Audi A6 Typ 4G: Rear Brake Pads, Removing and Installing

Brake Pads, Removing and Installing, Steel Brakes

Special tools and workshop equipment required

- Vehicle Diagnostic Tester

- Torque Wrench 1331 5-50Nm -VAG1331-

- Piston Resetting Tool -T10145-

- Lithium grease. Refer to the Parts Catalog.

Removing

- Loosen the parking brake.

- Switch off the ignition.

Note

Note

- Label the brake pads when removing if they are going to be used again. Install in the same position, otherwise the braking effect will be uneven.

- Do not disconnect the connectors from the parking brake motors.

- Remove the affected rear wheel, while observing the safety precautions for vehicles with ceramic brakes. Refer to → Suspension, Wheels and Steering; Rep. Gr.44; Wheels, Tires.

Note

Note

If the brake pads are replaced, use the Vehicle Diagnostic Tester to press back the parking brake pistons.

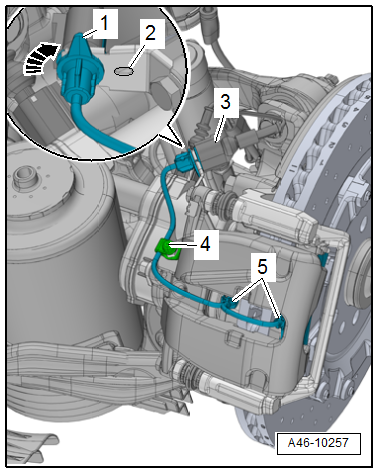

- Connect the Vehicle Diagnostic Tester to the vehicle diagnostic connection when the ignition is switched off.

- Switch the ignition on.

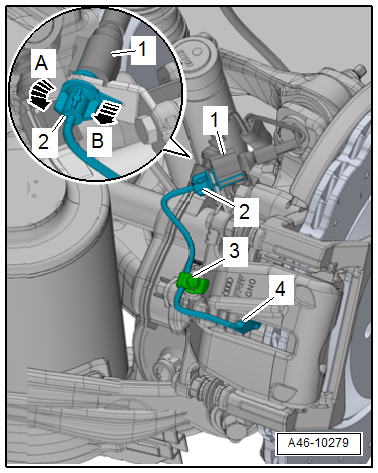

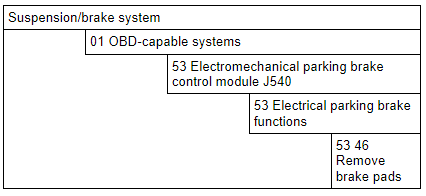

- After entering the VIN, select Guided Functions.

- Drive back the parking brake motor:

- Continue to follow the instructions in the vehicle diagnostic tester display.

- Remove the electrical connection for the electromechanical parking brake from the retainer.

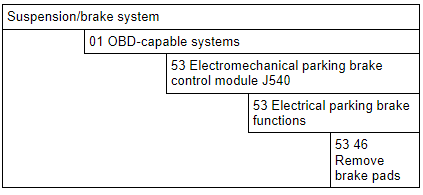

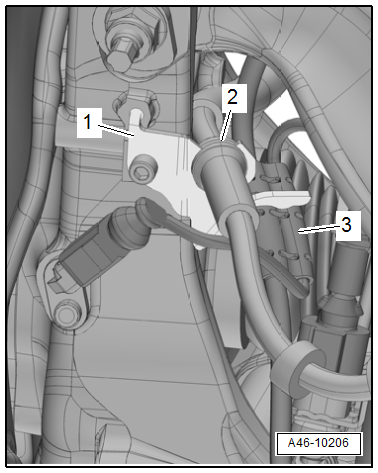

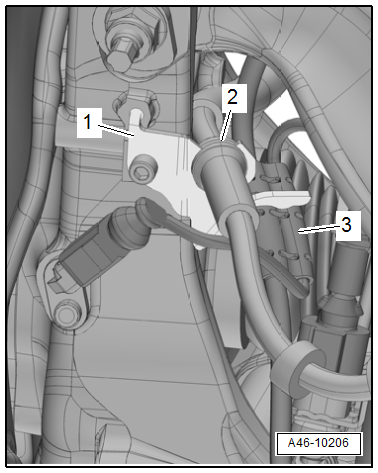

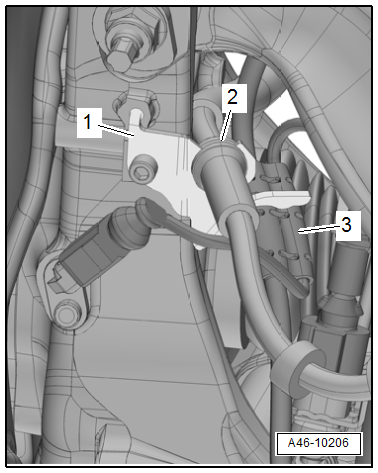

- Free up the brake hose -2- and the wiring harness -3- from the bracket -1-.

