Audi A6 Typ 4G: Rear Seat Pneumatic System, Checking

Preparations for Checking the Lumbar Support Air Cushion for Leaks

Special tools and workshop equipment required

- Pneumatic Repair Set -VAS6618A-

- Vehicle Diagnostic Tester

Note

Note

- When an appropriate entry is made in the event memory, you are prompted in "Guided Fault Finding" to perform a leak check using the Vehicle Diagnostic Tester.

- Then the preparations for this leak test are described that must be carried out directly in the rear seat.

- For the connection diagram with assignment of the pneumatic lines to the air cushions. Refer to → Chapter "Connection Diagram - Pneumatic System".

Procedure

- Multi-contour seat released in the vehicle and folded forward with electrical harness connectors connected. Refer to → Chapter "Rear Seat Backrest, Removing and Installing, Multi-contour Seat".

- Before disconnecting, mark the assignment of the pneumatic lines to each other using a waterproof permanent marker.

Note

Note

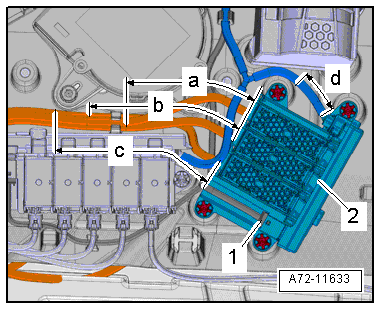

If only one error is displayed for an air cushion, it suffices to disconnect only two pneumatic lines at the described points.

- Disconnect pneumatic lines to the lumbar support air cushions at the following points. Refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting"

- a - 110 mm

- b - 120 mm

- c - 130 mm

Note

Note

Ignore items -1, 2 and d-.

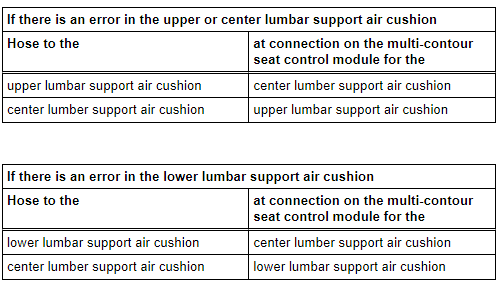

- For checking in the "Guided Fault Finding", connect the air cushion and valve block connections in a diagonal sequence as follows:

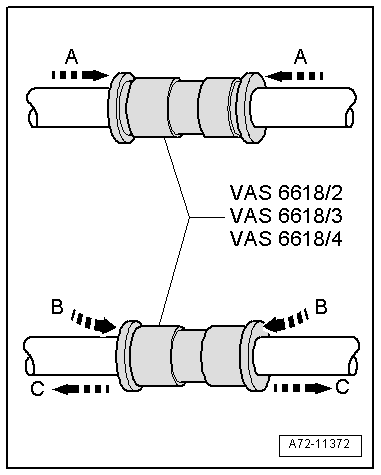

- To connect, attach the Pneumatic Repair Set - Exterior Connector 6x4 -VAS6618/2- to the pneumatic lines.

Note

Note

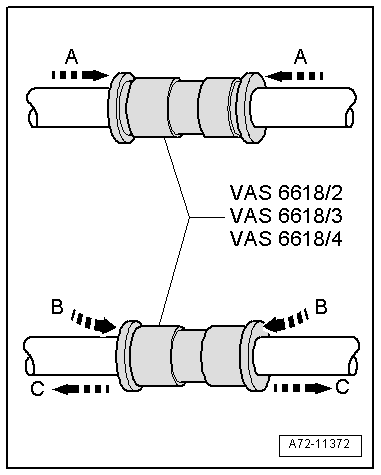

- To connect, insert the pneumatic lines in the Pneumatic Repair Set - Exterior Connector 6x4 -VAS6618/2- from both sides -A arrows-.

- To release, push release rings in direction of -B arrows- and simultaneously remove pneumatic lines in direction of -C arrows-.

- Connect pneumatic lines following the leak check. Refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting".

Preparations for Checking the Massage Mat Air Cushion for Leaks

Note

Note

- When an appropriate entry is made in the event memory, you are prompted in "Guided Fault Finding" to perform a leak check using the Vehicle Diagnostic Tester.

- Then the preparations for this leak test are described that must be carried out directly in the rear seat.

- For the connection diagram with assignment of the pneumatic lines to the air cushions. Refer to → Chapter "Connection Diagram - Pneumatic System".

