Audi A6 Typ 4G: Rear Brake Caliper

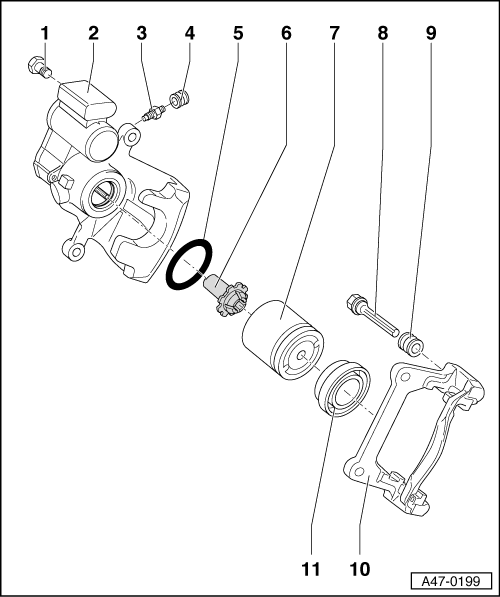

Overview - Rear Brake Caliper

1 - Bolt

- Tightening specification -item 6-.

2 - Brake Caliper Housing

3 - Bleed Screw

- Tightening specification -item 4-.

4 - Protective Dust Cap

5 - Seal

- Coat with a thin layer of lithium grease. Refer to Parts Catalog.

6 - Thrust Nut

- For actuating the parking brake

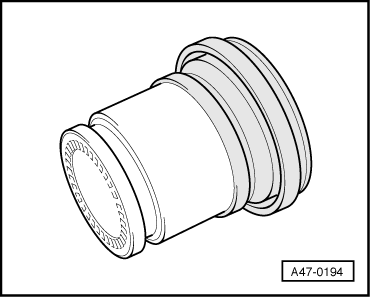

7 - Brake Caliper Piston

- Removing and installing. Refer to → Chapter "Brake Caliper Piston, Removing and Installing".

- Coat with a thin layer of lithium grease. Refer to Parts Catalog.

8 - Guide Pin

- Grease before pulling on the bearing bushing

- Delivered as a replacement part with sufficient grease.

9 - Bearing Bushing

- Pull onto the brake carrier and guide pin.

10 - Brake Carrier

- With guide pin and bearing bushing

- Delivered as an assembled replacement part with sufficient grease on the guide pins

- Install the repair kit if the caps or guide pins are damaged. Use the supplied grease packet to lubricate guide pins.

11 - Protective Cap

- Removing and installing. Refer to → Chapter "Brake Caliper Piston, Removing and Installing".

Brake Caliper Piston, Removing and Installing

Special tools and workshop equipment required

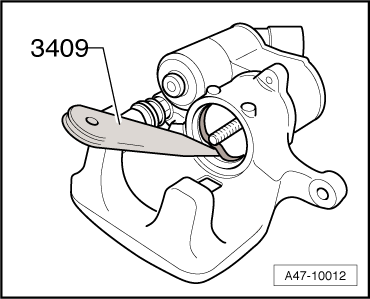

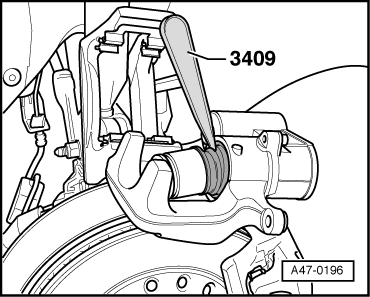

- Trim Removal Wedge -3409-

- Piston Resetting Tool -T10145-

- Protective Eyewear

- Safety Gloves

- Lithium grease. Refer to the Parts Catalog.

Removing

- Remove the brake caliper and disconnect from the hydraulic system. Refer to → Chapter "Brake Caliper, Replacing".

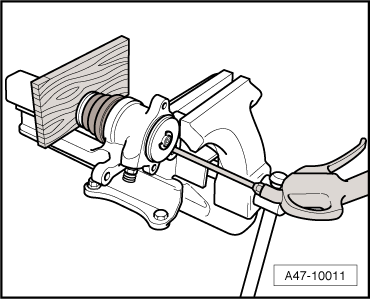

- Tension the brake caliper in a vise with protective covers over the jaws.

WARNING

WARNING

Risk of injury!

