Audi A6 Typ 4G: CV Joint, Replacing

Outer CV Joint, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

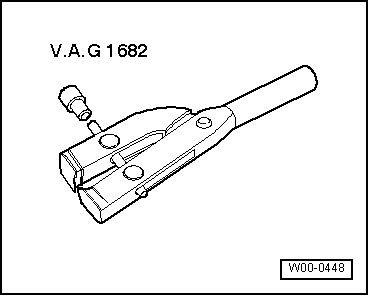

- Clamping Pliers -VAG1682A-

- Circlip Pliers (commercially available)

- Sealant. Refer to the Parts Catalog.

Removing Outer CV Joint

- Clamp the drive axle with protective jaws in a vise clamp.

- Open the clamps.

- Slide back protective boot.

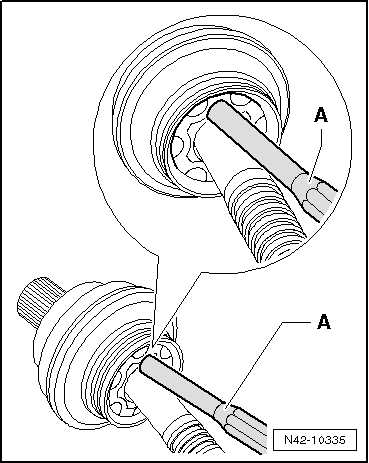

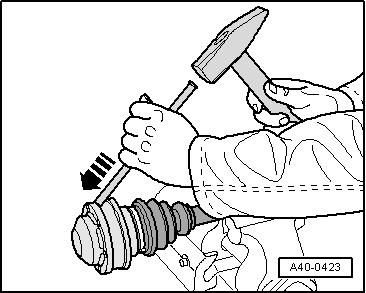

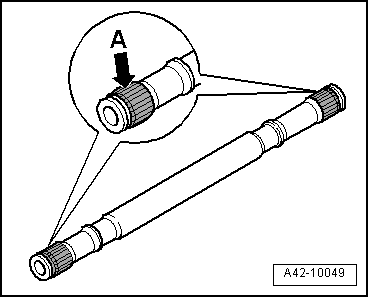

- Strike a copper or brass drift -A- on CV joint inner race with a hammer.

- Remove joint and protective joint boot.

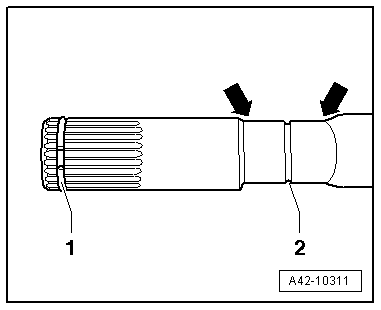

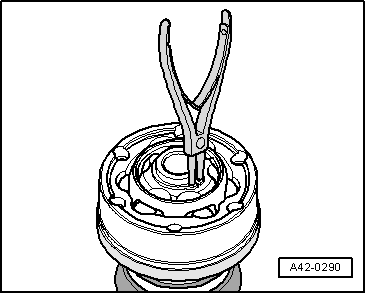

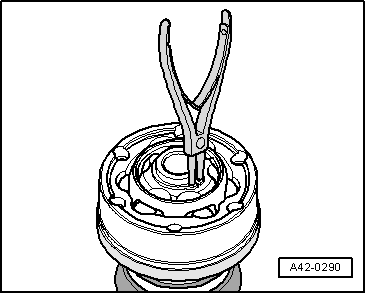

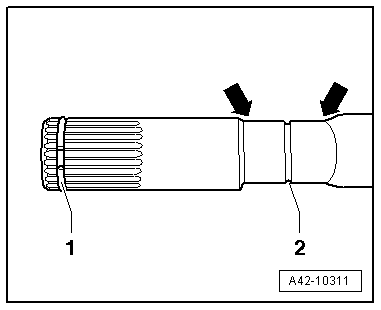

- Remove the circlip -1-.

Installing Outer CV Joint

- Push the joint protective boot and a new clamp onto the drive axle.

- Joints and protective joint boots must be free of grease.

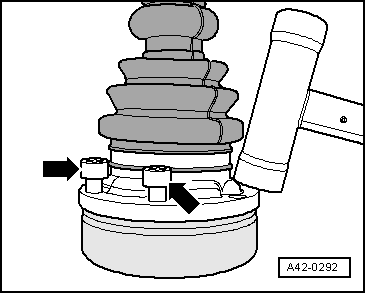

- Position the joint protective boot between the -arrows- into the groove -2-.