Procedure

- Multi-contour seat released in the vehicle and folded forward with electrical harness connectors connected. Refer to → Chapter "Rear Seat Backrest, Removing and Installing, Multi-contour Seat".

- Before disconnecting, mark the pneumatic line assignments to the connections at the valve block using a waterproof permanent marker.

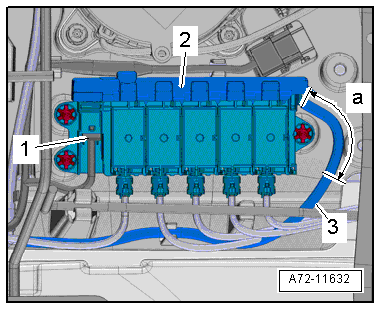

- Disconnect the pneumatic lines for all of the massage mat air cushions.

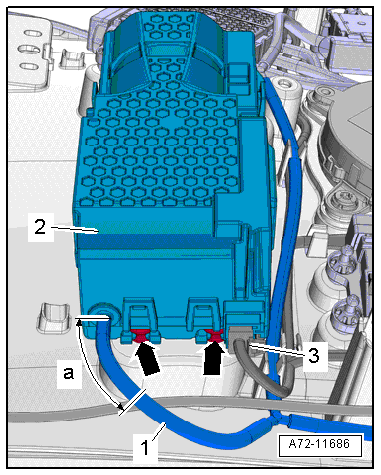

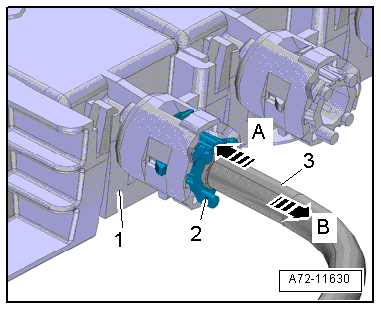

- To do this, press the release ring -2- in the direction of the valve block -1--arrow A- and at the same time pull out the pneumatic line -3--arrow B-.

- To check in the "Guided Fault Finding", remove both of the valve block from the module carrier (refer to → Chapter "Massage Mat Valve Block, Removing and Installing") and reinstall them at their respective opposite sides.

- Connect the connectors.

- Connect the pneumatic lines and check them with a final tug, whether the coupling is locked in correctly.

Preparations for Compressor and Pressure Line Leak Check

Note

Note

- When an appropriate entry is made in the event memory, you are prompted in "Guided Fault Finding" to perform a leak check using the Vehicle Diagnostic Tester.

- Then the preparations for this leak test are described that must be carried out directly in the rear seat.

- For the connection diagram with assignment of the pneumatic lines to the air cushions. Refer to → Chapter "Connection Diagram - Pneumatic System".

Procedure

- Multi-contour seat released in the vehicle and folded forward with electrical harness connectors connected. Refer to → Chapter "Rear Seat Backrest, Removing and Installing, Multi-contour Seat".

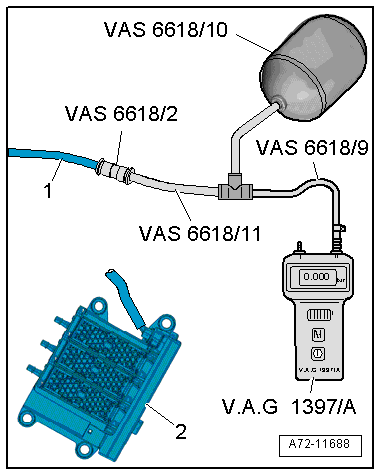

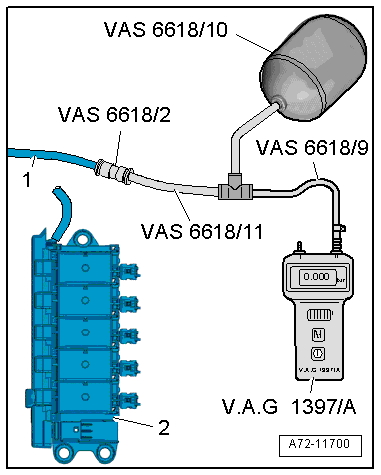

In one of the test steps in the "Guided Fault Finding", you are prompted to connect the Turbocharger Tester Kit -VAG1397A- at the pneumatic line to the Valve Block 2 in Driver Side Rear Seat -N480-/Valve Block 2 in Passenger Side Rear Seat -N482- and Valve Block 3 in Driver Side Rear Seat -N525-/Valve Block 3 in Passenger Side Rear Seat -N526-.

