Audi A6 Typ 4G: All Wheel Drive Pump -V415-, Removing and Installing

All Wheel Drive Pump -V415-, Removing and Installing, 0BE, 0BF

Special tools and workshop equipment required

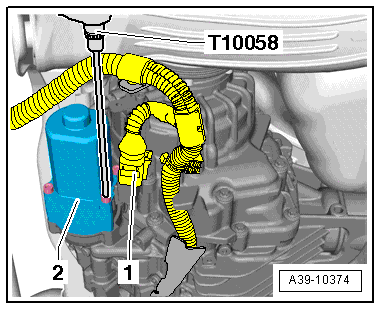

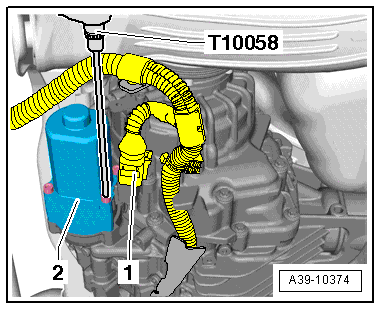

- Hex Ball Socket -T10058-

Note

Note

- Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- Pay attention to the safety precautions. Refer to → Chapter "Safety Precautions".

Removing

- Place the vehicle on a lift.

- The ignition is off.

- Place the Drip Tray under the rear final drive.

- Disconnect the connector -1- from the All Wheel Drive Pump -V415--2-.

- Remove the four bolts that connect the All Wheel Drive Pump -V415- to the hydraulic control unit using the Hex Ball Socket -T10058-.

- Carefully remove the All Wheel Drive Pump -V415--2-. Pay close attention to the adapter -item 4- inside the hydraulic pump while doing this.

Note

Note

- The adapter could fall out when removing the All Wheel Drive Pump -V415-.

- Insert the adapter into the recesses in the hydraulic pump before installing the All Wheel Drive Pump -V415-.

Installing

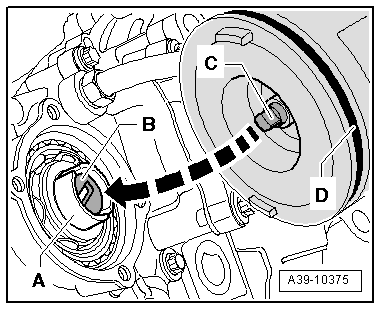

- The hydraulic pump -A- is installed inside the hydraulic control unit. Assembling the hydraulic pump. Refer to → Fig. "Assembling the Hydraulic Pump".

- The adapter -B- is installed in the recesses in the hydraulic pump.

- A new O-ring -D- is on the All Wheel Drive Pump -V415-.

- Install the All Wheel Drive Pump -V415- with the coupling -C- in the adapter -B-.

- Diagonally tighten the four bolts on the All Wheel Drive Pump -V415--2- to the tightening specification -item 1-.

- Connect the connector -1- to the All Wheel Drive Pump -V415-.

- Fill the ATF in the rear final drive. Refer to → Chapter "ATF, Filling, 0BE, 0BF".

Oil Pressure/Temperature Sensor -G437- or Oil Pressure/Temperature Sensor 2 -G640-, Removing and Installing

Oil Pressure/Temperature Sensor -G437- or Oil Pressure/Temperature Sensor 2 -G640-, Removing and Installing, 0BE, 0BF

Special tools and workshop equipment required

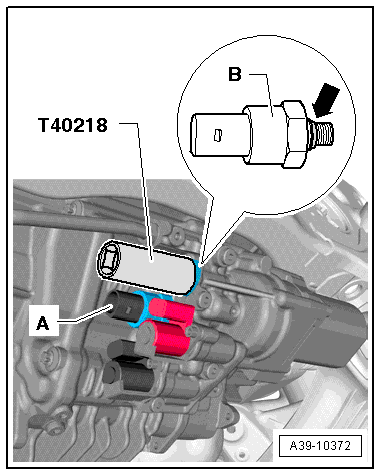

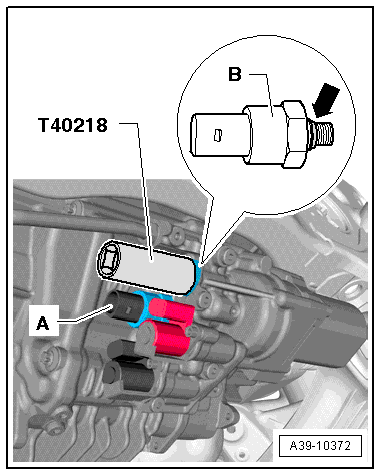

- Socket - 27mm -T40218-

- Vehicle Diagnostic Tester

Important Safety Precautions

Caution

Caution

- The identity of the sensor in the All Wheel Drive Control Module -J492- must be adapted using the Vehicle Diagnostic Tester after replacing the Oil Pressure/Temperature Sensor -G437- or the Oil Pressure/Temperature Sensor 2 -G640-.

