Audi A6 Typ 4G: Wiring Harnesses, Repairing

Airbag and Belt Tensioner Wires, Repairing

In addition to the general repairs on wiring harnesses, the following methods and instructions must be observed for repairs on airbag- and seat belt tensioner wires:

WARNING

WARNING

- The airbag and seat belt tensioner system can fail.

- Faulty repairs performed on airbag and seat belt tensioner system can lead to malfunction in passenger protection.

- When performing repairs on airbag and seat belt tensioner wiring harness, use only terminals, connectors and wires designated for it. Refer to the Parts Catalog.

Note

Note

- Air bag wires and the safety belt tensioner wiring harness may repaired only with the Wiring Harness Repair Set -VAS1978B- and previous versions.

- Observe general notes for repairs on the vehicle electrical system. Refer to → Chapter "Vehicle Electrical System, General Repair Information".

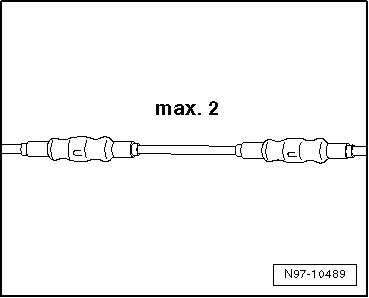

- A maximum of two repairs may be performed when repairing wires of airbag- and seat belt tensioner system. Repairs increase the electrical resistance in the wire and may trigger malfunctions in the system On Board Diagnostic (OBD).

- When repairing wiring harness of airbag- and seat belt tensioner system, the crimp connectors must always be heat-shrunk to prevent corrosion.

- Do not wrap the repair point again into the vehicle-specific wiring harness and mark the repair point quite visibly with yellow insulating tape.

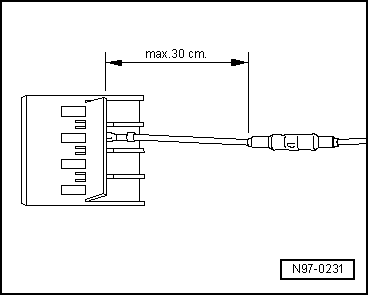

- Repairs in the area of the airbag or seat belt tensioner should be performed a maximum of 30 cm from the next connector housing. Together with the identification via yellow insulating tape, this procedure makes it possible to obtain a quick overview of previously performed repairs.

- Wires to the deploying units (airbags) have a wire-twisting with a length of lay of 20 mm +- 5 mm in series production. This length of lay is guaranteed via the norm part numbers for wire pairs in series production and must be observed strictly for the repair lengths of twisted wires.

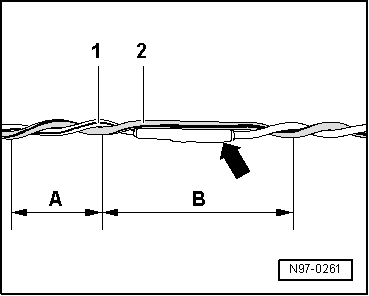

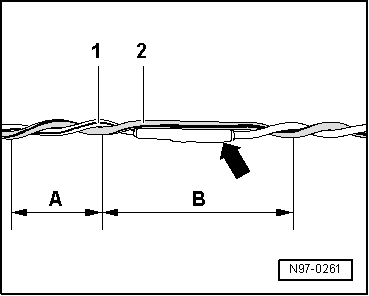

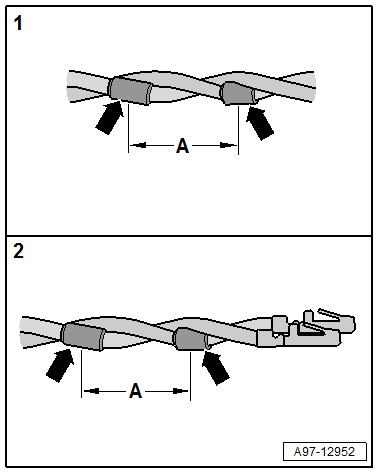

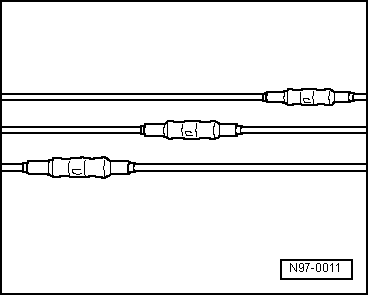

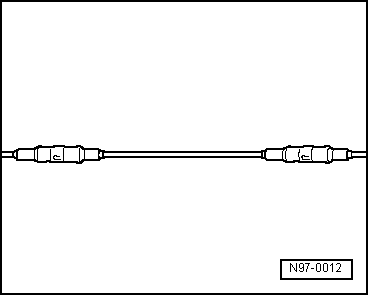

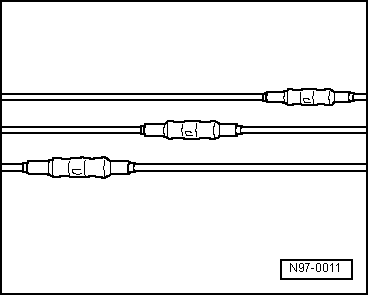

- During repair work, wires to deploying units (airbags) must have the same length. When twisting together wires -1 and 2-, length of lay of A = 20 mm +- 5 must be strictly observed.

- While doing this, no section of the wire, for example, in area of crimp connectors -arrow-, may be greater than B = 100 mm without twisting of the wires.

- Repairs are to be documented in the Audi Service Plan under "Space for workshop entries" with a short commentary of scope of repairs, workshop stamp and signature.

- Any warranty claims to Audi AG are void for repairs on airbag wiring set which were not performed using original replacement parts and Wiring Harness Repair Set -VAS1978-.

Repairing CAN bus Wires

- Unshielded, twisted two-wire lines -1 and 2- with a cross section of 0.35 mm 2 or 0.5 mm2 can be used as CAN-Bus wiring.

- Repairs on CAN-Bus wires can be performed with repair wire with matching cross section and also with twisted wires "green/yellow" or "white/yellow" from the Parts Catalog.

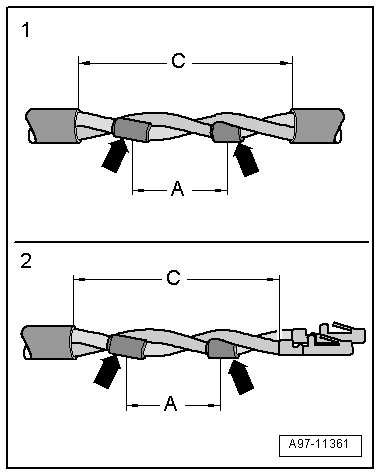

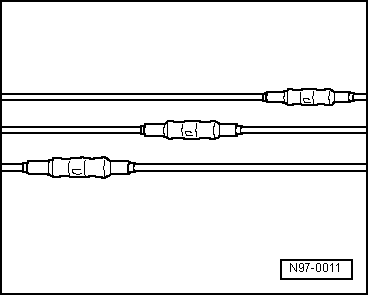

- When repairing CAN bus wires, both wires must be same length. When twisting together wires -1 and 2-, the lay length of A = 20 mm must be observed.

