Audi A6 Typ 4G: Shaft Seal for Flange/Propshaft, Replacing

Rear Final Drive 0BF - Flange/Driveshaft Shaft Seal, Replacing

Special tools and workshop equipment required

- Puller - Multiple Use -VW391-

- Puller - Unit Injector -T10055-

- -2-Puller - Unit Injector - Adapter 2 -T10055/2-

- Two M 8 x 30 Bolts

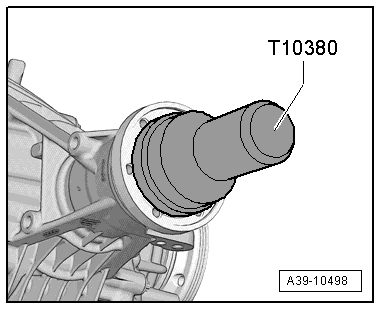

- Seal Installer - Hollow Shaft -T10380-

- Seal Installer - Input Shaft -T40222-

- Seal Installer - Input Shaft - Guide Sleeve -T40222/1-

- Sealing Grease -G 052 128 A1-

- Inductive Heater -VAS6414-

or

- Commercially Available Hot Plate

and

- Digital Thermometer -VAS6519-

Removing

- Rear final drive installed

- Follow the general repair information. Refer to → Chapter "General Repair Information".

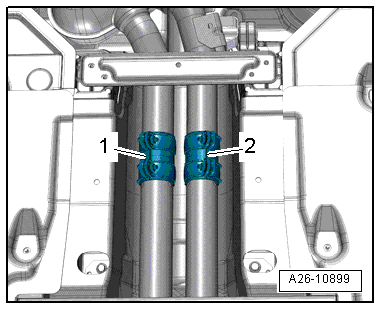

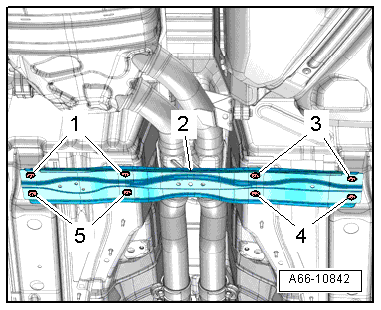

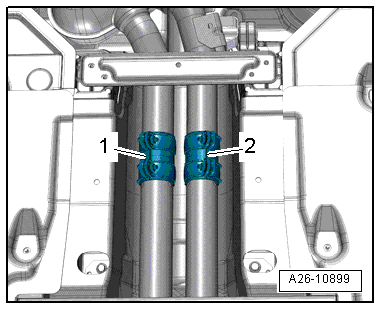

- Disconnect the exhaust system at the clamping sleeves -1- and -2-.

- Remove the rear section of the exhaust system.

Note

Note

A second technician is needed to help remove the rear section of the exhaust system.

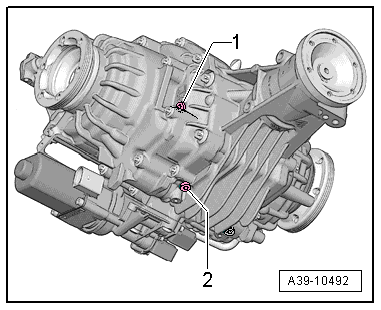

- Open the gear oil drain plug -2- and allow approximately 300 ml of gear oil to drain out.

- Insert the new drain plug -2- and tighten. Tightening specification -item 16-.

- Remove the driveshaft from the rear final drive. Refer to → Chapter "Driveshaft, Removing and Installing from Rear Final Drive".

Audi A8

- Guide the driveshaft between the fuel tank and the subframe downward toward the rear and attach it on the side.

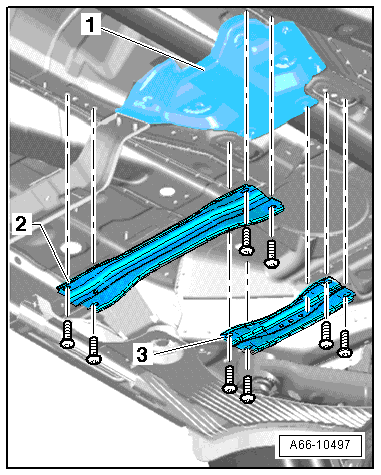

Audi A4, A5 Coupe/Sportback/Cabrio

- Remove the front crossmember -2-.