- Do not replace both the Oil Pressure/Temperature Sensor -G437- and Oil Pressure/Temperature Sensor 2 -G640- at the same time because a valid sensor identity is needed for the rear final drive classification to the All Wheel Drive Control Module -J492-. If the both sensors are replaced at the same time, the All Wheel Drive Control Module -J492- will interpret this as the rear final drive is being replaced. By doing this, adaptation values in the control module will be erased and the performance of the rear final drive will be impaired.

- If both the Oil Pressure/Temperature Sensor -G437- and the -G640- must be replaced due to mechanical damage, for example, if the connector housing gets damaged, then this must be performed in two steps. After replacing the first sensor, the identity of the must be adapted in the All Wheel Drive Control Module -J492- using the Vehicle Diagnostic Tester. Do the same for the second sensor.

- If both the Oil Pressure/Temperature Sensor -G437- and Oil Pressure/Temperature Sensor 2 -G640- must be replaced at the same time due to an electrical fault, then the clutch classification must be entered into the All Wheel Drive Control Module -J492- using the Vehicle Diagnostic Tester → Vehicle diagnostic tester. Also, the ATF in the rear final drive must be replaced. Refer to → Chapter "ATF, Draining and Filling".

Note

Note

- Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- Pay attention to the safety precautions. Refer to → Chapter "Safety Precautions".

Removing

- The ignition is off.

- Place the vehicle on a lift.

- Lower the back section of the exhaust system just a little and secure it.

- Remove the wiring harness bracket from the rear final drive, if necessary.

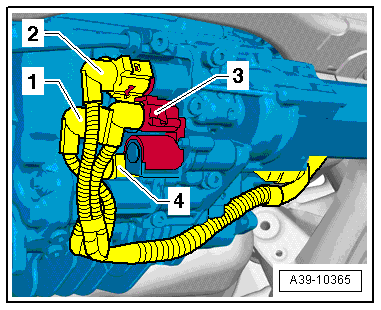

- Disconnect the connector -1- from the Oil Pressure/Temperature Sensor 2 -G640- and the connector -2- from the Oil Pressure/Temperature Sensor -G437-.

Note

Note

Disconnect connectors -3- and -4- if necessary.

- Place the Drip Tray under the rear final drive.

- Remove the Sensor with the Socket Wrench -T40218-.

-A- = Oil Pressure/Temperature Sensor 2 -G640- black connector

-B- = Oil Pressure/Temperature Sensor -G437- brown connector

Installing

- Install the new Sensor with a new o-ring -arrow- and tighten to the tightening specification -9- or -10-.

-A- = Oil Pressure/Temperature Sensor 2 -G640- black connector

-B- = Oil Pressure/Temperature Sensor -G437- brown connector

- Disconnect the connector -1- on the Oil Pressure/Temperature Sensor 2 -G640- and the connector -2- on the Oil Pressure/Temperature Sensor -G437-.

Note

Note

Connect connectors -3- and -4- if they were disconnected earlier.

- Attach the wiring harness bracket to the rear final drive if it was removed earlier.

- Connect the Vehicle Diagnostic Tester and turn on the ignition.

- Select the function 22 - Rear Final Drive Replacing in the Vehicle Diagnostic Tester under Guided Functions in the directory 22- Sensor Programing.

- Follow all the instructions given by the Vehicle Diagnostic Tester exactly.

The new sensor is "adapted" on the All Wheel Drive Control Module -J492- with the Vehicle Diagnostic Tester.

Note

Note

A system check will take place when the 22 - Sensor Programing function is complete. If malfunctions appear, then use "Guided Fault Finding" to correct them.

- Fill the ATF in the rear final drive. Refer to → Chapter "ATF, Filling, 0BE, 0BF".

- Install the rear section of the exhaust system on the body and align it so it is free of tension. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

All Wheel Drive Clutch Valve -N445- or All Wheel Drive Clutch Valve 2 -N446-, Removing and Installing

All Wheel Drive Clutch Valve -N445- or All Wheel Drive Clutch Valve 2 -N446-, Removing and Installing, 0BE, 0BF

Special tools and workshop equipment required

- Hex Socket - 4mm -T10370-

Note

Note

- Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- Pay attention to the safety precautions. Refer to → Chapter "Safety Precautions".

Caution

Caution

Malfunctions on the rear final drive.

Do not confuse the All Wheel Drive Clutch Valve -N445- component location with the All Wheel Drive Clutch Valve 2 -N446- component location.

Removing

- The ignition is off.

- Place the vehicle on a lift.

- Lower the back section of the exhaust system just a little and secure it.

- Remove the wiring harness bracket from the rear final drive.