- While doing this, no section of the wire, for example, in area of crimp connectors -arrow-, may be greater than B = 50 mm without twisting of the wires.

- Wrap repair points with yellow adhesive tape to mark a performed repair.

Repair Kit for FlexRay Wires with Coating

Note

Note

- The repair of FlexRay wires with coating can only take place using FlexRay wires with coating from the Parts Catalog.

- Observe general notes for repairs on the vehicle electrical system. Refer to → Chapter "Vehicle Electrical System, General Repair Information".

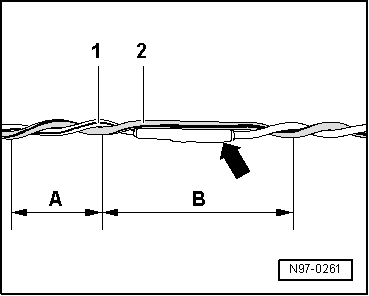

A two-layer wire -1 and 2- with a 0.35 mm 2 profile is used as a FlexRay wire.

- During repair work, both wires must have the same length.

- When twisting the wires -1 and 2- together, the -A- = 30 mm routing length must be maintained.

- While doing so, no section of wire may be greater than -B- = 50 mm without twisting the wires, for example in the area of crimp connectors -arrow-.

- Maximum exposed wire length: -C- = 100 mm.

- Protect the area being repairs from the environment. Use a crimp connector with heat-shrinkable tube over the untwisted location being repairs and waterproof insulation over the exposed wire.

- Mark the location of the repair with something suitable, for example, with yellow tape.

- Repairing both wires is identical to repair just one wire.

- Position both repaired location -arrows--A- = 30 mm opposite each other.

- Crimp the cables with connectors.

1 - Repair location in the area without insulation

2 - Repair location with connectors

C - Maximum exposed length = 100 mm

Repair Kit for FlexRay Wires without Coating

Note

Note

- The repair of FlexRay wires without coating can only take place using FlexRay wires without coating from the Parts Catalog.

- Observe general notes for repairs on the vehicle electrical system. Refer to → Chapter "Vehicle Electrical System, General Repair Information".

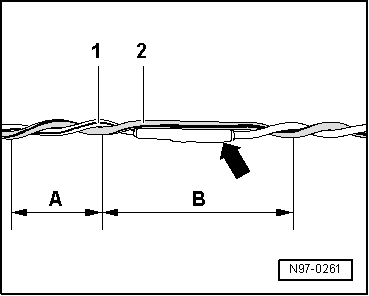

Unshielded, twisted two-wire lines -1 and 2- with a cross section of 0.35 mm 2 can be used as FlexRay wires.

- During repair work, both FlexRay wires must have the same length.

- When twisting the wires -1 and 2- together, the -A- = 20 mm routing length must be maintained.

- While doing so, no section of wire may be greater than -B- = 40 mm without twisting the wires, for example in the area of crimp connectors -arrow-.

- Mark the location of the repair with something suitable, for example, with yellow tape.

- Repairing both FlexRay wires is identical to repairing just one wire.

- Position both repaired locations -A- = 20 mm opposite each other.

- Crimp the cables with connectors.

1 - Repair location in wiring harness

2 - Repair location with connectors

0.22 mm 2 Wire, Repairing with Individual Crimp Connector

Procedure

- Free up the wire to be repaired approximately 20 cm on both sides of the repair point.

Caution

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses carefully.

- If necessary, removing the wiring harness wrapping using a knife.

