Audi A6 Typ 4G: Tire Requirement and Maintenance

Introduction

This revised information should supplement the knowledge and experience you already have.

With this information, we want to help you make as clear and certain a statement as possible concerning tire damage and complaints.

This chapter contains general information on tires and wheels.

Wheels are high-tech products which have been optimally matched to the operating conditions of modern vehicles.

As for all technically highly developed products, careful handling, care and maintenance are required for tires as well. Only then are the safety, performance and driving comfort guaranteed for the entire service life of the tire.

The tires are subject to a process of constant further development. As a result of modern construction techniques, finishing processes and constant quality checks, high-quality tires are produced. All tires approved by Audi have been tested by technical development and matched to the respective vehicle type in cooperation with the tire manufacturers.

Therefore, when replacing the tires, we recommend always to mount the approved and recommended tire brands.

Vehicle safety always has the highest priority. With regard to the various operating conditions, such as:

- Different speed ranges

- Winter and summer use

- Wet and dry roads

An optimal compromise must be found to ensure driver safety.

Every tire faces many different types of stress over distance and time. Therefore, it is important that the basic requirements for optimal use of tires are fulfilled.

The correct adjustment of the axle geometry is an important requirement for optimum service life of the tire. Therefore, the adjustment of the axle geometry must lie within the specified tolerance range.

Note

Note

There are many causes for tire damage and complaints. Therefore, it is very important to recognize whether the complaint arises from the tires or from other components.

The running characteristics of the tire change in the course of normal wear. Rolling noises and vibrations can result from this. These are not damage in the sense of tire defects, but rather symptoms resulting from use. These can be corrected, at least partially, by specific measures. In certain cases, rolling noise cannot be completely eliminated.

Tire Requirements

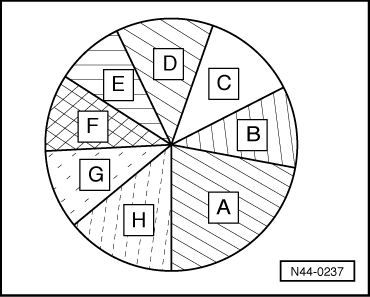

A - Wet braking behavior

B - Comfort

C - Steering precision

D - Driving stability

E - Tire weight

F - Service life expectancy

G - Rolling resistance

H - Hydroplaning

The pie chart represents the tire's performance. It shows how the extent of the demands A through H could be distributed in tire construction and rubber compound.

The improvement of one characteristic leads to the worsening of another one.

Example:

The improvement of wet braking behavior -A- leads to losses in comfort -B-, rolling resistance -G- and service life expectancy -F-.

The service life expectancy of car tires depends not only on the rubber compound and the tire construction. The operating conditions, circumstances specific to the vehicle and the driving style all have a strong influence on the tire's service life.

With modern vehicles and appropriate engines, especially gentle and economical but also extremely sporty driving is possible. Service life of 5,000 to 40,000 km (3,100 to 25,000 miles) and even more is possible.

Note

Note

Driving style is the decisive influencing factor on the life of the tires.

Tire Service Life, Influences

The following factors influence the service life of a tire in varying degrees.

- Speed

- Brakes

- Acceleration

- Cornering

- Driving Style

- Maintenance

- Tire Pressure

Area:

- Paving

- Exterior temperature/climate

Vehicle:

- Weight

- Tire Pressure

- Dynamic toe- + and camber values

Tire operating conditions

Speed range, wet or dry

Tire construction:

Winter/summer

Note

Note

Having the correct tire pressure in the tires also influences the life span of the tires.

Note

Note

Always make sure that the tires are inflated to the correct air pressure.

Maintenance (Tire Air Pressure)

The weight of the vehicle flattens the tire's contact patch. When the tire rolls, this results in deformation all around the circumference of the tread and the entire belt assembly. With low pressure, there is a greater deformation which results in more intense warming and greater rolling resistance. This all results in a greater wear and a greater safety risk.

Example: specified series production tire pressure depending on load on cold tires

.png)

Excessive air pressure leads to greater wear at the center of the tire and reduced rolling comfort. It is recommended always to maintain the air pressure indicated by the manufacturer.