Note

Note

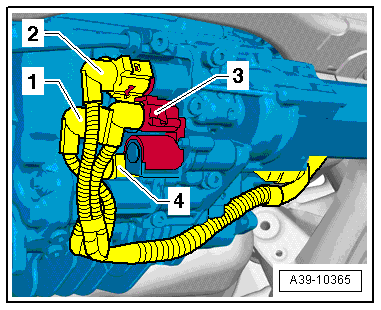

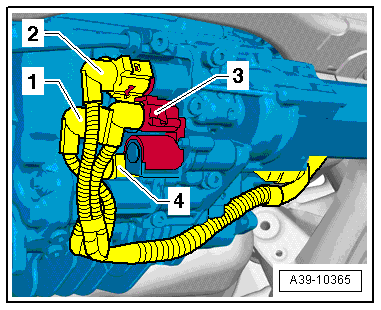

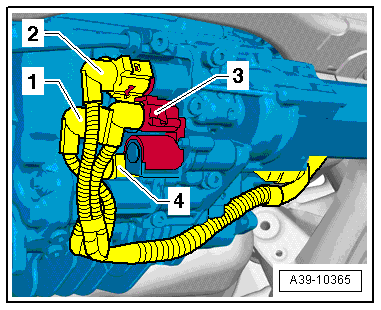

- Mark the connectors -1 through 4- for the Oil Pressure/Temperature Sensor and for the Clutch Valves.

- Disconnect the connectors -1 and 2-.

- Disconnect the connector -3- from the All Wheel Drive Clutch Valve 2 -N446- and the connector -4- from the All Wheel Drive Clutch Valve -N445-.

- Place the Drip Tray under the rear final drive.

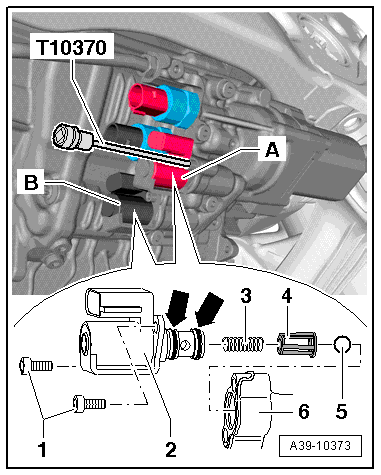

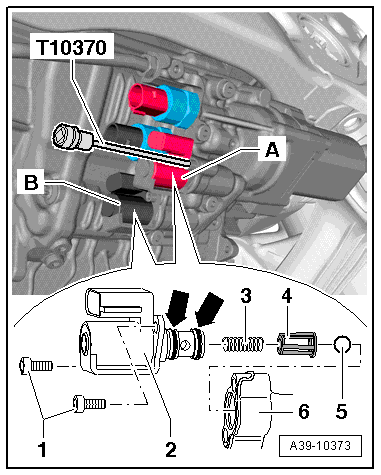

- Remove the bolts -1- from each of the Clutch Valves using the Hex Socket - 4mm -T10370-.

- Carefully pry out the Clutch Valve with a flat blade screwdriver -3-. Be careful of the pressure spring when doing this. The pressure spring could fall out of the opening in the hydraulic control unit -6-.

-A- = All Wheel Drive Clutch Valve 2 -N446- identification color brown

-B- = All Wheel Drive Clutch Valve -N445- identification color black

Installing

- The ball -5-, the guide -4- (the smaller diameter faces the spring) and the spring -3- must be installed in the housing opening -6- for the Clutch Valve-2-.

- Coat the O-rings with ATF and install the new Clutch Valve with the new O-rings -arrows-.

- Tighten the bolts -1- evenly until stop by hand. Then tighten to the tightening specification -item 13-.

Further installation is performed in reverse order of the removal. Note the following.

Note

Note

- Allocation for the Oil Pressure/Temperature Sensor and Clutch Valves connectors:

- -1- = Oil Pressure/Temperature Sensor 2 -G640- Connector

- -2- = Oil Pressure/Temperature Sensor -G437- Connector

- -3- = All Wheel Drive Clutch Valve 2 -N446- Connector

- -4- = All Wheel Drive Clutch Valve -N445- Connector

- Attach the wiring harness bracket to the rear final drive.

- Fill the ATF in the rear final drive. Refer to → Chapter "ATF, Filling, 0BE, 0BF".

- Install the rear section of the exhaust system on the body and align it so it is free of tension. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

Torque Displacement, Checking

Torque Development, Checking, 0BE, 0BFм

Special tools and workshop equipment required

- Vehicle Diagnostic Tester

Procedure:

Note

Note

- Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- Pay attention to the safety precautions. Refer to → Chapter "Safety Precautions".

After the following work the function 22- Checking the torque displacement must be performed:

- Working on the rear final drive wiring

- Working on the valves: All Wheel Drive Clutch Valve -N445- and All Wheel Drive Clutch Valve 2 -N446-.

- Working on the hydraulic control unit

- Lift the vehicle on a hoist just far enough until the wheels are no longer touching the floor.

- Connect the Vehicle Diagnostic Tester and turn on the ignition.

- Select the function 22 - Rear Final Drive Replacing in the vehicle diagnostic tester under Guided Functions in the directory 22- Torque Development, Checking.

- Follow all the instructions given by the Vehicle Diagnostic Tester exactly.

Use the Vehicle Diagnostic Tester to check if the torque is stored for the correct side when the rear final drive is activated.