Audi A6 Typ 4G: Overview - Front Brakes

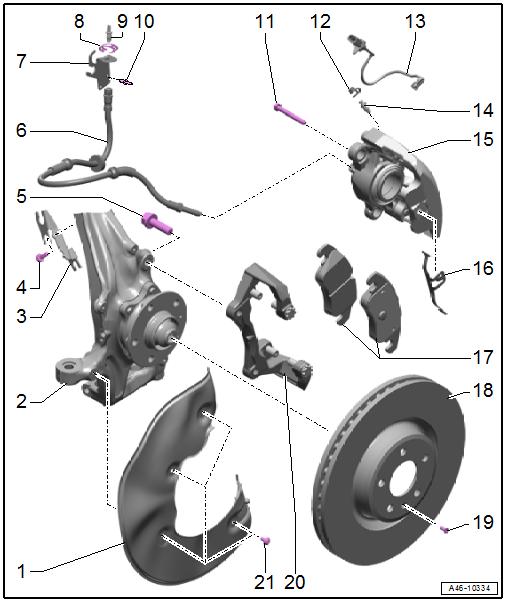

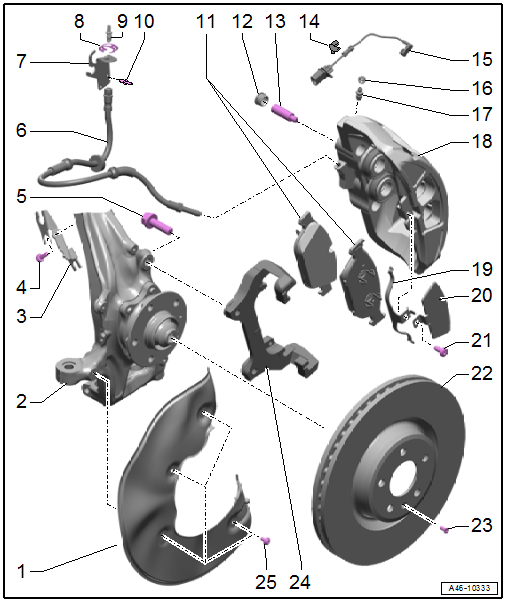

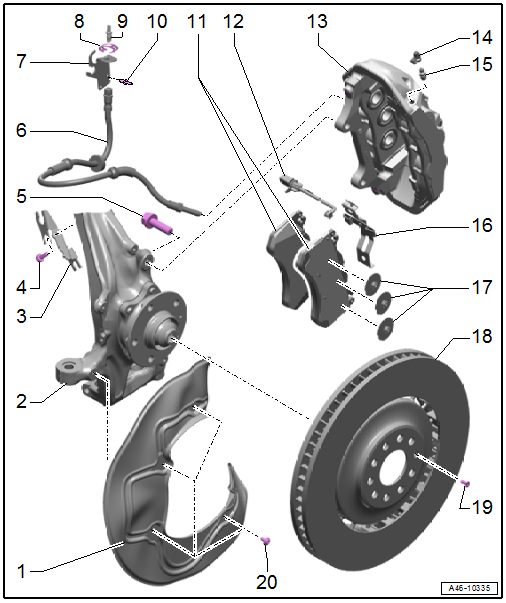

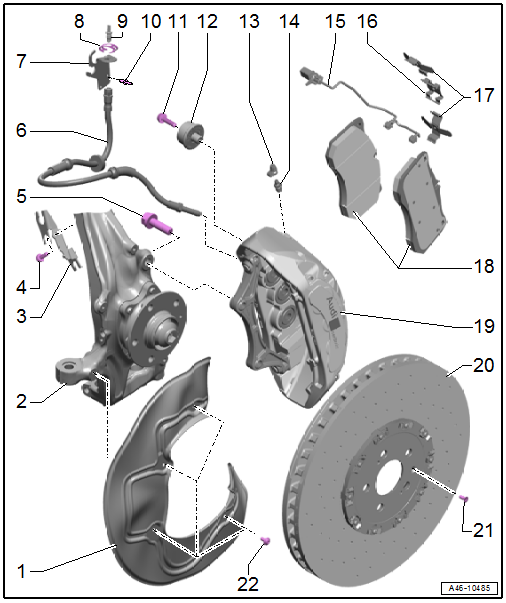

Overview - Front Brakes, Steel Brakes, 1LA/1LJ

1 - Brake Shield

2 - Stub Axle Carrier

3 - Bracket

- For brake hose and wire

4 - Bolt

- 9 Nm

5 - Bolt

- 196 Nm

- With a washer

- Quantity: 2

- Replace after removing

6 - Brake Hose

- Pay attention to the correct routing: make sure the brake hose is not blocked, bent or rubbing against the vehicle

