Audi A6 Typ 4G: Instrument Cluster

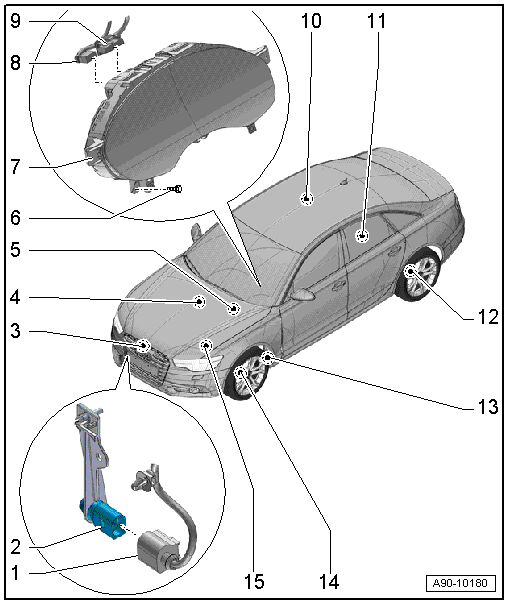

Overview - Instrument Cluster

1 - Connector

- For Outside Air Temperature Sensor -G17-

2 - Outside Air Temperature Sensor -G17-

- Removing and installing. Refer to → Chapter "Outside Air Temperature Sensor, Removing and Installing".

3 - Oil Level Thermal Sensor -G266-

- Removing and installing. Refer to → Rep. Gr.17; Oil Pan/Oil Pump; Oil Level Thermal Sensor G266, Removing and Installing.

4 - Oil Pressure Switch -F22-/Reduced Oil Pressure Switch -F378-

- Removing and installing. Refer to → Rep. Gr.17; Oil Filter/Oil Pressure Switch; Overview - Oil Filter Housing/Oil Pressure Switch.

5 - Brake Fluid Level Warning Switch -F34-

- Removing and installing. Refer to → Brake System; Rep. Gr.47; Brake Booster/Master Brake Cylinder; Overview - Brake Booster/Master Brake Cylinder.

6 - Screw

- 3 Nm

- Quantity: 2

7 - Instrument Cluster

- With Instrument Cluster Control Module -J285-

- Removing and installing. Refer to → Chapter "Instrument Cluster with Instrument Cluster Control Module -J285-, Removing and Installing".

- Multi-pin connector pin assignment. Refer to → Chapter "Instrument Cluster Multi-Pin Connector Contact Assignment".

8 - Fiber Optic Cable Connector

- Seal with Fiber-Optic Repair Set - Connector Protective Caps -VAS6223/9-

9 - Connector

- For instrument cluster

10 - Fuel Level Sensor -G-

- Connector assignment. Refer to → Chapter "Fuel Level Sensor -G- Connector Assignment".

11 - Fuel Level Sensor 2 -G169-

- Connector assignment. Refer to → Chapter "Fuel Level Sensor 2 -G169- Connector Assignment".

12 - Rear Brake Pad Wear Sensor

- Left Rear Brake Pad Wear Sensor -G36-, Right Rear Brake Pad Wear Sensor -G37-

- Removing and installing. Refer to → Brake System; Rep. Gr.46.

13 - Windshield Washer Fluid Level Sensor -G33-

- Removing and installing. Refer to → Chapter "Windshield Washer Fluid Level Sensor, Removing and Installing".

14 - Front Brake Pad Wear Sensor

- Left Front Brake Pad Wear Sensor -G34-, Right Front Brake Pad Wear Sensor -G35-

- Removing and installing. Refer to → Brake System; Rep. Gr.46.

15 - Engine Coolant Level Warning Switch -F66-

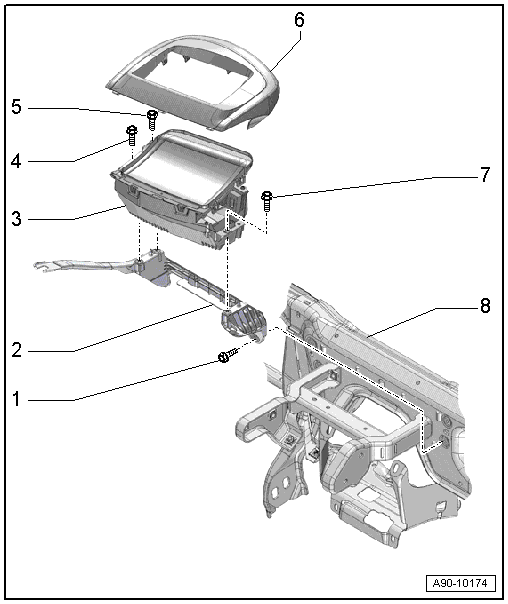

Overview - Windshield Projection Head Up Display

1 - Screw

- Quantity: 4

- Tightening specification. Refer to → Body Interior; Rep. Gr.70; Instrument Panel Central Tube; Overview - Instrument Panel Central Tube.

