Audi A6 Typ 4G: Lane Change Assistance

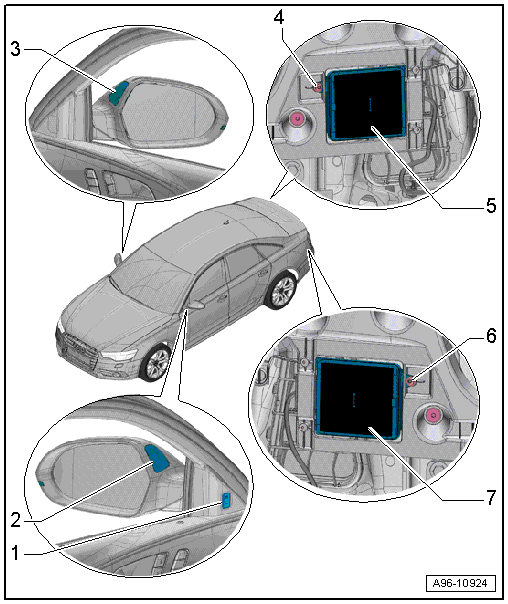

Overview - Lane Change Assistance

1 - Lane Change Assistance Button -E530-

- Removing and installing. Refer to → Chapter "Lane Change Assistance Button -E530-, Removing and Installing".

2 - Lane Change Assistance Warning Lamp In Driver Exterior Rearview Mirror -K233-

- Removing and installing. Refer to → Chapter "Lane Change Assistance Warning Lamp In Driver/Front Passenger Exterior Rearview Mirror -K233-/-K234-, Removing and Installing".

3 - Lane Change Assistance Warning Lamp In Front Passenger Exterior Rearview Mirror -K234-

- Removing and installing. Refer to → Chapter "Lane Change Assistance Warning Lamp In Driver/Front Passenger Exterior Rearview Mirror -K233-/-K234-, Removing and Installing".

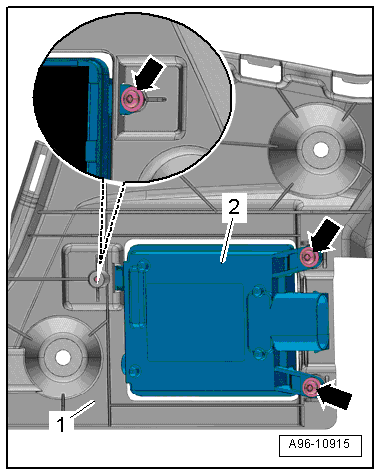

4 - Screw

- 2 Nm

- Quantity: 3

5 - Lane Change Assistance Control Module -J769-

- Removing and installing. Refer to → Chapter "Lane Change Assistance Control Module -J769-/Lane Change Assistance Control Module 2 -J770-, Removing and Installing".

- Calibrating. Refer to → Chapter "Lane Change Assistance, Calibrating".

6 - Screw

- 2 Nm

- Quantity: 3

7 - Lane Change Assistance Control Module 2 -J770-

- Removing and installing. Refer to → Chapter "Lane Change Assistance Control Module -J769-/Lane Change Assistance Control Module 2 -J770-, Removing and Installing".

- Calibrating. Refer to → Chapter "Lane Change Assistance, Calibrating".

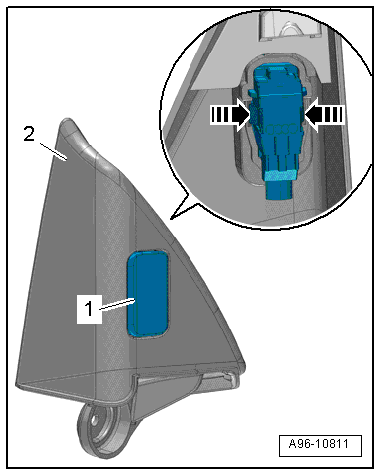

Lane Change Assistance Button -E530-, Removing and Installing

Removing

- Remove the inner cover. Refer to → Body Interior; Rep. Gr.70; Front Door Trim Panels; Overview - Front Door Trim Panel.