- Replace if damaged

- Make sure that tabs are properly seated in the grooves on the bracket.

- Tightening specification, brake hose to brake caliper, 20 Nm

7 - Bracket

- For brake hose

8 - Spring

- Replace if damaged

9 - Brake Line

- Tightening specification, brake line to brake hose, 16 Nm

10 - Rivet

- Quantity: 2

11 - Bolt

- 30 Nm

- Quantity: 2

12 - Protective Dust Cap

13 - Brake Pad Wear Sensor

- Left Front Brake Pad Wear Sensor -G34-, Right Front Brake Pad Wear Sensor -G35-

- For inner brake pad

- Replace if damaged

- Refer to → Chapter "Brake Pad Wear Indicator Wire, Removing and Installing, Steel Brakes, 1LA/1LJ"

14 - Bleed Screw

- 13 Nm

- Refer to → Chapter "Hydraulic System, Standard Bleeding"

15 - Brake Caliper

- Allocation. Refer to the Parts Catalog.

- Do not loosen the brake caliper threaded connections. Refer to → Fig. "Do not loosen the brake caliper threaded connections.".

- Servicing. Refer to → Chapter "Brake Caliper Piston, Removing and Installing, 1LA/1LJ".

Note

Note

- Depending on the model there are two balance weights installed in each front brake caliper.

16 - Balance Spring

- Make sure the balance spring is correctly installed

- Tab of the balance spring engages into the brake caliper

17 - Brake Pads

- Allocation. Refer to the Parts Catalog.

- Inner brake pad with brake pad wear sensor

- Checking pad thickness. Refer to → for the wear limit.

- Always replace on both sides of the axle

18 - Brake Rotor

- Allocation. Refer to the Parts Catalog.

- Wear limit. Refer to → Chapter "Technical Data, Brakes"

- Always replace on both sides of the axle

- Do not use force to separate the brake rotor from the wheel hub. If required use rust remover otherwise there will be damage to the brake rotors

19 - Bolt

- 10 Nm

20 - Brake Carrier

- Do not loosen the retaining pin. Refer to → Fig. "Do not loosen the retaining pin on the brake carrier".

- Brake Caliper with Brake Carrier, removing and installing. Refer to → Chapter "Brake Caliper, Removing and Installing, Steel Brakes, 1LA/1LJ".