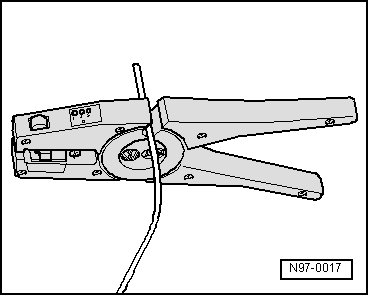

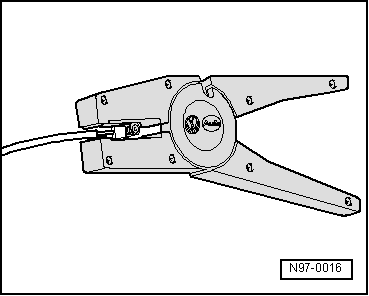

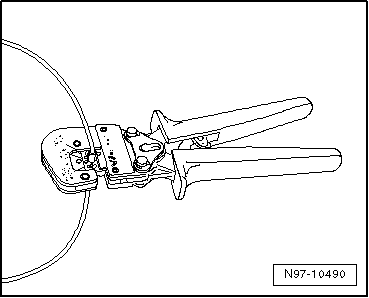

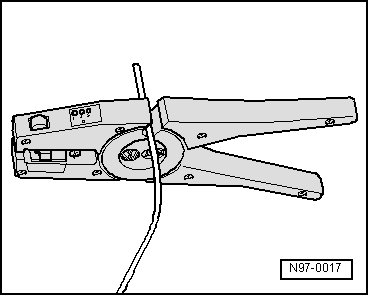

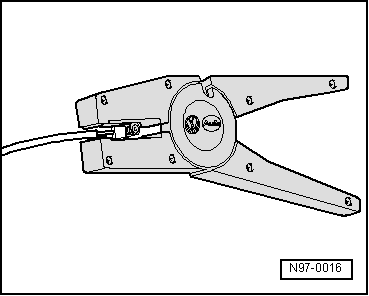

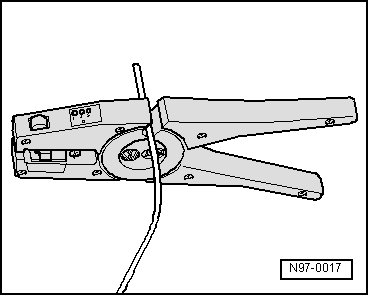

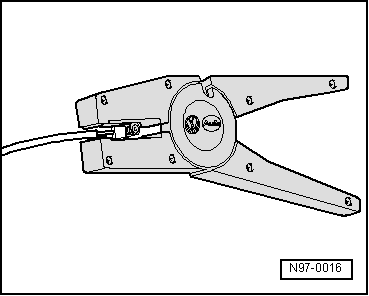

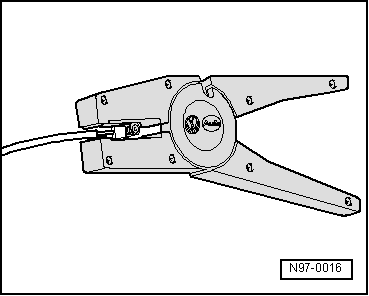

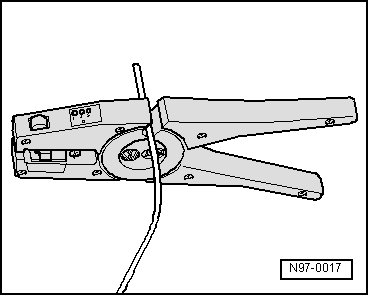

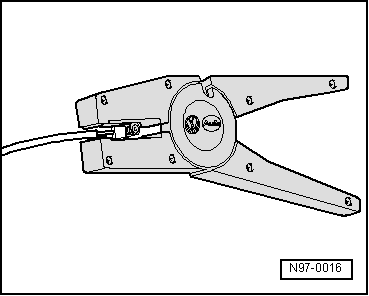

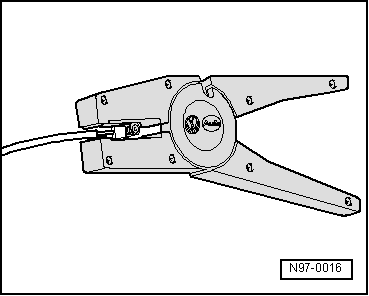

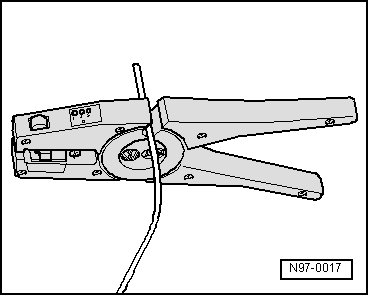

- Cut out the damaged section of wire using the Wiring Harness Repair Set - Wire Strippers -VAS1978/3-.

Note

Note

If, by cutting out the damaged wire section, both ends of the vehicle-specific single wire are too short for a repair using a single crimp connector, insert a repair wire section of matching length with two crimp connections. Refer to → Chapter "Repairing a 0.22 mm 2 Wire with Intermediate Wire Section".

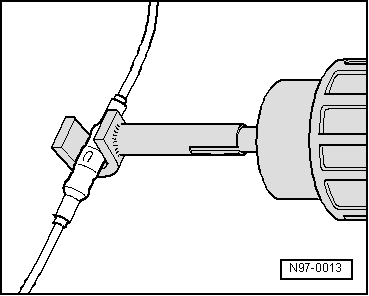

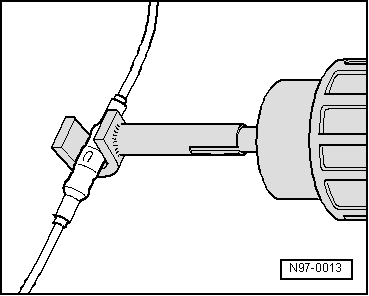

- Adjust the sliding stop in the Wiring Harness Repair Set - Wire Strippers -VAS1978/3- pliers jaws to 12 to 14 mm for the wire to be stripped.

- Insert wire end from front up to stop into jaws of pliers and squeeze the pliers completely.

- Open pliers again and remove the stripped wire end.

- Twist bare strands one-half turn.

- For the repair of a 0.22 mm 2 wire, use a small transparent crimp connector from the Wiring Harness Repair Set -VAS1978B-.

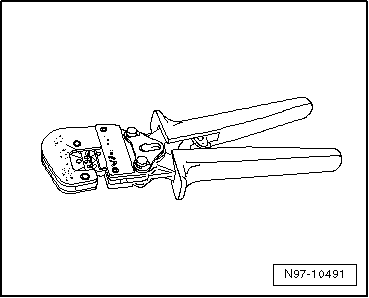

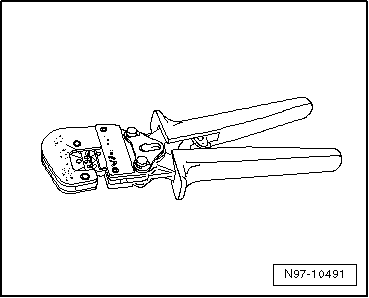

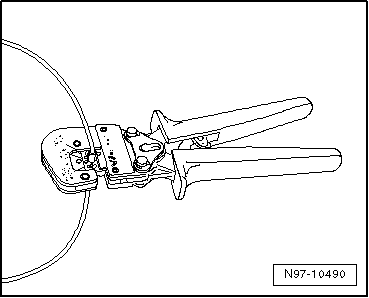

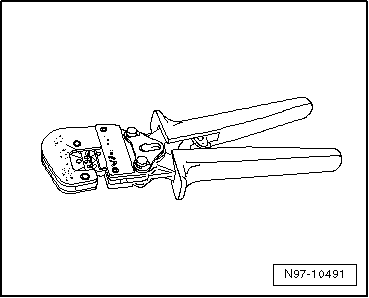

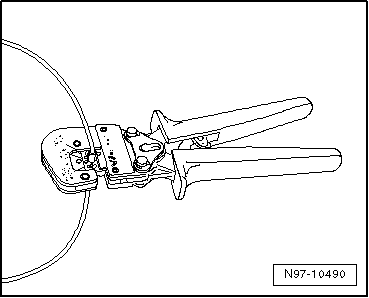

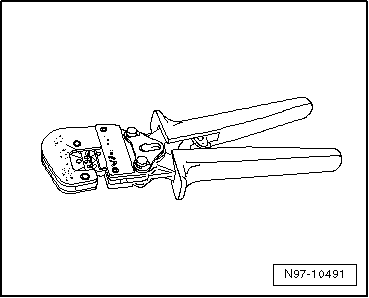

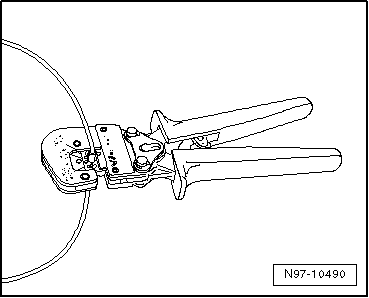

- To press the crimp connector, use the Wiring Harness Repair - Crimping Plier - Base Tool -VAS1978/1-2- with Wiring Harness Repair - Crimping Head -.35-2.5mm -VAS1978/1-1-.