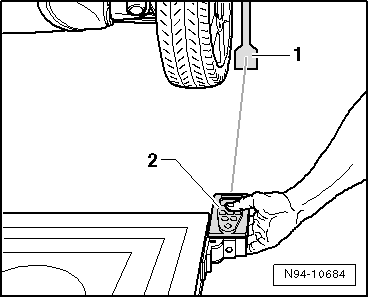

- Release the tabs in direction of -arrows- and remove the lane change assistance button -1- from the cover -2-.

Installing

Install in reverse order of removal.

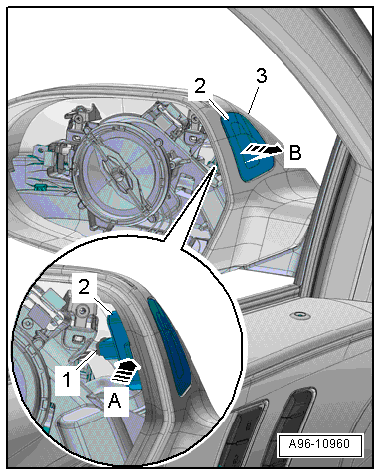

Lane Change Assistance Warning Lamp In Driver/Front Passenger Exterior Rearview Mirror -K233-/-K234-, Removing and Installing

Removing

- Remove the mirror glass. Refer to → Body Exterior; Rep. Gr.66; Exterior Rearview Mirror; Mirror Glass, Removing and Installing.

- Disconnect the connector -1-.

- Open the tab in direction of -arrow A- and remove the warning lamp -2- from the exterior rearview mirror housing -3- in direction of -arrow B-.

Installing

Install in reverse order of removal. Note the following:

Note

Note

If an LED is faulty, the entire lane change assistance warning lamp in the exterior rearview mirror must be replaced.

Lane Change Assistance Control Module -J769-/Lane Change Assistance Control Module 2 -J770-, Removing and Installing

Removing

- Remove the bumper cover exterior mount. Refer to → Body Exterior; Rep. Gr.63; Rear Bumper; Attachments, Removing and Installing.

- Remove the bolts -arrows-.

- Remove the lane change assistance control module -2- from the mount -1-.

Installing

Install in reverse order of removal. Note the following:

- Calibrate the Lane Change Assistance Control Module -J769-/Lane Change Assistance Control Module 2 -J770-. Refer to → Chapter "Lane Change Assistance, Calibrating".

Lane Change Assistance, Calibrating

Special tools and workshop equipment required

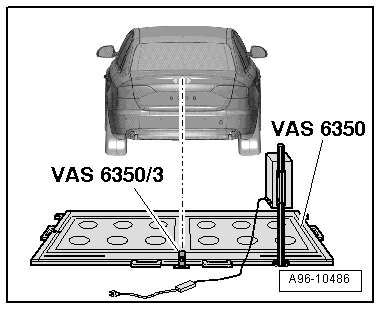

- Calibration Tool -VAS6350-

Conditions

- The Calibrate the Lane Change Assistance Control Module -J769-/Lane Change Assistance Control Module 2 -J770- must be calibrated in the "Guided Fault Finding" or "Guided Functions" operating mode under the following conditions using the Vehicle Diagnostic Tester:

- Lane Change Assistance Control Module -J769- or Lane Change Assistance Control Module 2 -J770- was replaced.

- The rear bumper cover was damaged.

- The rear bumper cover was removed and installed.

- The DTC "no or incorrect basic setting/adaptation" is stored in the DTC memory.