1 - Circlip (snap ring), always replace.

2 - Positioning groove, push the joint protective boot into the groove until it engages.

- Place 80 grams of drive axle grease evenly into the joint.

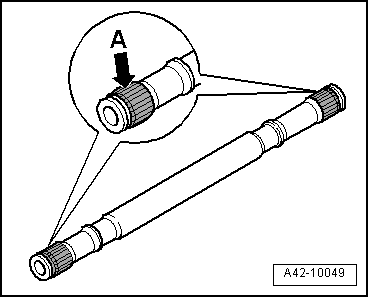

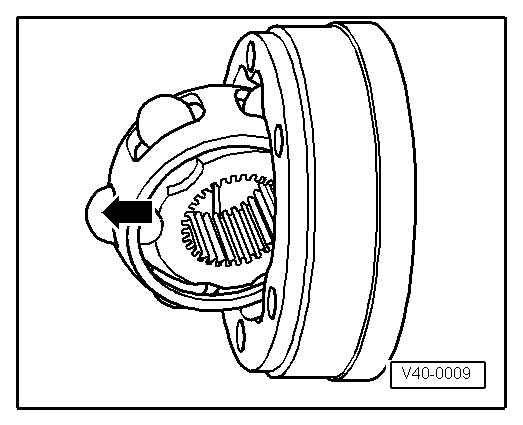

- Before installing joint piece, splines -A- must be lightly coated with grease used in joint.

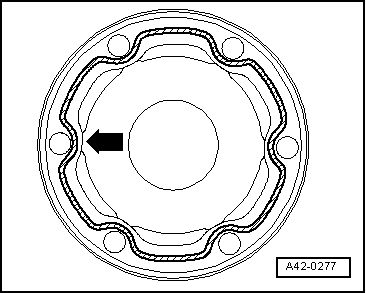

- Insert sealing ring in groove on shaft.

- Slide on CV joint up to sealing ring.

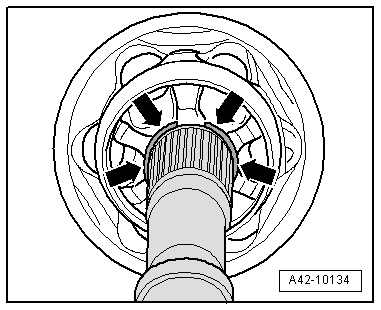

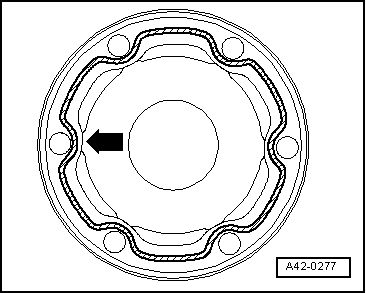

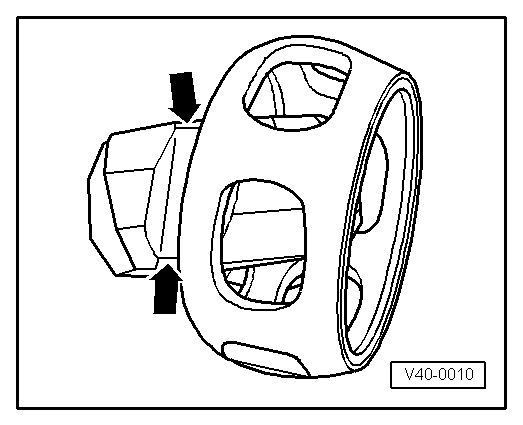

- Align sealing ring at center with opening upward -see arrows-.

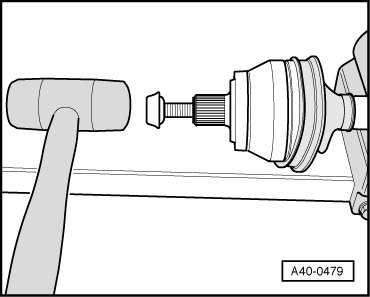

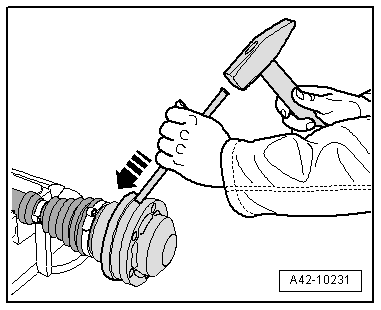

- Install the old drive axle bolt in the joint as shown in the illustration.

- Drive joint onto drive axle with plastic hammer until circlip engages.