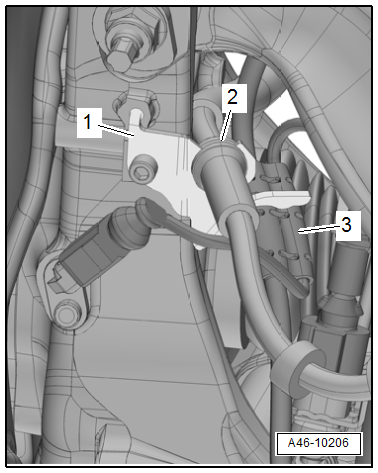

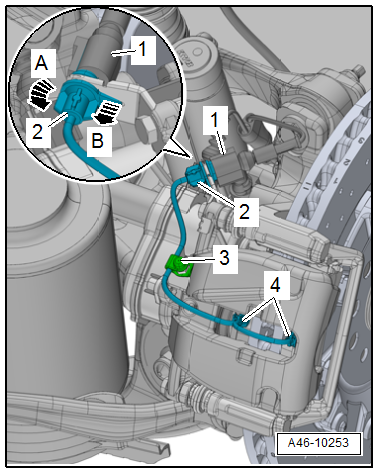

- Disconnect the brake pad wear sensor connector -1-.

- Release the connector -2- to the brake pad wear sensor from its bracket -arrow B- while turning it 90º at the same time -arrow A-.

- Remove the dust cap -3- from the bleed screw and free up the electrical wire.

Note

Note

Ignore -item 4-.

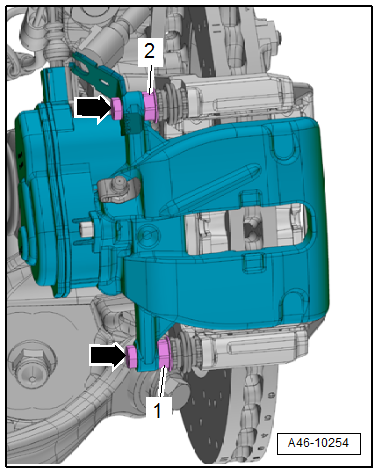

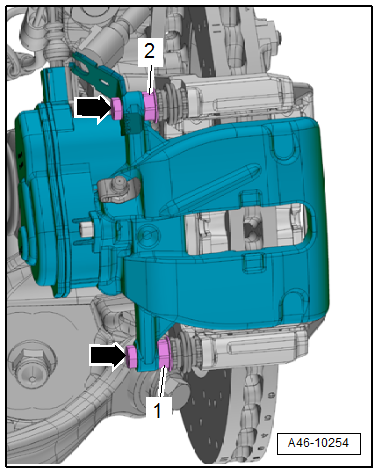

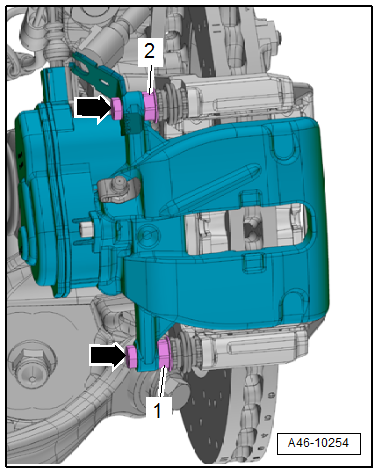

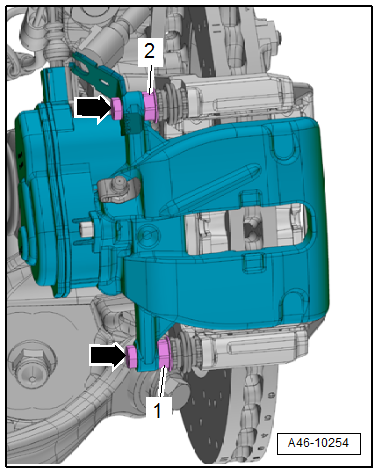

- Remove the bolts -arrows- by counter-holding the guide pins -1 and 2-.

