Audi A6 Typ 4G: Drive Axle, Removing and Installing

Removing

- Loosen the connection between the drive axle and wheel hub. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

- Remove the rear wheel. Refer to → Chapter "Wheels and Tires".

Vehicles with Steel Suspension

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing, Coil Spring".

Vehicles with Air Suspension

- Bleed the rear axle air spring. Refer to → Chapter "System, Venting or Filling".

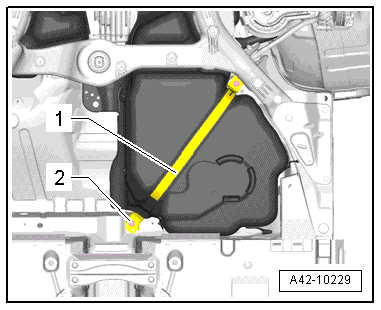

- Tighten the bolt -2- just hand-tight and secure the mounting strap -1-.

- Remove the rear final drive. Refer to → Rear Final Drive; Rep. Gr.39.

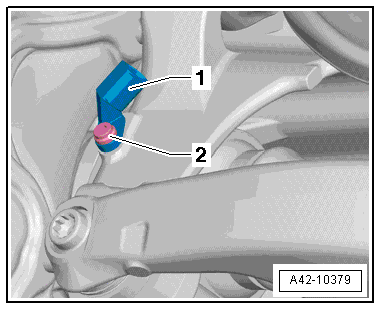

- Remove the bolt -2- and the rear speed sensor -1-.

- Remove the drive axle toward the inside.

Installing

Install in reverse order of removal. Note the following:

- Install the rear final drive. Refer to → Rear Final Drive 0BC, 0BD, 0BE, 0BF; Rep. Gr.39.

- Install the speed sensor. Refer to → Brake System; Rep. Gr.45.

- Install rear wheel. Refer to → Chapter "Wheels and Tires".

- Fill the rear axle air springs. Refer to → Chapter "System, Venting or Filling".

- Tighten the drive axle to wheel hub threaded connection. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

Drive Axle Threaded Connection, Loosening and Tightening

Special tools and workshop equipment required

- Torque Wrench 80-400Nm -VAG1576-

Loosen the threaded connection between the drive axle and wheel hub

- With vehicle still standing on its wheels, loosen bolt a maximum of 90º, otherwise wheel bearing will be pre-damaged.

- Remove the rear wheel. Refer to → Chapter "Wheels and Tires".

- Lift the vehicle just enough so that the wheels are hanging free.

- Have a second technician push the brake pedal.

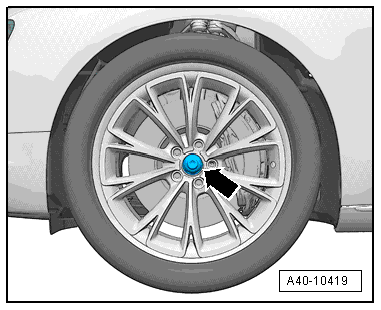

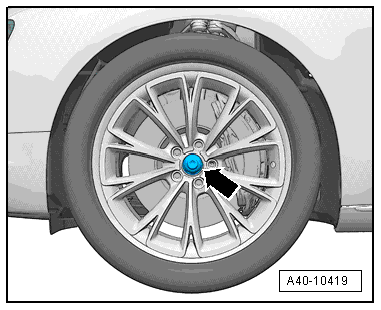

- Remove the bolt -arrow-.

Tighten the threaded connection between the drive axle and wheel hub

- Replace bolt -arrow-.

Note

Note

- Before installing, clean the threads in the CV joint with a tap.

- Wheels must not yet touch the ground to tighten the drive axle, wheel bearing may otherwise be damaged.

- Have a second technician push the brake pedal.

- Tighten bolt to 200 Nm.

- Lower the vehicle onto its wheels.

- Tighten bolt an additional 180º turn.