- Remove the rear crossmember -3- and the heat shield -1-.

Audi A6 and A7

- Remove the crossbrace -2-. Refer to →Body Exterior; Rep. Gr.66.

Audi A4, A5 Coupe/Sportback/Cabrio, A6, A7

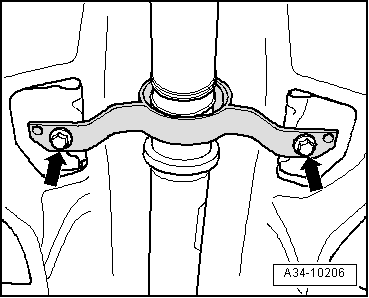

- Remove the bolts -arrows- for the driveshaft intermediate bearing.

- Lower the driveshaft at the intermediate bearing.

- Guide the driveshaft between the fuel tank and the subframe downward and toward the rear while doing this.

- Install the intermediate bearing bolts -arrows- by hand.

- Tie the driveshaft to the side.

Continuation for All Vehicles

- Remove the High Temperature Grease in the flange/driveshaft.

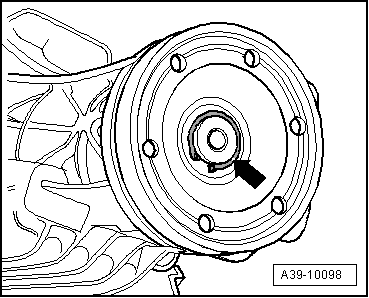

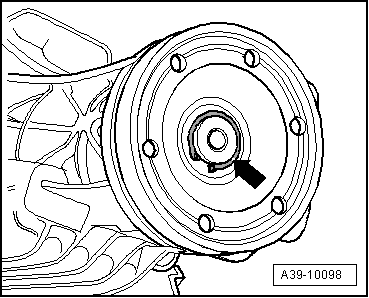

- Remove the circlip -arrow-.

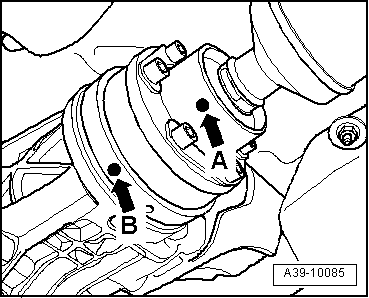

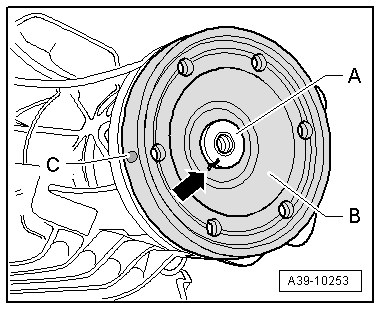

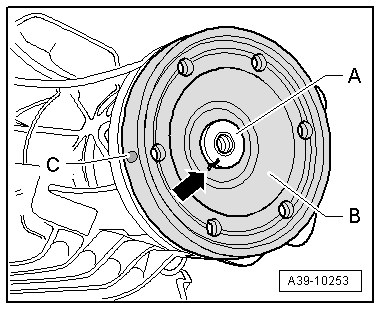

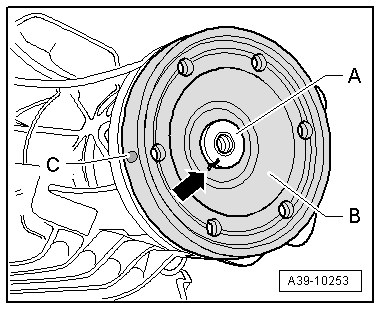

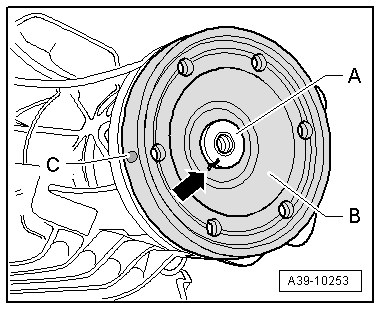

- Mark the position of the flange/driveshaft -B- on the pinion -A--arrow-.

Note

Note

- This marking -arrow- is needed so the colored dot -C- on the outer flange remains in its original position.

- This ensures the imbalance in the rear final drive will be as small as possible.

