Audi A6 Typ 4G: Stabilizer Bar

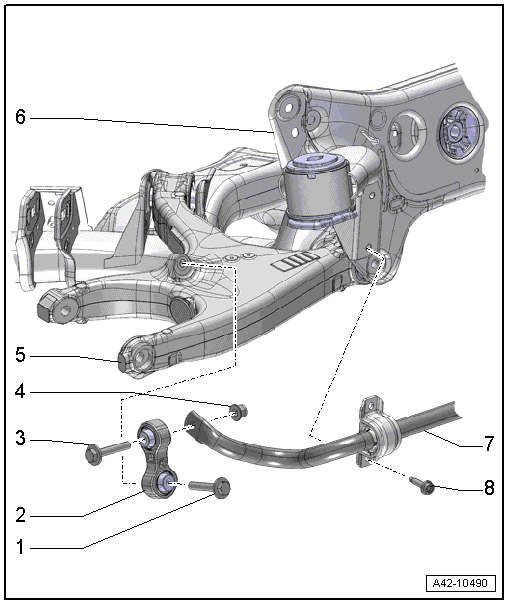

Overview - Stabilizer Bar

1 - Bolt

- 40 Nm +90º turn

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

2 - Coupling rod

- Removing and installing. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

3 - Bolt

- 40 Nm +90º turn

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

4 - Nut

- Always replace if removed

5 - Lower Transverse Link

6 - Subframe

7 - Stabilizer Bar

- Removing and installing. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

- The rubber bushing and clamp must not be separated from the stabilizer bar.

8 - Bolt

- 25 Nm +90º turn

- Always replace if removed

- Tighten evenly

Stabilizer Bar, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Engine and Gearbox Jack -VAS6931-

Removing

Caution

Caution

Do not damage the paint on the stabilizer bar when removing and installing.

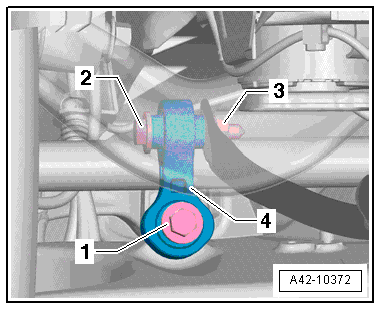

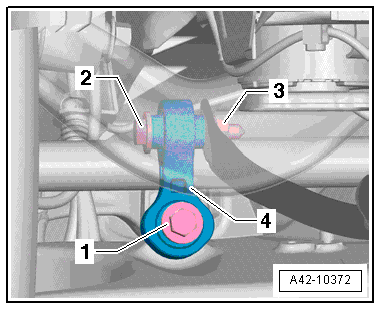

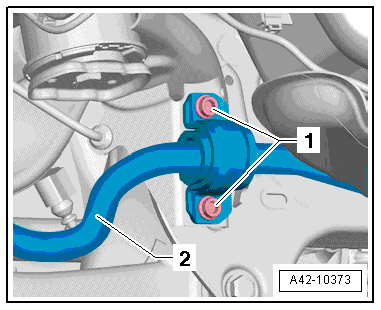

- Remove the bolt -1-.

Note

Note

- The threaded connection between the coupling rod and the lower transverse link is under tension.

- Press the lower transverse link gently downward when removing the bolt -1-.

- Remove the nut -3-, the bolt -2- and the coupling rod -4-.

- Remove the rear section from the exhaust system. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

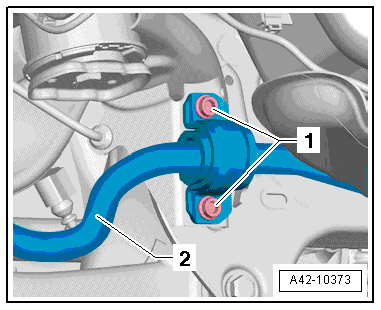

- Remove the left and right bolts -1-. Then remove the stabilizer bar -2- to the left.

Note

Note

The stabilizer bar -2- is removed and installed completely with the rubber bushings and clamps. Do not remove the clamps and rubber bushings.

Installing

Install in reverse order of removal. Note the following:

Note

Note

- Bonded rubber bushings have a limited range of motion. Only tighten suspension bolts when vehicle is in curb weight or control position.

- For lifting the wheel bearing into curb weight position, vehicles with steel suspension. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- For vehicles with air spring suspension, lift wheel suspension in control position. Refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension".

- Install the stabilizer bar from the left side.

- Install the left and right bolts -1- so they are still loose and then tighten them evenly.

- Install the coupling rod -4- and bolt -2-.

- Tighten the left and right nuts -3-.

- Tighten the left and right bolts -1-.

- Install the rear section from the exhaust system. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.