- Slide the small transparent crimp connector onto both stripped, non-insulated wire ends on the vehicle-specific single wire and crimp them using crimp pliers.

Note

Note

Do not crimp wire insulation.

After crimping, crimp connections must be heat-shrunk using hot air gun to prevent moisture penetration.

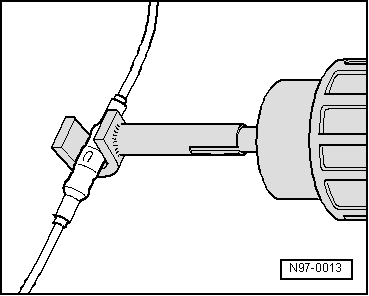

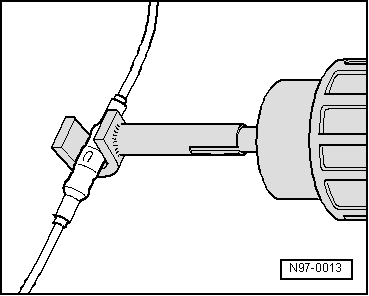

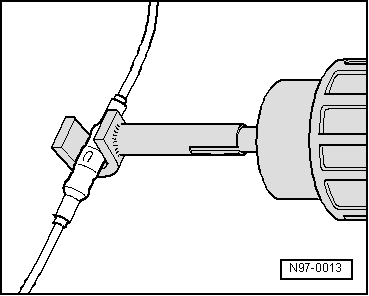

- Insert the Wiring Harness Repair - Blower - Shrink Element -VAS1978/15A- on the Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A-.

Caution

Caution

Risk of damaging surrounding components.

- When heat-shrinking crimp connections, be careful not to damage any other wiring, plastic parts or insulating material with the hot nozzle of the hot air blower.

- Always observe operating instructions of heat gun.

- Heat crimp connection using the hot air blower lengthwise from center outward until it is sealed completely and adhesive comes out the ends.

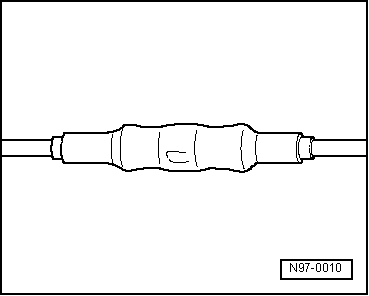

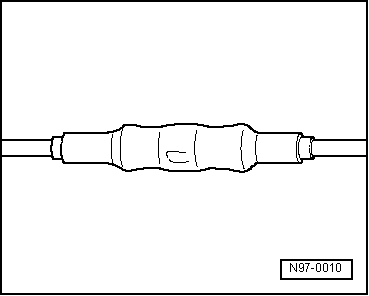

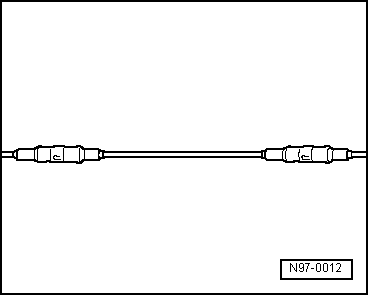

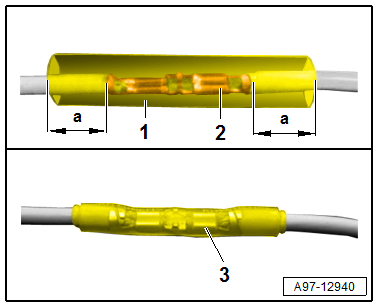

- This is how the completed repair location with individual crimp connector should appear.

Note

Note

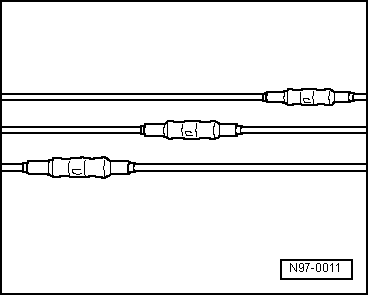

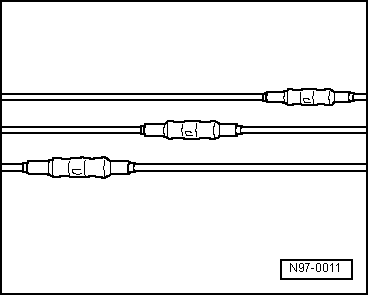

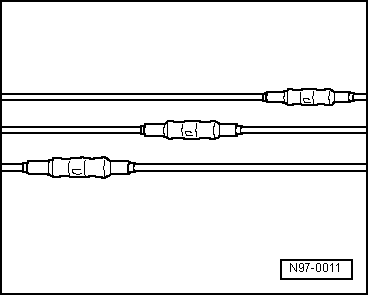

- Make sure that crimp connections do not lie directly next to each other when several wires need to be repaired. Arrange the crimp connectors at a slight offset so that the circumference of the wiring harness does not become too large.

- If the repair point was previous taped, this point must be taped again with yellow insulating tape after repairs.

- Secure the repaired wiring harness if necessary with a cable tie to prevent flapping noises while driving.

Repairing a Wire 0.35 mm 2 or Greater with Individual Crimp Connector

Procedure

- Free up the wire to be repaired approximately 20 cm on both sides of the repair point.

Caution

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses carefully.

- If necessary, removing the wiring harness wrapping using a knife.

- Cut out the damaged section of wire using the Wiring Harness Repair Set - Wire Strippers -VAS1978/3-.

Note

Note

If, by cutting out the damaged wire section, both ends of the vehicle-specific single wire are too short for a repair using a single crimp connector, insert a repair wire section of matching length with two crimp connections. Refer to → Chapter "Repair a wiring 0.35 mm 2 or greater with intermediate wire section".

- Adjust the sliding stop in the Wiring Harness Repair Set - Wire Strippers -VAS1978/3- pliers jaws to 6 to 7 mm for the wire to be stripped.

- Insert wire end from front up to stop into jaws of pliers and squeeze the pliers completely.

- Open pliers again and remove the stripped wire end.

- For the repair, use a suitable crimp connector from the Wiring Harness Repair Set -VAS1978B-.

Note

Note

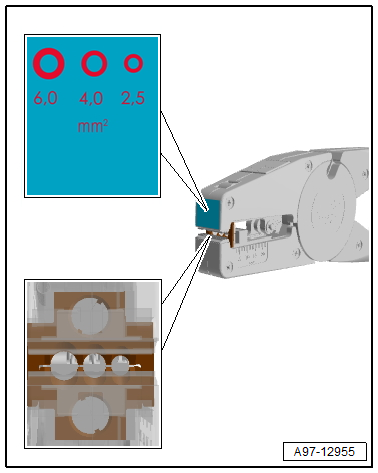

- Always be sure to use the corresponding crimp connector and the correct crimping slot for the crimping connection used. Refer to → Chapter "Crimping Pliers with Insert".

