Audi A6 Typ 4G: Bulkhead

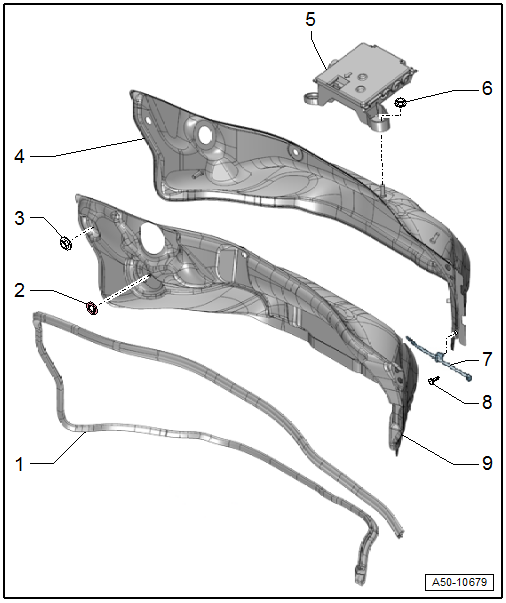

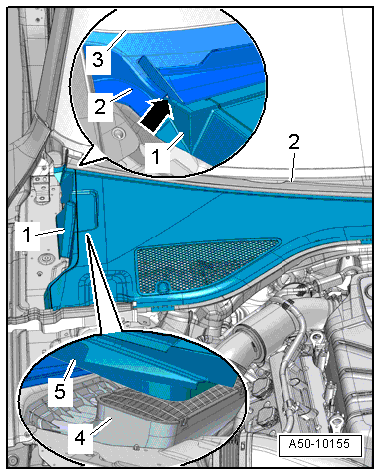

Overview - Bulkhead

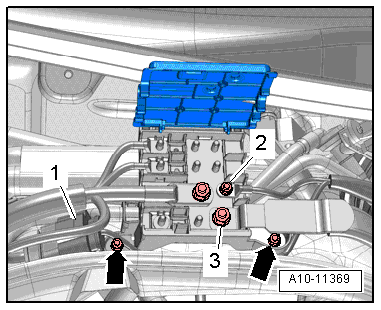

1 - Seal

- Install on the plenum chamber bulkhead

2 - Lock Washer

- Quantity: 2

3 - Nut

- 4 Nm

4 - Plenum Chamber Bulkhead

- There are different versions. Refer to the Parts Catalog.

- Removing and installing. Refer to → Chapter "Plenum Chamber Bulkhead, Removing and Installing".

5 - Terminal 30 Wire Junction -TV2-

- Removing and installing. Refer to → Electrical Equipment; Rep. Gr.97; Relay Carriers, Fuse Panels and E-Boxes; Overview - Relay Carriers, Fuse Panels and E-Boxes.

6 - Nut

- Tightening specification. Refer to → Electrical Equipment; Rep. Gr.97; Relay Carriers, Fuse Panels and E-Boxes; Overview - Relay Carriers, Fuse Panels and E-Boxes.

7 - Cable Bracket

- There are different versions. Refer to the Parts Catalog.

8 - Bolt

- 2 Nm

- There are different versions. Refer to the Parts Catalog.

9 - Heat Shield

- Overview. Refer to → Chapter "Overview - Heat Shield".

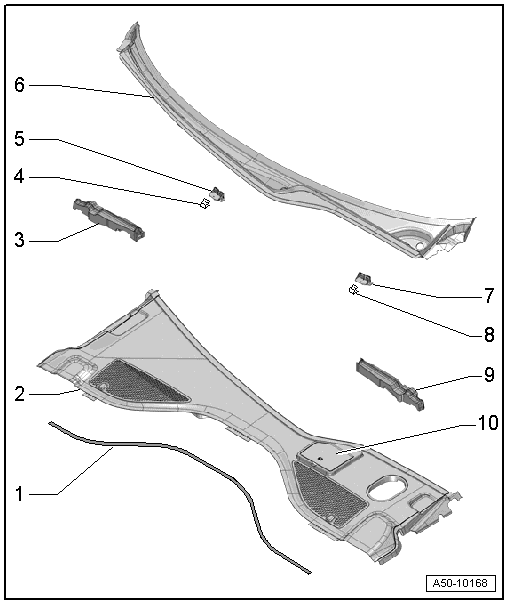

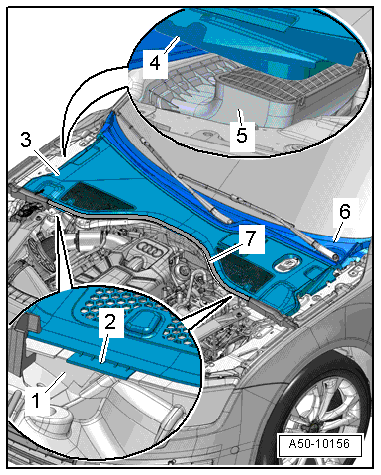

Overview - Plenum Chamber Cover

1 - Seal

- Replace if damaged.

