Audi A6 Typ 4G: Preparations for Checking the Seat Bolster Adjuster for Leaks, through 08/2012

Special tools and workshop equipment required

- Pneumatic Repair Set -VAS6618A-

- Vehicle Diagnostic Tester

Note

Note

- When an appropriate entry is made in the event memory, you are prompted in "Guided Fault Finding" to perform a leak check using the Vehicle Diagnostic Tester.

- Then the preparations for this leak test are described that must be carried out directly in the front seat.

- For the connection diagram with assignment of the pneumatic lines to the air cushions. Refer to → Chapter "Connection Diagram - Pneumatic System".

Procedure

- Remove the backrest cover. Refer to → Chapter "Backrest Cover, Removing and Installing, Multi-contour Seat".

- Move the front seat all the way forward/up.

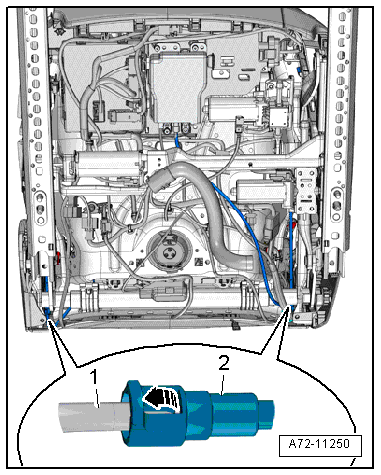

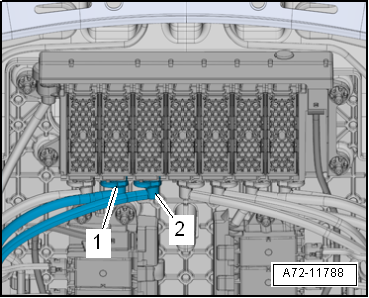

- Carefully release the retainer -arrow- and disconnect the pneumatic lines -1 and 2-.

- For checking in the "Guided Fault Finding", connect the air cushion and valve block connections in a diagonal sequence as follows:

.png)

Note

Note

To connect the pneumatic lines, make an adapter hose from the Pneumatic Repair Set - Hose 2.5m -VAS6618/5- and Pneumatic Repair Set - Gray Connector w/O-Ring -VAS6618/6- and Pneumatic Repair Set - White Connector -VAS6618/7-.

In one of the test steps in the "Guided Fault Finding", you are prompted to disconnect the pneumatic lines from the Front Passenger Multi-contour Seat Control Module -J872-/Driver Multi-contour Seat Control Module -J873-.

- Before disconnecting, mark the assignment of the pneumatic lines to each other using a waterproof permanent marker.

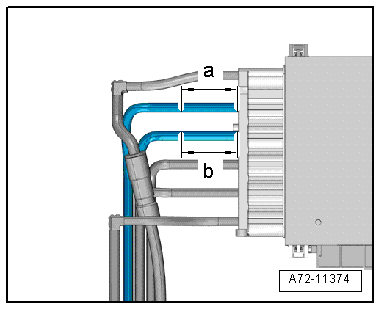

- Disconnect pneumatic lines to the seat bolster inflation adjuster air cushions at the following points (refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting"):

- a - 40 mm

- b - 40 mm

- For checking in the "Guided Fault Finding", connect the air cushion and valve block connections in a diagonal sequence as follows:

.png)

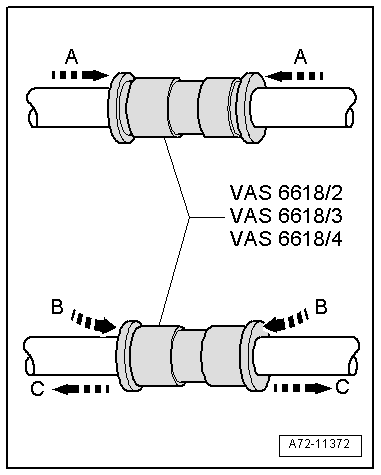

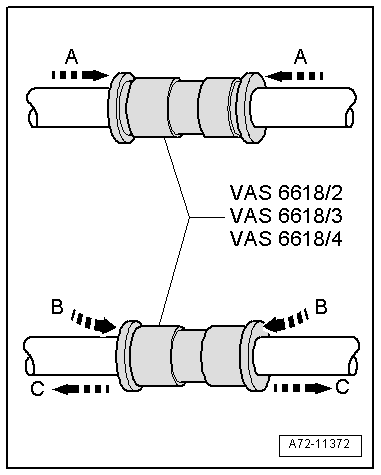

- To connect, attach the Connecting Sleeves -VAS6618/3- to the pneumatic lines.

