Audi A6 Typ 4G: Stabilizer Bar, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- For a vehicle with air suspension Vehicle Diagnostic Tester

Removing

- Place the vehicle on a hoist. Refer to → Chapter "Raising and Lowering with Open and Closed Air Suspension System".

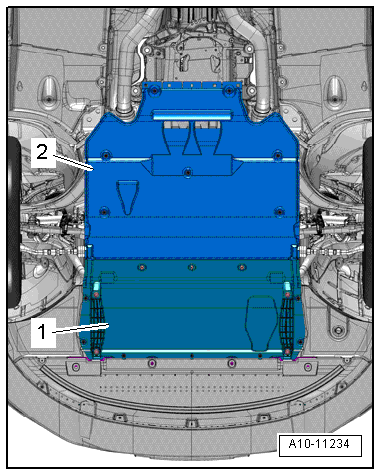

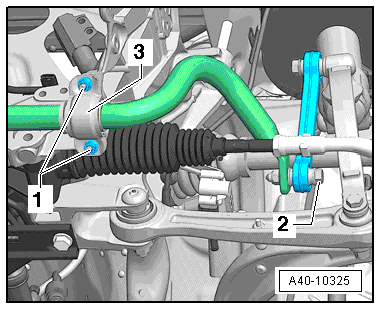

- Remove the noise insulation -1-. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

- Disconnect left and right connectors -2-.

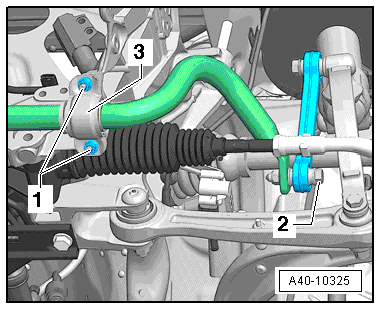

- Remove the left and right threaded connector -1- and remove the clamps -3-.

- Remove the stabilizer bar.

Installing

Install in reverse order of removal. Note the following:

Note

Note

- Bonded rubber bushings have a limited range of motion. Only tighten suspension bolts when vehicle is in curb weight or control position.

- Lift the wheel bearing into the curb weight or control position. Refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension" or → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- There must be no grease on the stabilizer bar and rubber bushing.

- Install the rubber bushing opening in the direction of the subframe contact surface.

- Before installing the clamp -3- again (if equipped) install any loose stud bolts -1- all the way.

- Install the threaded connector -1- but do not tighten it.

- Install the left and right threaded connections -2- but do not tighten them.

- Lift wheel bearing in control position. Refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension" or → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Tighten connections -1 and 2-.

Note

Note

- Install the threaded connector -1- alternating from side to side evenly.

- The opening on the rubber bushing must be facing up when installing the subframe.

- There must not be any grease on the stabilizer bar and rubber bushing when installing them.

Coupling Rod, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- For a vehicle with air suspension Vehicle Diagnostic Tester

Removing

- Place the vehicle on a hoist. Refer to → Chapter "Raising and Lowering with Open and Closed Air Suspension System".

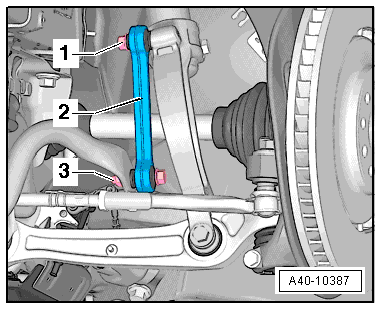

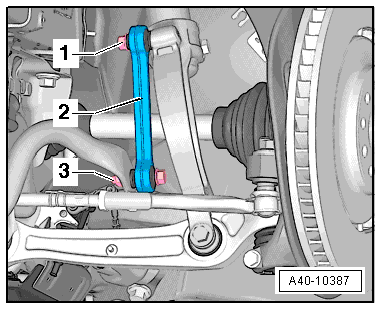

- Disconnect the bolting -1 and 3-.

- Remove the coupling rod -2-.

Installing

Install in reverse order of removal. Note the following:

Note

Note

- Note the installation position of the coupling rod.

- Bonded rubber bushings have a limited range of motion. Only tighten suspension bolts when vehicle is in curb weight or control position.

- Lift wheel bearing in control position. Refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension" or → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

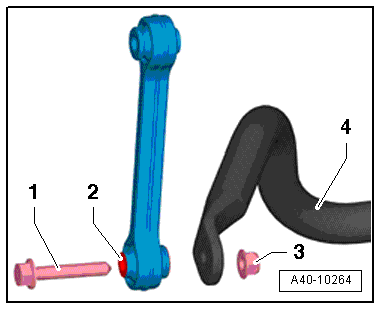

- The bolt -1- for connecting the coupling rod to the stabilizer bar -4- must be attached to the "small" surface -2- of the coupling rod collar and secured with the nut -3-.

- Install the threaded connections -1 and 3- but do not tighten them.

- Lift wheel bearing in control position. Refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension" or → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Tighten the threaded connections -1 and 3-.