2 - Bracket

- For windshield projection control module

- Removing and installing. Refer to → Body Interior; Rep. Gr.70; Instrument Panel Central Tube; Overview - Instrument Panel Central Tube

3 - Windshield Projection Head Up Display Control Module -J898-

- Removing and installing. Refer to → Chapter "Windshield Projection Head Up Display Control Module, Removing and Installing".

- Calibrating. Refer to → Chapter "Windshield Projection Head Up Display Control Module, Calibrating".

4 - Screw

- 5.5 Nm

5 - Screw

- 5.5 Nm

6 - Upper Cover

- Removing and installing. Refer to → Body Interior; Rep. Gr.70; Instrument Panel; Overview - Instrument Panel

7 - Screw

- 5.5 Nm

8 - Central Tube

Instrument Cluster with Instrument Cluster Control Module -J285-, Removing and Installing

Special tools and workshop equipment required

- Fiber-Optic Repair Set - Connector Protective Caps -VAS6223/9- from Fiber-Optic Repair Set -VAS6223B-

Note

Note

- All warning lamps in instrument cluster are fitted with light-emitting diodes. In case an indicator lamp is malfunctioning, the instrument cluster must be replaced.

- Do not disassemble the instrument cluster.

- It is not necessary to remove the steering wheel in order to remove the instrument cluster.

- If the instrument cluster with the Instrument Cluster Control Module -J285- was replaced, select the "Replace" function for the corresponding control module in the "Guided Fault Finding" or "Guided Functions" operating mode using the Vehicle Diagnostic Tester.

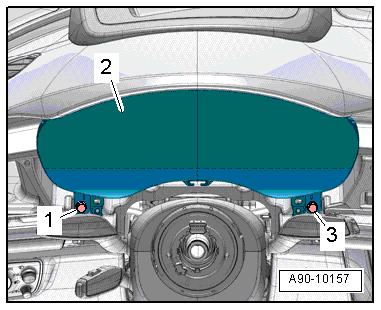

Removing

- Adjust steering wheel downward and to rear as far as possible, use entire adjustment range of steering column adjustment for this.

- Remove the light switch. Refer to → Chapter "Light Switch -E1-, Removing and Installing".

- Remove the instrument cluster frame. Refer to → Body Interior; Rep. Gr.70; Instrument Panel; Instrument Cluster Frame, Removing and Installing.

- Remove the bolts -1 and 3-.

- Pull the instrument cluster -2- out just far enough until it is touching the steering wheel.

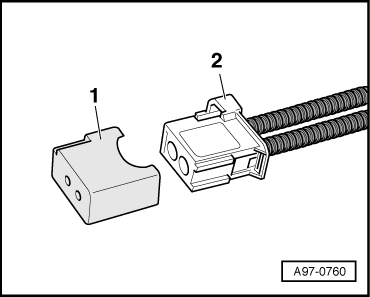

- Disconnect the connector -2- for the fiber-optic cable and the connector -1-.

- Seal open wiring harness connector -2- with Fiber-Optic Repair Set - Connector Protective Caps - VAS6223/9--item 1-.

Note

Note

The protective cap prevents contamination of or mechanical damage to end face of fiber optic cable which would impair signal transmission.

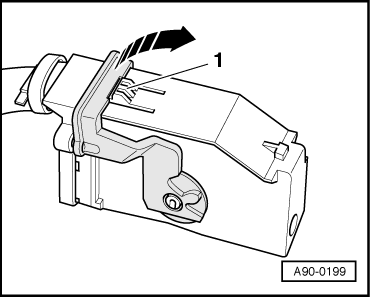

- To disconnect the connector, press the tab -1-, turn the retaining bracket in direction of the -arrow- and remove the connector.

