Audi A6 Typ 4G: Spring Tensioning System, Converting

Special tools and workshop equipment required

- Spring Tensioning System -VAS6274-

- Spring Tensioning System - Audi Set -VAS6274/10-

Note

Note

It must only be converted once. It is not necessary to convert back again.

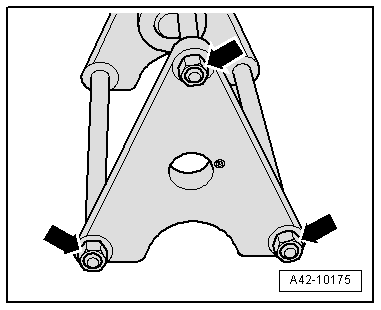

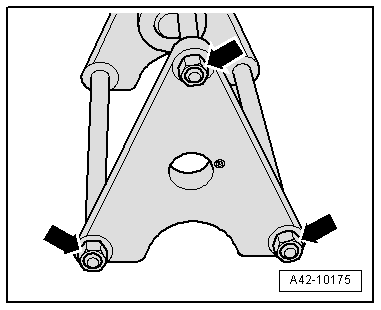

- Remove the tensioning system nuts -arrows- (quantity: six).

- Remove the plate and remove the rods from the tensioning system.

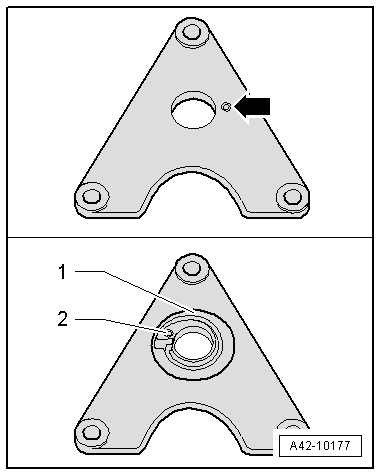

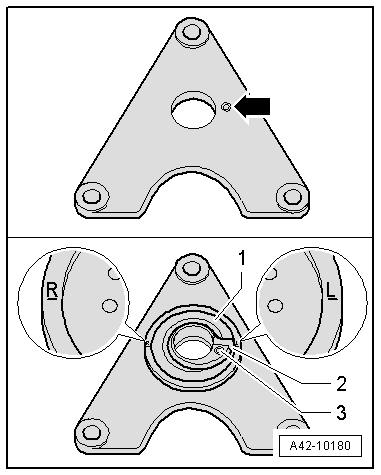

- Remove the bolt -arrow- and the previous spring plate -1- with the hole -2- without the counter bore.

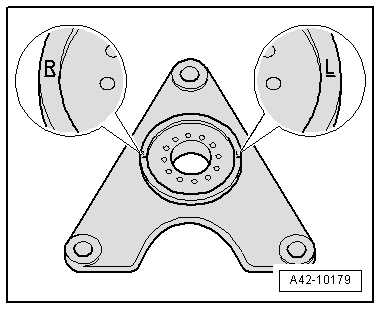

- Insert the new plate with the threaded holes from the supplementary set so the markings "R" and "L" are horizontal to the plate.

- Tighten the new plate with the new bolt -arrow- from the supplementary set. Do not rotate the plate.

- Insert the new spring plate -1- with the hole -3- with the counter bore from the supplementary set.

- Insert the new spring plate -1- so the stop -2- aligns with the marking "L".

- Tighten the new spring plate -1- with the new bolt from the supplementary set.

- Remove the spring plate at the hydraulic cylinder.

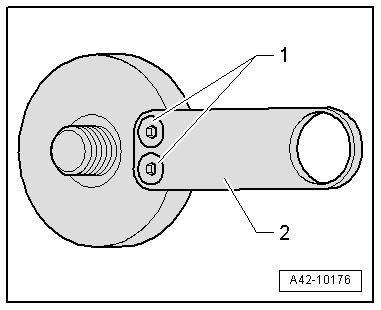

- Remove the tab -2- and replace with the new tab from the supplementary set.

- Tighten the new tab -2- with the new bolts -1- from the supplementary set.

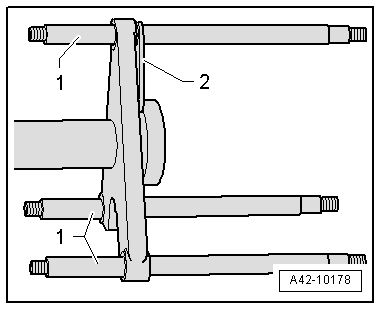

- Install the spring plate lightly as far as the stop on the tensioning system and then rotate it back again slightly.

- Insert the new rods with the long taper -1- in the tensioning system plate.

- Insert the upper rod in the tab -2-.

- Position the plate on the rods.

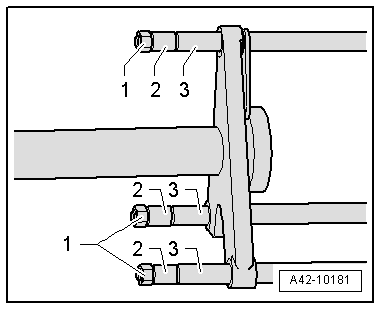

- Install the sleeves -2 and 3- from the supplementary seat and install the nuts -1- lightly.

- Position the tensioning system on a level surface and tighten the nuts -arrows-.