- Install the joint protective boot onto the metal cap.

- Bleed protective joint boot.

- Make sure the protective boot is seated on the joint correctly.

- Protective joint boot must fit in groove and on joint contour.

Tightening Hose Clamp on Outer Joint

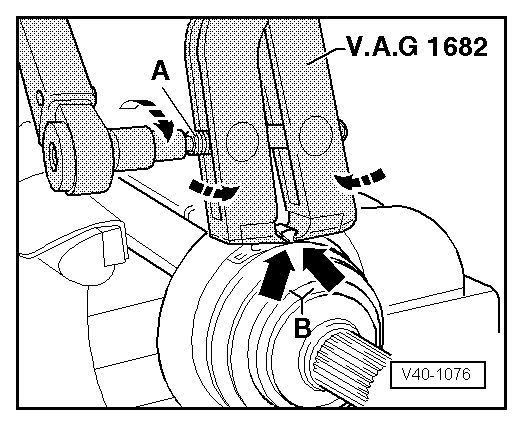

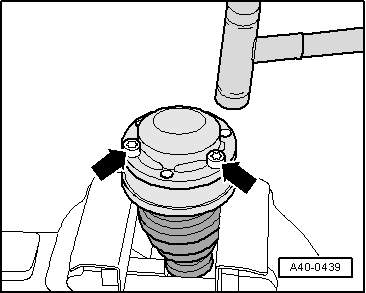

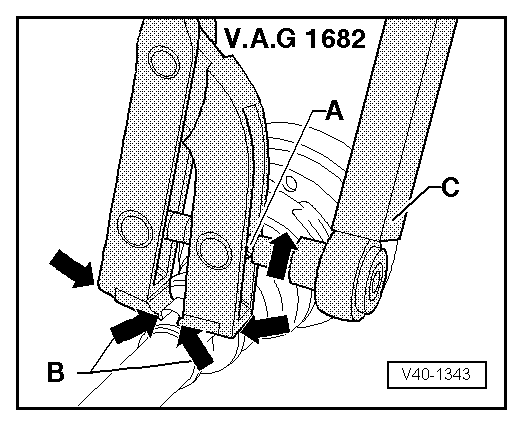

- Attach the Clamping Pliers -VAG1682A- as illustrated. When doing this, make sure that edges of clamping pliers are seated in corners -arrows B- of clamp.

- Tighten the clamp by turning the spindle using a torque wrench -C- (do not tilt the pliers).

- The hard material of the CV boot (compared to rubber) makes it necessary to use a stainless steel hose clamp. It is only possible to tighten the hose clamp with Clamping Pliers -VAG1682A-.

- Tightening specification: 20 Nm.

- Use torque wrench with 5 to 50 Nm range (for example, Torque Wrench 1331 5-50Nm -VAG1331-).

- Make sure the thread on the spindle -A- is easy to move. Lubricate with MoS2 grease, if necessary.

- If the thread is tight, for example, dirty, the required tensioning force for the hose clamp will not be achieved in spite of correct torque specification settings.