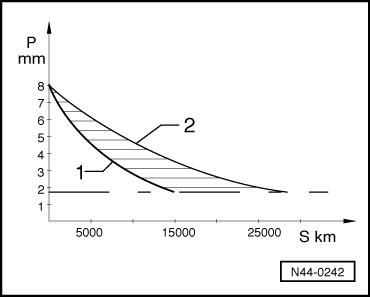

Diagram 1:

Tread depth over service life for vehicles with front wheel drive and V tires.

P - Tread Depth

S - Distance Driven

1 - Front Axle

2 - Rear Axle

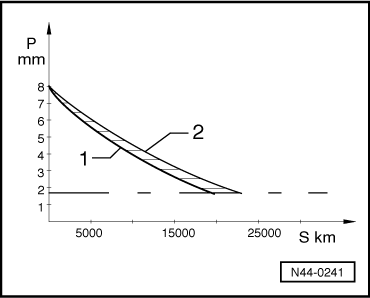

Diagram 2:

Tread depth over service life for vehicles with all wheel drive and V tires.

P - Tread Depth

S - Distance Driven

1 - Front Axle

2 - Rear Axle

Note

Note

- The diagrams presented cannot be applied in general.

- They only illustrate the wear characteristics on the front and rear axles as well as wear characteristics of front and all-wheel drive vehicles.

- Depending on operating conditions and chassis, the service life that can be attained may deviate substantially.

As can be seen in diagrams -1 and -2, for a given distance, more tread wears off tires with a complete tread than off tires which are quite worn. After the first 5,000 km (3100 miles), no conclusion can be made about the total service life because the wear curve is not linear.

On front-wheel drive vehicles, the front wheels must transmit the major portion of the lateral and braking forces as well as the steering and traction forces. Due to these demands, the front tires on front wheel vehicles wear more quickly than rear tires. Even usage of all tires is achieved by regularly exchanging front and rear tires. Rotating the wheels.

Driving Style

1. Constant driving without deceleration and acceleration.

Example:

.png)

2. Brakes

The highest abrasion is achieved when braking.

Example: Braking at 50 km/h.

.png)

1) g = gravitational acceleration: 9.81 m/s2

2) A deceleration with 0.4 g corresponds to heavy braking.

3. Acceleration (driving style)

The slip that occurs during a gentle acceleration from a stop is approximately the same as the slip that occurs at a steady speed of approximately 100 km/h (62 mph).

Example:

.png)

Cornering (driving style)

A sporty driving style and driving at higher speeds also cause greater wear when driving around curves.

In practice, this means doubling the speed in a curve leads to an increased abrasion by a factor of 16. This is the extra charge for driving faster.

Example: Driving around a curve with a radius of 150 m.

.png)

3) g = gravitational acceleration: 9.81 m/s2

Tread Depth, Measuring

Note

Note

- When measuring tread depth, take measurements in the main grooves.

- Do not measure on the TWI (tread wear indicator).

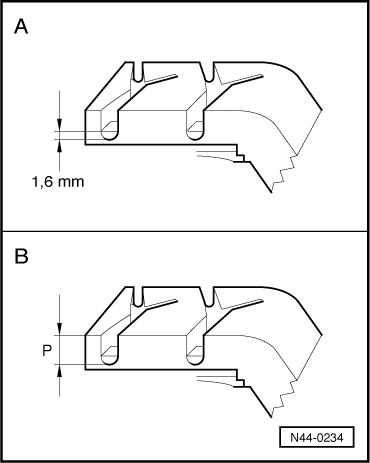

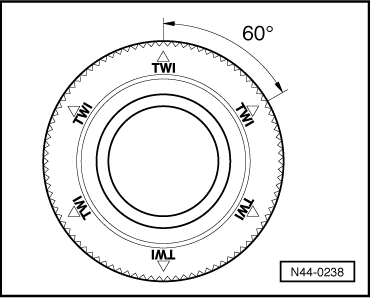

Tread depth of a tire must be measured in the main grooves at the points showing the most wear. Main tread grooves can be recognized by the TWI. The positions of the tread wear indicators are visible several times along the tire shoulder. The TWI protrusions are 1.6 mm tall. This is the minimum tread depth legally prescribed in Germany.

Different values may apply in other countries.

Tread Wear Indicators (TWI) must not be included in the measurement. The deepest point of the groove must be used for the measurement.

A - Tread wear indicators (TWIs) in main tread grooves. Items can be identified six times on the circumference of the tire shoulder.

B - Tread depth -P- in the main tread groove.

