Audi A6 Typ 4G: Brake Lines

Separating Points

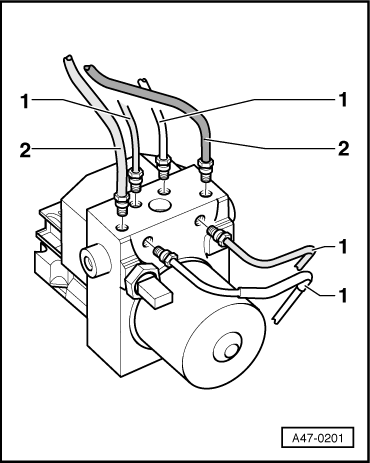

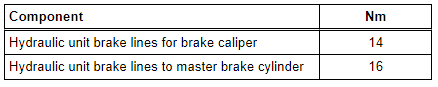

Hydraulic unit lines

Brake Line Routing

- Brakes and brake lines are delivered as ready-to-install replacement parts.

- Secure brakes and brake lines at original fastening points when installing.

WARNING

WARNING

Risk of accident!

Make sure the brakes are working correctly before driving the vehicle for the first time.

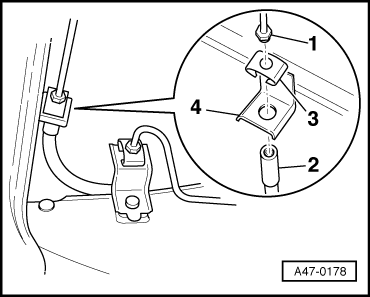

Brake Line Routing

1 - Brake Line

2 - Brake Hose

3 - Spring

4 - Brake Hose Bracket

Brake Lines, Repairing

Special tools and workshop equipment required

- Brake Line Tool Kit -VAS6056-

Flare the brake lines using Brake Line Tool Kit -VAS6056- without damaging coating. In this way, brake lines can be inexpensively replaced in partial sections in certain cases.

Caution

Caution

There is a risk of damaging the brake lines.

- Using the Brake Line Kit V.A.G. 1356 is not permitted because of the coating and diameter of the black brake lines.

- Brake lines must not be bent more than a maximum of 90º, otherwise they kink or deform, which causes unacceptable constriction in the line.

Note

Note

- Disconnect the brake lines preferably at the underbody.

- The position of intermediate pieces should be selected so that they cannot rub against moving parts.

- Do not lubricate spindle. Clean with mineral spirits or commercially available brake cleaner only.

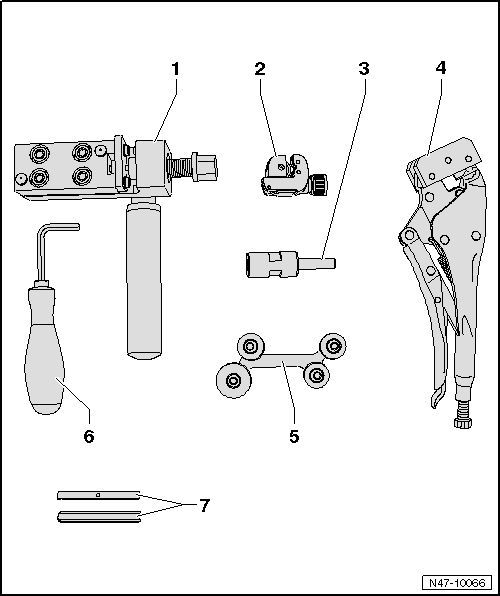

Listing of individual tools

1 - Brake Line Tool Kit - Flanging Tool -VAS6056/1- (including Clamp Jaws (Plastic Coated Brake Lines Diam = Approx. 5.25 mm) -VAS6056/6-)

2 - Brake Line Tool Kit - Pipe Cutter -VAS6056/2-

3 - Brake Line Tool Kit - Brake Line Scraper -VAS6056/3-

- The threaded pins (in shaft and at sides) are set and must not be adjusted!

4 - Brake Line Tool Kit - Line Grips -VAS6056/4-

5 - Brake Line Tool Kit - Pipe Bending Tool -VAS6056/5-

6 - 6 mm Offset Screwdriver

7 - Clamp Jaws (Plastic Coated Brake Lines Diam = Approx. 5.25 mm) -VAS6056/6-, Clamp Jaws (Brake Line Diam = Approx. 4.75 mm) -VAS6056/7-

Clamp Jaws (Plastic Coated Brake Lines Diam = Approx. 5.25 mm) -VAS6056/6-

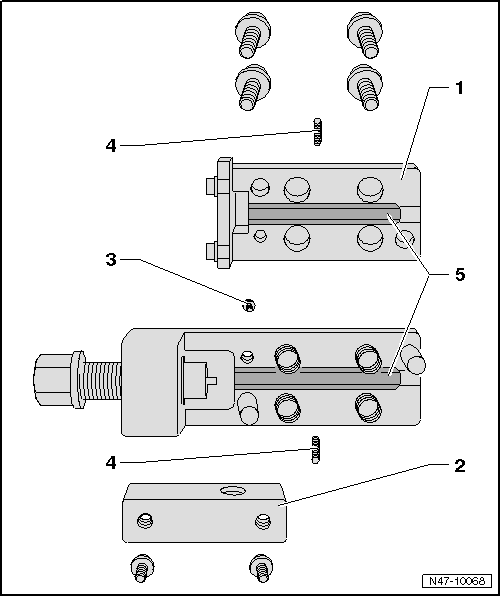

1 - Flanging Tool Upper Section

- Remove to replace the flaring jaws.