Inner CV Joint, Removing and Installing

Special tools and workshop equipment required

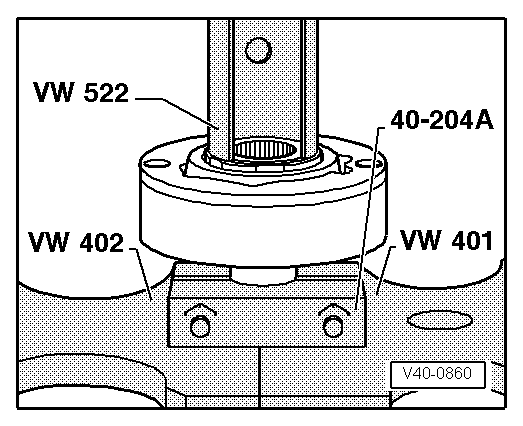

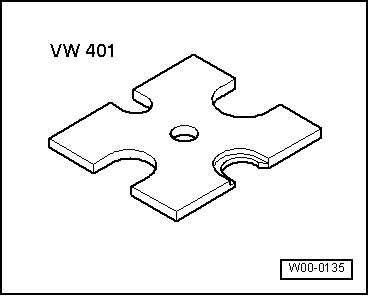

- Press Plate -VW401-

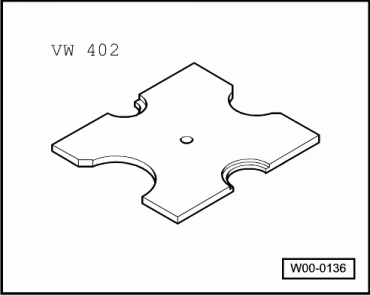

- Press Plate -VW402-

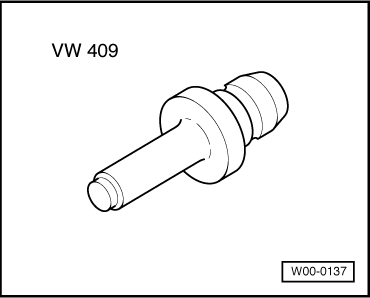

- Press Piece - Rod -VW409-

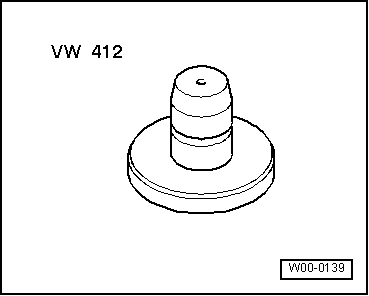

- Press Piece - Multiple Use -VW412-

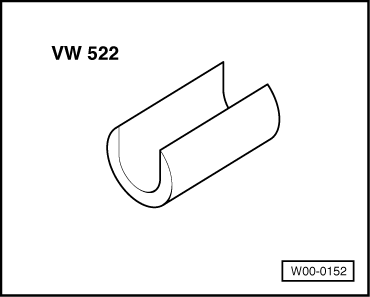

- CV Joint Press Sleeve -VW522-

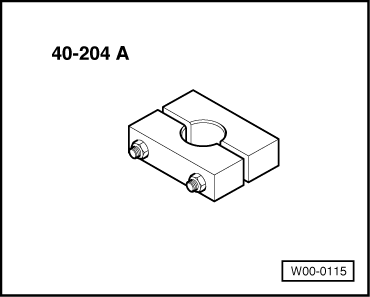

- Press Block -40-204A-

- Torque Wrench 1331 5-50Nm -VAG1331-

- Clamping Pliers -VAG1682A-

- Locking ring pliers (commercially available)

Remove the Inner CV Joint

- Clamp the drive axle with protective jaws in a vise clamp.

- Drive cover down with copper or brass drift.

- Drive cap down with copper or brass drift.

- Only open and remove the "small" protective boot clamp.

- Remove circlip.

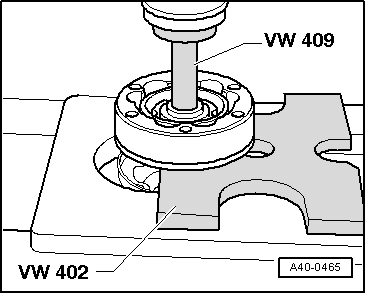

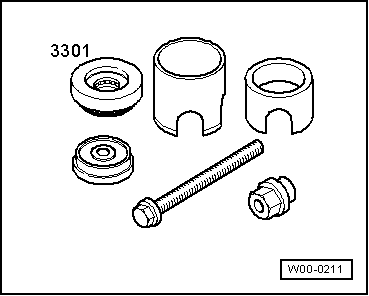

- Press inner CV joint off of drive axle with special tool shown in illustration.

- Remove the CV joint boot from the drive axle.

Installing the Inner CV Joint

- Slide the protective joint boot with the "small" clamp onto the drive axle.

- Before installing joint piece, splines -A- must be lightly coated with grease used in joint.

- Press on joint until stop.

- Chamfer on inner diameter of ball hub (splines) must face the contact shoulder on the drive axle.

- The Press Block -40-204 A- and clamping surfaces on drive axle must be free of grease.

Note

Note

- Use special tool shown in illustration.

- Circlip must be replaced.

- Install circlip.

- Check circlip for correct seating.

- Add half of the drive axle grease into the joint on the boot side before installing the joint protective boot.

- Lubricate the contact surface on the cover.

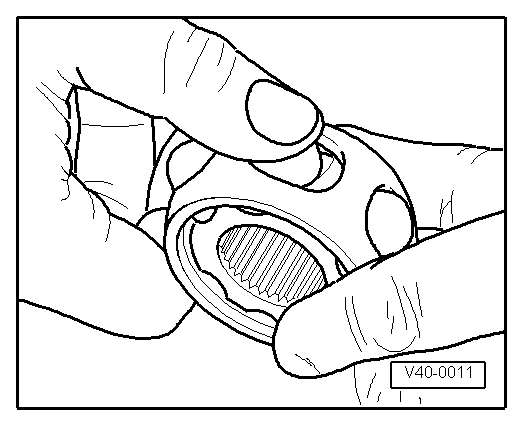

- Apply sealant -hatched surface- to clean surface on inner side of protective joint boot cap.