- Do not crimp wire insulation.

- Use the Wiring Harness Repair - Crimping Plier - Base Tool -VAS1978/1-2- to press the crimp connector.

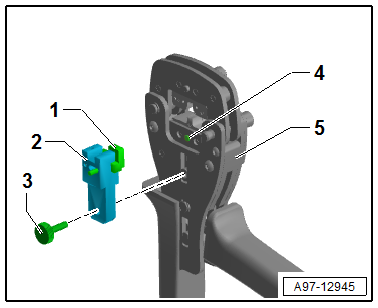

The following exchangeable heads are available for the Wiring Harness Repair - Crimping Plier - Base Tool -VAS1978/1-2-:

- Wiring Harness Repair - Crimping Head -.35-2.5mm -VAS1978/1-1-

- Wiring Harness Repair Set - Crimping Head - 4-6mm -VAS1978/2 A-

- Slide crimp connection onto both stripped wire ends of vehicle-specific single wire and crimp them using crimp pliers.

Note

Note

Do not crimp wire insulation.

After crimping, crimp connections must be heat-shrunk using hot air gun to prevent moisture penetration.

- Insert the Wiring Harness Repair - Blower - Shrink Element -VAS1978/15A- on the Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A-.

Caution

Caution

Risk of damaging surrounding components.

- When heat-shrinking crimp connections, be careful not to damage any other wiring, plastic parts or insulating material with the hot nozzle of the hot air blower.

- Always observe operating instructions of heat gun.

- Heat crimp connection using the hot air blower lengthwise from center outward until it is sealed completely and adhesive comes out the ends.

- This is how the completed repair location with individual crimp connector should appear.

Note

Note

- Make sure that crimp connections do not lie directly next to each other when several wires need to be repaired. Arrange the crimp connectors at a slight offset so that the circumference of the wiring harness does not become too large.

- If the repair point was previous taped, this point must be taped again with yellow insulating tape after repairs.

- Secure the repaired wiring harness if necessary with a cable tie to prevent flapping noises while driving.

Repairing a 0.22 mm 2 Wire with Intermediate Wire Section

Note

Note

For repairing a 0.222 a repair wire can be used as the intermediate wire with a cross section of 0.35-mm2 or 0.5-mm2.

Procedure

- Free up the wire to be repaired at two places approximately 20 cm on both sides of the repair point.

Caution

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses carefully.

- If necessary, removing the wiring harness wrapping using a knife.

- Route the yellow repair wire next to the damaged wiring harness and cut the repair wire to the required length using the Wiring Harness Repair Set - Wire Strippers -VAS1978/3-.

- Cut damaged wire section from the vehicle-specific single wire.

- Adjust the sliding stop in the Wiring Harness Repair Set - Wire Strippers -VAS1978/3- pliers jaws to 12 to 14 mm for the wire to be stripped.

- Insert the vehicle-specific single wire end from the front into the pliers jaws as far as the stop and squeeze the pliers together completely.

- Open pliers again and remove the stripped wire end.

- Twist bare strands one-half turn.

- Repeat the procedure on the other end of the vehicle-specific individual wire.

- Adjust the sliding stop in the Wiring Harness Repair Set - Wire Strippers -VAS1978/3- pliers jaws to 6 to 7 mm for the wire to be stripped.

- Insert the yellow repair wire end from the front into the pliers jaws as far as the stop and squeeze the pliers together completely.

- Open pliers again and remove the stripped wire end.

- Repeat this procedure on the other repair wire end.

- For the repair of a 0.22 mm 2 wire, use a small transparent crimp connector from the Wiring Harness Repair Set -VAS1978B-.

- Use die Wiring Harness Repair - Crimping Plier - Base Tool -VAS1978/1-2- with Wiring Harness Repair - Crimping Head -.35-2.5mm -VAS1978/1-1- from the Wiring Harness Repair Set -VAS1978B- to crimp the wire.

- Push the small transparent crimp connector on the side of the stripped, non-insulated wire ends of vehicle-specific single wire on the other side of the repair wire stripped wire ends.

- Crimp the crimp connection at both wire ends using crimp pliers.

- Repeat this procedure at the other repair wire end.

Note

Note

Do not crimp wire insulation.

After crimping, crimp connections must be heat-shrunk using hot air gun to prevent moisture penetration.

- Insert the Wiring Harness Repair - Blower - Shrink Element -VAS1978/15A- on the Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A-.

Caution

Caution

Risk of damaging surrounding components.

- When heat-shrinking crimp connections, be careful not to damage any other wiring, plastic parts or insulating material with the hot nozzle of the hot air blower.

- Always observe operating instructions of heat gun.

- Heat crimp connection using the hot air blower lengthwise from center outward until it is sealed completely and adhesive comes out the ends.

- This is how the completed repair location with the inserted wire and two crimp connectors should look.

Note

Note

- Make sure that crimp connections do not lie directly next to each other when several wires need to be repaired. Arrange the crimp connectors at a slight offset so that the circumference of the wiring harness does not become too large.

- If the repair point was previous taped, this point must be taped again with yellow insulating tape after repairs.

- Secure the repaired wiring harness if necessary with a cable tie to prevent flapping noises while driving.

Repair a wiring 0.35 mm 2 or greater with intermediate wire section

Note

Note

For the repair use repair wires with a cross section of 0.35 mm2 through 6.0-mm2.

Procedure

- Free up the wire to be repaired at two places approximately 20 cm on both sides of the repair point.

Caution

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses carefully.

- If necessary, removing the wiring harness wrapping using a knife.

- Route the yellow repair wire next to the damaged wiring harness and cut the repair wire to the required length using the Wiring Harness Repair Set - Wire Strippers -VAS1978/3-.

- Cut damaged wire section from the vehicle-specific single wire.

- Adjust the sliding stop in the Wiring Harness Repair Set - Wire Strippers -VAS1978/3- pliers jaws to 6 to 7 mm for the wire to be stripped.

- Insert the vehicle-specific single wire end from the front into the pliers jaws as far as the stop and squeeze the pliers together completely.

- Open pliers again and remove the stripped wire end.

- Repeat the procedure on the other end of the vehicle-specific individual wire.

- For the repair, use two suitable crimp connectors from the Wiring Harness Repair Set -VAS1978B-.

Note

Note

- Always be sure to use the corresponding crimp connector and the correct crimping slot for the crimping connection used. Refer to → Chapter "Crimping Pliers with Insert".