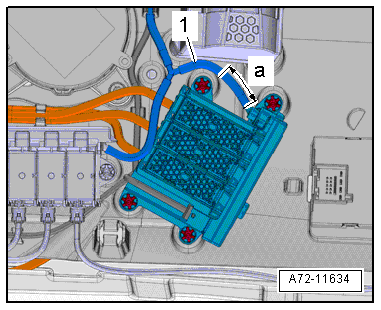

- Disconnect the pneumatic line -1- to the Valve Block 1 in Driver Side Rear Seat -N479-/Valve Block 1 in Passenger Side Rear Seat -N481- at the following position. Refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting".

- a - 30 mm

- Using hose and adapter pieces, as well as the Pneumatic Repair Set - Surge Tank -VAS6618/10-, connect the Turbocharger Tester Kit -VAG1397A- with the pneumatic line -1- coming from the compressor.

- To connect, attach the Pneumatic Repair Set - Exterior Connector 6x4 -VAS6618/2- to the pneumatic line.

2 - Valve Block 1 in Driver Side Rear Seat -N479-/Valve Block 1 in Passenger Side Rear Seat -N481-

Note

Note

- To connect, insert the pneumatic lines in the Pneumatic Repair Set - Exterior Connector 6x4 -VAS6618/2- from both sides -A arrows-.

- To release, push release rings -B arrows- and simultaneously remove pneumatic lines -C arrows-.

In one of the test steps in the "Guided Fault Finding", you are prompted to connect the Turbocharger Tester Kit -VAG1397A- at the pneumatic line to the Valve Block 1 in Driver Side Rear Seat -N479-/Valve Block 1 in Passenger Side Rear Seat -N481- and Valve Block 3 in Driver Side Rear Seat -N525-/Valve Block 3 in Passenger Side Rear Seat -N526- or Valve Block 2 in Driver Side Rear Seat -N480-/Valve Block 2 in Passenger Side Rear Seat -N482-.

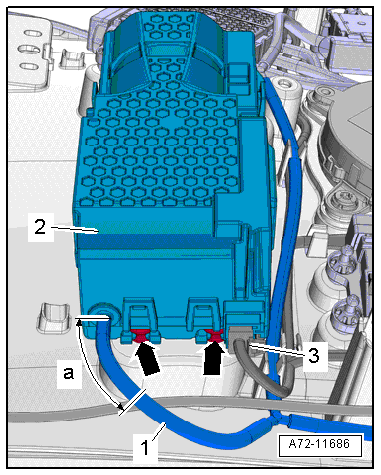

- Disconnect the pneumatic line -3- to the Valve Block 2 in Driver Side Rear Seat -N480-/Valve Block 2 in Passenger Side Rear Seat -N482- or Valve Block 3 in Driver Side Rear Seat -N525-/Valve Block 3 in Passenger Side Rear Seat -N526--2- at the following position. Refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting".

a - 40 mm

Note

Note

Ignore item -1-.

- Using hose and adapter pieces, as well as the Valve Block 1 in Passenger Side Rear Seat -N481-, connect the Turbocharger Tester Kit -VAG1397A- with the pneumatic line -1- coming from the compressor.

- Repeat the check on the pneumatic line coming from the compressor at the opposing valve block.

2 - Valve Block 2 in Driver Side Rear Seat -N480-/Valve Block 2 in Passenger Side Rear Seat -N482- or Valve Block 3 in Driver Side Rear Seat -N525-/Valve Block 3 in Passenger Side Rear Seat -N526-

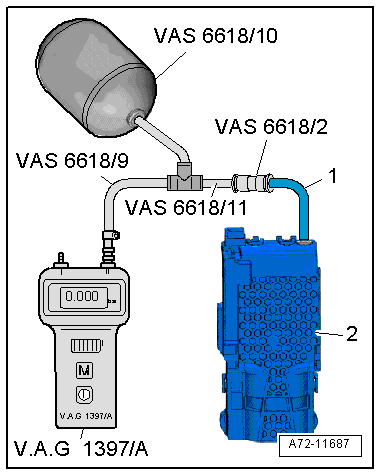

In one of the test steps in the "Guided Fault Finding", you are prompted to connect the Turbocharger Tester Kit -VAG1397A- directly to the compressor.

