Audi A6 Typ 4G: Overview - Suspension Strut, Shock Absorber and Spring

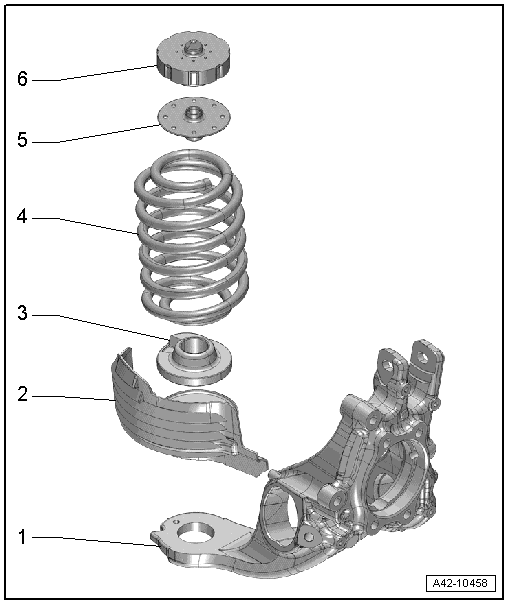

Overview - Suspension Strut, Shock Absorber and Spring, Coil Spring

1 - Wheel Bearing Housing

2 - Stone Chip Protection

3 - Lower Spring Plate

- Note the installed position. Refer to → Fig. "Lower Spring Plate Installed Position".

4 - Coil Spring

- Note the installed position. Refer to → Fig. "Coil Spring Installed Position".

5 - Spacer Piece

- Not installed on all vehicles. For the correct allocation. Refer to the Parts Catalog.

6 - Upper Spring Plate

- Vehicles with an upper eccentric spring plate. Refer to → Fig. "Upper Eccentric Spring Plate Installed Position"; for the correct allocation. Refer to the Parts Catalog.

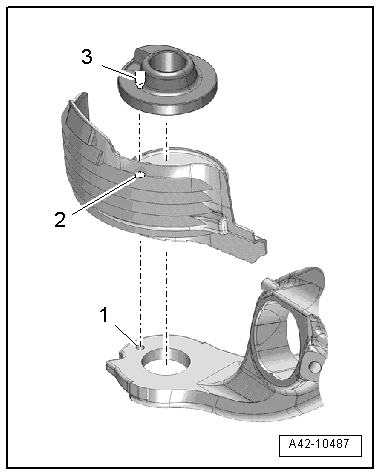

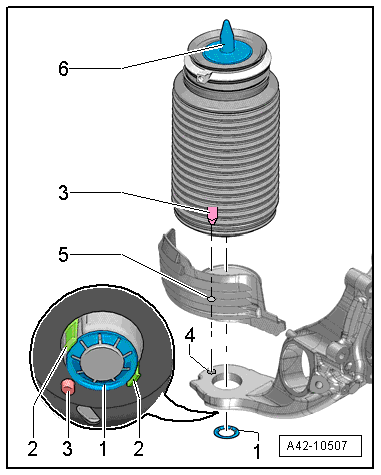

Lower Spring Plate Installed Position

- The centering pin -3- on the lower spring plate must fit into the hole -2- in the stone chip protection and into the hole -1- in the wheel bearing housing.

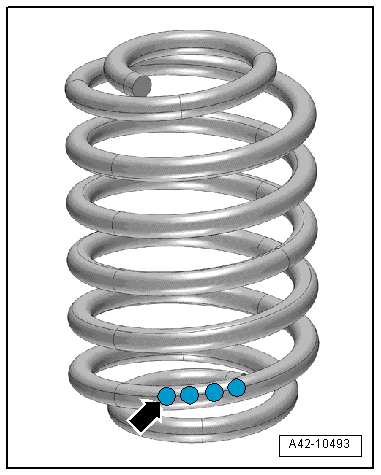

Coil Spring Installed Position

- Lower color marking -arrow-.

- Turn the end of the spring all the way to the lower spring plate.

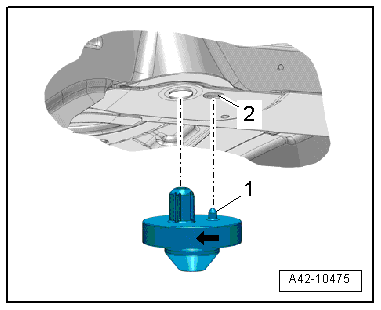

Upper Eccentric Spring Plate Installed Position

- The -arrow- indicates direction of travel.

- The centering pin -1- fit into the longitudinal member -2-.

Overview - Suspension Strut, Shock Absorber and Spring, Air Spring

1 - Spring Washer

2 - Wheel Bearing Housing

3 - Stone Chip Protection

4 - Air Spring

- Removing and installing. Refer to → Chapter "Spring, Removing and Installing, Air Spring".

- Note installed position. Refer to → Fig. "Air Spring Installed Position".

5 - Air line

- Tightening specification for the connector -Item 3-

Air Spring Installed Position

- The positioning pin -3- on the air spring must fit into the hole -5- in the stone chip protection and into the hole -4- in the wheel bearing housing.

- The hooks -2- must lock onto the lower wheel bearing housing.

- The spring washer -1- must be pushed on parallel up to the base of the air spring.

- The positioning pin -6- on the air spring must be installed correctly inside the body.