21 - Bolt

- 10 Nm

- Quantity: 4

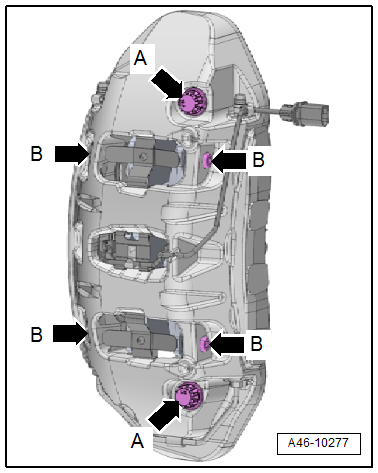

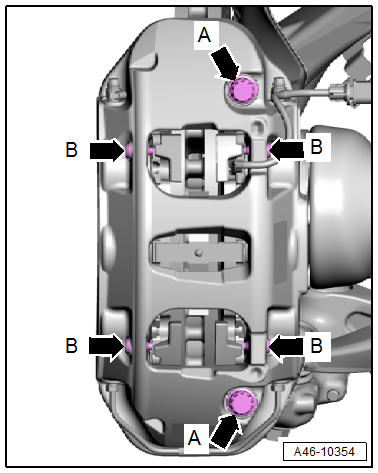

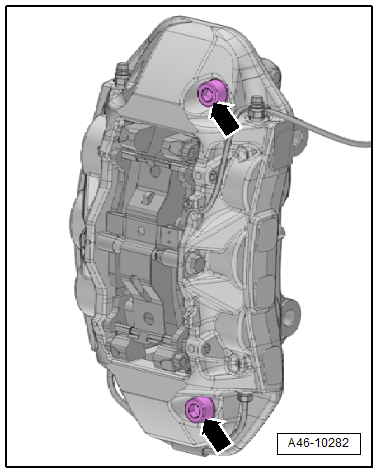

Do not loosen the brake caliper threaded connections.

Caution

Caution

Risk of malfunction.

Do not loosen the bolts -arrows- on the brake caliper.

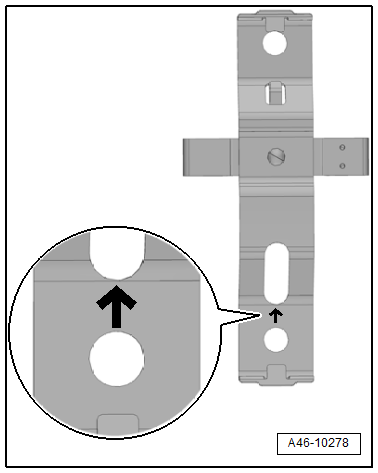

Do not loosen the retaining pin on the brake carrier

Caution

Caution

Risk of malfunction.

Do not loosen the retaining pins -arrows- on the brake carrier.

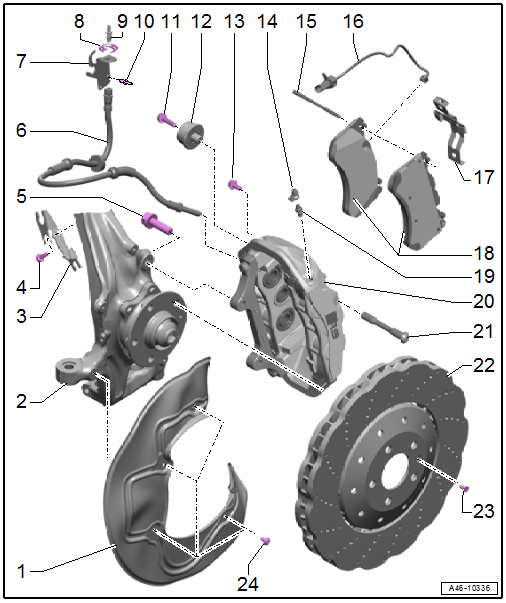

Overview - Front Brakes, Steel Brakes, 1LF/1LL/1ZK/FM0

1 - Brake Shield

2 - Stub Axle Carrier

3 - Bracket

- For brake hose and wire

4 - Bolt

- 9 Nm

5 - Bolt

- 196 Nm

- With a washer

- Quantity: 2

- Replace after removing

6 - Brake Hose

- 20 Nm (brake hose to brake caliper)

- Pay attention to the correct routing: make sure the brake hose is not blocked, bent or rubbing against the vehicle

- Replace if damaged

- Make sure that tabs are properly seated in the grooves on the bracket.

7 - Bracket

- For brake hose

8 - Spring

- Replace if damaged

9 - Brake Line

- 16 Nm (brake line to brake hose)

10 - Rivet

- Quantity: 2

11 - Brake Pads

- Allocation. Refer to the Parts Catalog.

- Inner brake pad with brake pad wear sensor

- Checking pad thickness. Refer to → for the wear limit.

- Always replace on both sides of the axle

12 - Protective Cap

13 - Guide Pin

- 55 Nm

- Seal with a protective cap

14 - Clip

15 - Brake Pad Wear Sensor

- Left Front Brake Pad Wear Sensor -G34-/Right Front Brake Pad Wear Sensor -G35-

- For inner brake pad

- Replace if damaged

- Refer to → Chapter "Brake Pad Wear Indicator Wire, Removing and Installing, Steel Brakes, 1LF/1LL"

16 - Protective Dust Cap

17 - Bleed Screw

- 13 Nm

- Refer to → Chapter "Hydraulic System, Standard Bleeding"

18 - Brake Caliper

- Allocation. Refer to the Parts Catalog.