Tread wear indicators - TWI

TWI → Note is visible six times on the circumference of the tire shoulder.

1) Tread Wear Indicator means profile wear display

Speed Code/High Speed

.png)

Winter Tires with Speed Rating "V". Refer to → Chapter "Winter Tires with Speed Rating V".

Tires, Speed Ratings

The speed rating (for example "T") behind the tire size specification (for example 185/65 R 14 86T) indicates the maximum permissible speed (vmax) for the tire.

When selecting the tires for a vehicle, ensure that their maximal permissible speed lies above the maximum speed attainable by the vehicle ("design-related").

Formula for Vehicles with Speed Rating "v" from 151 km/h (94 mph)

vmax = 1.01 x v + 6.5 km/h (4.04 mph)

Example: Indicated maximum speed v = 163 km/h (101.28 mph)

vmax = 1.01 x 163 km/h + 6.5 km/h = 171.13 km/h (1.01 x 101.28 mph + 4.04 mph = 106.34 mph)

In this example, a "S"-tire or a tire with a higher-order speed rating must be used.

Note

Note

For the letter "v", enter the specified maximum speed in the vehicle registration Part I or II in the field "T" or in the vehicle title under number 6. This conversion is necessary, because due to technical reasons, all vehicles reach different maxim speeds within a legally permissible range.

Winter Tires with Speed Rating "V"

The tire industry delivers winter tires with V-rating also. These tires can be applied up to the maximum permissible speed vmax = 240 km/h (150 mph) only under certain conditions.

Vehicles with V-tires:

Vehicles that require V-tires according to vehicle registration, can be driven with V winter tires without limitations up to speed rating "v"max = 240 km/h (150 mph).

Vehicles with W-, Y- or ZR-tires:

Vehicles that require W, Y, or ZR tires according to vehicle registration, cannot be driven with V winter tires up to "v"max = 240 km/h (150 mph) under certain conditions.

Why?

V summer tires and V winter tires without special designation guarantee 100% of the load capacity indicated by their Load Index ("LI") only up to a speed of 210 km/h (131 mph).

Speeds above 210 km/h (131 mph) are only possible if the maximum load capacity of the tire is not exceeded. The load capacity of the tire decreases as the speed increases.

The maximum permissible axle load and the attainable maximum speed of certain Audi vehicles are so high that the load capacity of V tires is not sufficient for speeds above 240 km/h (150 mph).

Example: Tire 205/55 R 16 91V

The Load index (LI) 91 for this tire indicates a load capacity of 615 kg (1356 lb) per tire up to 210 km/h (131 mph).

At 240 km/h (150 mph), the load capacity of this tire is reduced to only 560 kg (1235 lb) . For this reason, the axle load can only be maximum 1,120 kg (2469 lb).

The vehicle has an additional axle load of 1,150 kg (2535 lb) and an attainable maximum speed of 232 km/h (144 mph). This vehicle can be driven with V winter tires up to a speed of 230 km/h (143 mph).

This applies to all V winter tires that do not have a special designation.

Winter tires identified with Extra Load XL. Refer to → Chapter "Winter Tires, Extra Load, Speed Rating V".

Permission stipulations in Germany

Only when using winter tires is it permitted that the highest speed attainable by the vehicle lies above the highest speed of winter tires specified by the speed rating.

In this case, a warning sign in the view of the driver must be applied with the following content:

Attention, winter tires!Maximum permissible speed ...km/h (mph)

Load Rating/Load Index (LI)

The load rating can be found on the sidewall of the tire. It provides information about the maximum load that the tire can bear.

The load rating is located in the tire size designation, for example 195 R 15 91 H. It is indicated on the tire as a code in accordance with an ETRTO standard. The following table shows the load capacity index used by Audi with the corresponding load rating of the tires.

.png)

.png)

Tires, Reinforced, Extra Load

Tires with XL designation have a higher load capacity than the tires without this designation.

Some time ago, the designation "Reinforced" was replaced with the designation "Extra Load" by some tire manufacturers. In countries outside Europe, this designation has been conventional for some time. There are no technical differences.

Some tire manufacturers also use the "XL" designation for Extra Load tires.

Tires with the designations "Reinforced" or "Extra Load (XL)" are the same.

Winter Tires, Extra Load, Speed Rating V

V winter tires with XL designation have a higher load capacity than the V winter tires without this designation.

