Audi A6 Typ 4G: Driver Assistance Systems Front Camera

Driver Assistance Systems Front Camera, Calibrating

Special tools and workshop equipment required

- Setting Device Basic Set -VAS6430/1-

- Vehicle Diagnostic Tester

- Wheel Alignment Computer

Note

Note

- Make sure the Camera Control Module -J852- fits correctly in the bracket.

- Perform a visual inspection to see if the camera visual area is free.

- Check the Diagnostic Trouble Code (DTC) memory and correct any malfunctions before beginning the calibration.

There Are Two Choices for Calibrating:

The "Quick Access"

This procedure should be selected for the following activities if only the calibration will be performed.

- "No or incorrect basic setting/adaptation" is stored actively in the DTC memory.

- The Camera Control Module -J852- was removed and installed again or replaced,

- The windshield is replaced or removed,

- The control position on vehicles with air suspension was reprogrammed.

The "Complete Alignment"

This procedure should be selected for the following activities if a calibration and a suspension adjustment will be performed.

- The rear axle toe was adjusted.

- The vehicle suspension was changed, for example, changing from standard to sport suspension.

Note

Note

Both procedures are programmed into the axle alignment computer. The respective procedure is performed automatically. It is only necessary to select the appropriate program for the procedure that will be performed.

Preparation work for calibrating and adjusting driver assist systems. Refer to → Chapter "Preparation Work for Calibrating and Adjusting Driver Assist Systems".

Calibration/adjusting without a previous axle alignment

- Select calibrate the lane assist / Camera Control Module - J852- in the wheel alignment computer.

- Install the quick clamps on all four wheels.

- Mount the measurement sensor to the rear wheels.

- Perform a wheel run-out compensation and the rear wheels.

Calibrating/adjusting with a previous axle alignment

- Connect the battery charger. Refer to → Electrical Equipment; Rep. Gr.27; Battery; Battery, Charging.

- Position the front wheels so they are straight.

- Connect the Vehicle Diagnostic Tester to the vehicle and guide the diagnostic cable through the open window.

- Turn off all vehicle exterior lamps.

- Close all vehicle door.

Calibration/adjusting procedure with or without a previous axle alignment

- Select calibration/adjusting on the wheel alignment computer.

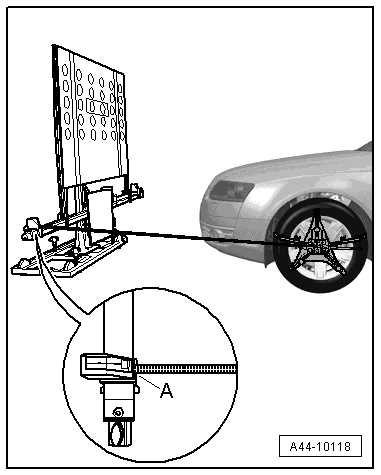

- Position the Setting Device Basic Set -VAS6430/1- at a distance of -A- 150 cm +- 2.5 cm from the center of the wheel hub on the front wheels to the beam on the Setting Device Basic Set -VAS6430/1- as shown in the illustration.

Note

Note

The Setting Device Basic Set -VAS6430/1- must not be moved on the calibration beam.

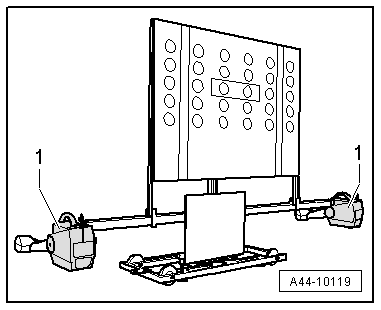

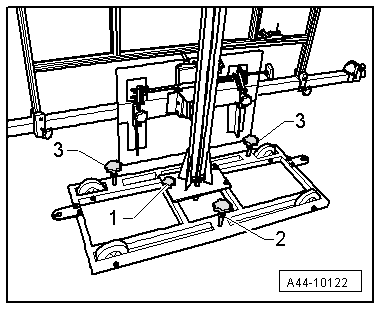

- Mount the front wheel measuring sensors -1- to the Setting Device Basic Set -VAS6430/1-.

Note

Note

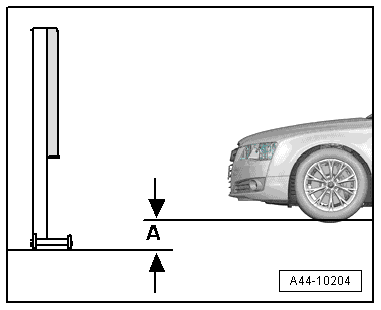

The alignment stand must be in the lowest level position for the next step.

- Enter the height value -A- between the Setting Device Basic Set -VAS6430/1- contact patch and the wheel contact surface as shown in the illustration and enter it in the alignment computer.

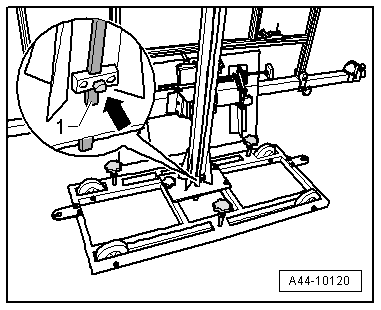

- Loosen the bolt -arrow- and place the measuring bar -1- on the floor.