- Do not crimp wire insulation.

- Use the Wiring Harness Repair - Crimping Plier - Base Tool -VAS1978/1-2- to press the crimp connector.

The following exchangeable heads are available for the Wiring Harness Repair - Crimping Plier - Base Tool -VAS1978/1-2-:

- Wiring Harness Repair - Crimping Head -.35-2.5mm -VAS1978/1-1-

- Wiring Harness Repair Set - Crimping Head - 4-6mm -VAS1978/2 A-

- Slide the crimp connector onto the vehicle-specific single wire at one side and onto repair wire at the other side.

- Crimp the crimp connection at both wire ends using crimp pliers.

- Repeat this procedure on the other wire ends.

Note

Note

Do not crimp wire insulation.

After crimping, crimp connections must be heat-shrunk using hot air gun to prevent moisture penetration.

- Insert the Wiring Harness Repair - Blower - Shrink Element -VAS1978/15A- on the Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A-.

Caution

Caution

Risk of damaging surrounding components.

- When heat-shrinking crimp connections, be careful not to damage any other wiring, plastic parts or insulating material with the hot nozzle of the hot air blower.

- Always observe operating instructions of heat gun.

- Heat crimp connection using the hot air blower lengthwise from center outward until it is sealed completely and adhesive comes out the ends.

-

This is how the completed repair location with the inserted wire and two crimp connectors should look.

Note

Note

- Make sure that crimp connections do not lie directly next to each other when several wires need to be repaired. Arrange the crimp connectors at a slight offset so that the circumference of the wiring harness does not become too large.

- If the repair point was previous taped, this point must be taped again with yellow insulating tape after repairs.

- Secure the repaired wiring harness if necessary with a cable tie to prevent flapping noises while driving.

10 mm2- or 16 mm2 Wires with Separate Butt Connectors, Repairing

Special tools and workshop equipment required

- Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A- from the Wiring Harness Repair Set -VAS1978B-

- Wiring Harness Repair - Blower - Shrink Element -VAS1978/15A- from the Wiring Harness Repair Set -VAS1978B-

- Wiring Harness Repair Set VAS 631 003 -VAS631003-

Note

Note

- For the repair there are repair wires with a 10mm2 or 16mm2 cross section.

- There are also separate repair wires with a crimped on/connected contact available for the repair.

Procedure

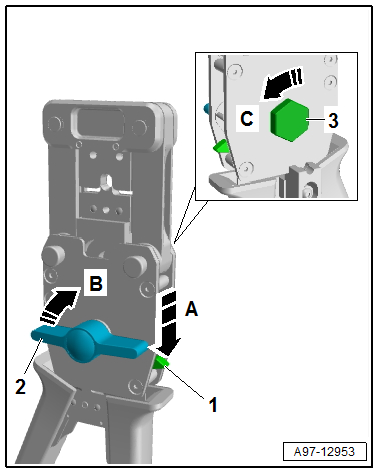

- For the wire cross-section install the suitable crimp insert and crimp stamp as follows on the crimping pliers:

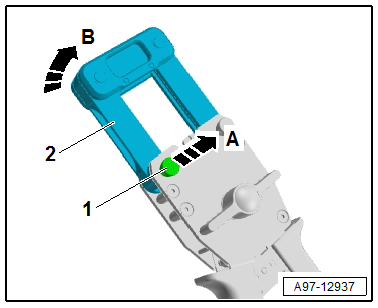

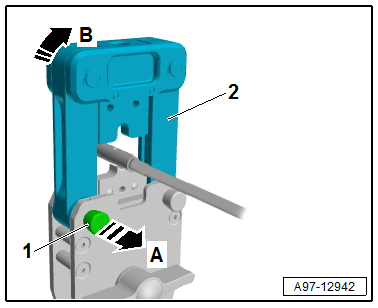

- Open the crimping pliers from the Wiring Harness Repair Set -VAS631003-.

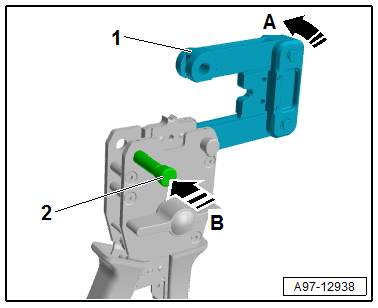

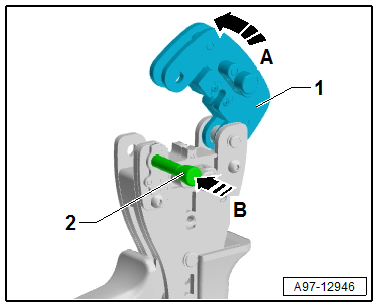

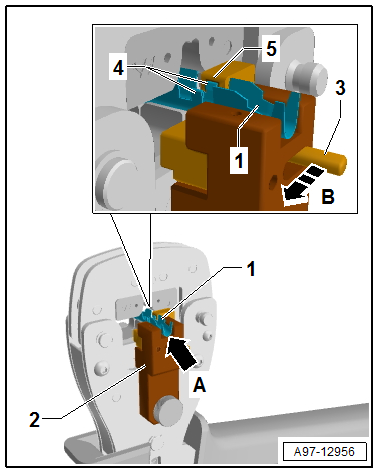

- Remove the locking pin -1- all the way in the direction of -arrow A-.

- Open the adapter -2- in the direction of -arrow B-.

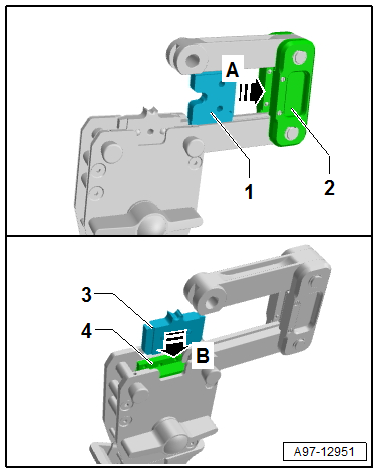

- Push in the crimp stamp -1- until it clicks into place in the mount -2- on the adapter -arrow A-.

- Push in the crimp insert -3- until it engages audibly in the mount -4- of the crimping pliers -arrow B-.

- Close the adapter -1- in the direction of -arrow A-.

- Push the locking pin -2- in the direction of -arrow- all the way.

- Free up the wire to be repaired approximately 20 cm on both sides of the repair point.

Caution

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses carefully.

- If necessary, removing the wiring harness wrapping using a knife.

- Cut the damaged section of the wire with wire cutters from the Wiring Harness Repair Set -VAS631003-.