Higher speeds can be attained with XL V-winter tires, but the maximum speed of the V tires of 240 km/h (150 mph) is not permissible for every vehicle.

Note

Note

The same conditions apply for these tires as for V winter tires. Refer to → Chapter "Winter Tires with Speed Rating V" without special designation!

Snow Chains

Snow chains may be mounted only on the drive wheels.

Only the front wheels on all wheel drive vehicles and also the back wheels on the Audi Q5 are equipped with snow chains.

Snow chains are not possible with all wheel/tire combinations.

If no special snow chain type is specified, a snow chain with small chain links can be used. Only chains which do not stand up more than 15 mm, including chain lock, may be applied on tire tread and inner sides.

With some models and certain wheel/tire combinations, only snow chains with small chain links can be used.

Note

Note

The legally permitted maximum speed when driving with snow chains is 50 km/h (31 mph).

Remove the snow chains before driving on snow-free roads. This is because the handling characteristics become worse. During this, the tires are stressed unnecessarily and the chain wear is particularly high.

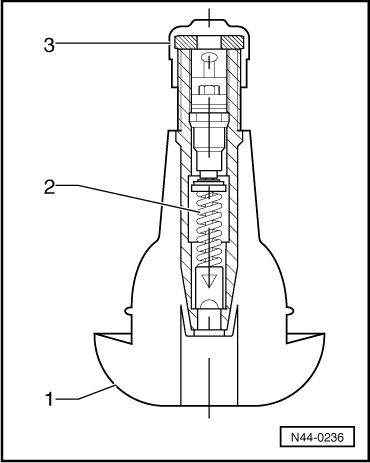

Rubber Valve

1 - Valve body

2 - Valve Insert

3 - Valve cap

1. The Valve Body

The rubber valve for tubeless tires is designed to seal air-tight in the hole in the rim. The elastic material of the rubber body presses itself tightly into the hole in the rim.

When valves with threaded metal feet are used, a rubber seal is used to seal the rim. The area around the edge of the valve hole is a sealing area. Therefore, they must be free of rust, dirt and damage.

2. The Valve Insert

The valve insert has the most important role in the valve: it seals and makes it possible to regulate the tire pressure. The small plate seal on the valve core can only do its job when it is free of impurities, dirt and moisture.

3. Valve Cap

A valve cap must always be screwed onto the valves. It prevents dirt from getting into the valve. Dirt which may be in the valve would reach the seal of the valve plate when the tire is inflated and cause a leak.

The valve must be replaced every time a new tire is fitted.

If the vehicle is driven without caps on the valves, there is the danger that dirt may get into the valve. This leads to gradual loss of air and therefore lead to the destruction of the tire.

- Separation of shell and rubber

- Wide circumferential furrows in the area of the bead

- Disintegrated tread

Note

Note

CAUTION! An air-tight seal is ensured only if the valve cap is secured tightly.

Caution

Caution

Do not use valve caps made of aluminum on a valve body made of steel.

Tires, Storing

The storage room

Tire storage must be:

- Dark

- Dry

- Cool

- Ventilated

Stored tires must not come in contact with fuel, oil, grease or chemicals under any circumstances. Otherwise, the material in the tire will be damaged by chemical reactions which are not always visible.

This may lead to life-threatening situations when the car is driven. However, tire damage occurs only when the reaction time of the chemicals is long. If a few drops of fuel land on a tire during a fill-up, this is harmless.

Tire Storage

Complete wheels

Tires mounted on wheels can be stored flat, stacked on upon another. The air pressure should be raised to a maximum of 3 bar.

Tires without rims

Tires without rims are best stored standing upright. If tires lie stacked upon another for longer periods of time, they will be strongly pressed together. This makes mounting more difficult because the tires do not lie on the bead seat. If the tires are stored standing vertically, it is recommended to turn them every 14 days to avoid severe flattening.

Tires, Aging

Tires age as a result of physical and chemical processes whereby the function can be impaired. Tires which are stored for longer periods of time become harder and brittle faster than tires which are constantly in use on a vehicle. Older tires may develop hairline cracks from aging. When tires are in constant use, the kneading activates softeners in the rubber, preventing hardening and the development of cracks.

Therefore, one should note not just the tread depth but also the age of spare tires, stored tires and tires which are not permanently in use. Tire age can be determined from the DOT code which contains, among other things, the tire's production date.