- Remove the instrument cluster on the front passenger side between the steering wheel and the instrument panel.

Installing

Install in reverse order of removal. Note the following:

- Follow the instructions on the Vehicle Diagnostic Tester display with a new instrument cluster.

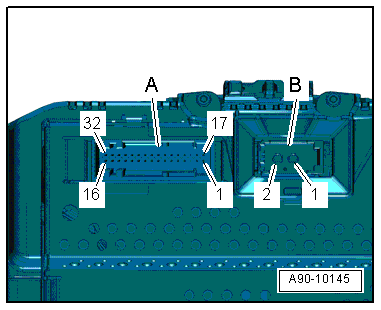

Instrument Cluster Multi-Pin Connector Contact Assignment

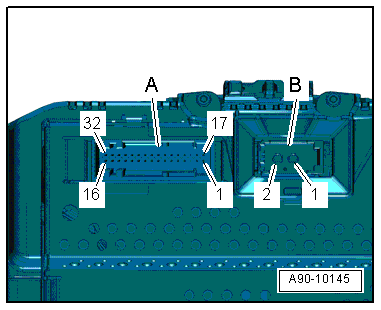

Gray 32-pin connector -A-

1 - MOST bus ring break diagnosis

2 - Not Assigned

3 - CAN bus instrument cluster low

4 - CAN bus instrument cluster high

5 - Fuel tank sensor ground

6 - Fuel Level Sensor -G-

7 - Fuel Level Sensor -G-

8 - Display Unit Button -E506- (Reset Button)

9 - Fuel Level Sensor 2 -G169-

10 - Fuel Level Sensor 2 -G169-

11 - Not Assigned

12 - Not Assigned

13 - Not Assigned

14 - Not Assigned

15 - Not Assigned

16 - Not Assigned

17 - Not Assigned

18 - Not Assigned

19 - Night Vision System Control Module -J853-"-"

20 - Night Vision System Control Module -J853-"+"

21 - Not Assigned

22 - Not Assigned

23 - Not Assigned

24 - Not Assigned

25 - Not Assigned

26 - Not Assigned

27 - Not Assigned

28 - Not Assigned

29 - Terminal 31

30 - Terminal 31

31 - Terminal 30

32 - Terminal 30

Optical MOST-Bus connection (fiber optic) -B-

1 - MOST bus input

2 - MOST bus output

Fuel Level Sensor Connector Assignment

Fuel Level Sensor -G- Connector Assignment

Disconnect the connector on the fuel tank locking flange. For the procedure. Refer to → Rep. Gr.20; Fuel Delivery Unit/Fuel Level Sensor; Fuel Level Sensor G, Removing and Installing.

Note

Note

Check the exact connector assignment in the current wiring diagram → Wiring diagrams, Troubleshooting & Component locations.

Fuel Level Sensor 2 -G169- Connector Assignment

Disconnect the connector on the fuel tank locking flange. For the procedure. Refer to → Rep. Gr.20; Fuel Delivery Unit/Fuel Level Sensor; Fuel Level Sensor 2 G169, Removing and Installing.

Note

Note

Check the exact connector assignment in the current wiring diagram → Wiring diagrams, Troubleshooting & Component locations.

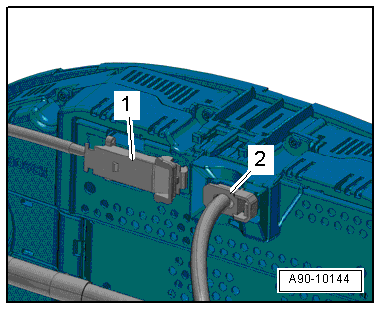

Outside Air Temperature Sensor, Removing and Installing

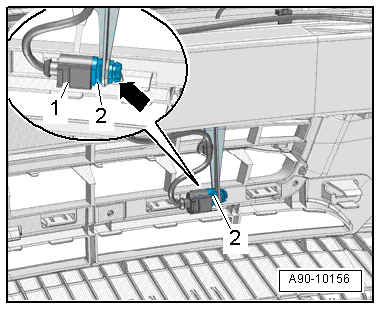

Removing

- Remove the lock carrier cover. Refer to → Body Exterior; Rep. Gr.63; Front Bumper; Attachments, Removing and Installing.

- Squeeze the clips carefully -arrow- and remove the Outside Air Temperature Sensor -G17--item 2-.

