Audi A6 Typ 4G: Overview - Steering Gear

Overview - Steering Gear, Steering Gear with Tie Rods

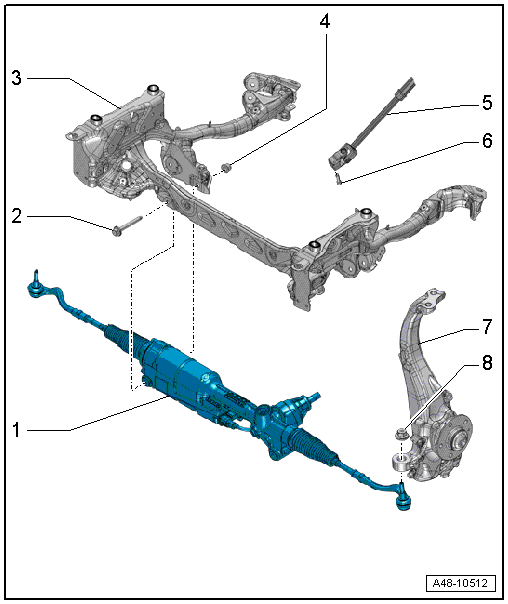

1 - Electromechanical Steering Gear with Tie Rods

- With Power Steering Control Module -J500-

- Removing and installing. Refer to → Chapter "Steering Gear, Removing and Installing".

- Servicing. Refer to → Chapter "Overview - Steering Gear".

- There are different versions. Refer to the Parts Catalog.

A removable heat shield mat was installed on the steering gear at start of production. Be sure to install this mat if installing the old steering gear again.

A removable heat shield mat on the steering gear was replaced by a bonded heat shield mat as a running change. It is therefore not necessary to take the mat from the old steering gear and installing on a new steering gear.

A replacement steering gear comes with the bonded heat shield mat.

2 - Bolt

- 80 Nm +180º turn

- Always replace if removed

3 - Subframe

4 - Nut

- Pushed into the subframe

- Always replace if removed

5 - Steering Intermediate Shaft

6 - Bolt

- Tightening specification -Item 1-

7 - Wheel Bearing Housing

8 - Nut

- 100 Nm

- Always replace if removed

Overview - Steering Gear

Note

Note

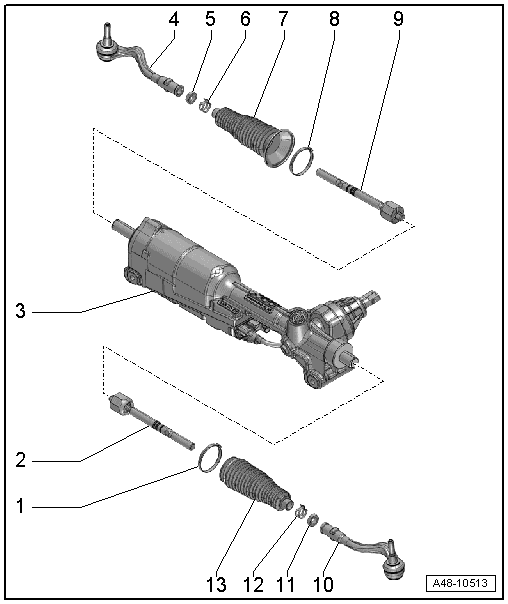

- Always replace self-locking nuts and bolts.

- Welding or straighten work on any steering components is not permissible.

- Use only Power Steering Gear Grease to lubricate the steering rack (on the pinion side) and the ball paths (on the engine side). Note: There are different types of grease for the left and right. For allocation. Refer to the Parts Catalog.

- The clamps -1 and 8- are tensioned to different tightening specifications.

1 - Clamp

- Always replace if removed

- Use the CV Joint Boot Clamp Tool to tension the clamp.

Note

Note

It is not permitted to open the new clamp.

- For the correct version. Refer to the Parts Catalog.

2 - Tie Rod

- 100 Nm

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing".

- Grease the joint with Power Steering Gear Grease

3 - Electromechanical Steering Gear

- Removing and installing. Refer to → Chapter "Steering Gear, Removing and Installing".

- Grease the steering rack with Power Steering Gear Grease Note: There are different types of grease for the left and right. For allocation. Refer to the Parts Catalog.

- There are different versions. Refer to the Parts Catalog.

A removable heat shield mat was installed on the steering gear at start of production. Be sure to install this mat if installing the old steering gear again.