Example of a DOT number:

.png)

In this example, the production date is the 50th week in 2002. Through 12/31/1999, the DOT number was a three-digit number.

Recommendation:

- It is recommended using tires more than 6 years old only in emergencies and only with a cautious driving style.

- When new tires are fitted, the spare tire may also be used if it is in flawless condition and is not more than six years old. The age of the tire has a great influence on the high-speed capability of the tire. The combination of a spare tire which is several years old with new tires is possible, but it can influence the car's handling.

- Tires are constantly being further developed, this can lead, for example, to slight changes in the rubber compound, even if the tires are of the same make, size and tread.

- For driving safety reasons, tires of the same make and with the same tread should be mounted on one axle.

- Vehicles with AWD always must be equipped with four wheels that have tires of the same size, construction, tread pattern and make. Excepted are vehicles that were shipped by Audi AG with different sized tires on the front and rear axle.

Note

Note

- For all four wheels use only tires of the same construction type, size, and tread.

- Excepted are vehicles that were shipped by Audi AG with different sized tires on the front and rear axle.

Tires, Replacing

Note

Note

We recommend using tires that have "AO" on them. These tires are suited for each Audi model.

Tires must be changed when:

- The legal minimum tread depth of 1.6 mm is reached.

- There is visible damage from mechanical damage.

- The tires are more than six years old.

Light Alloy Wheels, Care and Maintenance

To maintain the decorative appearance of light alloy wheels for a long time, regular care is necessary.

In particular, road salt and dust from brake abrasion must be thoroughly washed off every two weeks. Otherwise, the paint of the light alloy wheel will be attacked.

The following are appropriate cleaning agents:

- Water or water and soft soap.

- Water and vinegar essence.

- Light alloy wheel cleaning agents without acids or harsh solvents.

Do not exceed the soaking time of the cleaning agent.

The shorter the specified soaking time is, the stronger and more aggressive the cleaning solution is.

If the paint is damaged, for example by impact from a stone, the paint damage must be repaired immediately.

Remove adhesive residue from light alloy rim adhesive balancing weights:

- Harsh solvents and acids attack the paint on light alloy wheels and the surface of the wheel becomes matte and milky. These agents therefore must not be used.

- To remove adhesive residue on light alloy wheels, use light alloy cleansers or benzene-based cleanser. Do not exceed the soaking time of the cleaning agent.

- After cleaning or removing adhesive residue on the tires, they must be rinsed again with water.

Wheels, rotating:

- Vehicles with front-wheel drive experience more tread wear on the front wheels due to the increased stress on them.

- In order for all four wheels on the vehicle to have the same service life, it is recommended to rotate the front and rear wheels.

- Be sure not to mix up tires, which have the direction of rotation marked on them.

- The longer the tire runs at one position, the more it wears at certain points, therefore, it is recommended to rotate the wheels at short intervals. Refer to Maintenance Intervals.

- Diagonal rotation is possible only with non-directional tires. This wheel rotation is especially advantageous for heel-and-toe wear. Heel-and-toe wear. Refer to → Chapter "Heel and Toe Wear".

- If heel-and-toe wear has already progressed very far and the tread is more than 50% worn, only slight improvement can be achieved and rotation is no longer recommended. The elasticity of the tread blocks declines and the heel-and-toe wear does not progress.

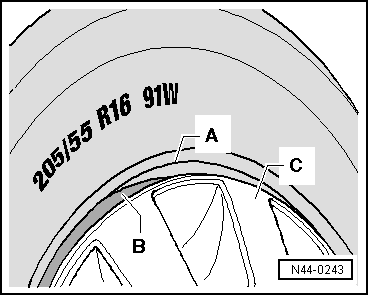

Tires with Rim Protector

The tire industry produces tires with rim protector for light alloy wheels (rim protector). The rim protector prevents damage to the light alloy wheels caused by contact with curbs.

Using tires with rim protector on steel wheels with wheel covers may lead to the loss of the wheel cover while driving. The cover separates from its secure seating due to the flexing of the tire.

WARNING

WARNING

When installing tires on steel rims, ensure only tires without rim protector are mounted.

The illustration shows the non-permissible combination of steel rim, wheel cover and tire with rim protector.

A - Rim protector

B - Rim flange of a steel rim

C - Wheel cover

WARNING

WARNING

This combination must not be mounted!