Overview - Suspension Strut, Shock Absorber and Spring, Shock Absorber

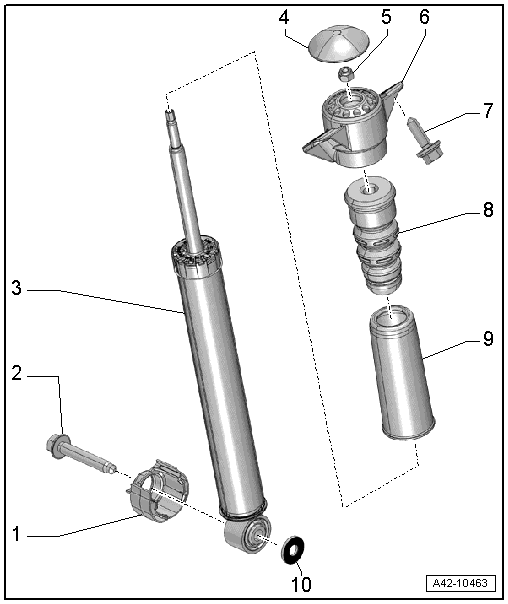

Conventional Shock Absorber

1 - Stone Chip Protection

2 - Bolt

- 150 Nm +180º turn

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

3 - Shock Absorber

- Because of different shock absorber valve systems, only install new shock absorbers from the same manufacturer on both axles.

- Removing and Installing. Refer to → Chapter "Shock Absorber, Removing and Installing".

- Servicing. Refer to → Chapter "Shock Absorber, Servicing, Standard Shock Absorber/with DRC System".

4 - Protective Cap

5 - Nut

- 35 Nm

- Always replace if removed

6 - Upper Shock Absorber Mount

7 - Bolt

- 50 Nm +90º turn

- Always replace if removed

8 - Stop Buffer

9 - Protective Sleeve

10 - Washer

- Serves as corrosion protection

- Always use

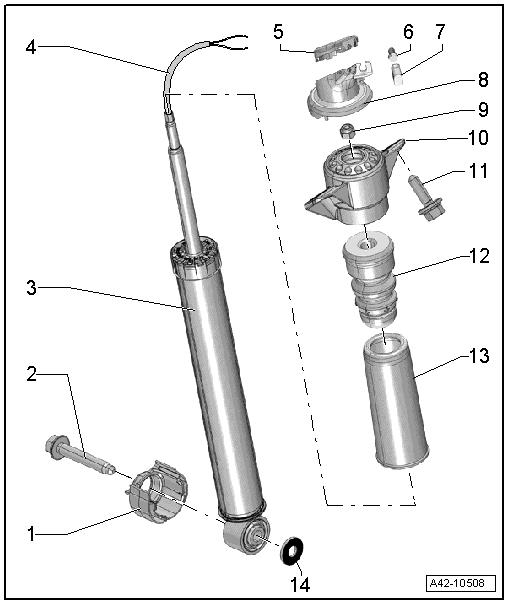

Shock Absorber with Electronic Damping

1 - Stone Chip Protection

2 - Bolt

- 150 Nm +180º turn

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

3 - Shock Absorber

- Removing and installing. Refer to → Chapter "Shock Absorber, Removing and Installing".

- Servicing. Refer to → Chapter "Shock Absorber, Servicing, Standard Shock Absorber/with DRC System".

4 - Cable

5 - Protective Cap

6 - Seal

- For the connector

7 - Connector Housing

- Do not bend or twist the electric wire when connecting the connector

8 - Protective Cap

9 - Nut

- 50 Nm

- Always replace if removed

10 - Upper Shock Absorber Mount

11 - Bolt

- 50 Nm +90º turn

- Always replace if removed

12 - Stop Buffer

13 - Protective Sleeve

14 - Washer

- Serves as corrosion protection

- Always use

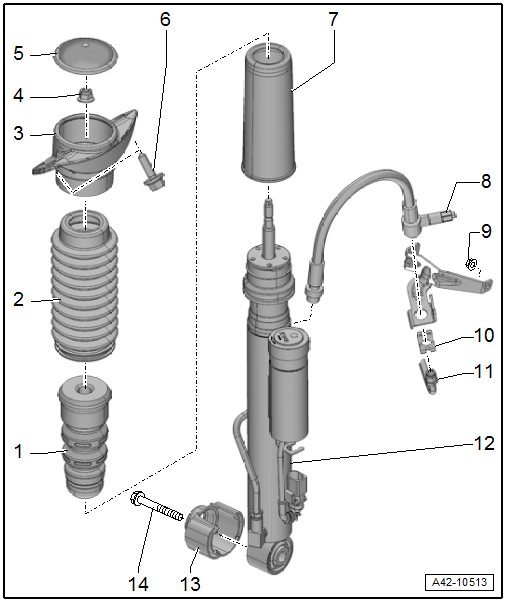

Shock Absorber with Dynamic Ride Control (DRC) System

1 - Stop Buffer

2 - Protective Sleeve

3 - Shock Absorber Mount

4 - Nut

- 35 Nm

- Always replace if removed

5 - Protective Cap

6 - Bolt

- 50 Nm +90º turn

- Always replace if removed

7 - Protective Sleeve

8 - Suction/Fill Valve with Hose Line

- Make sure not under tension when installing

9 - Nut

- 9 Nm

10 - Clip

11 - Bolt

- 14 Nm

- Always replace if removed

12 - Shock Absorber

- For the Dynamic Ride Control (DRC) system

- Removing and installing. Refer to → Chapter "Shock Absorber, Removing and Installing".

- Servicing. Refer to → Chapter "Shock Absorber, Servicing, Standard Shock Absorber/with DRC System".

13 - Stone Chip Protection

14 - Bolt

- 150 Nm +180º turn

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".