- Servicing. Refer to → Chapter "Brake Caliper Piston, Removing and Installing, 1LF/1LL".

Note

Note

- Depending on the model there are two balance weights installed in each front brake caliper.

19 - Balance Spring

- Make sure the cover and balance spring are installed correctly

- Tab of the balance spring engages into the brake caliper

- Tip of the balance spring fits under the trim

20 - Trim

- Make sure the cover and balance spring are installed correctly

- Tip of the balance spring fit into the brake caliper

- Tip of the balance spring fits under the trim

21 - Bolt

- 22 Nm

22 - Brake Rotor

- Allocation. Refer to the Parts Catalog.

- Wear limit. Refer to → Chapter "Technical Data, Brakes"

- Always replace on both sides of the axle

- Do not use force to separate the brake rotor from the wheel hub. If required use rust remover otherwise there will be damage to the brake rotors

23 - Bolt

- 10 Nm

24 - Brake Carrier

- Bolt to wheel bearing housing

- Brake Caliper with Brake Carrier, removing and installing. Refer to → Chapter "Brake Caliper, Removing and Installing, Steel Brakes, 1LF/1LL".

25 - Bolt

- 10 Nm

- Quantity: 4

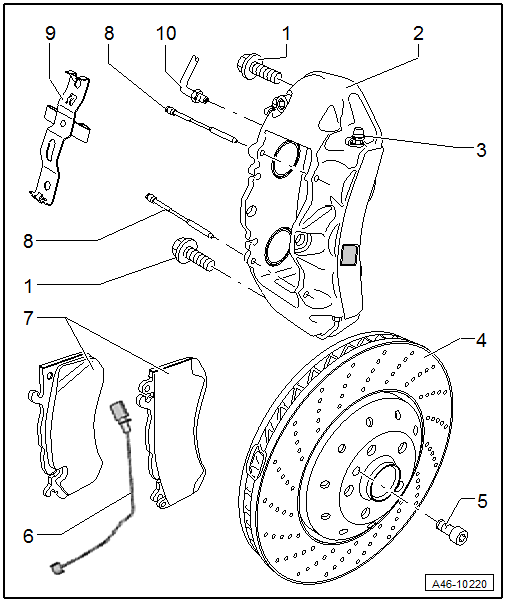

Overview - Front Brakes, 1LP

1 - Bolt

- 196 Nm

Note

Note

Loosen only the coil spring bolts

2 - Brake Caliper

- Do not loosen any screws on the brake caliper.

Note

Note

- Depending on the model there are two balance weights installed in each front brake caliper.

3 - Bleed Screw

4 - Brake Rotor

- Allocation. Refer to the Parts Catalog.

- Always replace on both sides of the axle

- Wear limit

- Clean and lubricate contact surfaces between brake rotor and wheel hub. Refer to the Parts Catalog.

5 - Bolt

- 10 Nm

- Brake rotor to wheel hub

6 - Brake Pad Wear Wire

- on inner brake pad

7 - Brake Pads

- With the brake pad wear wire on the inside of the brake pad

- Check the pad thickness.

- Wear limit.

- Before installing the brake pads, clean the pad guide surface and coat it with a film of grease. Grease. Refer to Parts Catalog.

- Make sure it is in the installation position

8 - Brake Pad Pins

- Make sure it is in the installation position

- Press all the way from the inside toward the outside

9 - Brake Pad Spring

- Make sure it is in the installation position

10 - Brake Line Hose

- 19 Nm

Note

Note

Do not loosen when changing brake pads

Installed position for the brake pad spring brake pad pin -7-, brake pad pin -8-

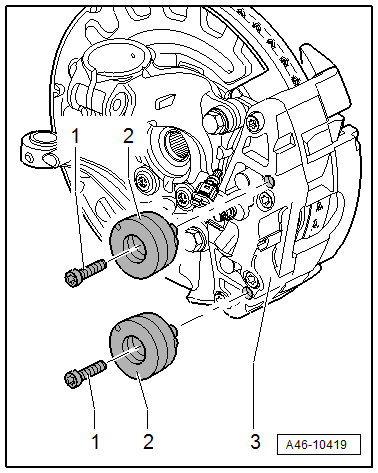

Overview - Brake Caliper Balance Weight

Depending on the model there are two balance weights installed in each front brake caliper.