2 - Plenum Chamber Cover

- Removing and installing. Refer to → Chapter "Plenum Chamber Cover, Removing and Installing".

3 - Right Foam Piece

4 - Clip

5 - Right Mount

- For clip

6 - Cowl Panel Trim

- Removing and installing. Refer to → Chapter "Cowl, Removing and Installing".

7 - Left Mount

- For clip

8 - Clip

9 - Left Foam Piece

10 - Cover

- For the brake fluid reservoir

Plenum Chamber Bulkhead, Removing and Installing

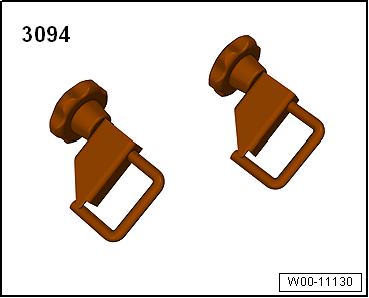

Special tools and workshop equipment required

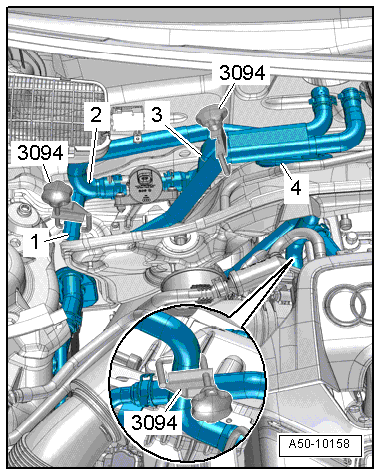

- Hose Clamps - Up To 25 mm -3094-

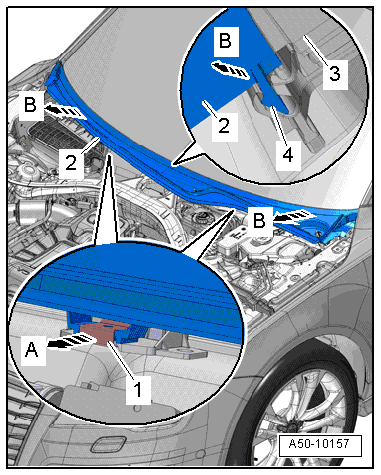

Removing

- Remove the tower brace. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Suspension Strut and Upper Control Arm; Tower Brace, Removing and Installing.

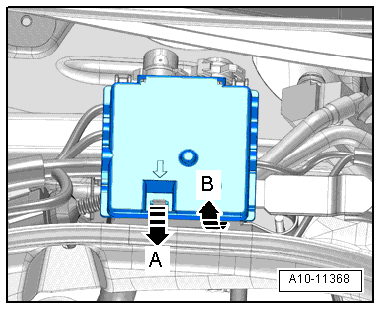

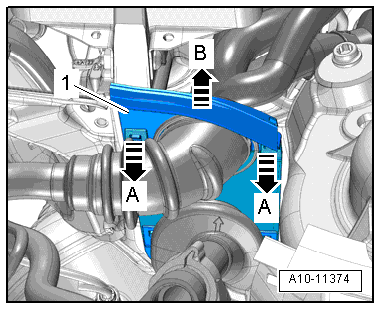

- Release the retainer -arrow A- and open the cover -arrow B-.

- Remove the nut -3- and free up the wire.

- Remove the connector -1- from the bracket.

- Remove the nuts -arrows- and then remove Terminal 30 Wire Junction 2 -TV22- from the plenum chamber bulkhead.

Note

Note

Ignore -item 2-.

- Free up the wiring harness on the plenum chamber bulkhead.

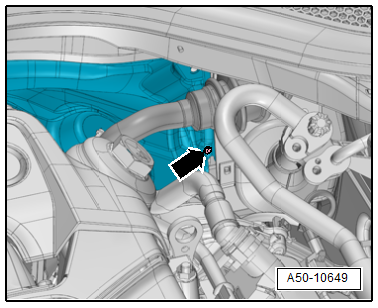

Vehicles with a Gasoline Engine:

- Cover the area under the shut-off valve with an absorbent cloth or paper.

- Clamp off the coolant hoses -1 and 3- with Hose Clamps - Up To 25mm -3094-.