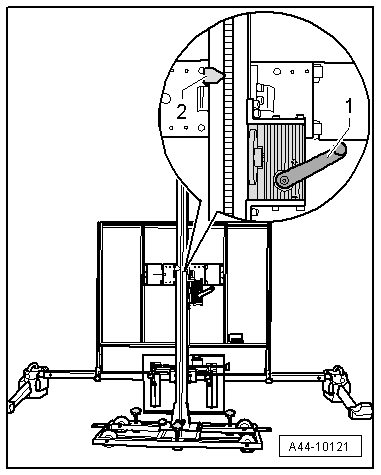

- Adjust the calibration panel to the specified height -2- according to the alignment computer using the crank -1-.

If the specified height was reached -2-, then the measuring bar must be pushed slightly upward and secured with the clamping screw.

Note

Note

If in later procedure the height of the calibration board must be corrected, make sure the measuring bar is touching the ground when this is being done.

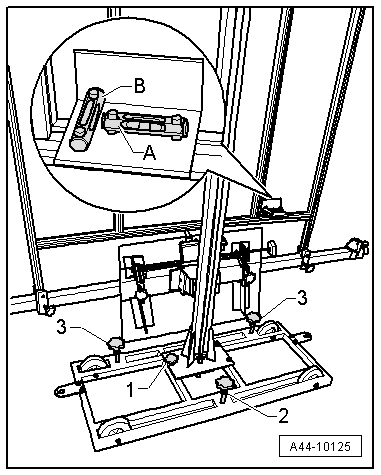

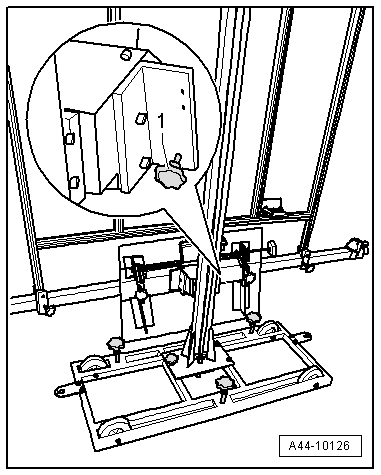

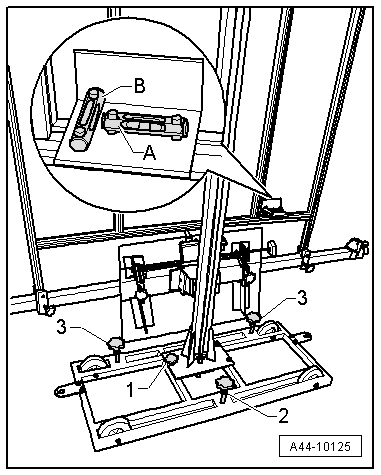

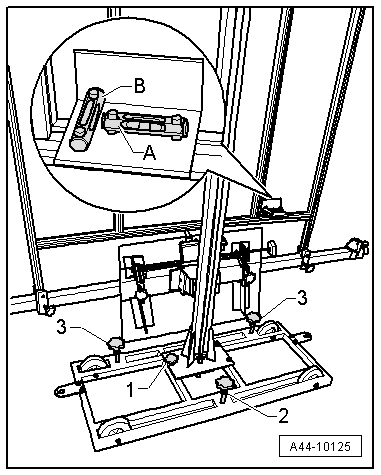

- Level the bubble level -A- using the adjusting screw -1-.

The bubble adjustment -A- serves to compare the ground conditions.

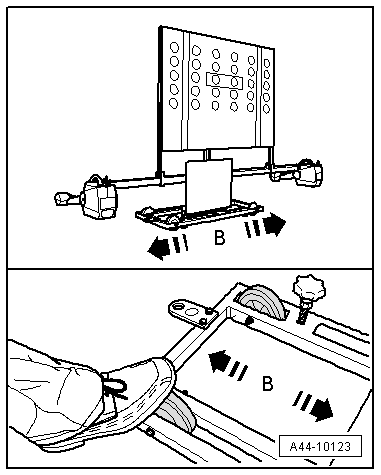

- Move the Setting Device Basic Set -VAS6430/1- sideways -arrow B- until the display on the alignment computer is within the tolerance range.

- Secure the Setting Device Basic Set -VAS6430/1- by tightening the bolts -2- and -3- slightly. (This prevents the Setting Device Basic Set -VAS 6430- from rolling away).

- Turn the precision adjustment screw -1- until the display on the wheel alignment computer is located within the tolerance range.

- Level the bubble level -A- using the adjusting screw -1-.

- Level the bubble level -B- using the adjusting screw -2-.

Perform any subsequent work using the Vehicle Diagnostic Tester.

- Connect the Vehicle Diagnostic Tester and proceed with a vehicle-specific entry in Guided Fault Finding.

Wait until the Vehicle Diagnostic Tester has checked all the vehicle control module.

- Press the GO TO button and select "function/component selection".

- Select the program in Guided Functions.

Now follow the instructions on the screen to perform the calibration.

Note

Note

A step is performed in guided fault finding next to determine the body height.

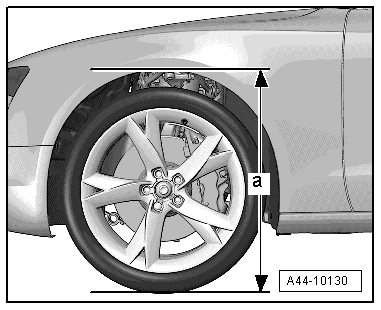

- Determine the body height -a- at all four wheels in the center of the wheel between the wheel contact surface and the lower edge of the fender.