- Remove the brake caliper and guide out the electrical wire for the brake pad wear sensor at the same time.

Caution

Caution

There is a risk of damaging the brake hose.

- Do not let the brake caliper hang on the brake hose. Do not support the weight with the brake hose.

- Replace the brake hose if damaged.

There is a risk of damaging the brake caliper piston.

Do not operate the brakes or the electromechanical parking brake when the brake caliper is removed.

- Hang the brake caliper on the body using a suitable wire.

- Remove the brake pads.

Installing

Install in reverse order of removal and note the following:

- When the brake pads are replaced, check the brake rotors for wear and damage:

- Brake rotor wear limit. Refer to → Chapter "Technical Data, Brakes".

Note

Note

- Always replace brake pads on both sides of the axle.

- Use the complete repair kit when installing new brake pads.

- Replace the brake caliper bolts after removing.

WARNING

WARNING

Health Risk.

Do not blow out brake system with compressed air.

Note

Note

- Use only mineral spirits to clean the brake caliper.

- Check the brake caliper piston protective caps for damage and install the complete repair kit, if necessary. Refer to → Chapter "Brake Caliper Piston, Removing and Installing, 1LU/1LM/1LX/1LN/1LW".

Caution

Caution

There is a risk of contamination and paint damage from escaping brake fluid.

- If the brake pads are worn out and brake fluid is filled unnecessary, the brake fluid may overflow, causing the pistons in the brake cylinders to be pressed back.

- Check the brake fluid level before pressing back the pistons. If there is brake fluid up to the "MAX" mark, some brake fluid will need to be extracted.

- Use the Brake Charger/Bleeder Unit -VAS5234- to extract brake fluid from the brake fluid reservoir.

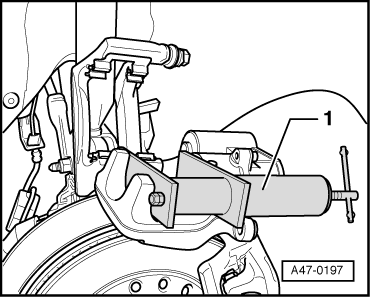

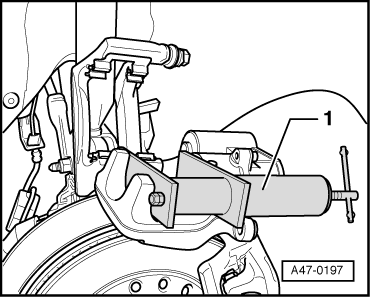

- Use the Piston Resetting Tool -T10145- to completely press back the piston.

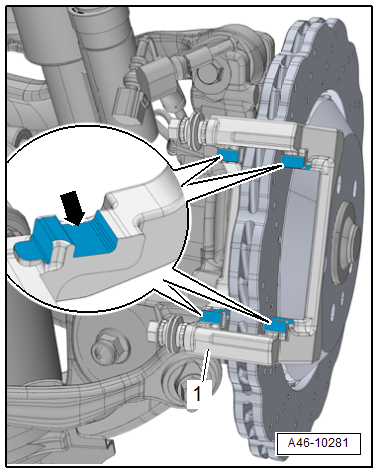

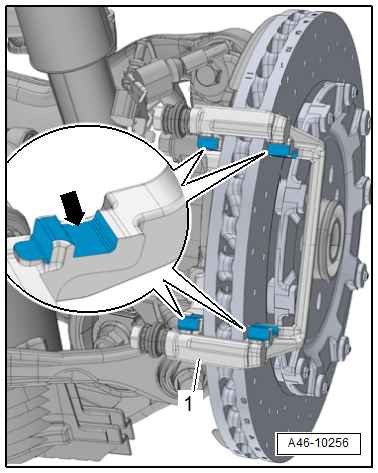

- Clean the brake carrier on the brake pad spring contact surfaces -arrow- and thinly coat them with lithium grease.

- Install the brake pad springs while paying attention to the installed position.

- If reusing, install the marked brake pads in the same location.

- Insert brake pads in brake carrier.

Note

Note

Make sure the brake pads are seated in the brake pad springs -arrows-.

- Push the brake caliper over the installed brake pads.

Note

Note

If the previous brake pads are being installed again, guide the brake pad wear indicator wire through the brake caliper.

- Tighten the new brake caliper bolts -arrows- by counter-holding the guide pins -1 and 2-.

- Secure the brake hose -2- and wiring harness -3- in the bracket -1-.

Note

Note

- Make sure that the electrical wire and brake hose are routed correctly.