- Open the clamps and remove the coolant hose -2- from the shut-off valve.

- Remove the grommet -4- on the plenum chamber bulkhead to the engine.

Note

Note

A vehicle with an auxiliary heater is shown in the illustration.

Continuation for all Vehicles:

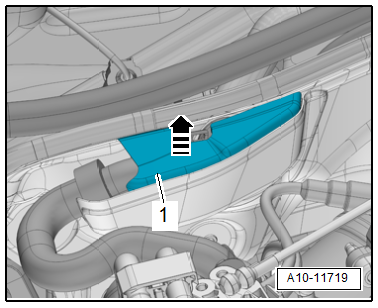

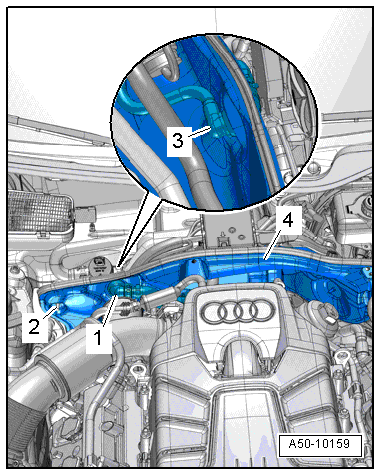

- Remove the heat shield -1- upward -arrow-, if equipped.

- Release the retainers -A arrows- and remove the wiring bushing -1- upward -arrow B-.

- Remove the bolt -arrow-.

Note

Note

Different types of fasteners may be installed. There can be a cable bracket, clip or bolt.

- Remove the brake booster vacuum line -3-.

- Remove the grommet -1- from the vacuum connection.

- Remove the nut -2- and then remove the plenum chamber bulkhead -4- upward.

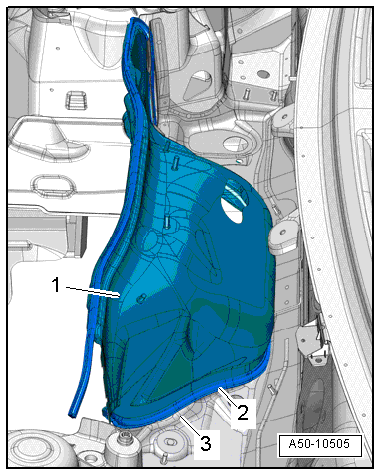

Installing

- Tightening specification: Refer to → Chapter "Overview - Bulkhead".

Install in reverse order of removal. Note the following:

- Make sure the seal -2- on the plenum chamber bulkhead -1- fits correctly into the mount -3- on the plenum chamber.

- Check the coolant level. Refer to → Rep. Gr.19; Coolant System/Coolant; Coolant, Draining and Filling.

Plenum Chamber Cover, Removing and Installing

Plenum Chamber Cover, Removing and Installing

Removing

- Remove the seal -7-.

- Lift the plenum chamber cover -3- far enough so that the frame -4- is above the air intake shroud -5- for the fresh air blower.

- Remove the plenum chamber cover from the cowl panel -6-.

Note

Note

The tab -2- over the cover -1- will get damaged if the seal is not removed.

Installing

Install in reverse order of removal. Note the following:

Note

Note

- Be careful not to damage the plenum chamber cover -2- and the plenum chamber cover with frame -5- for the air intake shroud -4- to prevent water from getting into the air conditioner when the plenum chamber cover is installed -1-.

- The plenum chamber cover cowl panel must lock completely into the windshield frame -3-.

- The plenum chamber cover must be installed correctly and completely into the mount -arrow- for cowl panel.

Cowl, Removing and Installing

Removing

- Remove the plenum chamber cover. Refer to → Chapter "Plenum Chamber Cover, Removing and Installing".

- Remove the windshield wiper arms. Refer to → Electrical Equipment; Rep. Gr.92; Windshield Wiper System; Windshield Wiper Arms, Removing and Installing.

- Remove the clip -1--arrow A-.

Caution

Caution

Danger of causing damage to the wind cowl.

Coat the transition between the windshield and the cowl panel with a soapy solution.

- Remove the cowl panel -2- from the retainer -4- on the windshield -3- vertically upward -arrows B- starting on the edge of the glass.

Installing

Install in reverse order of removal. Note the following:

Note

Note

- Be careful not to damage the cowl panel otherwise water can get into the air conditioner via the air intake shroud.

- The plenum chamber cover cowl panel must lock completely into the windshield frame.

Special Tools

Special tools and workshop equipment required

- Drill

- Brill diameter 4 mm.

- Hose Clamps - Up To 25 mm -3094-

- Pry Lever -80 - 200-