Audi A6 Typ 4G: Axle Alignment Specified Values

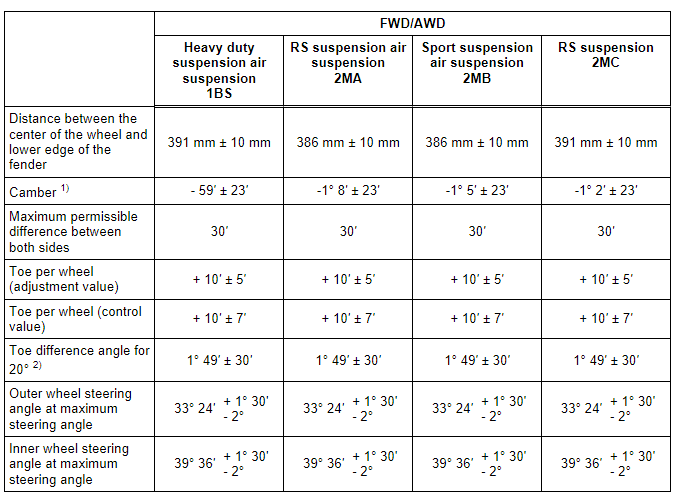

Axle Alignment Specified Values, Sportback Front Axle

Note

Note

The specified values apply to all engine versions.

.png)

1) On RHD vehicles, the camber must be determined based on the distance between the wheel center and the lower edge of the fender.

2) Wheel stop on outer wheel is reduced by this amount. It can also be indicated negatively in alignment computer, depending on manufacturer.

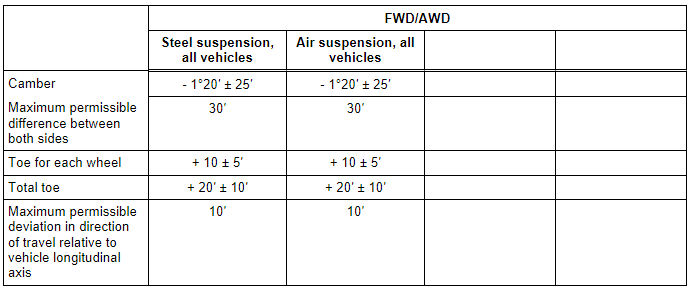

1) On RHD vehicles, the camber must be determined based on the distance between the wheel center and the lower edge of the fender.

2) Wheel stop on outer wheel is reduced by this amount. It can also be indicated negatively in alignment computer, depending on manufacturer.

Additional Vehicle Data for Vehicles with FWD and AWD:

This additional vehicle data only serves for a faster diagnosis in the case of accidents.

Table. Refer to → Chapter "Suspension".

Axle Alignment Specified Values, Sportback Rear Axle

Note

Note

The specified values apply to all engine versions.

Additional Vehicle Data for Vehicles with FWD and AWD:

This additional vehicle data only serves for a faster diagnosis in the case of accidents.

Table. Refer to → Chapter "Suspension".

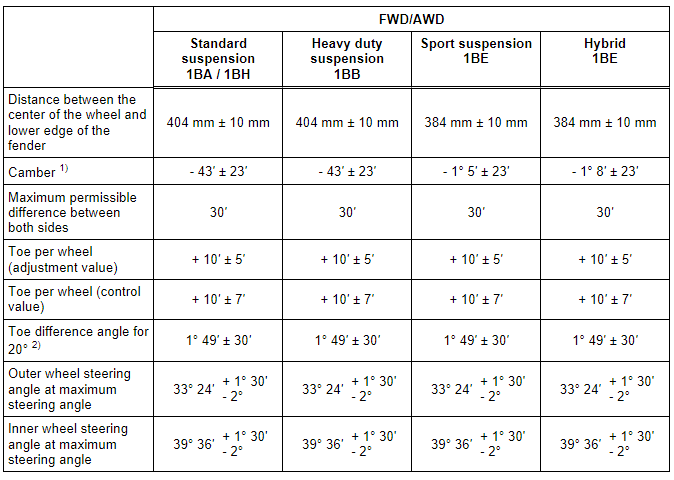

Axle Alignment Specified Values, Sedan/Avant Front Axle

Note

Note

The specified values apply to all engine versions.

1) On RHD vehicles, the camber must be determined based on the distance between the wheel center and the lower edge of the fender.

2) Wheel stop on outer wheel is reduced by this amount. It can also be indicated negatively in alignment computer, depending on manufacturer.

.png)

1) On RHD vehicles, the camber must be determined based on the distance between the wheel center and the lower edge of the fender.

2) Wheel stop on outer wheel is reduced by this amount. It can also be indicated negatively in alignment computer, depending on manufacturer.

.png)

1) On RHD vehicles, the camber must be determined based on the distance between the wheel center and the lower edge of the fender.

2) Wheel stop on outer wheel is reduced by this amount. It can also be indicated negatively in alignment computer, depending on manufacturer.

Additional Vehicle Data for Vehicles with FWD and AWD:

This additional vehicle data only serves for a faster diagnosis in the case of accidents.

Table. Refer to → Chapter "Suspension".

Axle Alignment Specified Values, Sedan/Avant Rear Axle

Note

Note

The specified values apply to all engine versions.

.png)

Additional Vehicle Data for Vehicles with FWD and AWD:

This additional vehicle data only serves for a faster diagnosis in the case of accidents.

Table. Refer to → Chapter "Suspension".

