Audi A6 Typ 4G: Run-Flat Tires

Caution

Caution

It is mandatory for run-flat tires to have a tire pressure monitoring system in the vehicle.

Installing/Conditions for Using Run-Flat Tires

Caution

Caution

It is mandatory for run-flat tires to have a tire pressure monitoring system in the vehicle.

Because pressure loss in a run-flat tire is not always visible, these tires should only be used on vehicles equipped with a tire pressure monitoring system. This system warns the driver when the tire pressure falls below a certain value.

The following are permitted:

- Direct measuring systems

- Indirect measuring systems

Only mount run-flat tires on disc wheels with an extended double hump (extended hump - EH2).

Pay close attention to the installation instructions.

Do not install both run-flat tires and standard tires, even if the two tires on each axle will be the same.

A standard tire can only be installed in exception cases for a short time or a limited driving distance. The specific characteristics designed for driving with a flat tire will not be available. The driver must be informed of this.

Tires with emergency running characteristics, PAX

Caution

Caution

It is mandatory for run-flat tires to have a tire pressure monitoring system in the vehicle.

Work on tires with emergency running characteristics (PAX) must only be performed at skilled facilities.

These have the corresponding trained personnel and necessary tools available.

PAX Tires, Construction

Caution

Caution

It is mandatory for run-flat tires to have a tire pressure monitoring system in the vehicle.

PAX tires involve specially developed system that exhibits the following differences in comparison to conventional tires:

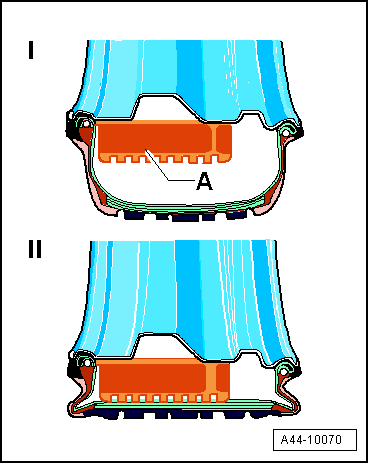

Pax tires with supporting ring

- -I- PAX tires with air

- -II- PAX tires without air

- The tire is anchored to a special rim that prevents it from sliding off when pressure is lost. The rubber supporting ring ensures stability in emergency operation.

- The inner and outer bead diameter are different sizes. This makes it possible to place the tire in a supporting ring.

- The tire is anchored to the rim differently.

- In this way, the tire height could be reduced considerably. That was possible because the area near the bead could be considerably smaller due to the special connection between the tire and rim.

- The tire bead is formed so that it can engage in the rim seat. Therefore, it remains firmly in the seat when pressure is lost.

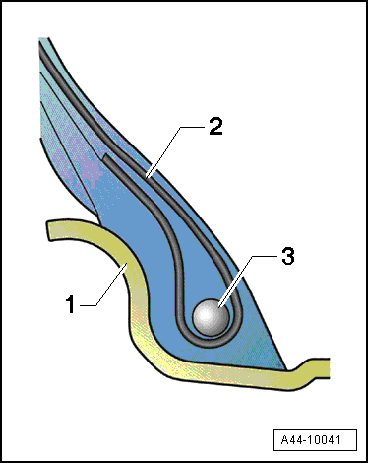

Standard tire, beat area construction

1 - Rim flange

2 - Fabric shell

3 - Bead bundle

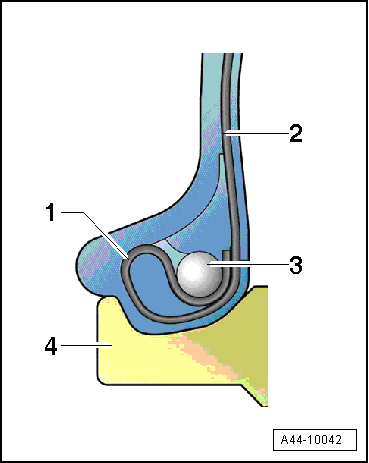

PAX tire, bead area construction

1 - Loop

2 - Fabric shell

3 - Bead bundle

4 - Rim flange

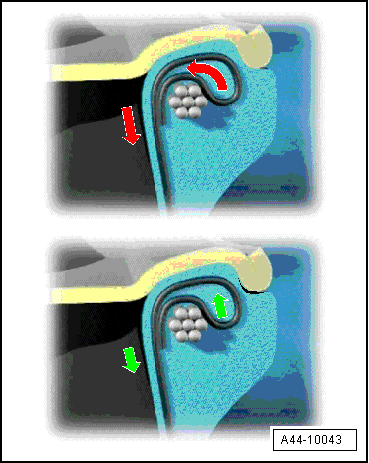

PAX tires, anchoring

The secure seating of the tire in the rim is ensured in all driving situations due to the type of construction.

A wedge-shaped component of the tire is pressed between the bead bundle and rim when loaded. This happens independently of the pressure in the tire.

PAX tires, dimensions

In contract to conventional tires, tires with emergency running characteristics (PAX) exhibit differences in regard to dimensions and designations.

Therefore, PAX tires can only be mounted on special rims (PAX).