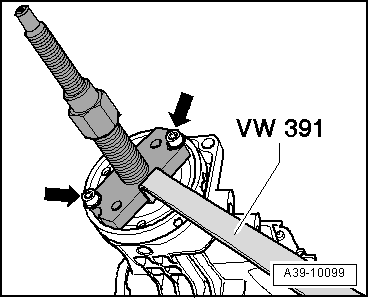

- Install the Two M8 x 33 bolts-arrow- in the flange.

- Remove the flange/driveshaft with the Puller - Multiple Use -VW391-.

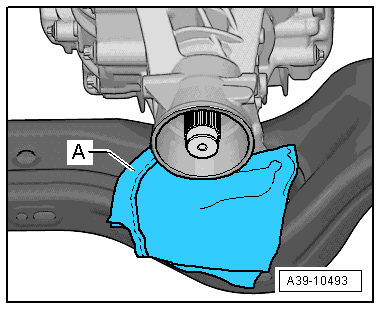

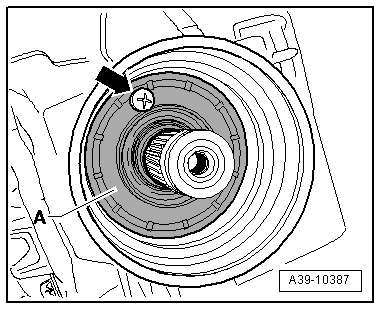

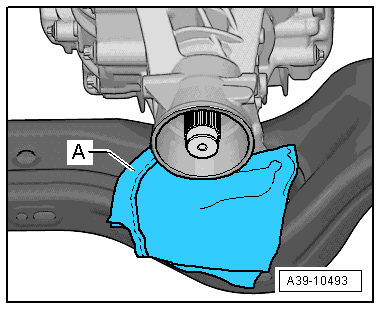

- Lay a super absorbent cloth -A- under the final drive on the subframe.

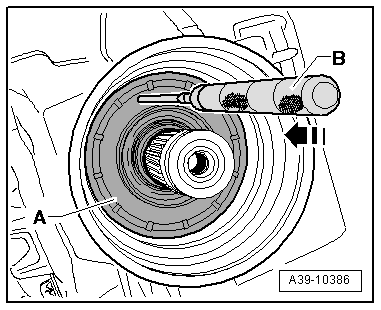

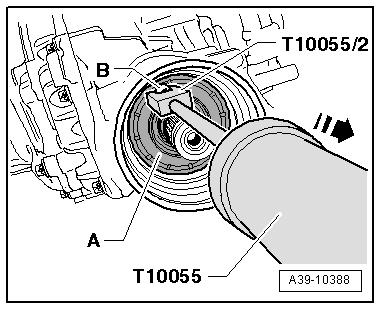

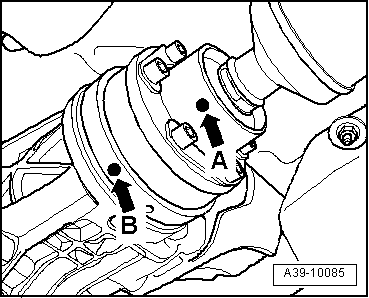

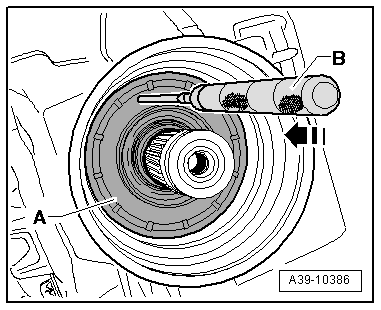

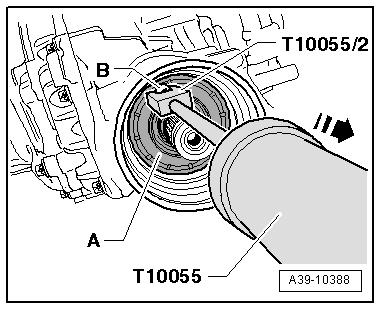

- Knock through the metal ledge of the shaft seal -A-, for example, with a scriber -B- direction of the -arrow-.

- Then install a bolt -arrow- in this shaft seal opening -A-.

- Remove the flange/driveshaft seal -A- in the direction of -arrow-.

-B- bolt

Installing

Install in reverse order of removal. Pay attention to the following:

- Fill the space between the sealing/dust lip halfway with Sealing Grease -G 052 128 A1-.