- Disconnect the pneumatic line -1- to the compressor -2- at the following locations. Refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting".

- a - 50 mm

Note

Note

Ignore item -3 and arrows-.

- Using line and adapter pieces, as well as the Valve Block 1 in Passenger Side Rear Seat -N481-, connect the Turbocharger Tester Kit -VAG1397A- with the pneumatic line -1- for the compressor -2-.

- Connect pneumatic lines following the leak check. Refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting".

Pneumatic Lines, Disconnecting and Connecting

Special tools and workshop equipment required

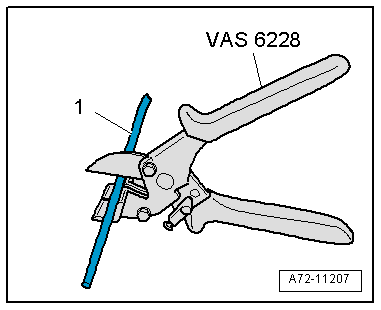

- Hose Cutting Pliers -VAS6228-

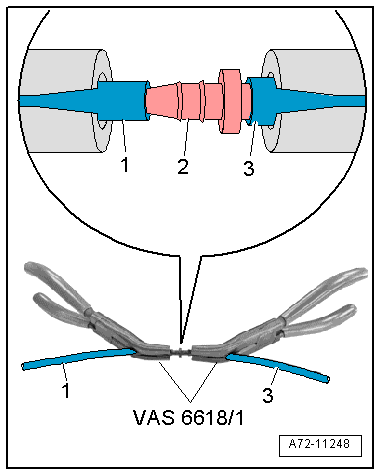

- Pneumatic Repair Set - Pliers -VAS6618/1- (quantity: 2)

Cutting Pneumatic Lines

- Position the Hose Cutting Pliers -VAS6228- at a right angle and cut the pneumatic line -1-.

Connecting Pneumatic Line

- Slide the pneumatic lines -1 and 3- onto the line connector -2- on both sides using the Pneumatic Repair Set - Pliers -VAS6618/1-. Refer to the Parts Catalog.

Pneumatic Lines, Servicing

- A repair kit with pneumatic lines and line connectors is available for the repair of pneumatic lines. Refer to the Parts Catalog.

- Pneumatic lines must not be disconnected directly at the components, only disconnection and connection according to the methods described below is permissible.

- Original replacement parts are delivered with short sections of line to which pneumatic lines with line connectors are connected.

- Protect pneumatic lines and line connectors from soiling.

- Heating the pneumatic lines to connect them to the line connectors is NOT permissible.

- The use of lubricant to connect the pneumatic lines to the line connectors is NOT permissible.

- The repaired pneumatic line is to be exactly as long as the previous line - tolerance +- 10 mm.

- Dirt on the connecting points can cause leaks. Therefore, during tests, make sure the pneumatics and the measuring instruments remain clean.

Compressor with Multi-contour Seat Control Module, Removing and Installing

Removing

WARNING

WARNING

- Follow all Safety Precautions when working with pyrotechnic components. Refer to → Chapter "Pyrotechnic Components Safety Precautions".

- Before handling pyrotechnic components (for example, disconnecting the connector), the person handling it must "discharge static electricity". This can be done by touching the door striker, for example.

- Remove the Multi-contour seat. Refer to → Chapter "Rear Seat Backrest, Removing and Installing, Multi-contour Seat".

- Disconnect the connector -3-.

- Remove the compressor -2- sideways out of the rubber buffers (4 pieces) -arrows-.

- Disconnect the pneumatic line -1- to the compressor at the following locations. Refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting".

- a = 50 mm

Installing

- Cut the pneumatic line for the new compressor according to the design of the old compressor.

- Connect the pneumatic line. Refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting".

WARNING

WARNING

- Follow all Safety Precautions when working with pyrotechnic components. Refer to → Chapter "Pyrotechnic Components Safety Precautions".

- Before handling pyrotechnic components (for example, connecting the connector), the person handling it must "discharge static electricity". This can be done by touching the door striker, for example.

- Observe all measures when installing the Multi-contour seat. Refer to → Chapter "Rear Seat Backrest, Removing and Installing, Multi-contour Seat".

Install in reverse order of removal. Note the following:

Note

Note

The rubber buffer must not be installed under tension or twisted.

Installation notes, for example tightening specifications, replacing components. Refer to → Chapter "Overview - Pneumatic System".