Axle Alignment Procedure

Note

Note

- Vehicle must only be measured in the control position or curb weight position. Refer to → Chapter " Test Prerequisites"!

- Check which suspension is installed in the vehicle. This information can be found on the vehicle data plate. Refer to → Chapter "Production Control Number (PR number) Explanation".

Observe the Following Work Sequence!

1 - Drive the vehicle onto the alignment rack without tension. Move the vehicle back and forth if necessary to relieve any tension on the axle components.

2 - The steering wheel must be "evened out" into the center position before beginning the measuring and adjusting. Use Steering Wheel Scales -VAS 6458- for this.

3 - Perform wheel run-out compensation. Refer to → Chapter "Wheel Run-Out Compensation".

4 - Check the maximum steering angle. Refer to → Chapter "Maximum Steering Angle, Checking".

5 - Check rear axle camber and adjust if necessary. Refer to → Chapter "Rear Axle Camber, Adjusting".

6 - Check rear axle toe and adjust if necessary. Refer to → Chapter "Rear Axle Toe, Adjusting".

7 - Check front axle camber and adjust if necessary. Refer to → Chapter "Front Axle Camber, Adjusting".

8 - Check the front axle toe and adjust if necessary. Refer to → Chapter "Front Axle Toe, Adjusting".

Note

Note

If the adjustments on the suspension were changed, then perform a zero compensation on the Steering Angle Sensor -G85- with the Vehicle Diagnostic Tester.

Perform a basic setting on the dynamic steering, if equipped, if adjustments on the front and/or rear axles were changed. Refer to → Chapter "Dynamic Steering Basic Setting".

If the rear axle setting was corrected, then the ACC sensors must be adjusted on vehicles with ACC (refer to → Chapter "Adaptive Cruise Control (ACC), Calibrating"), the lane assist must be calibrated on vehicles with lane assist (refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating"), the night vision system must be adjusted/calibrated on vehicles with infrared system (refer to → Chapter "Infrared System, Calibrating") and the rearview camera must be calibrated on vehicles with a rearview camera. Refer to → Communication; Rep. Gr.91; Rearview Camera System; Rearview Camera System, Aligning and Calibrating.

Evaluating Need for Axle Alignment

- Vehicle shows handling problems.

- Involved in an accident.

- Axle components have been removed or replaced.

- Tire wear patterns are uneven.

.png)

1) Even if the subframe was secured with the Subframe Locating Pins -T40242-, an axle alignment may be necessary. Perform a road test. Refer to → Chapter "Subframe, Securing, FWD".

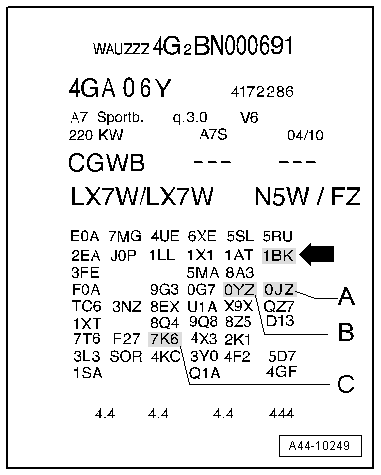

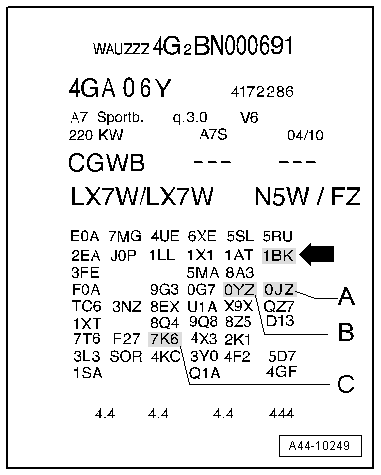

Production Control Number (PR number) Explanation

The vehicle data plate documents which front/rear axle or tire pressure monitoring system is installed using the corresponding PR numbers.

There is a vehicle data label in the spare wheel well and also one in the customer Maintenance booklet.

Front/Rear Axle

The front/rear axle PR No. is in illustration -A and B-.

- The front axle PR number is Item -A-.

- Item -B- shows PR number for rear axle

Use the PR number to find the correct shock absorber combination in the Parts Catalog.

Suspension Versions

The suspension version PR No. is in illustration -arrow-

In this example the vehicle has standard suspension 1BK installed.

1BA / 1BH= Standard suspension

1BE = Sport suspension

1BB/1BR = Heavy duty suspension

1BK = Standard suspension air suspension

1BS = Heavy duty suspension air suspension

1BV = Sport suspension S line

1BY = allroad

2MA = RS suspension air suspension

2MB = Sport suspension air suspension

2MC = RS suspension

Tire Pressure Monitoring System/Tire Pressure Monitoring System Display

The tire pressure monitoring system PR number can be found in ELSA in Vehicle Individual under "Vehicle Data".

7K0 = Without tire pressure monitoring system

7K6 = Tire pressure monitoring system display

7K8 = Tire pressure monitoring system, frequency 315 MHz Basis

Driver Assist System

The driver assist system PR number can be found in ELSA in Vehicle Individual under "Vehicle Data".

1N7, 1N8 = dynamic steering

7Y2 = Lane assist

7Y3 = Lane change assistance and lane assist

7Y4 = Lane assist (Heading Control Assist)

8T4 = Adaptive cruise control (ACC)

8T5 = Adaptive cruise control plus cruise control

9R1 = Night vision system