- Apply 2 - 3 mm diameter unbroken bead of sealant.

- The inner sealant bead runs near the holes -arrow-.

- Use sealant. Refer to the Parts Catalog.

- Protective boot and cap contact surfaces must be free of grease!

- Align new cover with bolts -arrows- to bolt holes.

Note

Note

It must be aligned exactly because it cannot be aligned after driving on.

- Drive cover on with a plastic hammer.

- Clear away leaking sealing immediately.

- Apply the rest of the drive axle grease through the ball paths into the CV joint.

- Remove any grease on the cover contact surface and on the CV joint.

- Apply sealant -hatched area- to the clean surface in the inside of the cover.

- Apply 2 - 3 mm diameter unbroken bead of sealant.

- The inner sealant bead runs near the holes -arrow-.

- Use sealant. Refer to the Parts Catalog.

- Align new cover with bolt -arrows- to bolt holes.

It must be aligned exactly because it cannot be aligned after driving on.

- Drive cover on with a plastic hammer.

- Clear away leaking sealing immediately.

Joints and protective joint boots must be free of grease.

- Position the joint protective boot between the -arrows- into the groove -2-.

1 - ignore

2 - Positioning groove, push the joint protective boot into the groove until it engages.

Note

Note

The inner joint is not shown in the illustration.

Installing a Clamp on the Inner Joint and Clamping

- Attach the Clamping Pliers -VAG1682A- as illustrated. When doing this, make sure that edges of clamping pliers are seated in corners -arrows B- of clamp.

- Tighten the clamp by turning the spindle using a torque wrench -C- (do not tilt the pliers).

- The hard material of the CV boot (compared to rubber) makes it necessary to use a stainless steel hose clamp. It is only possible to tighten the hose clamp with Clamping Pliers -VAG1682A-.

- Tightening specification: 20 Nm.

- Use torque wrench with 5 to 50 Nm range (for example, Torque Wrench 1331 5-50Nm -VAG1331-).

- Make sure the thread on the spindle -A- is easy to move. Lubricate with MoS2 grease, if necessary.

- If the thread is tight, for example, dirty, the required tensioning force for the hose clamp will not be achieved in spite of correct torque specification settings.

Outer CV Joint, Checking

The outer CV joint and cap cannot be disassembled.

The outer CV joint and cap can only be inspected visually.

The grease still in the joint must be free of water and dirt.

If wear or damage is found on the ball journal surfaces, then the entire outer CV joint and cap must be replaced.

Grease quantities and types, drive shaft with outer constant velocity joint.

Inner CV Joint, Checking

It is necessary to disassemble the joint whenever replacing the grease or if the ball surfaces show wear or damage.

Disassembling

Note

Note

Ball hub and joint are paired and should be identified before removal. Do not interchange cage allocation.

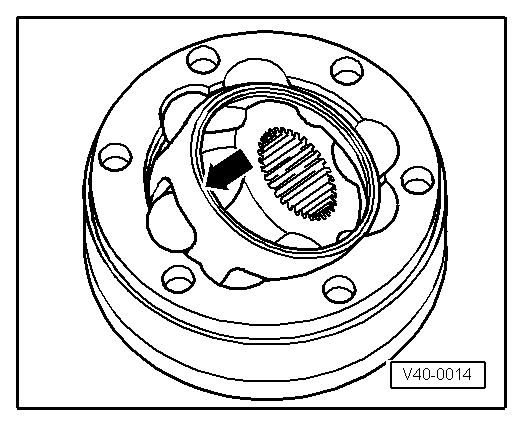

- Swivel the ball hub and ball cage.

- Remove the joint in direction of -arrow-.

- Remove the balls from the cage.

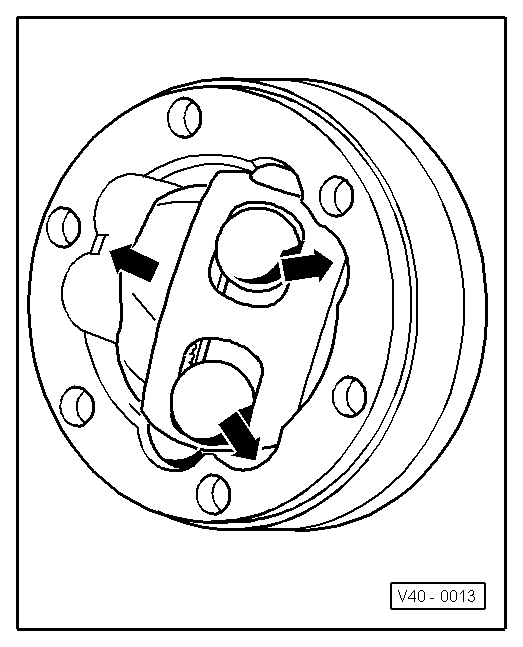

- Flip out ball hub from ball cage via running path of ball -arrows-.