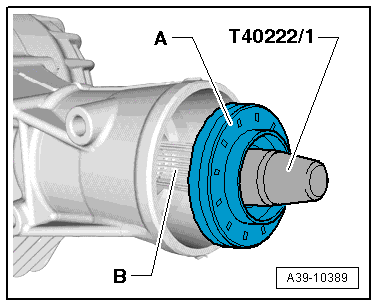

- Place the new shaft seal -A- on the Seal Installer - Input Shaft - Guide Sleeve -T40222/1-.

Note

Note

Make sure the shaft seal spring is in its installation position behind the sealing lip.

- Coat outer edge of the seal with gear oil.

- Push the Seal Installer - Input Shaft - Guide Sleeve -T40222/1- and the shaft seal -A- onto the pinion -B-.

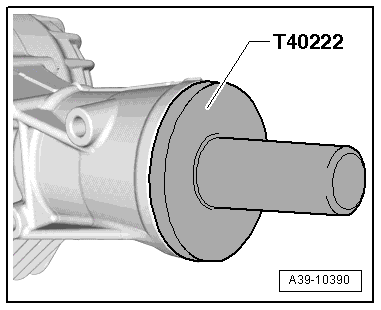

- Install the shaft seal all the way. Be careful not to bend it.

- Warm the flange/driveshaft -B- with a Inductive Heater -VAS6414- or a Heating Plate to 115 ºC (239 ºF).

WARNING

WARNING

- Wear safety gloves.

- If using a Heating Plate the temperature must be observed using a Digital Thermometer -VAS6519-.

- Position the flange/driveshaft -B- on the pinion -A- so that the marking -arrow- lines up.

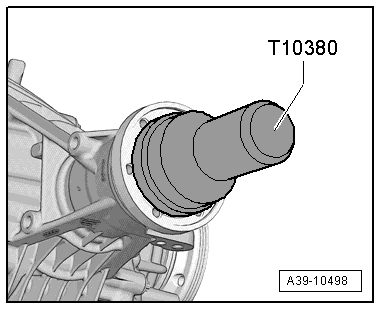

- Install the flange/driveshaft with the Seal Installer - Hollow Shaft -T10380-.

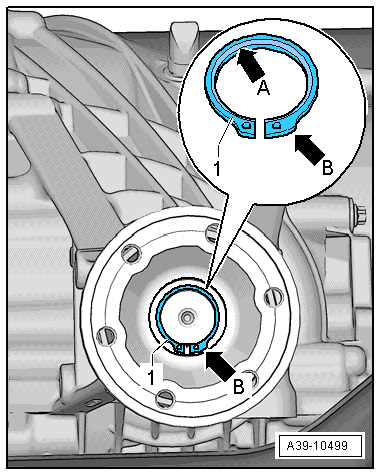

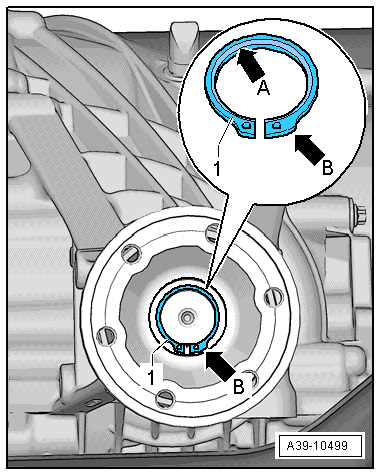

Install the circlip -1- as follows:

- Always replace the circlip -1-.

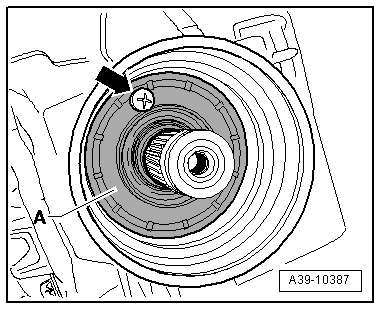

- The bevel on the inner diameter of the circlip -arrow A- faces out, toward the drive axle.

- The wide tab on the circlip -arrow B- must be on the right side, as illustrated.

- Measure the thickness of the old circlip -1-.

- Install a new circlip -1- having the same thickness as the old one. Refer to the Part Catalog.

- Install the new circlip -1-.

Note

Note

- A new circlip -arrow- must be selected when replacing the flange/driveshaft.