- Make sure the brake hose is not blocked, bent, twisted or rubbing against the vehicle.

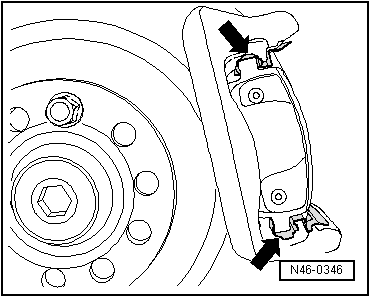

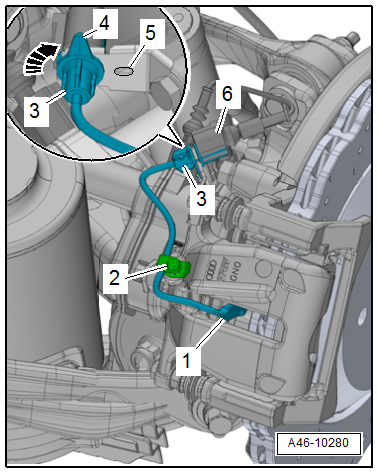

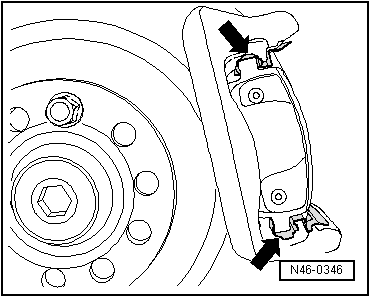

- If new brake pads are being installed, insert the brake pad wear sensor contact -1- into the inner brake pad until it engages.

Note

Note

Make sure that the contact fits correctly in the brake pad.

- Secure the brake pad wear indicator wire with the dust cap -2- as shown.

- Bring the connector -3- into its installed position and turn in the direction of the -arrow- until the tab -4- engages in the hole -5- on the bracket.

- Assemble connector -6-.

- Install the rear wheel. Refer to → Suspension, Wheels, Steering; Rep. Gr.44; Wheels, Tires.

- With the vehicle stationary, firmly press the brake pedal several times so that the brake pads in the operating condition properly sit in their respective position.

- Drive the parking brake motors up using the Vehicle Diagnostic Tester by following the instructions in the display.

WARNING

WARNING

Risk of accident!

- With the vehicle stationary, firmly press the brake pedal several times so that the brake pads in the operating condition properly sit in their respective position.

- Make sure the brakes are working correctly before driving the vehicle for the first time.

Brake Pads, Removing and Installing, Ceramic Brakes

Special tools and workshop equipment required

- Vehicle Diagnostic Tester

- Torque Wrench 1331 5-50Nm -VAG1331-

- Piston Resetting Tool -T10145-

- Lithium grease. Refer to the Parts Catalog.

Removing

- Loosen the parking brake.

- Switch off the ignition.

Note

Note

- Label the brake pads when removing if they are going to be used again. Install in the same position, otherwise the braking effect will be uneven.

- Do not disconnect the connectors from the parking brake motors.

- Remove the affected rear wheel. Refer to → Suspension, Wheels, Steering; Rep. Gr.44; Wheels, Tires.

Note

Note

If the brake pads are replaced, use the Vehicle Diagnostic Tester to press back the parking brake pistons.

- Connect the Vehicle Diagnostic Tester to the vehicle diagnostic connection when the ignition is switched off.

- Switch the ignition on.

- After entering the VIN, select Guided Functions.

- Drive back the parking brake motor:

- Continue to follow the instructions in the vehicle diagnostic tester display.

- Free up the brake hose -2- and the wiring harness -3- from the bracket -1-.

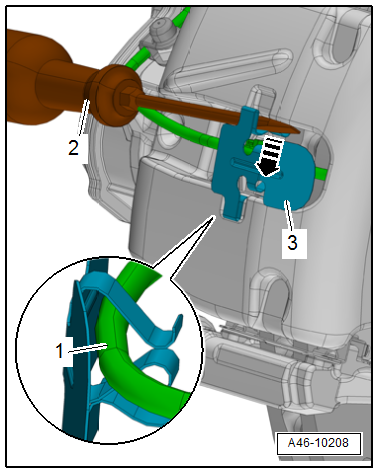

- Unclip the bracket -3- with a screwdriver -2--arrow-.

- Free up the electrical brake pad wear sensor wire -1-.

- Disconnect the brake pad wear sensor connector -1-.

- Release the connector -2- to the brake pad wear sensor from its bracket -arrow B- while turning it 90º at the same time -arrow A-.

