Audi A6 Typ 4G: Repair Information

General Repair Information

The highest level of care and cleanliness along with tools that function properly are required to ensure a proper and successful transmission repair. Of course the general safety precautions also apply when carrying out repair work.

A list of general instructions that apply to multiple repair procedures throughout the repair manual are summarized once here under the "Components" section. Refer to → Chapter "Components". They apply to this repair manual.

Safety Precautions and Test Procedures

WARNING

WARNING

Incorrect repairs to the rear final 0BF and 0BE could cause the final drive to malfunction.

Testing, assembling and servicing must be performed by qualified personnel only.

Correct Oil Level

- Make sure the rear final drive is filled to specified oil capacity. Refer to → Chapter "Capacities".

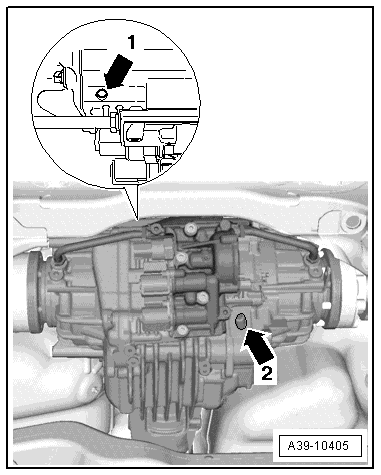

- Fix any leaks on the rear final drive, for example, on the sealing surfaces or the seals. The oil can leak out through the holes between the left -arrow 1- or right -arrow 2- chamber and the rear final drive.

Caution

Caution

Rear final drive malfunction.

- Do not drive the rear final drive if there are leaks or insufficient oil.

- Leaks on the rear final drive must be corrected.

- Fill the ATF and/or gear oil if the levels are low.

- Only use ATF or gear oil available as a replacement part. Refer to the Parts Catalog.

- If the leaks cannot be repaired, then the rear final drive must be replaced.

Rear Final Drive Performance

WARNING

WARNING

Transmission control malfunction.

Always maintain all specifications when replacing transmission components. Only by doing so assures the performance and the response characteristics of the rear final drive 0BF and 0BE.

Replacing Transmission Components

- When replacing the All Wheel Drive Control Module -J492-, the adaptation values for the transmission mount (for example clutch wear, oil ageing) must be transmitted with the Vehicle Diagnostic Tester otherwise the performance of the rear final drive will be impaired.

- When replacing a chamber or the complete rear final drive, the clutch classification must be entered again in the All Wheel Drive Control Module -J492- using the Vehicle Diagnostic Tester. If the clutch classification is not performed in the All Wheel Drive Control Module -J492- then the rear final drive performance will be impaired. When replacing a chamber, the classification identification on the rear final drive housing must be made unrecognizable. The identification of the new classification is made on the new chamber housing.

- Do not place the removed rear final drive on any of the components from the hydraulic control unit (for example, clutch valves). This could damage the components.

Replacing the Oil Pressure/Temperature Sensor -G437- and/or Oil Pressure/Temperature Sensor 2 -G640-.

- The identity of the sensor in the All Wheel Drive Control Module -J492- must be adapted using the Vehicle Diagnostic Tester after replacing the Oil Pressure/Temperature Sensor -G437- or the Oil Pressure/Temperature Sensor 2 -G640-.

- Do not replace both the Oil Pressure/Temperature Sensor -G437- and Oil Pressure/Temperature Sensor 2 -G640- at the same time because a valid sensor identity is needed for the rear final drive classification to the All Wheel Drive Control Module -J492-. If the both sensors are replaced at the same time, the All Wheel Drive Control Module -J492- will interpret this as the rear final drive is being replaced. By doing this, adaptation values in the control module will be erased and the performance of the rear final drive will be impaired.

- If both the Oil Pressure/Temperature Sensor -G437- and the Oil Pressure/Temperature Sensor 2 -G640- must be replaced due to mechanical damage, for example, if the connector housing gets damaged, then this must be performed in two steps. After replacing the first sensor, the identity of the must be adapted in the All Wheel Drive Control Module -J492- using the Vehicle Diagnostic Tester. Do the same for the second sensor.

- If both the Oil Pressure/Temperature Sensor -G437- and Oil Pressure/Temperature Sensor 2 -G640- must be replaced at the same time due to an electrical fault, then the clutch classification must be entered into the All Wheel Drive Control Module -J492- using the Vehicle Diagnostic Tester. Additionally the ATF must be changed. Refer to → Chapter "ATF, Draining and Filling".

Torque Displacement, Checking

After the following work the function 22- Checking the torque displacement must be performed:

- Working on the rear final drive wiring

- Working on the valves: All Wheel Drive Clutch Valve -N445- and All Wheel Drive Clutch Valve 2 -N446-.

- Working on the hydraulic control unit

Vehicle Lift Mode, Vehicles with Air Suspension

Activate the lift mode before lifting the vehicle on a frame contact hoist (when there is no weight on the wheels). Refer to → Suspension, Wheels Steering; Rep. Gr.00; Repair Instructions; Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension.