- For this, determine and insert the thickest circlip -arrow- that can still be installed in the groove. Refer to the Parts Catalog for the part number.

- Fill the rear final drive gear oil 0BF. Refer to → Chapter "Gear Oil in Rear Final Drive 0BF, Filling".

- Install the driveshaft on the rear final drive.

Audi A4, A5 Coupe/Sportback/Cabrio, A6, A7

- Attach the driveshaft center support to the body free of tension. Tightening specification -item 9-.

- Install the heat shield and the crossmember.

Continuation for All Vehicles

- Install the rear section of the exhaust system.

Rear Final Drive 0BE - Replacing, Flange/Driveshaft Shaft Seal

Special tools and workshop equipment required

- Press Piece - Multiple Use -VW431-

- Puller - Unit Injector -T10055-

- Puller - Unit Injector - Adapter 2 -T10055/2-

- Seal Installer - Hollow Shaft -T10380-

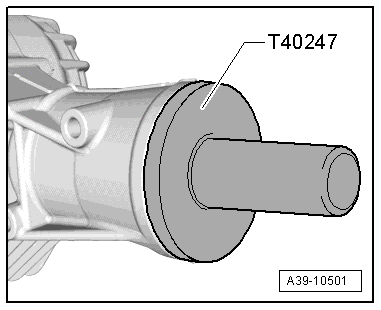

- Seal Installer - Propshaft -T40247-

- Seal Installer - Propshaft - Guide Sleeve -T40247/1-

- -1-Puller - Kukko 2-Arm - 70-180mm -20/10-

- Inductive Heater -VAS6414-

or

- Commercially Available Hot Plate

and

- Digital Thermometer -VAS6519-

- Drip Tray

- Sealing Grease -G 052 128 A1-

Removing

- Rear final drive installed

- Disconnect the exhaust system at the clamping sleeves -1 and 2-.

- Remove the rear section of the exhaust system.

Note

Note

A second technician is needed to help remove the rear section of the exhaust system.

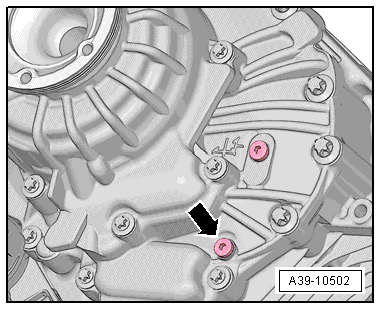

- Open the gear oil drain plug -arrow- and allow approximately 300 ml of gear oil to drain out.

- Insert the new drain plug -arrow- and tighten. Tightening specification -item 16-.

- Remove the driveshaft from the rear final drive. Refer to → Chapter "Driveshaft, Removing and Installing from Rear Final Drive".

- Guide the driveshaft between the fuel tank and the subframe downward toward the rear and attach it on the side.

- Remove the High Temperature Grease in the flange/driveshaft.

- Remove the circlip -arrow-.

- Mark the position of the flange/driveshaft -B- on the pinion -A--arrow-.

Note

Note

- This marking -arrow- is needed so the colored dot -C- on the outer flange remains in its original position.

- This ensures the imbalance in the rear final drive will be as small as possible.

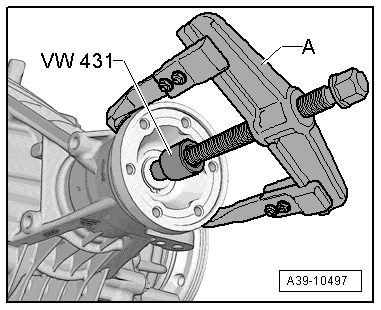

- Remove the flange/driveshaft.

A - For example the Puller - Kukko 2-Arm - 70-180mm -20/10-

- Lay a super absorbent cloth -A- under the final drive on the subframe.

- Knock through the metal ledge of the shaft seal -A-, for example, with a scriber -B- direction of the -arrow-.

- Then install a bolt -arrow- in this shaft seal opening -A-.

- Remove the flange/driveshaft seal -A- in the direction of -arrow-.

B - Bolt

Installing

Install in reverse order of removal. Pay attention to the following:

- Fill the space between the sealing/dust lip halfway with Sealing Grease -G 052 128 A1-.

- Coat outer edge of the seal with gear oil.

