Audi A6 Typ 4G: Wheel Covers, Removing and Installing

Fender Molding, Replacing

Special tools and workshop equipment required

- Roller -3356-

- Gauge - Gap Adjustment -3371-

- Front and Rear Door Template -T40038 /8-

Note

Note

- The attached trim can only be replaced, removal without destruction is not possible.

- Remove adhesive residue on body if necessary.

- Clean the adhesive surfaces on the vehicle body with Cleaning Solution -D 009 401 04-.

- Adhesion surfaces must be free of dust and grease

- Heat the adhesive surface and trim to approximately 40º C (104 ºF) before bonding

- When installing, the trim must be applied according to the contours. It is not possible to make corrections later.

- Press the covers with the Roller -3356- after installation.

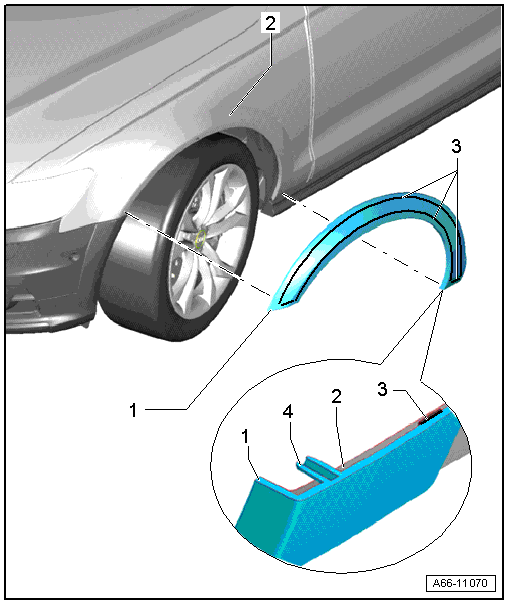

1 - Wheel Cover

- Removing:

- Warm the adhesive surface with a hot air gun and pull off the cover little by little.

- Remove any remaining adhesive on the side panel, if necessary.

- Installing:

- Remove the protective film sideways so that they can be reached when the fender cover is dismantled.

- Position it above the centering pin from rear to front and in line with the contour when installing.

- Pull off the protective backing at the removal tabs between the side panel and molding and then press the molding on using Roller -3356-.

2 - Fender

3 - Adhesive Tape

- Before installing, bend the protective backing 90º so it can be reached when the protective molding is installed on the fender.

4 - Centering Pin

Wheel Cover for Side Panel and Rear Door, Replacing

Special tools and workshop equipment required

- Roller -3356-

- Gauge - Gap Adjustment -3371-

- Front and Rear Door Template -T40038 /8-

Note

Note

- The attached trim must be replaced, removal without destruction is not possible.

- Remove adhesive residue on body if necessary.

- Clean the adhesive surfaces on the vehicle body with Cleaning Solution -D 009 401 04-.

- Adhesion surfaces must be free of dust and grease

- Heat the adhesive surface and trim to approximately 40º C (104 ºF) before bonding

- When installing, the trim must be applied according to the contours. It is not possible to make corrections later.

- Press the covers with the Roller -3356- after installation.

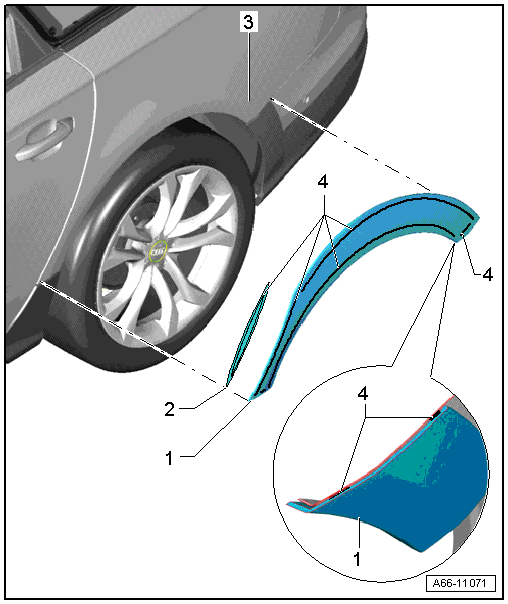

1 - Side Panel Fender Molding

- Removing:

- Warm the adhesive surface with a hot air gun and pull off the cover little by little.

- Installing:

- Remove the protective film sideways so that they can be reached when the side panel cover is dismantled.

- Position it exactly along the contour on the sill panel trim and door trim

- Remove the protective film by the removal tabs between the side panel and trim and press it on by hand in stages.

2 - Rear Door Trim

- Removing and installing is identical to removing and installing the fender molding.

3 - Side Panel

4 - Adhesive Tape

- Before installing, bend the protective backing 90º so it can be reached when the protective molding is installed on the fender.