- Remove the dust cap -3- from the bleed screw and free up the electrical wire.

Note

Note

Ignore -item 4-.

- Remove the bolts -arrows- by counter-holding the guide pins -1 and 2-.

- Remove the brake caliper and guide out the electrical wire for the brake pad wear sensor at the same time.

Caution

Caution

There is a risk of damaging the brake hose.

- Do not let the brake caliper hang on the brake hose. Do not support the weight with the brake hose.

- Replace the brake hose if damaged.

There is a risk of damaging the brake caliper piston.

Do not operate the brakes or the electromechanical parking brake when the brake caliper is removed.

- Hang the brake caliper on the body using a suitable wire.

- Remove the brake pads and brake pad springs.

Installing

Install in reverse order of removal and note the following:

- When the brake pads are replaced, check the brake rotors for wear and damage:

- Cracks in connection area. Refer to → Chapter "Cracks in Ceramic Brake Rotor Connection Area".

- Chamfer. Refer to → Chapter "Chamfer".

- Nicks. Refer to → Chapter "Nicks on Ceramic Brake Rotor".

- Crack in cooling channel. Refer to → Chapter "Crack in Cooling Channel".

- Brake Rotor Thickness. Refer to → Chapter "Ceramic Brake Rotor, Determining Wear".

Note

Note

- Always replace brake pads on both sides of the axle.

- Use the complete repair kit when installing new brake pads.

- Replace the brake caliper bolts after removing.

WARNING

WARNING

Health Risk.

Do not blow out brake system with compressed air.

Note

Note

- Use only mineral spirits to clean the brake caliper.

- Check the brake caliper piston protective caps for damage and install the complete repair kit, if necessary. Refer to → Chapter "Brake Caliper Piston, Removing and Installing".

Caution

Caution

There is a risk of contamination and paint damage from escaping brake fluid.

- If the brake pads are worn out and brake fluid is filled unnecessary, the brake fluid may overflow, causing the pistons in the brake cylinders to be pressed back.

- Check the brake fluid level before pressing back the pistons. If there is brake fluid up to the "MAX" mark, some brake fluid will need to be extracted.

- Use the Brake Charger/Bleeder Unit -VAS5234- to extract brake fluid from the brake fluid reservoir.

Note

Note

- When using the Vehicle Diagnostic Tester to press back the pistons, the thrust nut drives back on the spindle.

- The piston must then be completely pressed back using the Piston Resetting Tool -T10145-

- Use the Piston Resetting Tool -T10145- to completely press back the piston.

- Clean the brake carrier on the brake pad spring contact surfaces -arrow- and thinly coat them with lithium grease.

- Install the brake pad springs while paying attention to the installed position.

- If reusing, install the marked brake pads in the same location.

- Insert brake pads in brake carrier.

Note

Note

Make sure the brake pads are seated in the brake pad springs -arrows-.

- Push the brake caliper over the installed brake pads.

Note

Note

If the previous brake pads are being reinstalled, the electrical wire for the brake pad wear sensor must be guided through the brake caliper.

- Tighten the new brake caliper bolts -arrows- by counter-holding the guide pins -1 and 2-.

- Secure the brake hose -2- and wiring harness -3- in the bracket -1-.

Note

Note

- Make sure that the electrical wire and brake hose are routed correctly.

- Make sure the brake hose is not blocked, bent, twisted or rubbing against the vehicle.

- If new brake pads are being installed, insert the brake pad wear sensor contacts -5- in the brake pads until they engage.

Note

Note

Make sure that the brake pad wear sensor contacts fit correctly in the brake pads.

- Secure the electrical wire for the brake pad wear sensor with the dust cap -4- as illustrated.

- Bring the connector into its installed position and turn in the direction of the -arrow- until the tab -1- engages in the hole -2- on the bracket.

- Connect the connector -3-.

- Install the rear wheel, while observing the safety precautions for vehicles with ceramic brakes. Refer to → Suspension, Wheels and Steering; Rep. Gr.44; Wheels, Tires.

- With the vehicle stationary, firmly press the brake pedal several times so that the brake pads in the operating condition properly sit in their respective position.

- Drive the parking brake motors up using the Vehicle Diagnostic Tester by following the instructions in the display.

WARNING

WARNING

Risk of accident!

- With the vehicle stationary, firmly press the brake pedal several times so that the brake pads in the operating condition properly sit in their respective position.

- Make sure the brakes are working correctly before driving the vehicle for the first time.