- Disconnect the connector -1-.

Installing

Install in reverse order of removal. Note the following:

After completing the repair, perform the following on the Front A/C Display Control Head -E87- in the "Guided Fault Finding" function using the Vehicle Diagnostic Tester:

- Read the DTC memory and erase any entries.

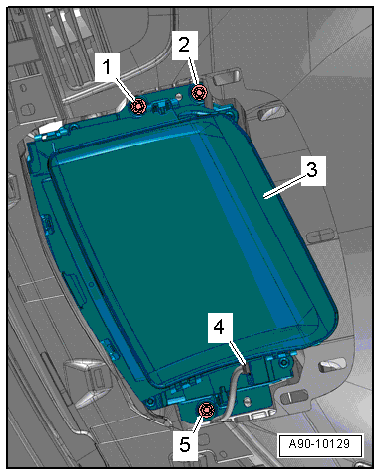

Windshield Projection Head Up Display Control Module, Removing and Installing

Caution

Caution

Danger of causing damage.

- Remove only the marked screws from the Windshield Projection Head Up Display Control Module -J898-.

- The Windshield Projection Head Up Display Control Module -J898- must be replaced if the screws are removed from the housing upper section.

- If the Windshield Projection Head Up Display Control Module -J898- should fall down, it must be replaced because the inner components will get damaged even though there is no damage on the outside.

- Do not place any force on the upper section of the Windshield Projection Head Up Display Control Module -J898- housing. Otherwise the Windshield Projection Head Up Display Control Module -J898- will have to be replaced.

Removing

- Remove the windshield projection control module cover. Refer to → Body Interior; Rep. Gr.70; Instrument Panel; Overview - Instrument Panel.

- Cover the control module -3- with a soft towel.

- Remove the windshield. Refer to → Body Exterior; Rep. Gr.64; Windshield; Windshield, Removing and Installing.

- Remove the bolts -1, 2 and 5-.

- Lift the control module slightly and disconnect the connector -4-.

- Remove the control module.

Installing

Install in reverse order of removal. Note the following:

- Install the control module and tighten the screws.

- Mount the windshield and secure it - do not bond it.

- Turn on the ignition and check the control module function.

- A number must be appear on the windshield.

- Calibrate the windshield projection control module. Refer to → Chapter "Windshield Projection Head Up Display Control Module, Calibrating".

Windshield Projection Head Up Display Control Module, Calibrating

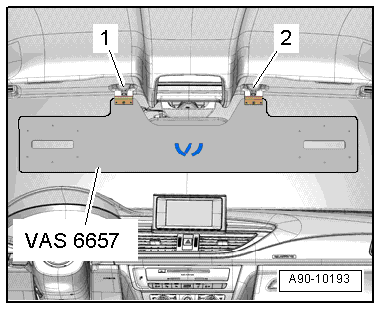

Special tools and workshop equipment required

- Head-Up Display Calibration Board - Audi A6 -VAS6657-

- Calibration Board - Head-Up Display -VAS6658-

Conditions

- The windshield projection control module must be calibrated during the following conditions:

- The Windshield Projection Head Up Display Control Module -J898- was replaced.

- The windshield was removed and installed.

- The DTC "no or incorrect basic setting/adaptation" is stored in the DTC memory.

Procedure

- Move the vehicle onto a secure flat surface.

- Set the parking brake - the vehicle must not move during the measuring.

- Remove the windshield projection control module cover. Refer to → Body Interior; Rep. Gr.70; Instrument Panel; Overview - Instrument Panel.

- Fold down the left and right sun visors, disengage them and move them to the side.

- Engage the Calibration Board - Head-Up Display -VAS6658- to the center support -1 and 2- for the sun visor.

Performing Calibration

Vehicle Diagnostic Tester is attached.

- Select the Diagnostic mode and start the diagnostics.

- Select the tab test plan.

- Select select individual tests and choose the following sequence.

- Body

- Electrical Equipment

- 01 - OBD-capable systems

- 82 - Windshield Projection Head Up Display Control Module - J898

- 82 - windshield projection control module, function

- 82 - calibrating the head up display

From here using the Vehicle Diagnostic Tester advances the calibration procedure forward.

- After calibrating the windshield projection head up control module successfully, end "calibration", turn off the ignition and disconnect the diagnostic connector.