- Check joint piece, ball hub, ball cage and balls for small broken off depressions (pitting build-up) and chafing.

Note

Note

Excessive backlash in joint will be noticed as a knock during load changes. Joint must be replaced in such cases. Flattening and running marks of balls are no reason to replace joint.

Assembling

- Insert ball hub into ball cage via two chamfers. The installation position is at random. Press balls into cage.

- Insert hub with cage and balls upright into joint piece.

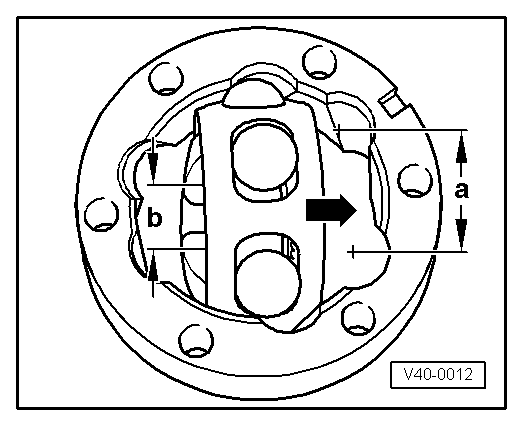

- When inserting, make sure that in each case the wide gap -a- at joint piece contacts narrow gap -b- at hub after swinging in.

- Chamfer on inner diameter of wheel hub (splines) must face toward drive axle.

- Swing in ball hub, to do so swing out hub far enough from cage -arrows- so that the balls have the distance of the running paths.

- Swing in hub with balls by pressing forcefully onto cage -arrow-.

Check the CV Joint for Function.

CV joint is properly assembled, if ball hub can be slid back and forth by hand over whole compensation length.

- Press grease into joint body.

Grease quantities and types, drive shaft with inner CV joint.

