Audi A6 Typ 4G (2011–2018) Workshop Manual / Chassis / Suspension, Wheels, Steering / Rear Suspension / Overview - Drive Axle

Audi A6 Typ 4G: Overview - Drive Axle

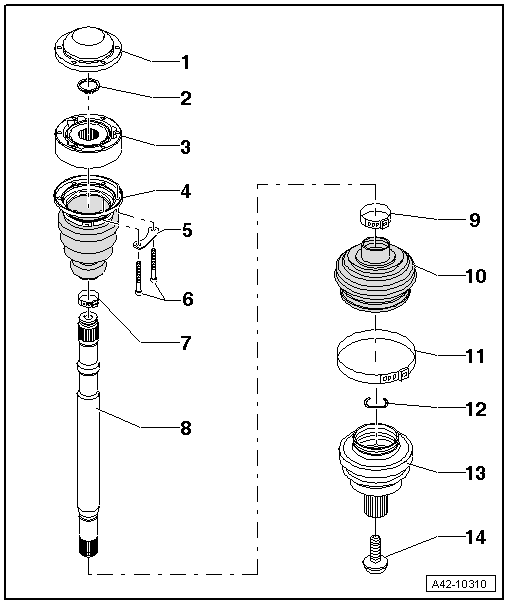

1 - Cover

- Carefully remove the cover using a drift, replace if damaged.

- The adhesive surfaces on the cover/inner CV joint must be free of grease when installing.

- Before mounting on the CV joint, coat the sealing surface with Sealant.

2 - Locking Ring

- Remove and install using commercially available locking ring pliers.

- Always replace if removed

3 - Inner CV Joint

- Replace only as complete unit.

- Checking. Refer to → Chapter "Inner CV Joint, Checking".

- Grease quantity and type.

- Adhesive surface must be free of oil and grease

- When installing joint on axle shaft, splines on axle shaft must be lightly coated with grease used in joint.

4 - Protective Boot for Inner CV Joint with Cap

- Without vent hole

- Carefully remove the cap using a drift, replace if damaged.

- Check the inner CV joint if damaged. Refer to → Chapter "Inner CV Joint, Checking".

- The sealing surfaces on the cap/inner CV joint must be free of grease when installing.

5 - Locking Plate

6 - Bolt

- 70 Nm

- M 10

- Always replace if removed

7 - Clamp

- Always replace if removed

- Tensioning.

8 - Drive Axle

- Removing and installing. Refer to → Chapter "Drive Axle, Removing and Installing".

9 - Clamp

- Always replace if removed

- Tensioning.

10 - CV Boot for Outer CV Joint

- Without vent hole

- Check for tears and chafing; replace if necessary

- Check the outer CV joint if damaged. Refer to → Chapter "Outer CV Joint, Checking".

- The protective boot/metal cap sealing surfaces must be free of grease when installing.

- The protective boot/drive shaft sealing surfaces must be free of grease when installing.

11 - Clamp

- Always replace if removed

- Tensioning.

12 - Locking Ring

- Replacing

- Allocation. Refer to the Parts Catalog.

- Insert into ring groove of shaft before installation (not visible on installed joint)

- Before installing CV joint, align sealing ring in center with opening facing upward.

13 - Outer CV Joint

- Replace only as complete unit.

- Checking. Refer to → Chapter "Outer CV Joint, Checking".

- Removing. Refer to → Chapter "Outer CV Joint, Removing and Installing".

- Installing: Drive onto the shaft using a plastic mallet until the compressed circlip seats.

- Circlip must lie in joint chamfer when guiding in, guide with pliers if necessary.

- Grease quantity and type. Refer to → .

- The protective boot/outer CV joint sealing surfaces must be free of grease when installing.

- When installing joint on axle shaft, splines on axle shaft must be lightly coated with grease used in joint.

14 - Bolt

- 200 Nm +180º turn

- Always replace if removed

- Follow the assembly information when loosening and tightening. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

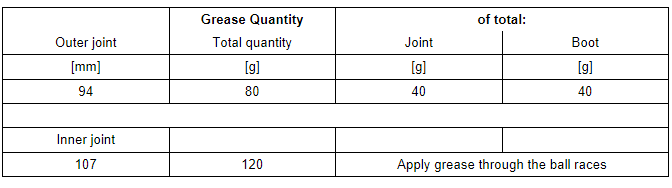

Grease Quantity and Type

Grease joint when replacing CV boot.

Pack the joint with grease. Refer to the Parts Catalog.

Note

Note

Note that the outer and inner joints use different types of grease.