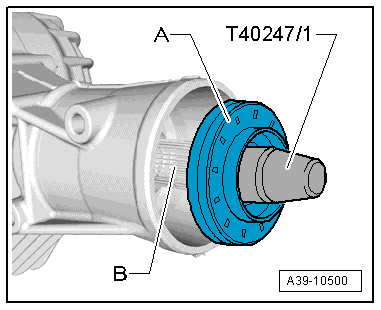

- Place the new shaft seal -A- on the Seal Installer - Propshaft - Guide Sleeve -T40247/1-.

Note

Note

Make sure the shaft seal spring is in its installation position behind the sealing lip.

- Push the Seal Installer - Propshaft - Guide Sleeve -T40247/1- and the shaft seal -A- onto the pinion -B-.

- Install the shaft seal all the way. Be careful not to bend it.

- Warm the flange/driveshaft -B- with a Inductive Heater -VAS6414- or a Heating Plate to 115 ºC (239 ºF).

WARNING

WARNING

- Wear safety gloves.

- If using a Heating Plate the temperature must be observed using a Digital Thermometer -VAS6519-.

- Position the flange/driveshaft -B- on the pinion -A- so that the marking -arrow- lines up.

- Install the flange/driveshaft with the Seal Installer - Hollow Shaft -T10380-.

Install the circlip -1- as follows:

- Always replace the circlip -1-.

- The bevel on the inner diameter of the circlip -arrow A- faces out, toward the driveshaft.

- The wide tab on the circlip -arrow B- must be on the right side, as illustrated.

- Measure the thickness of the old circlip -1-.

- Install a new circlip -1- having the same thickness as the old one. Refer to the Part Catalog.

- Install the new circlip -1-.

Note

Note

- A new circlip -arrow- must be selected when replacing the flange/driveshaft.

- For this, determine and insert the thickest circlip -arrow- that can still be installed in the groove. Refer to the Parts Catalog for the part number.

- Fill with gear oil in the rear final drive 0BE. Refer to → Chapter "Gear Oil in Rear Final Drive 0BE, Filling".

- Install the driveshaft on the rear final drive.

- Install the rear section of the exhaust system.

Flange/Driveshaft Seal, Replacing

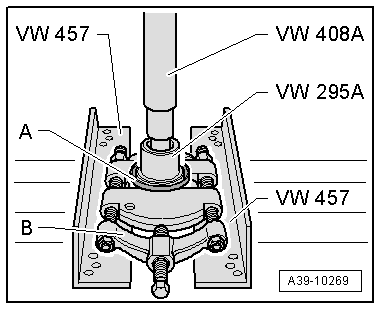

Special tools and workshop equipment required

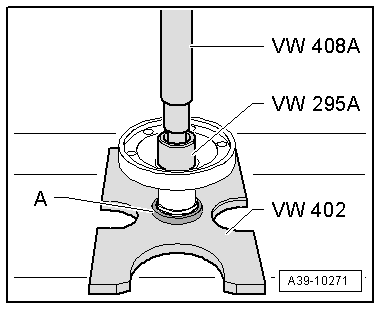

- Bearing/Bushing Installer - Multiple Use -VW295A-

- Press Plate -VW402-

- Press Piece - Rod -VW408A-

- Support Channels -VW457-

- Separating tool 22 to 75 mm, such as Puller - Kukko Quick Action Separating Tool - 12-75mm -17/1-

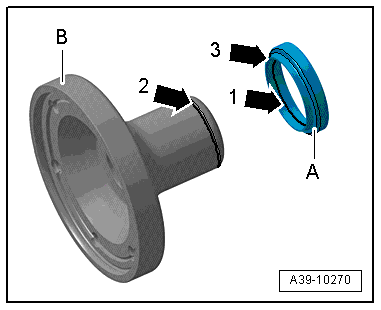

Remove the Ring -A- from the Flange/Driveshaft.

B - Separating Tool - 12-75mm, such as Puller - Kukko Quick Action Separating Tool - 12-75mm -17/1-

Installation Location of the Protective Ring -A- on the Flange/Driveshaft

- The ridge -arrow 1- on the protective ring -A- must fit into the groove -arrow 2- on the flange -B-. The smaller outer circumference -arrow 3- faces the flange.

Install the Protective Ring -A- onto the Flange/Driveshaft.

- The protective ring -A- must fit into the groove all around the flange. Refer to → Fig. "Installation Location of the Protective Ring -A- on the Flange/Driveshaft".