Special Tools

Refer to the Special Tools Catalog for the complete list of special tools used in this repair manual.

Components

Rear Final Drive

- Allocate bolts and other components according to final drive code using the Parts Catalog

- When installing, check the oil level in the rear final drive (Refer to → Chapter "Gear Oil, Checking Level".) and the ATF level (Refer to → Chapter "ATF Level, Checking".) and fill if necessary.

- Capacities and specifications. Refer to → Chapter "Capacities".

- Clean the contact surfaces when installing brackets and waxed components. Contact surfaces must be free of wax and grease.

- Thoroughly clean the connection points and the surrounding area before loosening.

Oil, Environmental and Disposal Regulations

- Handle ATF, transmission fluid and other oils with care.

- Dispose of drained fluid properly.

- Follow the legal environmental and disposal regulations.

- Follow the instructions listed on the fluid packaging.

ATF and Gear Oil

Rear final drive 0BF and 0BE works with separated oil chambers for the ATF and gear oil.

- For the hydraulics (hydraulic control unit and left and right chambers) use only ATF which can be obtained as replacement part. Refer to Parts Catalog.

- For the final drive (gear set, differential) use only the gear oil which can be obtained as replacement part. Refer to the Parts Catalog.

- Other ATF or gear oil can cause function problems.

Caution

Caution

Gear oil and ATF fluid change.

- For some RS models the gear oil as well as the ATF must be changed.

- For all other vehicles there is no change interval.

Shaft Seals

- Lightly coat the shaft seal on the outer diameter with oil before installing.

- The open side on the shaft seals faces the fluid to be sealed off.

- After replacing any of the shaft seals, check the gear oil level (Refer to → Chapter "Gear Oil, Checking Level".) or the ATF level in the final drive (Refer to → Chapter "ATF Level, Checking".).

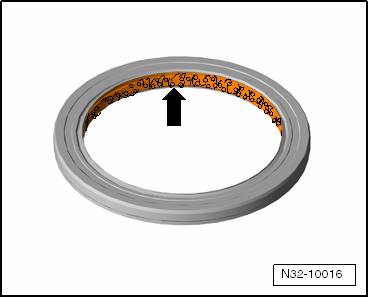

Shaft Seal for the Flange/Driveshaft

- Fill the space between the sealing lips -arrow- halfway with Sealing Grease -G 052 128 A1-.

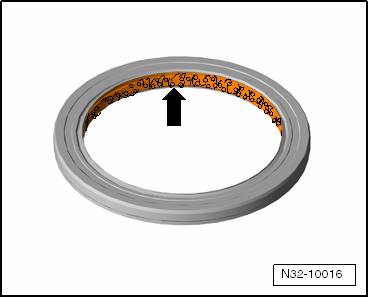

Flange Shaft Seals

- Coat the space between the sealing lips -arrow- with ATF.

O-Rings, Gaskets and Seals

- O-rings, gaskets and seals must always be replaced.

- After removing the seals, examine the contact surface on the housing or shaft for burrs resulting from removal or for other signs of damage.

- Thoroughly clean the housing separating surfaces before assembling.

- Lightly lubricate the O-rings before inserting to prevent the rings from being crushed during assembly.

- After replacing any of the gaskets, seal and o-rings, check the gear oil level (Refer to → Chapter "Gear Oil, Checking Level".) or the ATF level in the final drive (Refer to → Chapter "ATF Level, Checking".).

Circlips

- Do not stretch the circlips.

- Always replace damaged or stretched circlips.

- The circlips must rest at the bottom of the groove.

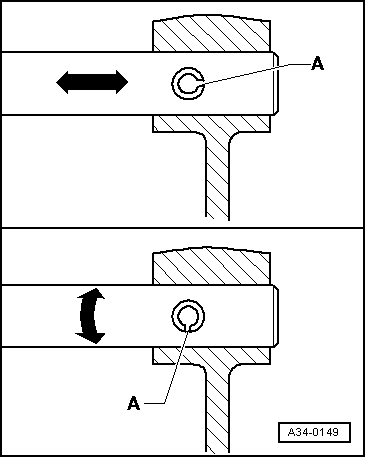

- Replace the adapter sleeves. Installation position: the slot -A- should align with the line of force -arrow-.

Bolts and Nuts

- Always loosen or tighten bolts and nuts on covers and housings diagonally.

- Parts which are particularly sensitive must not be tilted and must be loosen or tighten diagonally in stages.

- The tightening specifications given apply to unoiled bolts and nuts.

- Always replace self-locking bolts and nuts.

- Clean threads of bolts that were applied with locking fluid using a wire brush (does not apply to driveshaft bolts: these must be replaced). Then insert the bolts with Locking Fluid -AMV 185 101 A1-.

- If self-locking bolts were installed or if regular bolts were installed with locking fluid, then the threaded holes must be cleaned, for example with a thread tap. Otherwise there is the risk that the bolts could break off the next time they are removed.