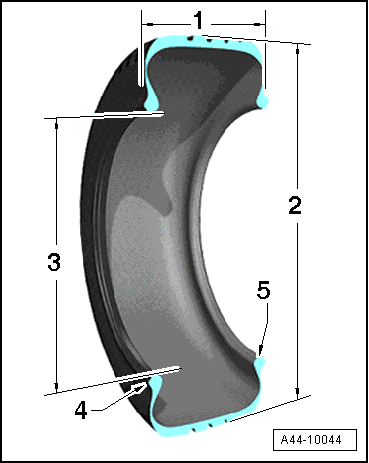

1 - Width in mm: the tire width from flank to flank on standard rim (corresponds to width specification on standard tire)

2 - Outer circumference in mm: maximum diameter of a new tire

3 - Designated diameter in millimeters on standard rim seat

4 - Smaller bead diameter in millimeters: rim seat on outer side

5 - Larger bead diameter in millimeters: rim seat on inner side

PAX Tires, Designations

In contrast to conventional tires, other designations are found on the tire flanks of PAX tires. In this way, these tires can be allocated clearly.

PAX tires, designations

245 - Tire width in millimeters

690 - Outer diameter in millimeters

R - Radial construction

500 - Designated diameter on standard rim seat

A - Tire quality grading for PAX tires (A- "asymmetrical") because both rim seats have different diameters

99 - Indicator of maximum load permitted for this tire (99 = 1550 kg (3417 lb)

Y - Speed code letter ("Y") corresponds to a permitted maximum speed of 300 km/h (186 mph)

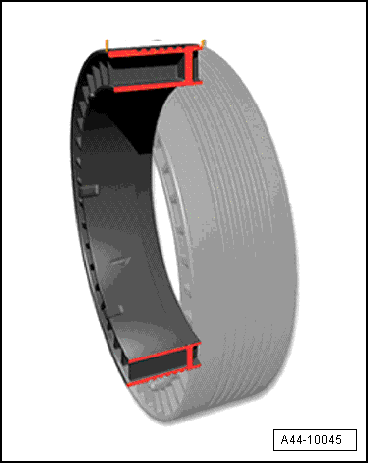

Support Ring on PAX Wheels

Dimensions

Overview of the most important dimensions:

Designations

Example: 90-500(35) CLI A 1 876107

90 - Designated width in millimeters

500 - Designated diameter in millimeters

35 - Height in millimeters

CLI - Support ring versions: CLI - Clip supporting ring/FL - standard supporting ring

A - Build type index, asymmetrical. Indication of wheels with emergency running characteristics (PAX)

1 - Supporting ring versions

876107 - CAI, international item code

Dimensions and Designations on PAX Rims

Example: 235 x 500 A - 5 - 41

235 - Designated width in millimeters

x - One-part

500 - Designated diameter of standardized rim seat in millimeters

A - Asymmetrical

5 - Number of bolt holes

41 - Offset in millimeters

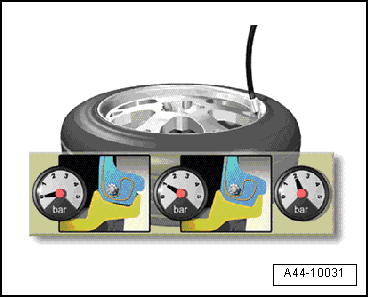

Tire Inflation on PAX Wheels

When filling tires, pay special attention to the following points:

- After mounting the tires with inserted valve insert, fill with air. At 1 bar (14.5 psi), check whether both beads are seated correctly.

- If one of the beads is not seated correctly, do not deflate air from tire but rather position the assembly roller on the affected beat and press on by rotating slightly. The bead then seats itself.

- Then continue filling until the tire pressure recommended for the vehicle is reached. Tires can also be filled with tire filling gas as with conventional tires.

Note

Note

Do not briefly overinflate tires to 3.5 bar (50.76 psi) as is common with conventional tires.

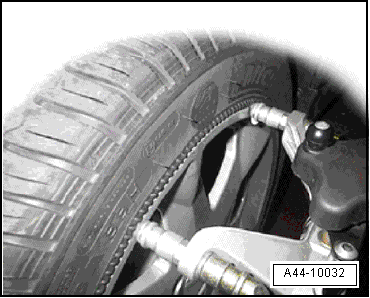

Vehicle Alignment and Adjustment

The chassis adjustment is done on vehicle with tires with emergency running characteristics (PAX) in the same way as on vehicle that are equipped with conventional tires.

Generally, the same gauge heads and mounts that are suitable for conventional tires with a rim protection strip can be used for tires with emergency running characteristics (PAX). (Supports on inner side, mount in tire tread).

Tires with Emergency Running Characteristics (PAX), Repairing

General Information

It is generally not necessary to replace a tire after going flat and after driving on a flat tire.

Note

Note

The affected tire should be removed and checked for damaged by trained professionals. Assembly work and damage diagnosis on the affected tire should only be performed by trained personnel.