1 - Bolt

- 10 Nm

- Replace after removing

2 - Vibration Damper

- Installed twice in each front brake caliper

3 - Brake Caliper

Overview - Front Brakes, Steel Brakes, 1LU

1 - Brake Shield

2 - Stub Axle Carrier

3 - Bracket

- For brake hose and wire

4 - Bolt

- 9 Nm

5 - Bolt

- 196 Nm

- With a washer

- Quantity: 2

- Replace after removing

6 - Brake Hose

- 20 Nm (brake hose to brake caliper)

- Pay attention to the correct routing: make sure the brake hose is not blocked, bent or rubbing against the vehicle

- Replace if damaged

- Make sure that tabs are properly seated in the grooves on the bracket.

7 - Bracket

- For brake hose

8 - Spring

- Replace if damaged

9 - Brake Line

- 16 Nm (brake line to brake hose)

10 - Rivet

- Quantity: 2

11 - Brake Pads

- Allocation. Refer to the Parts Catalog.

- Inner brake pad with brake pad wear sensor

- Checking pad thickness. Refer to → for the wear limit.

- Always replace on both sides of the axle

12 - Brake Pad Wear Sensor

- Left Front Brake Pad Wear Sensor -G34-/Right Front Brake Pad Wear Sensor -G35-

- For inner brake pad

- Replace if damaged

- Removing and installing. Refer to → Chapter "Brake Pad Wear Indicator Wire, Removing and Installing, Steel Brakes, 1LU".

13 - Brake Caliper

- Allocation. Refer to the Parts Catalog.

- Do not loosen the brake caliper threaded connections. Refer to → Fig. "Do not loosen the brake caliper threaded connections.".

- Servicing. Refer to → Chapter "Brake Caliper Piston, Removing and Installing, 1LU/1LM/1LX/1LN/1LW".

Note

Note

- Depending on the model there are two balance weights installed in each front brake caliper.

14 - Protective Dust Cap

15 - Bleed Screw

- 13 Nm

16 - Brake Pad Spring

- Note the installation position. Refer to → Fig. "Installation position of the brake pad spring".

- Replace when pads are replaced.

- Make sure then fits correctly inside the brake caliper

17 - Shim

- With adhesive pad

- Quantity: 6

- Insert into the brake caliper pistons before inserting the outer brake pads

Note

Note

- Use new shims when installing new brake pads. Insert the shims into the brake pistons before inserting the brake pads.

- If the old brake pads are reinstalled, insert the brake pads with the shims attached into the brake caliper.

18 - Brake Rotor

- Allocation. Refer to the Parts Catalog.

- Wear limit. Refer to → Chapter "Technical Data, Brakes"

- Always replace on both sides of the axle

- Do not use force to separate the brake rotor from the wheel hub. If required use rust remover otherwise there will be damage to the brake rotors

19 - Bolt

- 10 Nm

20 - Bolt

- 10 Nm

- Quantity: 4

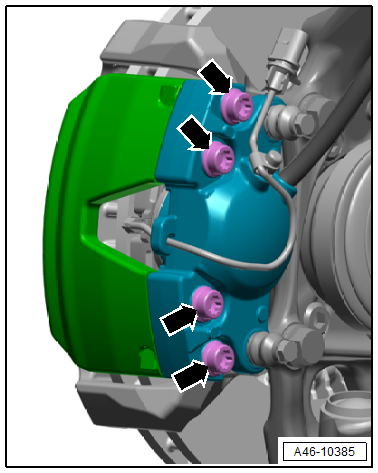

Do not loosen the brake caliper threaded connections.

Caution

Caution

Risk of malfunction.

- Do not loosen the bolts -arrows- on the brake caliper.

- Do not remove the guide pins -arrows B-.

Note

Note

The guide pins -B arrows- are only replaced on the ceramic brakes.