A removable heat shield mat on the steering gear was replaced by a bonded heat shield mat as a running change. It is therefore not necessary to take the mat from the old steering gear and installing on a new steering gear.

A replacement steering gear comes with the bonded heat shield mat.

4 - Tie Rod End

- Removing and installing. Refer to → Chapter "Tie Rod End, Removing and Installing".

- Check dust caps for damage and correct seating

- Check dimension. Refer to → Fig. "Tie Rod End Check Dimension"

5 - Nut

- 80 Nm

- Counterhold on the tie rod end when loosening or tightening

6 - Spring Clamp

- Always replace if removed

- Spring clamp, installing.

7 - Boot

- Check for damage

- Always replace if removed

- Coat the inside of the joint boot seats all the way around and evenly with Power Steering Gear Grease before installing. Refer to the Parts Catalog.

- Check the seat for the boot on the steering gear for damage before installing. If the steering gear housing is damaged, replace the steering gear.

- Must not be twisted when toe is being adjusted

- Make sure it is installed correctly.

- Replacing. Refer to → Chapter "Boot, Removing and Installing".

8 - Clamp

- Always replace if removed

- Use the CV Joint Boot Clamp Tool to tension the clamp.

Note

Note

It is not permitted to open the new clamp.

- For the correct version. Refer to the Parts Catalog.

9 - Tie Rod

- 100 Nm

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing".

- Grease the joint with Power Steering Gear Grease

10 - Tie Rod End

- Removing and installing. Refer to → Chapter "Tie Rod End, Removing and Installing".

- Check dust caps for damage and correct seating

- Check dimension. Refer to → Fig. "Tie Rod End Check Dimension"

11 - Nut

- 80 Nm

- Counterhold on the tie rod end when loosening or tightening

12 - Spring Clamp

- Always replace if removed

- Spring clamp, installing.

13 - Boot

- Check for damage

- Always replace if removed

- Coat the inside of the joint boot seats all the way around and evenly with Power Steering Gear Grease before installing. Refer to the Parts Catalog.

- Check the seat for the boot on the steering gear for damage before installing. If the steering gear housing is damaged, replace the steering gear.

- Must not be twisted when toe is being adjusted

- Make sure it is installed correctly.

- Replacing. Refer to → Chapter "Boot, Removing and Installing".

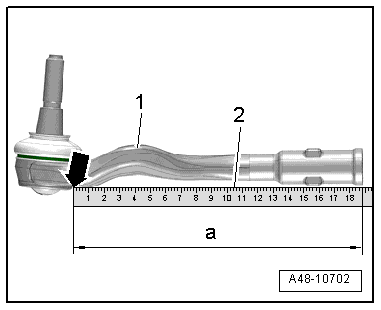

Tie Rod End Check Dimension

- Place a steel ruler -2- on the tie rod end and push it all the way up to the edge -arrow- of the tie rod end -1-.

- Replace the complete steering gear with the tie rod and tie rod end if the check dimension -a- is less than 188 mm.

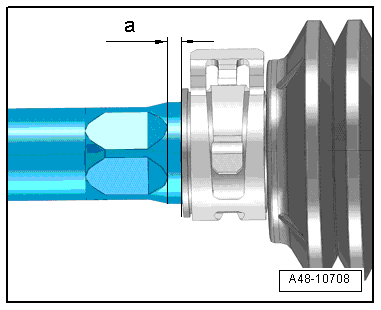

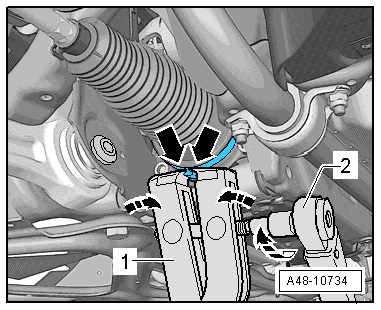

Tensioning the Inner Clamp

- Mount the CV Joint Boot Clamp Tool-1- as illustrated. Make sure that the jaws of the clamp tool are seated in the corners -arrows- of the clamp.

- Tighten the clamp by turning the spindle using a torque wrench -2- (do not tilt the pliers).

- Use torque wrench -2- with 5 to 50 Nm range (for example, Torque Wrench 1331 5-50Nm -VAG1331-).

- Make sure the thread on the spindle -1- is easy to move. Lubricate with MoS2 grease, if necessary.

- If the thread is tight, for example, dirty, the required tensioning force for the hose clamp will not be achieved in spite of correct torque specification settings.

.png)

Outer Boot Assembly

- Dimension -a- 2 mm.