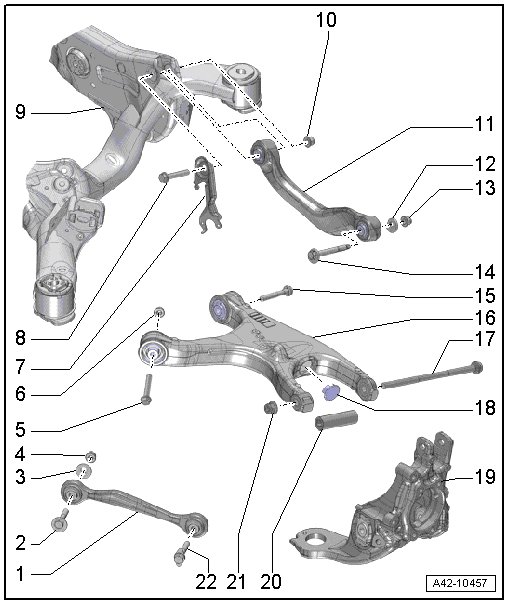

Audi A6 Typ 4G: Overview - Transverse Link

1 - Tie Rod

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing".

- There are different versions and installed positions. Refer to → Fig. "Tie Rod on A Vehicle with Steel Suspension" and → Fig. "Tie Rod on A Vehicle with Air Suspension". For the correct allocation. Refer to the Parts Catalog.

2 - Eccentric Bolt

- Always replace if removed

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring") or in the control position (refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension").

3 - Eccentric Washer

4 - Nut

- 95 Nm

- Always replace if removed

5 - Bolt

- 70 Nm +180º turn

- Always replace if removed

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring") or in the control position (refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension").

6 - Nut

- Always replace if removed

7 - Bracket

- For the Left Rear Level Control System Sensor -G76- / Right Rear Level Control System Sensor -G77-

8 - Bolt

- 70 Nm +180º turn

- Always replace if removed

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring") or in the control position (refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension").

9 - Subframe

10 - Nut

- Always replace if removed

11 - Upper Transverse Link

- Removing and installing. Refer to → Chapter "Upper Transverse Link, Removing and Installing".

12 - Shim

13 - Nut

- 95 Nm

- Always replace if removed

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring") or in the control position (refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension").

14 - Adjusting Bolt

15 - Bolt

- 70 Nm +180º turn

- Always replace if removed

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring") or in the control position (refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension").

16 - Lower Transverse Link

- Removing and installing. Refer to → Chapter "Lower Transverse Link, Removing and Installing".

17 - Bolt

- 120 Nm +360º turn

- Always replace if removed

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring") or in the control position (refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension").

Note

Note

Axle alignment is necessary if the bolt is loosened.

18 - Cap

19 - Wheel Bearing Housing

20 - Spacer Tube

- Always replace if removed

21 - Nut

- Always replace if removed

Caution

Caution

Do not tighten the threaded connection using the nut.

Note

Note

Axle alignment is necessary if the nut is loosened.

22 - Bolt

- 90 Nm +90º turn

- Always replace if removed

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring") or in the control position (refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension").

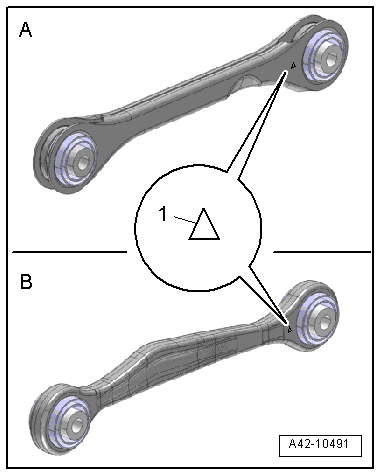

Tie Rod on A Vehicle with Steel Suspension

A - Steel tie rod

B - Aluminum cast tie rod

1 - Installed position: The marking must be on the outside and the tip of the triangle points up.

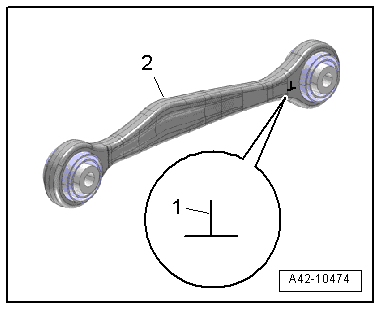

Tie Rod on A Vehicle with Air Suspension

1 - Installed position: The marking must be on the outside and the horizontal line points up.

2 - Aluminum cast tie rod