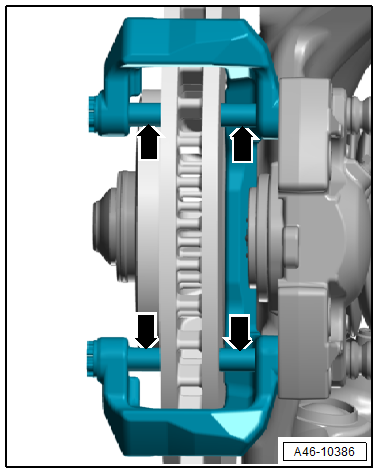

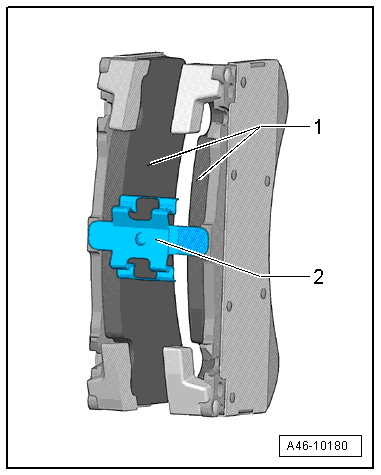

Installation position of the brake pad spring

Note

Note

Pay attention to the correct installation position of the brake pad spring -2- between the brake pads -1-.

Overview - Front Brakes, Steel Brakes, 1LM/1LX

1 - Brake Shield

2 - Stub Axle Carrier

3 - Bracket

- For brake hose and wire

4 - Bolt

- 9 Nm

5 - Bolt

- 196 Nm

- With a washer

- Quantity: 2

- Replace after removing

6 - Brake Hose

- 20 Nm (brake hose to brake caliper)

- Make sure the brake hose is routed correctly. Make sure the brake hose is not blocked, bent or rubbing against the vehicle.

- Replace if damaged

- Make sure that tabs are properly seated in the grooves on the bracket.

7 - Bracket

- For brake hose

8 - Spring

- Replace if damaged

9 - Brake Line

- 14 Nm (Brake line to brake hose)

10 - Rivet

- Quantity: 2

11 - Bolt

- 9 Nm

- Quantity: 4

12 - Balance Weight

- Quantity: 2

13 - Bolt

- 30 Nm

- For the tension strut

- Replace after removing

14 - Protective Cap

15 - Brake Pad Pin

- Quantity: 2

- Replace when pads are replaced.

- Note the installation position

- Drive out from the outside toward the inside

16 - Brake Pad Wear Sensor

- Left Front Brake Pad Wear Sensor -G34-/Right Front Brake Pad Wear Sensor -G35-

- For inner brake pad

- Replace if damaged

- Cannot be removed without being damaged

- Removing and installing. Refer to → Chapter "Brake Pad Wear Indicator Wire, Removing and Installing, Steel Brakes, 1LM/1LX".

17 - Brake Pad Spring

- Note the installation position. Refer to → Fig. "Installed Position for the Brake Pad Spring".

- Replace when pads are replaced.

- Make sure then fits correctly inside the brake caliper

18 - Brake Pads

- Checking pad thickness. Refer to → for the wear limit.

- Always replace on both sides of the axle

- Allocation. Refer to the Parts Catalog.

- Note installed position: inner brake pad with brake pad wear sensor mount

19 - Bleed Screw

- 13 Nm

20 - Brake Caliper

- May not be removed from the brake carrier. Refer to → Fig. "Do not loosen the caliper/brake carrier bolted connections."

- Allocation. Refer to the Parts Catalog.

- Servicing. Refer to → Chapter "Brake Caliper Piston, Removing and Installing, 1LU/1LM/1LX/1LN/1LW".

Note

Note

- Depending on the model there are two balance weights installed in each front brake caliper.

21 - Tension Strut

- Replace when pads are replaced.

22 - Brake Rotor

- Wear limit. Refer to → Chapter "Technical Data, Brakes".

- Allocation. Refer to the Parts Catalog.