Preparing for Calibration

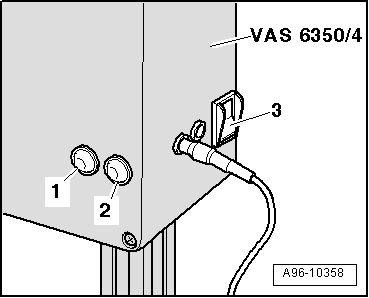

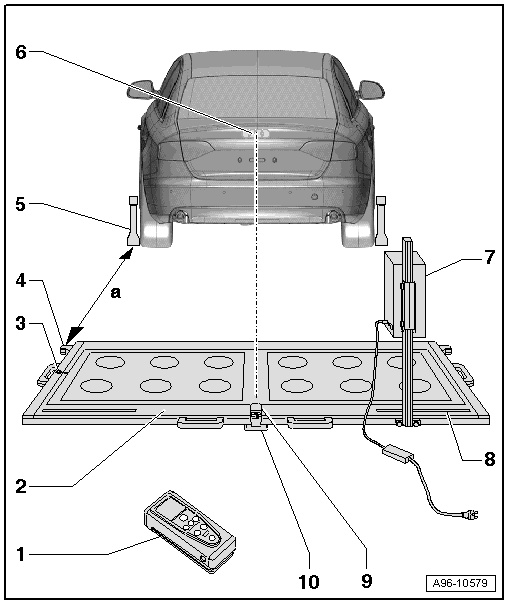

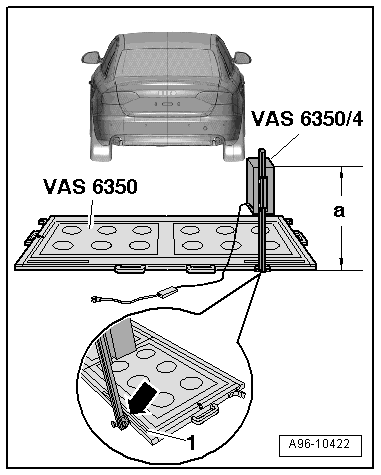

1 - Calibration Tool - Spacing Laser -VAS6350/2-

- For distance measurement

- For information on usage. Refer to the Calibration Tool -VAS6350- Operating Instructions

2 - Calibration Tool -VAS6350-

3 - Level

- On the Calibration Tool -VAS6350-

- To check the horizontal position of the Calibration Tool -VAS6350-

4 - Catch Bracket

- To mount the Calibration Tool - Spacing Laser -VAS6350/2- for the distance measurement

- Distance to the Calibration Tool - Wheel Center Mounting -VAS6350/1- on the rear wheels: dimension -a- = 1700 +- 2 mm

5 - Calibration Tool - Wheel Center Mounting -VAS6350/1-

- With wheel bolt adapter and measuring paddle

6 - Brand Emblem

- The laser point is aligned on the center of the brand emblem

7 - Calibration Tool - Lane Change Calibration Tool -VAS6350/4-

- Is moved from one side of measuring field to the other during calibration

- When installed correctly, vehicle electrical system voltage line must be connected at bottom left of calibration tool (as seen in direction of travel)

8 - Measurement Scale

- For positioning the Calibration Tool - Lane Change Calibration Tool -VAS6350/4-

9 - Calibration Tool - Linear Laser -VAS6350/3-

- With "laser eye protection"

- On the Calibration Tool -VAS6350-

- To turn on and off. Refer to the Calibration Tool -VAS6350- Operating Instructions

10 - Plastic Foot

- Quantity: 3

- Can be adjusted for adjusting the horizontal position of the Calibration Tool -VAS6350-

Procedure

- Move the vehicle onto a solid, flat surface.

- Set the parking brake - the vehicle must not move during the measuring.

- Place the front wheels in a straight-ahead position - steering wheel in 0 position.

- Connect the Vehicle Diagnostic Tester.

Note

Note

If a malfunction message appears in the display using the Vehicle Diagnostic Tester.

- Turn on the ignition.

- Remove the label with the metal foil from the bumper cover, if necessary.

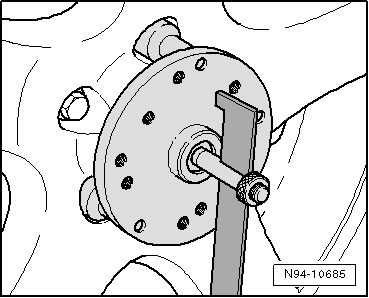

- Secure three suitable wheel bolt adapters for the wheel bolts on each Calibration Tool - Wheel Center Mounting -VAS6350/1-.

- Insert the measuring paddle on both Calibration Tool - Wheel Center Mounting -VAS6350/1- and secure it with the locking nut.

- Place the Calibration Tool - Wheel Center Mounting -VAS6350/1- onto the wheel bolts on both rear wheels.

- The wheel center sensor rotation center must be in wheel rotation center.

Note

Note

Place the Calibration Tool - Wheel Center Mounting -VAS6350/1- on wheels so that "anti-theft wheel bolts" are not connected with wheel center mounting.

- Adjust the measuring paddle with aid of lock nuts so that they move freely just above the floor.

- The measuring paddles must move easily.

- The measuring paddles must be vertical.