- Wear protective eyewear.

- When removing the brake caliper piston, never touch the brake caliper chamber with fingers.

- Place a cloth over the brake caliper chamber to catch any spraying brake fluid. Place another cloth tightly around the compressed air gun nozzle on the brake caliper.

- To prevent skin contact with brake fluid, wear chemical resistant safety gloves.

Note

Note

- When removing the brake caliper piston and the protective cap make sure that the paint coating on the brake caliper is not damaged.

- When removing, make sure that the cylinder surface is not damaged.

- Remove the piston from the brake caliper as far as possible.

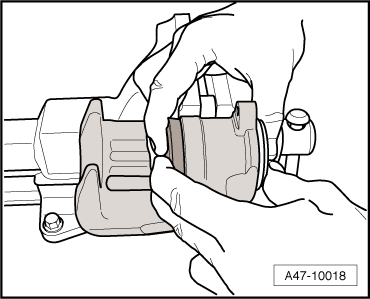

- Place a piece of wood in the brake caliper chamber so that the brake caliper piston will not be damaged when pressed out.

- Position the compressed air gun nozzle on the hole for the brake hose and press the brake caliper piston out of the brake caliper.

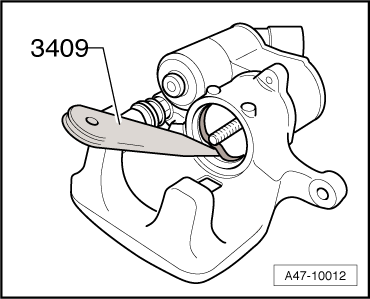

- Remove the seal from the brake caliper using the Trim Removal Wedge -3409-.

Installing

Note

Note

- Install the entire repair kit.

- Only use mineral spirits to clean the brakes.

- When a brake caliper piston or a piston cylinder are damaged, the brake caliper must be replaced.

- Clean the surfaces on the pistons and seal only with mineral spirits and then dry.

- Thinly coat the brake caliper pistons and seals with lithium grease before installing.

- Install the seal in the brake caliper using the Trim Removal Wedge -3409-.

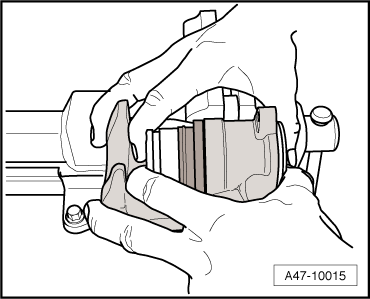

- Place the protective cap on the brake caliper piston as shown.

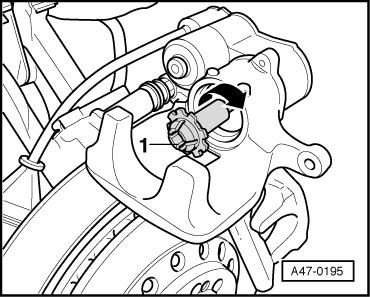

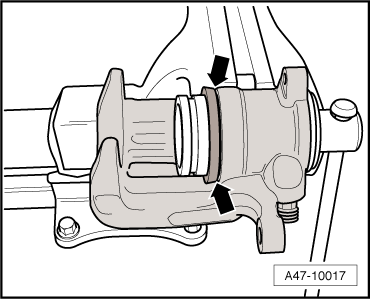

- Install the pressure nut -1- clockwise -arrow- all the way into the brake caliper and then loosen it one quarter of a turn.

- Insert the protective cap into the groove in the brake caliper using the Trim Removal Wedge -3409-.

- Push the brake caliper piston carefully into the brake caliper. Move the brake caliper piston while doing this.

- The brake caliper piston must be guided over the pressure nut.

- After the brake caliper piston has been guided onto pressure nut, press it as far as stop into brake caliper.

Note

Note

Be careful not to damage the pressure nut.

- The seal must contact the brake caliper all the way around -arrows-.

- Press the piston into the brake caliper by hand

- The inner sealing lip of the protective cap thereby slips into the groove on the piston.

Note

Note

- The Piston Resetting Tool -T10145- can also be used to push in the brake caliper piston.

- Make sure that the protective cap is guided into brake caliper piston groove when the brake caliper piston is pressed all the way in.

- Install the brake caliper. Refer to → Chapter "Brake Caliper, Replacing".