Note

Note

- When both ends of the vehicle-specific single wire are too short after cutting out the damaged wire section for a repair with a separate butt connector, insert a corresponding long piece of yellow repair wire with two butt connectors.

- When repairing the single wire with crimped on/connected contact place the yellow repair wire near the damaged vehicle-specific single wire and cut to the required length.

- Adjust the sliding stop in the wire stripper pliers jaws from the Wiring Harness Repair Set -VAS631003- to the length for the wire to be stripped.

- 10 mm2 wires: 14 mm

- 16 mm2 wires: 16.5 mm

- Insert wire end from front up to stop into jaws of pliers and squeeze the pliers completely.

- Open pliers again and remove the stripped wire end.

- The insolation must be cut cleanly and remove from the wires.

- No insolation can remain on bare wires.

- The single wires must not be damaged.

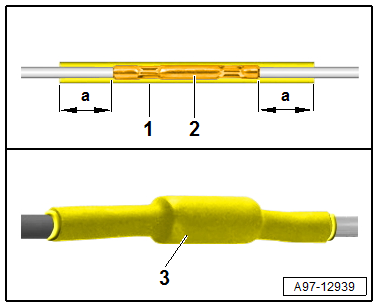

- For the repair remove the corresponding butt connection and a heat-shrinkable tube from the Wiring Harness Repair Set -VAS631003-.

- Push the heat-shrinkable tube on one of the wires.

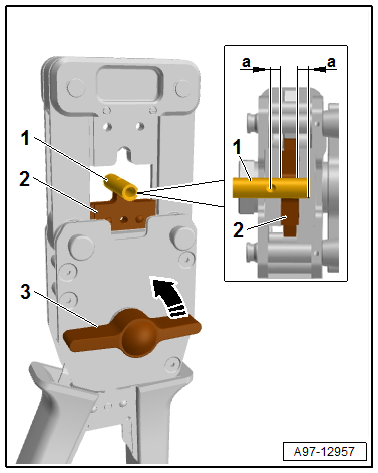

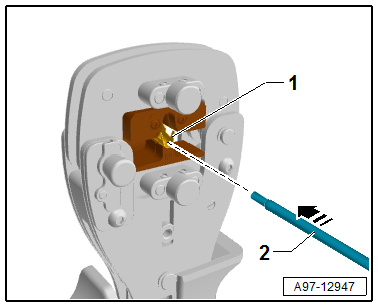

- Position the butt connection -1- with the first crimping position centered on the crimp insert -2-.

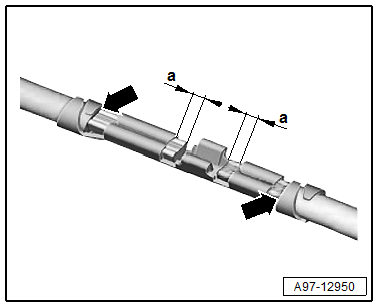

- The dimension -a- must be the same on both sides

- Turn the quick feed lever -3- counter-clockwise -arrow- until the butt connection -1- is secured.

- Insert the wire -2- with the bare wire end all the way in the butt connection -1--arrow-.

- All single wires must be pushed into the butt connection.

- Completely close and open the crimping pliers several times, until the crimp insert goes downward by itself in its original position.

Note

Note

The wire insulation must not be crimped at the same time.

- Repeat the wire crimping on the other side as described.

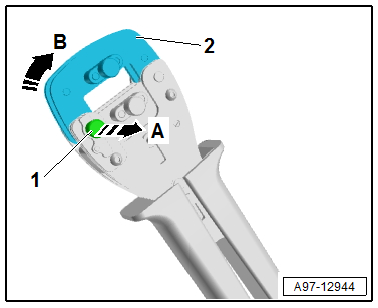

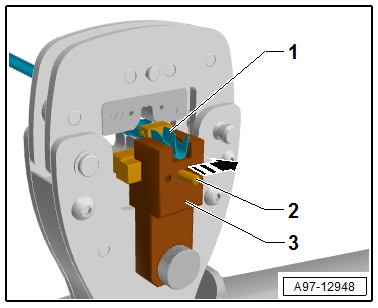

- Remove the securing pin in the direction of -arrow A- until it stops.

- Open the adapter in the direction of -arrow B-.

- Remove the crimped butt connectors.

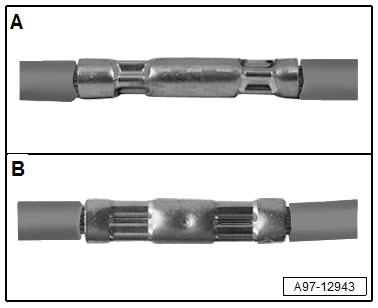

Correct crimping results

A - 10 mm2, Star crimp

B - 16 mm2, B-Crimp

After crimping the heat-shrinkable tube must positioned over the butt connection and heat-shrunk with a hot air gun, to prevent moisture from entering.

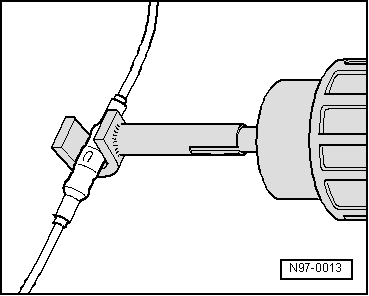

- Insert the Wiring Harness Repair - Blower - Shrink Element -VAS1978/15A- on the Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A-.

Caution

Caution

Risk of damaging surrounding components.

- When heat-shrinking the heat-shrinkable tube, be careful not to damage any other wiring, plastic parts or insulating material with the hot nozzle of the hot air blower.

- Always observe operating instructions of heat gun.

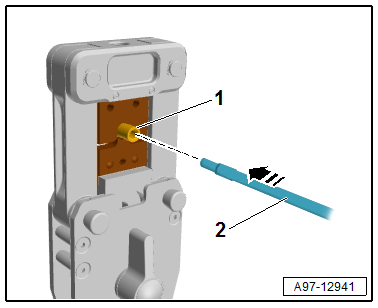

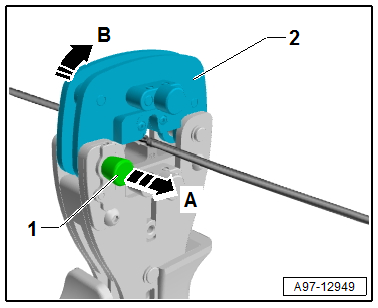

- Position the heat-shrinkable tube -1- by feeling the contours centered over the butt connection -2-.

- The dimension -a- must be approximately the same on both sides

- Heat the heat-shrinkable tube using the hot air blower lengthwise from center outward until it is sealed completely and adhesive comes out the ends.

- The completed repair location -3- must look like so.