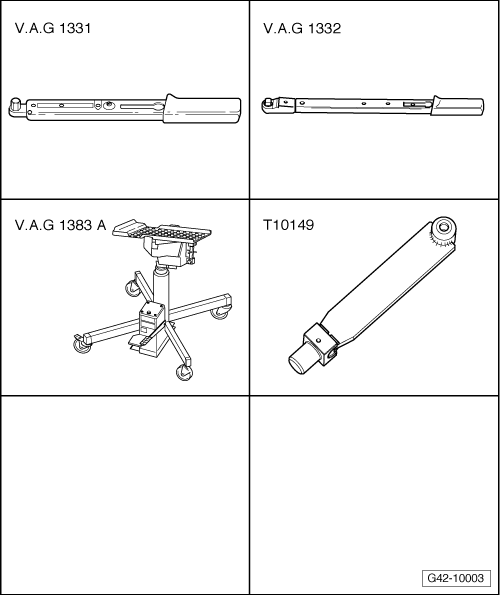

Special Tools

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

- Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

Special tools and workshop equipment required

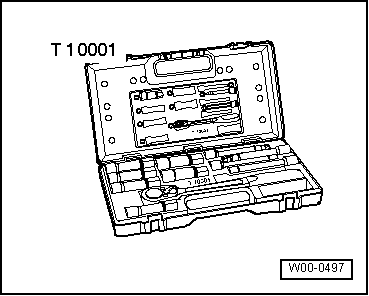

- Shock Absorber Set -T10001-

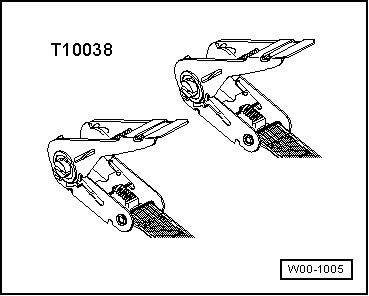

- Tensioning Strap -T10038-

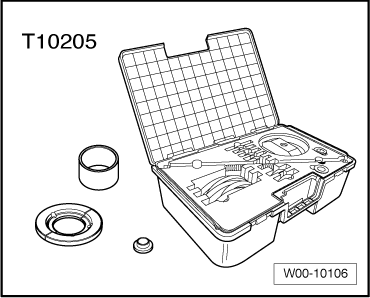

- Bearing Installer - Wheel Hub/Bearing Kit -T10205-

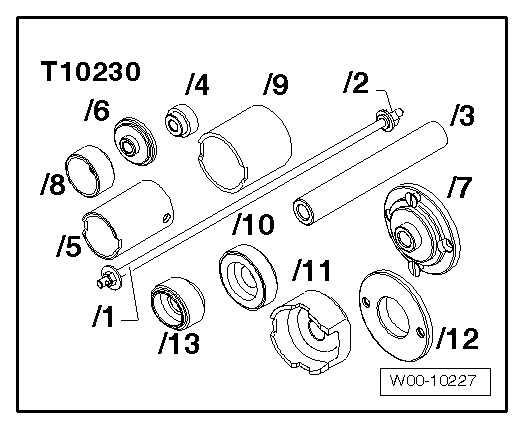

- Hydraulic Press - Bushing Assembly Tool Kit -T10230-

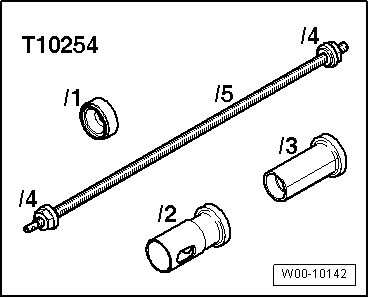

- Hydraulic Press - Ball Joint Assembly Tools -T10254-

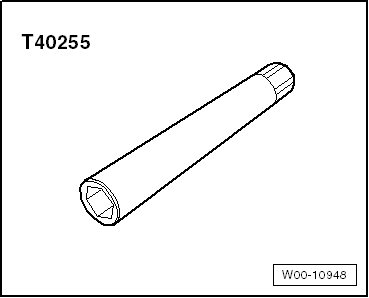

- Counterhold - Shock Absorber - 9mm-T40255-

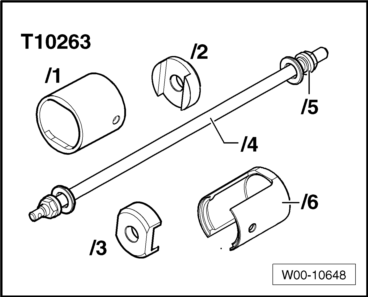

- Hydraulic Press - Rear Subframe Bushing Tool Kit -T10263-

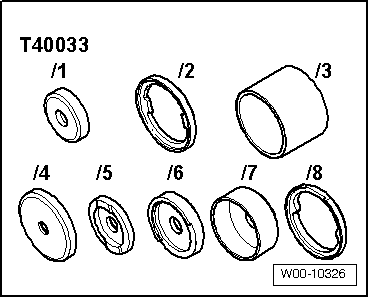

- Rear Bushing Tool -T40033-

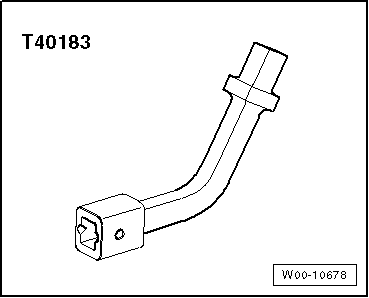

- Track Rod Tool Insert -T40183-

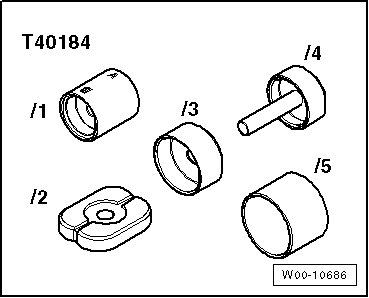

- Bearing Installer - Wheel Bearing Bushing -T40184-

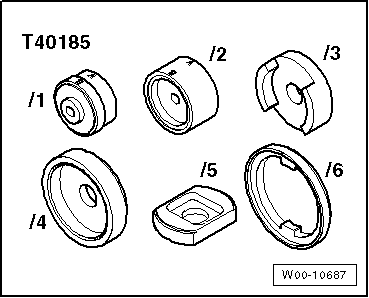

- Subframe Bushing Assembly Tool -T40185-

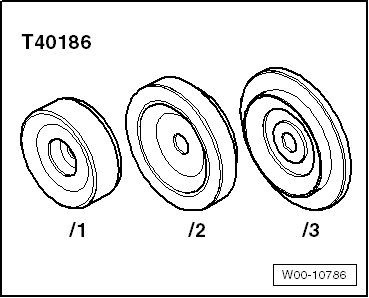

