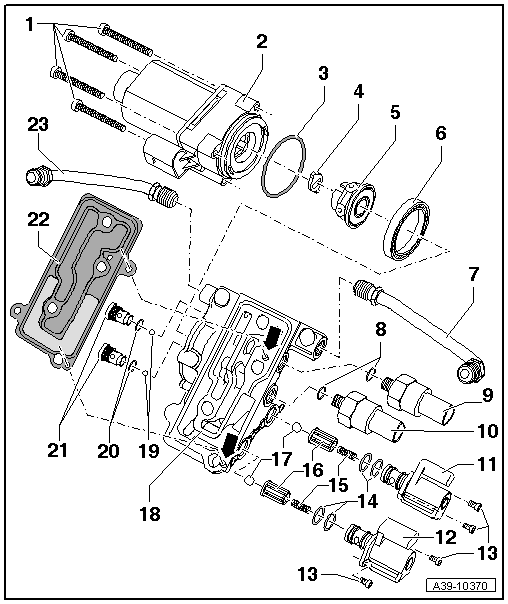

1 - Bolt

- 5 Nm

2 - All Wheel Drive Pump -V415-

- Removing and installing. Refer to → Chapter "All Wheel Drive Pump -V415-, Removing and Installing".

3 - O-Ring

- Always replace.

4 - Adapter

Note

Note

- The adapter could fall out when removing the All Wheel Drive Pump -V415-.

- Insert the adapter into the recesses in the hydraulic pump before installing the All Wheel Drive Pump -V415-.

5 - Hydraulic Pump

- Consists of a guide ring, the housing and six pistons

- Assembling. Refer to → Fig. "Assembling the Hydraulic Pump"

6 - Ball Bearing

- Can be installed and removed by hand

7 - Left Line

- Tighten the nuts to 30 Nm.

- Is installed between the hydraulic control unit and the left chamber

- Tighten both nuts hand-tight when installing

8 - O-Ring

- Always replace.

9 - Oil Pressure/Temperature Sensor -G437-

- 10 Nm

- Brown connector

- Removing and installing. Refer to → Chapter "Oil Pressure/Temperature Sensor -G437- or Oil Pressure/Temperature Sensor 2 -G640-, Removing and Installing".

10 - Oil Pressure/Temperature Sensor 2 -G640-

- 10 Nm

- Black connector

- Removing and installing. Refer to → Chapter "Oil Pressure/Temperature Sensor -G437- or Oil Pressure/Temperature Sensor 2 -G640-, Removing and Installing".

11 - All Wheel Drive Clutch Valve 2 -N446-

- Color: brown

- Removing and installing. Refer to → Chapter "All Wheel Drive Clutch Valve -N445- or All Wheel Drive Clutch Valve 2 -N446-, Removing and Installing".

- Installed position, the connector faces upward toward the Oil Pressure/Temperature Sensor

Caution

Caution

Do not interchange with the All Wheel Drive Clutch Valve -N445-.

12 - All Wheel Drive Clutch Valve -N445-

- Color: black

- Removing and installing. Refer to → Chapter "All Wheel Drive Clutch Valve -N445- or All Wheel Drive Clutch Valve 2 -N446-, Removing and Installing".

- Installed position, the connector faces upward toward the Oil Pressure/Temperature Sensor

Caution

Caution

Do not interchange with the All Wheel Drive Clutch Valve 2 -N446-.

13 - Bolt

- 2.5 Nm

14 - O-Ring

- Always replace.

- Mount onto the Clutch Valve

15 - Pressure Spring

- Insert into the guide -item 16-

16 - Guide

- Installation position, large diameter faced the ball -item 17-

17 - Ball

- Insert into the guide before installing -item 16-

18 - Hydraulic Control Unit Housing

- with centering pins -arrows-

- The centering pins lock the hydraulic control unit and seal to the final drive housing.

19 - Ball

- Install in the hole in the shuttle valve before installing -item 21-

20 - O-Ring

- Always replace.

21 - Shuttle Valve

- 8 Nm

- Removing and installing. Refer to → Fig. "Removing and Installing the Shuttle Valves".

22 - Seal

- With strainer

- Install on the centering pins in the hydraulic control unit housing

23 - Right Line

- Tighten the nuts to 30 Nm.

- Is installed between the hydraulic control unit and the right chamber

- Tighten both nuts hand-tight when installing

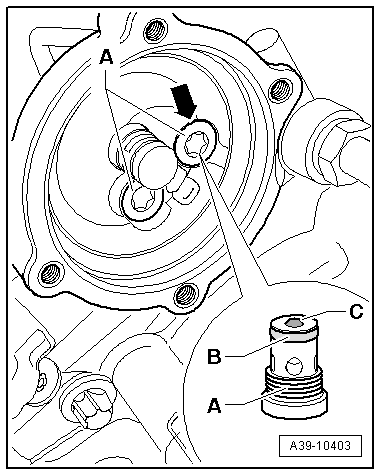

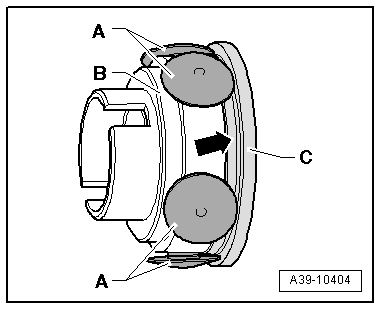

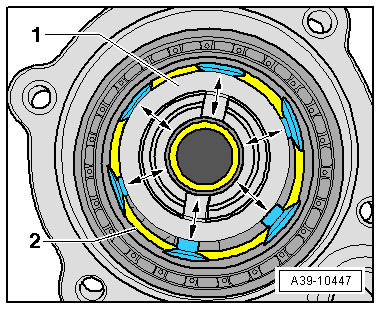

Assembling the Hydraulic Pump

- Install the six pistons -A- in the housing -B-.

- Install the guiding ring -C- so that the piston touches the collar -arrow-.

- Insert the hydraulic pump -1- with the guide ring -2- in the in the hydraulic control unit housing.

Function Test:

- Turn the hydraulic pump -1- several times. While doing so pay attention to the following:

- When turning the hydraulic pump must not become hooked or tilted.

- All pistons must be removed and pressed in.

Removing and Installing the Shuttle Valves

Note

Note

Remove the All Wheel Drive Pump -V415-, hydraulic pump and ball bearing -item 6- beforehand.

- Remove the shuttle valves -A-. Always remove the ball -C- as well.

- Insert the ball into the hole in the shuttle valve when installing.

- Install the shuttle valve all the way with a new O-ring -B-.

- The shuttle valve must rest lower than the opposing housing surface -arrow-. If this is not the case, then the remove the valve again and adjust the position of the ball.

- Tighten the shuttle valve to the tightening specification -item 21-