Note

Note

- Make sure that the butt connections do not lie directly next to each other when several wires need to be repaired. Arrange the butt connection at a slight offset so that the circumference of the wiring harness does not become too large.

- If the repair point was previous taped, this point must be taped again with yellow insulating tape after repairs.

- Secure the repaired wiring harness if necessary with a cable tie to prevent flapping noises while driving.

Early Release

- Push the lever -1- downward in direction of -arrow A-.

- Turn the quick feel lever -2- clockwise in direction of -arrow B- until the crimp insert is in its original position.

If releasing by hand is not possible then:

- Push the lever -1- downward in direction of -arrow A-.

- Place the socket from the Wiring Harness Repair Set -VAS 631 003- on the bolt -3- on the rear side.

- Turn the socket counter-clockwise in direction of -arrow C- until the crimp insert is in its original position,

Caution

Caution

Do not use the butt connectors after they are early released.

2.,5 mm2, 4 mm2 or 6 mm2 Aluminum Wires with Separate Butt Connectors, Repairing

Special tools and workshop equipment required

- Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A- from the Wiring Harness Repair Set -VAS1978B-

- Wiring Harness Repair - Blower - Shrink Element -VAS1978/15A- from the Wiring Harness Repair Set -VAS1978B-

- Wiring Harness Repair Set -VAS631001-

Note

Note

- For the repair there are copper repair wires with a 2.5mm2 or 4 mm2 or 6 mm2 cross section.

- There are also separate copper repair wires with a crimped on contacts available for the repair.

Procedure

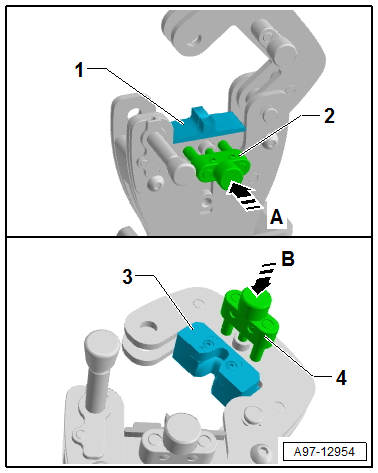

- Install the corresponding crimp insert, crimp stamp and contact positioner for the wire cross-section with the contact cross bar as follows on the crimping tool.

- Open the crimping tool from the Wiring Harness Repair Set -VAS 631 001-.

- Remove the locking pin -1- all the way in the direction of -arrow A-.

- Open the mount -2- in the direction of -arrow B-.

- Insert the crimp insert -1- in the crimping tool so that the crimp insert -1- is flush with the front of the clamps.

- Tighten the crimp insert with the pins -2- in direction of -arrow A- and the knurled screw hand tight.

- Insert the crimp stamp -3- that fits the crimp insert in the mount.

- Secure the crimp stamp with the pin -4- in direction of -arrow B- and the knurled screw hand-tight.

- Close the adapter -1- in the direction of -arrow A-.

- Push the locking pin -2- in the direction of -arrow- all the way.

- Insert the contact cross bar -1- in the contact positioner -2-.

- Position the contact positioner with the contact cross bar on the crimping tool -5- at the same time push the holes in the contact positioner -2- over the knurled screw -4-.

- Install the knurled bolt -3- and tighten hand-tight.

- Free up the wire to be repaired approximately 20 cm on both sides of the repair point.

Caution

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses carefully.

- If necessary, removing the wiring harness wrapping using a knife.

- Cut the damaged section of the wire with wire stripper from the Wiring Harness Repair Set -VAS 631 001-.

Note

Note

When both ends of the vehicle-specific single wire are too short after cutting out the damaged wire section for a repair with a separate butt connector, insert a corresponding long piece of yellow copper repair wire with two butt connectors.

- Insert the wire end from the front all the way in to the wire cross-section corresponding mount in the jaws of the pliers.

- Push the pliers completely together.

- Open pliers again and remove the stripped wire end.

- The insolation must be cut cleanly and remove from the wires.

- No insolation can remain on bare wires.

- The single wires must not be damaged.

- For the repair remove the corresponding butt connection with a heat-shrinkable tube from the Wiring Harness Repair Set -VAS 631 001-.

- Push the heat-shrinkable tube on one of the wires.

- Place the butt connection -1- in the contact positioner -2-.

- The butt connection -1- must be flush with the contact positioner -2--arrow A-.

- Push the contact cross bar -3- all the way in the direction of the -arrow B- and secure it with the butt clamp -1-.

- The tab -4- on the butt connection -1- must engage in the groove -5- on the contact cross bar -3-.

- Insert the wire -2- with the bare wire end all the way in the butt connection -1--arrow-.

- All single wires must be pushed into the butt connection.

- The insolation end can at a maximum be flush with the front edge of the insolation crimps.

- Close the crimping tool completely until it reopens by itself.

- Push the contact cross bar -2- all the way in the direction of -arrow-.

- Remove the butt connection -1- from the contact positioner -3-.

- Turn the crimping tool for the second crimping.

- Repeat the wire crimping on the other side as described.

- Remove the securing pin -1- in the direction of -arrow A- until it stops.

- Open the mount -2- in the direction of -arrow B-.

- Remove the crimped butt connectors.

Correct crimping results

- The wire ends must project 0.1 mm to 1.0 mm on the front edge of the wire crimps, dimension -a-

- The insolation end must not be crimped in the wire crimps.

- The insolation end can at a maximum be flush with the front edge of the insolation crimps -arrows-.

After crimping the heat-shrinkable tube must positioned over the butt connection and heat-shrunk with a hot air gun, to prevent moisture from entering.

- Insert the Wiring Harness Repair - Blower - Shrink Element -VAS 1978/15A- on the Wiring Harness Repair Set - Hot Air Blower -VAS 1978/14A-.

Caution

Caution

Risk of damaging surrounding components.

- When heat-shrinking the heat-shrinkable tube, be careful not to damage any other wiring, plastic parts or insulating material with the hot nozzle of the hot air blower.

- Always observe operating instructions of heat gun.

- Position the heat-shrinkable tube -1- centered over the butt connection -2-.

- The dimension -a- must be approximately the same on both sides

- Heat the heat-shrinkable tube using the hot air blower lengthwise from center outward until it is sealed completely and adhesive comes out the ends.

- The completed repair location -3- must look like so.

Note

Note

- Make sure that the butt connections do not lie directly next to each other when several wires need to be repaired. Arrange the butt connection at a slight offset so that the circumference of the wiring harness does not become too large.

- If the repair point was previous taped, this point must be taped again with yellow insulating tape after repairs.

- Secure the repaired wiring harness if necessary with a cable tie to prevent flapping noises while driving.