Audi A6 Typ 4G: Left Seal, Replacing

Left Seal, Replacing, 0BC

- In this chapter "right seal, replacing" is also described.

- The shaft seal can be only be replaced with the final drive removed.

Special tools and workshop equipment required

- Puller - Flanged Shaft -T10037-

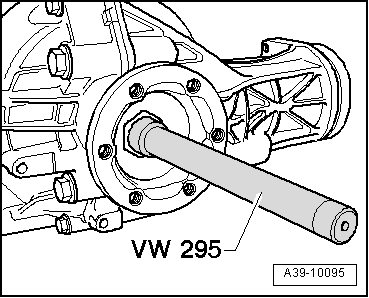

- Bearing/Bushing Installer - Multiple Use -VW295-

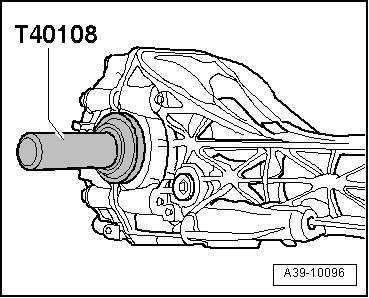

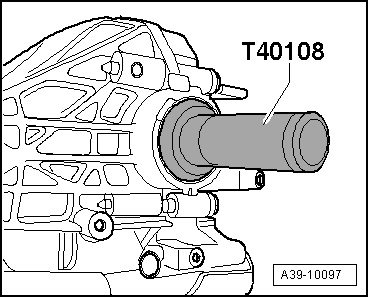

- Seal Installer - Flange Shaft -T40108-

- Sealing Grease -G 052 128 A1-

Removing

- Follow all general repair information. Refer to → Chapter "Repair Information".

- Remove the rear final drive. Refer to → Chapter "Final Drive, Removing and Installing".

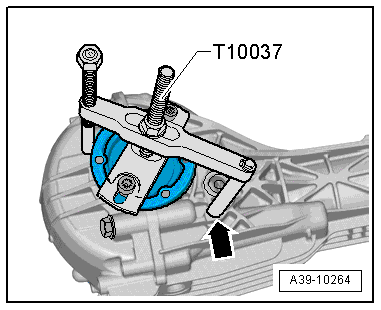

Remove the Right Flange Shaft.

- Attach the Puller - Flanged Shaft -T10037- to the housing -arrow- and remove the flange shaft.

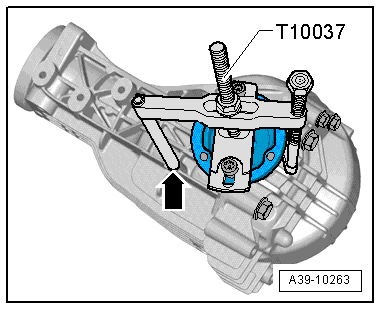

Left Flange Shaft, Removing

- Attach the Puller - Flanged Shaft -T10037- to the housing -arrow- and remove the flange shaft.

- Use a suitable tool to pry out the seal.

Installing

Install in reverse order of removal. Note the following:

Right Shaft Seal, Installing

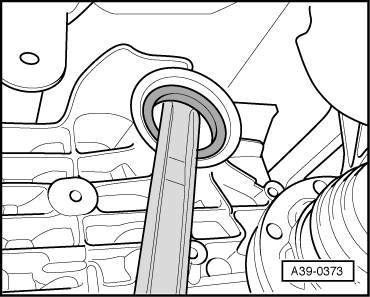

- Coat outer edge of the seal with gear oil.

- Fill the space between the sealing/dust lip halfway with Sealing Grease -G 052 128 A1-.

- Drive in new shaft seal as far as stop without tilting it.

Left Shaft Seal, Installing

- Coat outer edge of the seal with gear oil.

- Fill the space between the sealing/dust lip halfway with Sealing Grease -G 052 128 A1-.