Proceed as follows to examine a tire with emergency running characteristics (PAX) after going flat:

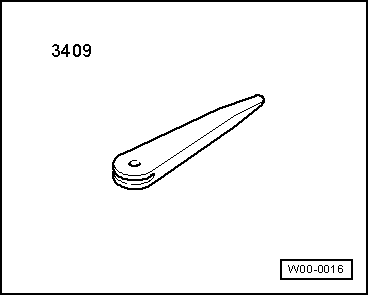

- First, the remaining gel must be removed from the tire. The flat side of the spatula is suitable for this

- Then clean the tire and supporting ring with water and a cloth to remove the remaining gel residue

- After separating tire and supporting ring, evaluate both of these components (PAX) according to the criteria described in the following section

Additional information:

- When remounting, ensure the used supporting ring fits the tire and rim dimensions

- The rim must be inspected before mounting, as with conventional wheel/tire systems

- A damaged rim should be replaced

PAX Tires, Examining

Pay special attention to the following criteria when examining the tire:

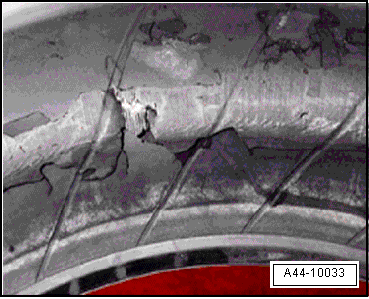

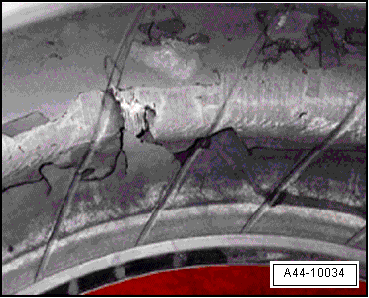

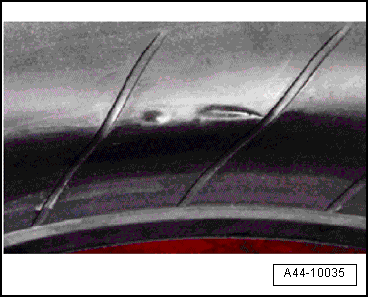

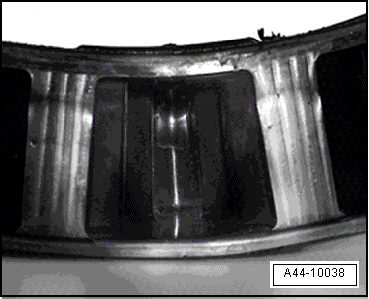

- Surface erosion or marbling on the inner side (pressure was too low or insufficient for the load)

- Detached rubber or loose cords

- Exposed or deformed bead bundle

- Damage to tire bead with visible cords

Supporting Ring, Examining

As with the tire, the supporting ring is generally not replaced after driving with flat tire.

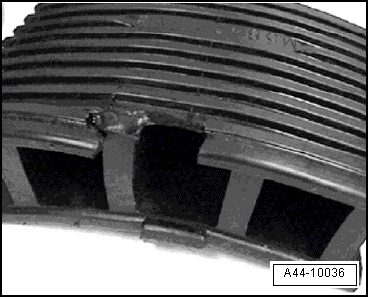

Replace the support ring if the following damages have occurred:

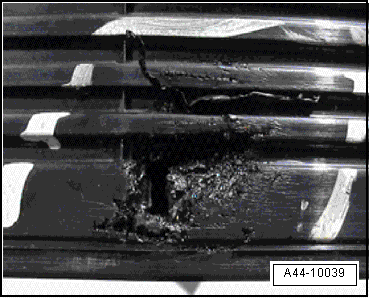

- Blowouts or missing parts

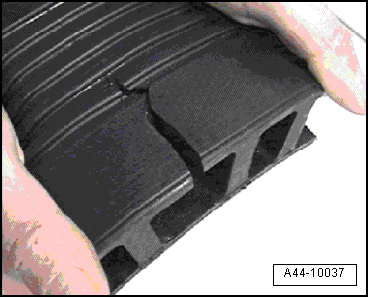

- Cracks in partitions

- Stitch damage and holes

- Bubbles and discoloration due to overheating

Repairs on Tires

Note

Note

- Repairs on tires with emergency running characteristics (PAX) must not be performed with adhesive tape.

- Tire repair sprays must not be used on tires with emergency running characteristics (PAX) because these products are not compatible with the gel in the tires.

Special Tools

Special tools and workshop equipment required

- Trim Removal Wedge -3409-

- Wheel Lock Set -T10101-

- Wheel Lock Set -T10101A-

- Wheel Lock Set -T40004-

- Wheel Lock Set -T40073-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Torque Wrench 1410 -VAG1410-

- Hot Air Blower -VAG1416-

- Cartridge Gun -VAG1628-

- Wheel Centering System Adapter -VAS5271-

- Hunter RFT33VAG Road Force Touch Wheel Balancer -VAS6230B4-

- Wheel Balancer Clamping Adapter - 5 Lug -VAS6243-

- Tension Plate -VAS6652-

- Pressure Bolt -VAS6652/1-

Revision History

DRUCK NUMBER: A00ARRA0021

.png)