- Press Piece - Front Final Drive Bushing -T40186-

- Subframe Locating Pins -T40242-

- Shop Press -VAG1290A-

- Torque Wrench -VAG1410-

- Torque Wrench 80-400Nm -VAG1576-

- Clamping Pliers -VAG1682A-

- Hydraulic Press -VAS6178-

- Pneumatic/Hydraulic Foot Pump -VAS6179-

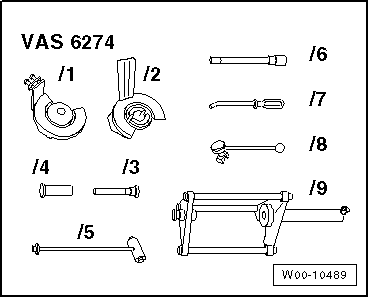

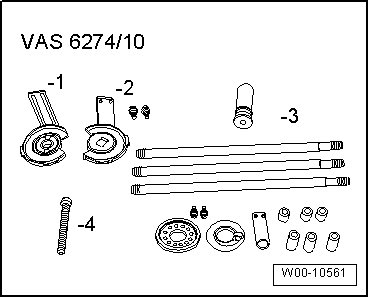

- Spring Tensioning System -VAS6274-

- Spring Tensioning System - Audi Set -VAS6274/10-

- Press Plate -VW401-

- Press Plate -VW402-

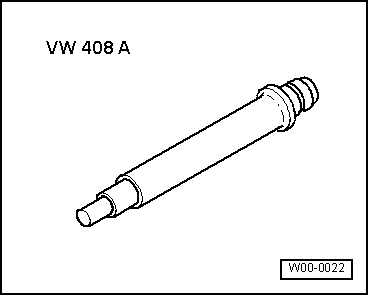

- Press Piece - Rod -VW408A-

- Press Piece - Rod -VW409-

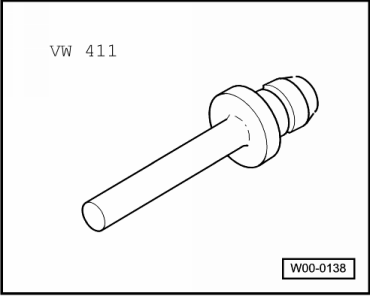

- Press Piece - Rod -VW411-

- Press Piece - Multiple Use -VW412-

- CV Joint Press Sleeve -VW522-

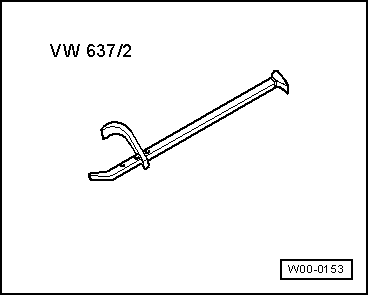

- Puller - Grease Cap -VW637/2-

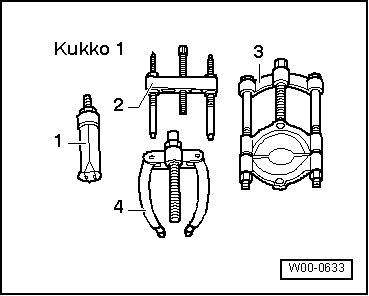

- -3-Puller - Kukko Separating Tool - Diameter 25-155mm with Puller - Kukko Quick Action Separating Tool - 25-155mm -15/3 with 17/3-

- Press Block -40-204A-

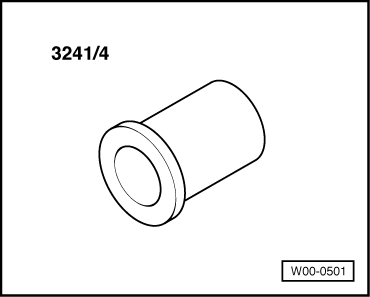

- Sleeve -3241/4-

- Subframe Bushing Tool Kit -3301-

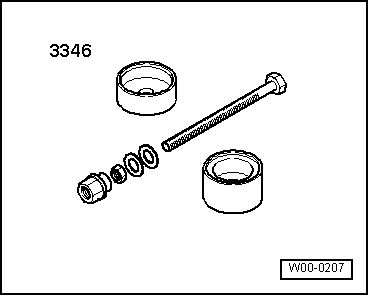

- Bearing Installer - Control Arm -3346-

- Subframe Lowering Tool -T40253-