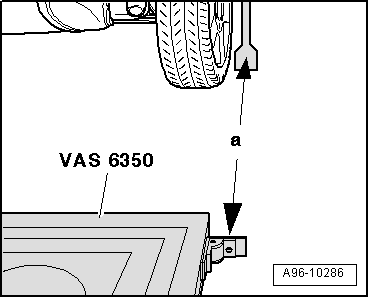

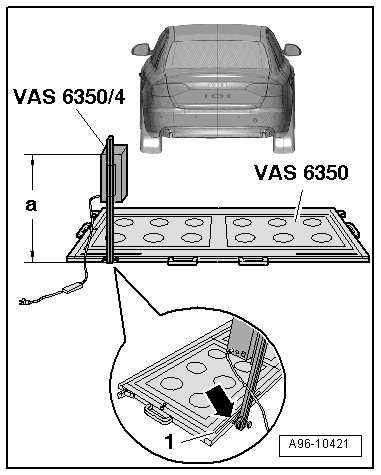

- Position the Calibration Tool -VAS6350- at distance -a- to the rear wheels.

- Dimension -a- = 1,700 mm

- Switch on the Calibration Tool - Spacing Laser -VAS6350/2- with the ON button.

Display on the Calibration Tool - Spacing Laser -VAS6350/2-:

- "- - - m"

Note

Note

The laser is switched on at same time.

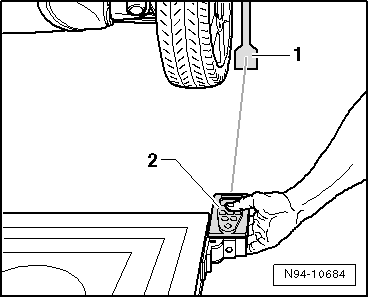

- For distance measurement, hold the Calibration Tool - Spacing Laser -VAS6350/2--item 2- flush to the right stop bracket as illustrated.

- The Calibration Tool - Spacing Laser -VAS6350/2- must lie firmly against the catch bracket.

- Make sure the "laser beam" for the distance measurement contacts the enlarged lower part on the paddle -1-.

If this is not the case, measure paddle height must be corrected using locking nuts on Calibration Tool - Wheel Center Mounting -VAS6350/1-.

- Briefly press ON button for distance measurement.

Display on the Calibration Tool - Spacing Laser -VAS6350/2-:

- "1.700 m" (specified value: 1700 +- 2 mm).

- Repeat the measuring procedure from the left catch bracket to the left rear wheel

- The distance value must be the same on both sides.

If both measured values are not the same, adjust the Calibration Tool -VAS6350- accordingly.

Performing Calibration

Vehicle Diagnostic Tester is attached.

- Select the Diagnostic mode and start the diagnostics.

- Select the tab test plan.

- Select select individual tests and choose the following sequence.

- Body

- Electrical Equipment

- 01 - OBD-capable systems

- 3C - Lane change assistance control module - J769

- 3C - Lane change assistance control module, functions

- 3C - Calibration

From here using the Vehicle Diagnostic Tester advances the calibration procedure forward.

Note

Note

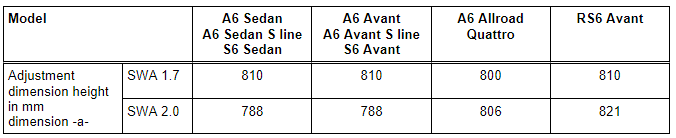

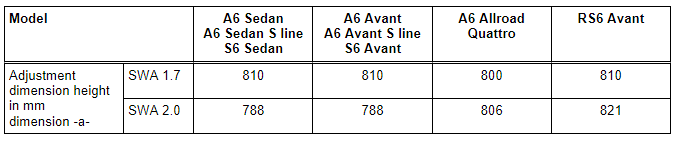

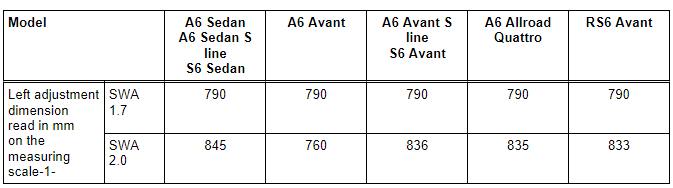

- The following information clarifies which version of the lane change assist is installed (version SWA1.7).

- This information for adjusting the calibration device is important for later steps in the procedure to avoid malfunctions.