2 - Handle Fastener

- must be removed to reach the upper section retaining bolt

3 - Bolt

- For the flanging tool upper section

4 - Threaded Pins for Flaring Jaws

- Center and hold the flaring jaws

- 2 mm inner hex socket

5 - Flaring Jaws

- Variance

- Assembly instructions. Refer to → Fig. "Assembly Instructions for Flaring Jaws"

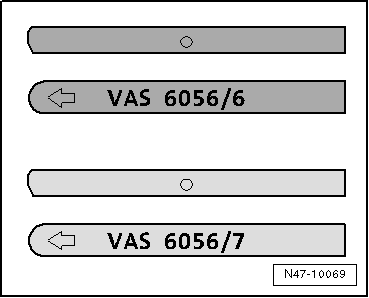

Assembly Instructions for Flaring Jaws

- Clamp Jaws (Plastic Coated Brake Lines Diam = Approx. 5.25 mm) -VAS6056/6- - (dark) for black brake lines

- Clamp Jaws (Brake Line Diam = Approx. 4.75 mm) -VAS6056/7- - (light) for green brake lines

Note

Note

The arrow on the rounded side of the flaring jaws must face toward edge of housing and the straight side of the flaring jaws must be installed toward spindle, otherwise the flared head will not be formed correctly.

Instructions

- Remove the affected brake line at brake caliper or brake cylinder and collect escaping brake fluid and dispose of it correctly.

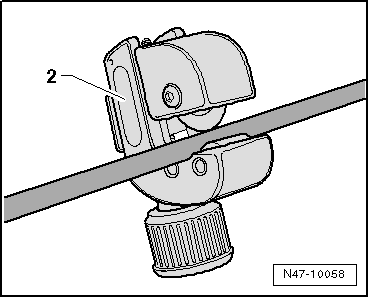

- Disconnect the brake line at appropriate location (straight, accessible part) with the pipe cutter -2-.

- Remove the piece to be exchanged.

- Grease the brake line surface.

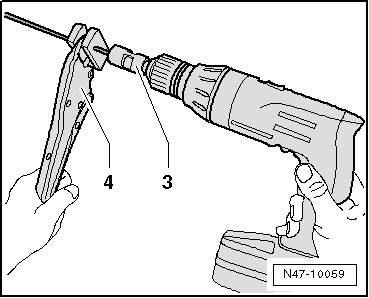

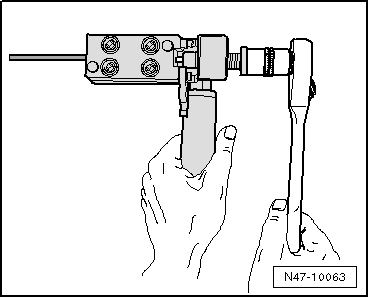

- Clamp the brake line in self-grip pliers -4- so that 50 mm of the plastic clamping jaws show.

- Clamp the shearing tool -3- in a drill and place it on the brake line.

- Shear the coating from the brake line at a slow drill RPM and with light pressure against the line.

The length of the sheared-off portion is determined by the stop in the shearing tool.

- Remove the shearing tool from the brake line and remove the shearing remains.

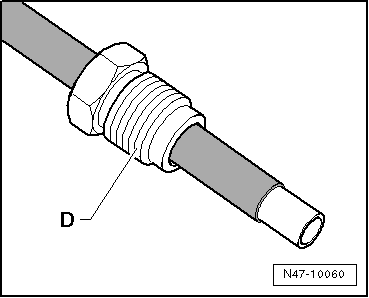

- Remove locking pliers and union bolt -D- from brake line.

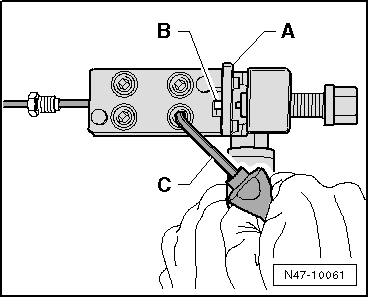

- Slide the brake line -B- against the stop -A- in the flaring tool.

Note

Note

The brake line must contact the stop when tightening the hex socket bolts, otherwise the flanged head will not be formed correctly.

C - Long reach special wrench

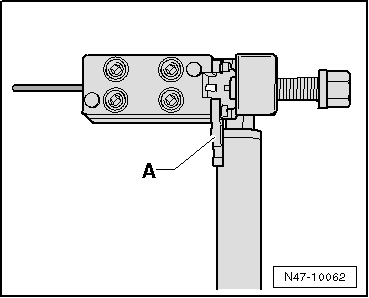

- Pretension the brake line inside the flaring unit until the brake line can no longer be moved. Fold stop -A- up and tighten hex socket head screws diagonally with long reach special wrench.

- Turn the spindle until it stops in the flaring tool.

- Turn the spindle back.

- Loosen the hex socket bolts diagonally.

- Remove the brake line from the flaring tool, clean and check the brake line and the flared head.

- Quickly rinse the part of the brake line still in the vehicle by connecting the Brake Charger/Bleeder Unit -VAS5234-.

- Connect the container hose to the flared head of the brake line and let the Brake Charger/Bleeder Unit -VAS5234- run briefly until some brake fluid runs through.

- Clean the new brake line to be inserted with compressed air.

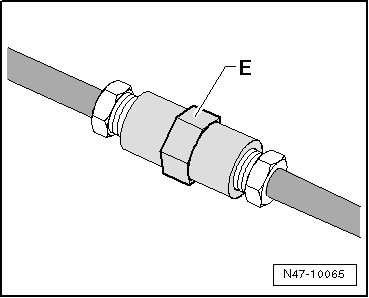

- Join the brake lines with the connecting piece -E-.

- Assemble the brake line.

- Then bleed the brake system. Refer to → Chapter "Hydraulic System, Standard Bleeding".