- Drive in new shaft seal as far as stop without tilting it.

Right and Left Flange Shafts, Installing

- Drive the flange shaft in using a Bearing/Bushing Installer - Multiple Use -VW295-.

- Install the rear final drive. Refer to → Chapter "Final Drive, Removing and Installing".

- Check the gear oil in rear final drive. Refer to → Chapter "Gear Oil, Checking Level, 0BC".

Left Seal, Replacing, 0BE, 0BF

- In this chapter "right seal, replacing" is also described.

- The shaft seal can be only be replaced with the final drive removed.

Special tools and workshop equipment required

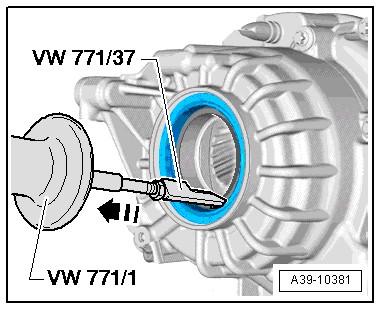

- Slide Hammer Set -VW771-

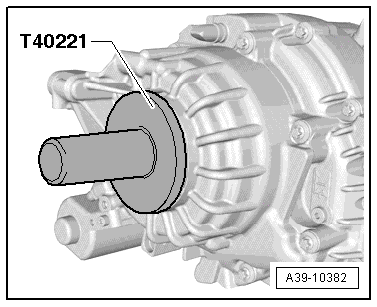

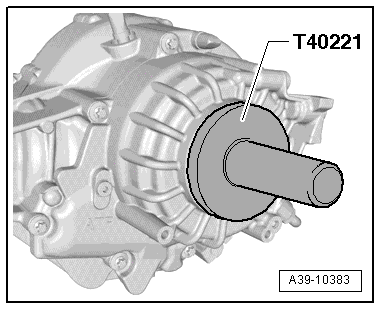

- Seal Installer - Drift Shaft -T40221-

- ATF

Removing

- Follow all general repair information. Refer to → Chapter "Repair Information".

- Remove the rear final drive. Refer to → Chapter "Final Drive, Removing and Installing".

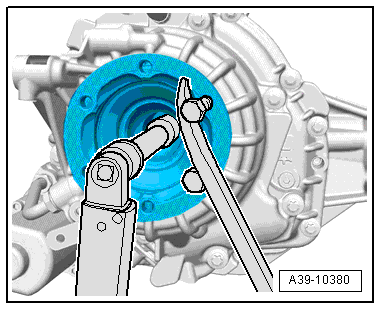

- Remove the flange shaft bolt. To do this, install two bolts into the flange and counterhold the flange shaft using an assembly lever.

- Remove the flange shaft.

Note

Note

If it not possible to remove the flange shaft by hand, then use the Slide Hammer Set -VW771- to remove it.

- Remove flange shaft seal with the Slide Hammer Set -VW771- and Slide Hammer Set - Pulling Hook -VW771/37-.

Installing

Install in reverse order of removal. Note the following:

Right Shaft Seal, Installing

- Coat the outer circumference and the sealing lips on the shaft seal with ATF.

- Install the shaft seal all the way. Be careful not to bend it.

Left Shaft Seal, Installing

- Coat the outer circumference and the sealing lips on the shaft seal with ATF.

- Install the shaft seal all the way. Be careful not to bend it.

- Install the flange shaft.

Note

Note

If it is not possible to install the flange shaft all the way in by hand, then use a plastic mallet.

- Tighten the new flange shaft bolt to the tightening specification. Refer to -item 1-.

- Install the rear final drive. Refer to → Chapter "Final Drive, Removing and Installing".

- Check the ATF level in the rear final drive. Refer to → Chapter "ATF Level, Checking, 0BE, 0BF".

Right Seal, Replacing

Note

Note

Replacing the right seal is described in the chapter "left seal, replacing".