- Secure the right rear Calibration Tool - Lane Change Calibration Tool -VAS6350/4- to the Calibration Tool -VAS6350- mount.

- When installed correctly, vehicle electrical system voltage line must be connected at bottom left of calibration device (as seen in direction of travel).

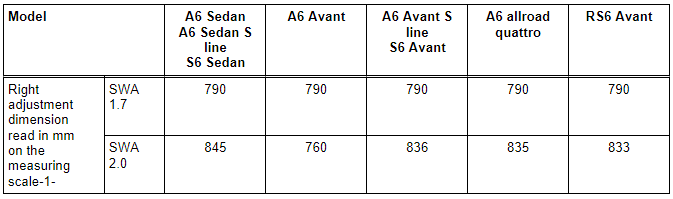

Dimension -a- is measured from the upper edge of calibration device to the floor.

- The indicator on the base of the Calibration Tool - Lane Change Calibration Tool -VAS6350/4- must align with adjustment dimension on the measuring scale -1- on measuring field -arrow-.

- Connect the Calibration Tool - Lane Change Calibration Tool -VAS6350/4- to the vehicle electrical system voltage.

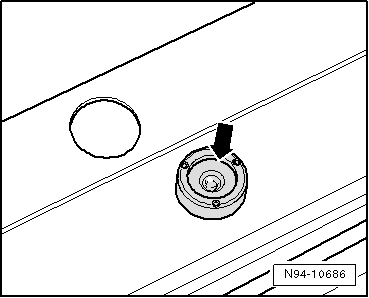

- Bring Calibration Tool -VAS6350- into horizontal position by turning the plastic feet.

- Observe the bubble level (sight glass) on the Calibration Tool -VAS6350--arrow-.

- Turn on the Calibration Tool - Linear Laser -VAS6350/3- on the Calibration Tool -VAS6350-.

- Wear "laser protective eyewear".

- Align the Calibration Tool -VAS6350- so that the Calibration Tool - Linear Laser -VAS6350/3- strikes the center of the brand emblem on the rear lid.

- Check left and right distance between catch bracket on Calibration Tool -VAS6350- and measuring paddle -1- on wheel mountings again.

- Specified value: 1700 +- 2 mm

Calibration Procedure

The following should not occur during the calibration procedure:

- No metal reflectors may be located within a two m radius of the calibration device (for example, tool carts, metal cabinets).

- Vehicle doors must not be opened or closed.

- People should not sit in the vehicle.

- People must not go between the vehicle and the Calibration Tool - Lane Change Calibration Tool -VAS6350/4-.

Procedure

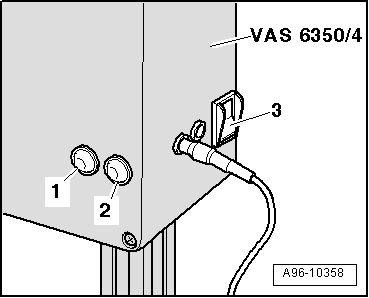

- Turn on the Calibration Tool - Lane Change Calibration Tool -VAS6350/4- on the voltage switch -3-.

- The green LED -1- must light up.

Note

Note

If the red LED -2- illuminates: Check the Calibration Tool - Lane Change Calibration Tool -VAS6350/4-.

- Follow the instructions in the Vehicle Diagnostic Tester display.

During the course of the program, a request is made to switch the Calibration Tool - Lane Change Calibration Tool -VAS6350/4- from the right to the left side of the Calibration Tool -VAS6350-.

- Turn off the Calibration Tool - Lane Change Calibration Tool -VAS6350/4- and remove the calibration tool.

- When installed correctly, vehicle electrical system voltage line must be connected at bottom left of calibration device (as seen in direction of travel).

Dimension -a- is measured from the upper edge of calibration device to the floor.

- The indicator on the base of the Calibration Tool - Lane Change Calibration Tool -VAS6350/4- must align with adjustment dimension on the measuring scale -1- on measuring field -arrow-.

- Turn on the Calibration Tool - Lane Change Calibration Tool -VAS6350/4- on the voltage switch -3-.

- The green LED -1- must light up.

- Follow the instructions in the Vehicle Diagnostic Tester display.

- After calibrating the lane change assistance successfully, end "calibration", switch off the ignition and disconnect the diagnostic connector.