- Always replace on both sides of the axle

23 - Bolt

- 10 Nm

24 - Bolt

- 10 Nm

- Quantity: 4

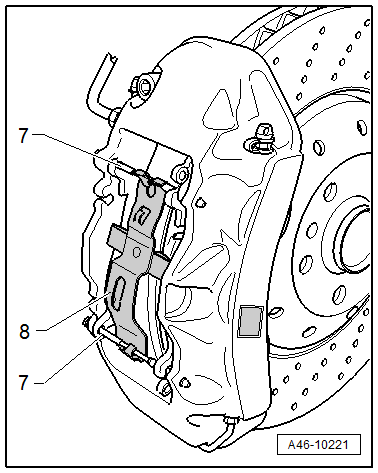

Do not loosen the caliper/brake carrier bolted connections.

Caution

Caution

Risk of malfunction.

Do not loosen the bolts -arrows- on the brake caliper.

Installed Position for the Brake Pad Spring

- The "arrow" points in the direction of forward wheel rotation.

Overview - Front Brakes, Ceramic, 1LN/1LW

1 - Brake Shield

2 - Stub Axle Carrier

3 - Bracket

- For brake hose and wire

4 - Bolt

- 9 Nm

5 - Bolt

- 196 Nm

- With a washer

- Quantity: 2

- Replace after removing

6 - Brake Hose

- Make sure the brake hose is routed correctly. Make sure the brake hose is not blocked, bent or rubbing against the vehicle.

- Replace if damaged

- Make sure that tabs are properly seated in the grooves on the bracket.

- 20 Nm (brake hose to brake caliper)

7 - Bracket

- For brake hose

8 - Spring

- Replace if damaged

9 - Brake Line

- 14 Nm (brake line to brake hose)

10 - Rivet

- Quantity: 2

11 - Bolt

- 9 Nm

- Quantity: 4

12 - Balance Weight

- Quantity: 2

13 - Protective Cap

14 - Bleed Screw

- 13 Nm

15 - Brake Pad Wear Sensor

- Left Front Brake Pad Wear Sensor -G34-/Right Front Brake Pad Wear Sensor -G35-

- Replace if damaged

- Cannot be removed without being damaged

- Removing and installing. Refer to → Chapter "Brake Pad Wear Indicator Wire, Removing and Installing, Ceramic Brakes, 1LN/1LW".

16 - Bracket

- For brake pad wear sensor electrical wire

- Replace if damaged

- Make sure then fits correctly inside the brake caliper

17 - Brake Pad Springs

- Note the installation position

- Replace when pads are replaced.

- Make sure then fits correctly inside the brake caliper

18 - Brake Pads

- Checking pad thickness. Refer to → for the wear limit.

- Always replace on both sides of the axle

- Allocation. Refer to the Parts Catalog.

- Note the installation position

19 - Brake Caliper

- 24 Nm (guide pin for the brake pads). Refer to → Fig. "The threaded connections -arrow A- on the brake caliper must not be loosened.".

- May not be removed from the brake carrier. Refer to → Fig. "The threaded connections -arrow A- on the brake caliper must not be loosened."

- Allocation. Refer to the Parts Catalog.

- Servicing. Refer to → Chapter "Brake Caliper Piston, Removing and Installing, 1LU/1LM/1LX/1LN/1LW".

Note

Note

- Depending on the model there are two balance weights installed in each front brake caliper.

- Refer to → Chapter "Overview - Brake Caliper Balance Weight"

20 - Brake Rotor

- Allocation. Refer to the Parts Catalog.

- Brake Rotor Thickness. Refer to → Chapter "Ceramic Brake Rotor, Determining Wear".

- Additionally check for:

- Cracks in connection area. Refer to → Chapter "Cracks in Ceramic Brake Rotor Connection Area".

- Chamfer. Refer to → Chapter "Chamfer".

- Nicks. Refer to → Chapter "Nicks on Ceramic Brake Rotor".

- Crack in cooling channel. Refer to → Chapter "Crack in Cooling Channel".

- Always replace on both sides of the axle

- Make note of the direction of travel

21 - Bolt

- 10 Nm

22 - Bolt

- 10 Nm

- Quantity: 4

The threaded connections -arrow A- on the brake caliper must not be loosened.

Caution

Caution

Risk of malfunction.

- Do not loosen the bolts -arrows- on the brake caliper.

- Replace the guide pins -B arrows- after removing.

Tighten the guide pin -B- to 24 Nm.