Note

Note

- To connect, insert the pneumatic lines into the Connecting Sleeves -VAS6618/3- from both sides -A arrows-.

- Because of the danger of leaks, do not place the connecting sleeves in a bend in the hose.

- To release, push release rings -B arrows- and simultaneously remove pneumatic lines -C arrows-.

- Connect pneumatic lines following the leak check. Refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting".

Preparations for Checking the Seat Bolster Adjuster for Leaks, from 09/2012

Special tools and workshop equipment required

- Pneumatic Repair Set -VAS6618A-

- Vehicle Diagnostic Tester

Note

Note

- When an appropriate entry is made in the event memory, you are prompted in "Guided Fault Finding" to perform a leak check using the Vehicle Diagnostic Tester.

- Then the preparations for this leak test are described that must be carried out directly in the front seat.

- For the connection diagram with assignment of the pneumatic lines to the air cushions. Refer to → Chapter "Connection Diagram - Pneumatic System".

Procedure

- Remove the backrest cover. Refer to → Chapter "Backrest Cover, Removing and Installing, Multi-contour Seat".

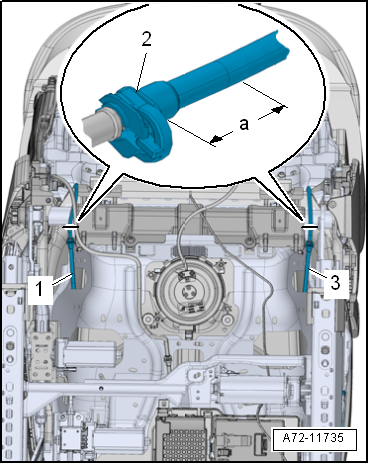

- Front seat released in the vehicle and folded forward with electrical harness connectors connected. Refer to → Chapter "Front Seat, Removing and Installing".

Note

Note

To check, the pneumatic line to the seat bolster adjuster is not disconnected at the connection, but is disconnected by the described procedure. Refer to → Chapter "Pneumatic Lines, Disconnecting and Connecting".

- Disconnect the pneumatic lines -1 and 3- to the seat bolster inflation adjuster air cushions at the following points:

- a - 30 mm

- For checking in the "Guided Fault Finding", connect the air cushion and valve block connections in a diagonal sequence as follows:

.png)

Note

Note

- To connect the pneumatic lines, make an adapter hose from the Pneumatic Repair Set -VAS6618A-.

- To connect during the leak test, insert the pneumatic lines into the Pneumatic Repair Set - Exterior Connector 6x4 -VAS6618/2- from both sides -A arrows-.

- To release, push release rings in direction of -B arrows- and simultaneously remove pneumatic lines -C arrows-.

In one of the test steps in the "Guided Fault Finding", you are prompted to disconnect the pneumatic lines from the valve block.

- Before disconnecting, mark the pneumatic line assignments to the connections at the valve block using a waterproof permanent marker.

- Disconnect the pneumatic lines -1 and 2- to the seat bolster inflation adjuster air cushions.

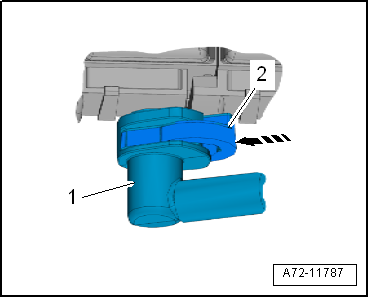

- To do this, press the release mechanism -2--arrow- and simultaneously remove the pneumatic line -1-.

- For checking in the "Guided Fault Finding", connect the air cushion and valve block connections in a diagonal sequence as follows:

.png)

- Connect the pneumatic lines and check them with a final tug, whether the coupling is locked in correctly.