Audi A6 Typ 4G: Ball Joint, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- Torque Wrench 1332 Insert - Ring Wrench - 21mm -VAG1332/7-

- Puller - Ball Joint -T40010A-

- For a vehicle with air suspension Vehicle Diagnostic Tester

Removing

- Remove the control arm. Refer to → Chapter "Control Arm, Removing and Installing".

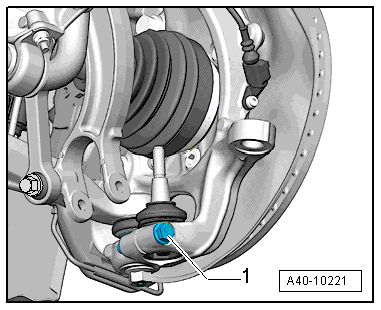

- Remove the bolt -1-.

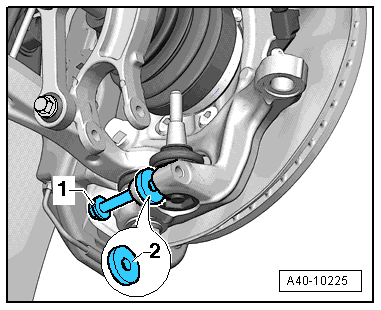

- Insert a washer or something similar -2- into the wheel bearing housing slot. The washer, or something similar, must the be exact same width as the slot.

- Install the bolt -1- until it touches the back of the washer.

- Side the wheel bearing housing slot by installing the bolt -1- further (one half turn).

- Remove the ball joint from the wheel bearing housing.

Installing

Install in reverse order of removal. Note the following:

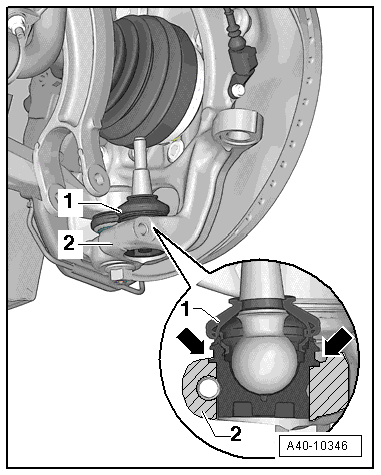

- Install the ball joint -1- into the wheel bearing housing -2- as far as the contact surface -arrows-.

Note

Note

If the ball joint -1- is not inserted up to the contact surface -arrows- then the threaded connection on the wheel bearing housing -2- could get damaged.

- Install the control arm. Refer to → Chapter "Control Arm, Removing and Installing".

- Install the wheel. Refer to → Chapter "Wheels and Tires".

- To determine if an axle alignment is required, see Table. Refer to → Chapter "Evaluating Need for Axle Alignment".

Guide Link Bonded Rubber Bushing, Removing and Installing

Special tools and workshop equipment required

- Press Plate -VW402-

- Press Piece - Multiple Use -VW412-

- Press Piece - Split Tube -VW463/2-

- Bearing Installer - Wheel Bearing -3144-

- Shop Press -VAG1290A-

- Installation Lubricant (1:20 thinned with water). For allocation. Refer to the Parts Catalog.

Pressing Out Bonded Rubber Bushing

- The guide link is removed. Refer to → Chapter "Guide Link, Removing and Installing"

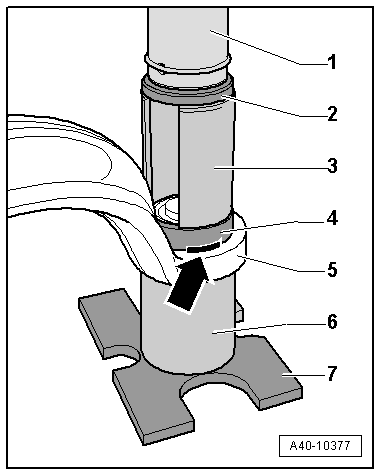

- Mark the upper and lower installed position -arrow- on the bonded rubber bushing -4-.

Use a water-proof marker.

- Order the special tools as illustrated.

1 - Workshop Press -VAG1290A- punch

2 - Press Piece - Multiple Use -VW412-

3 - Press Piece - Split Tube -VW463/2-

4 - Bonded rubber bushing

5 - Guide link

6 - Bearing Installer - Wheel Bearing -3144-

7 - Press Plate -VW402-

- Remove the bonded rubber bushing -4- from the guide link -5-.

Note

Note

Hold the guide link steady when removing/installing the bonded rubber bushing.

Installing Bonded Rubber Bushing

- Transfer the marking of the press-in depth from the old bonded rubber bushing to the new one.

- Lightly coat the new bonded rubber bushing with installation lubricant. Refer to the Parts Catalog.

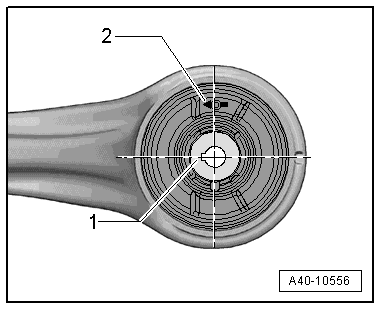

Bonded Rubber Bushing Installed Position

The groove on the inner core -1- is on the steering axle and faces the inside of the guide link.

The arrow -2- faces the inside of the guide link.

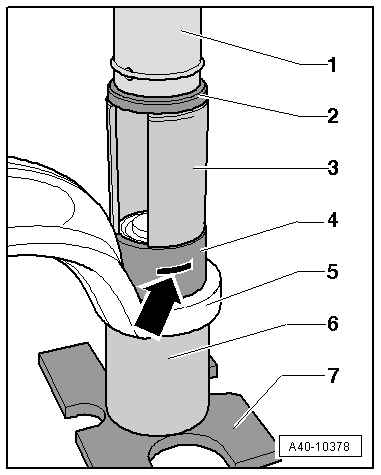

- Install the bonded rubber bushing -4- in the guide link -5-. Pay attention to the installed position

- Order the special tools as illustrated.

1 - Workshop Press -VAG1290A- punch

2 - Press Piece - Multiple Use -VW412-

3 - Press Piece - Split Tube -VW463/2-

4 - Bonded rubber bushing

5 - Guide link

6 - Bearing Installer - Wheel Bearing -3144-

7 - Press Plate -VW402-

Note

Note

Do not tilt the bonded rubber bushing when installing it.

- Install the bonded rubber bushing -4- in the guide link -5-.

- Pay close attention to the marking -arrow-.

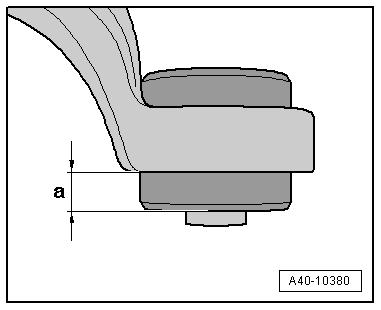

- Check the depth -a- of the bonded rubber bushing inside the guide link.

Dimension -a- = 18 mm.

- If dimension -a- has not been reached, then press the bonded rubber bushing again.

- Install the guide link. Refer to → Chapter "Guide Link, Removing and Installing".