Audi A6 Typ 4G: Subframe with Steering Gear, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

- Tensioning Strap -T10038-, quantity: 2

- Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

- For a vehicle with air suspension Vehicle Diagnostic Tester

Removing

- Place the vehicle on a hoist. Refer to → Chapter "Raising and Lowering with Open and Closed Air Suspension System".

- For vehicles with an air suspension system, bleed the air suspension system. Refer to → Chapter "System, Venting or Filling".

- Remove the engine cover.

- Support the engine completely using the Engine Support Bridge. Refer to → Engine Mechanical, Fuel Injection and Ignition; Rep. Gr.10; Subframe Mount; Engine, Supporting in Installed Position.

- Remove the front wheels.

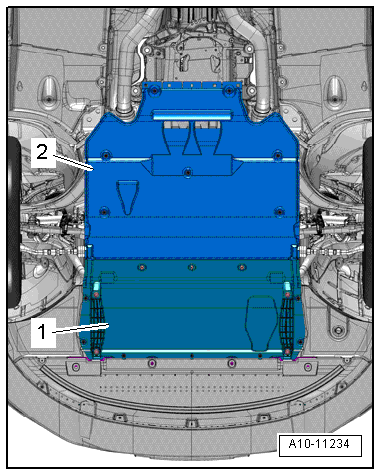

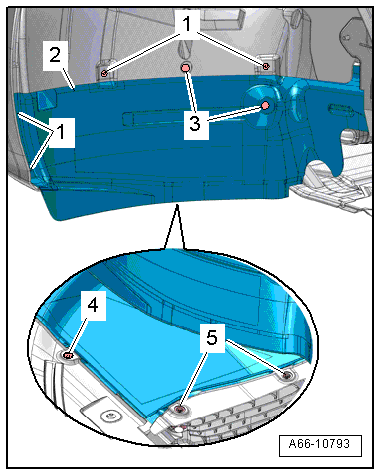

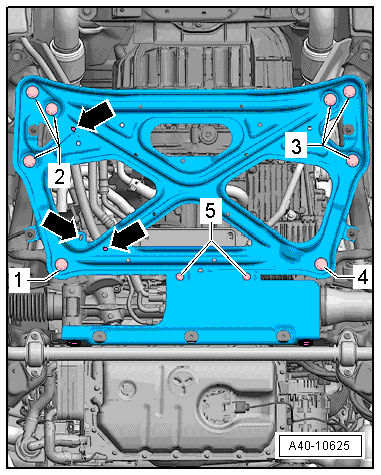

- Remove the noise insulation -1 and 2-. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

- Remove the left and right front wheel housing liners. Refer to → Body Exterior; Rep. Gr.66; Wheel Housing Liner; Front Wheel Housing Liner, Removing and Installing.

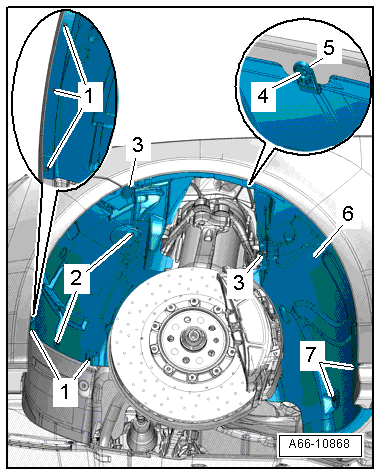

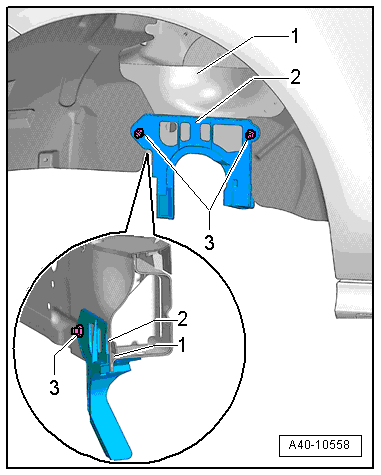

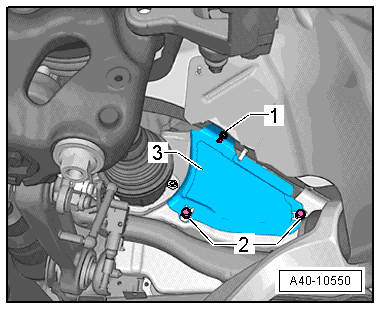

- Remove the nuts -3- and remove the cover -2- (if equipped) from the right and left drive axle.

- Tip the top of the cover -2- toward the outside and guide it downward by the seam -1-.

- Remove the left and right wheel spoiler. Refer to → Body Exterior; Rep. Gr.66; Wheel Housing Liner; Overview - Front Wheel Housing Liner.

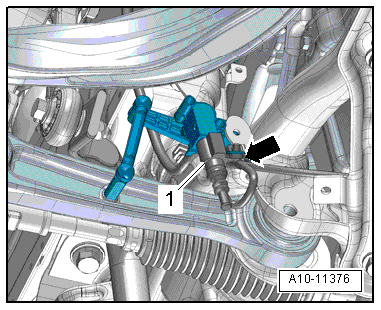

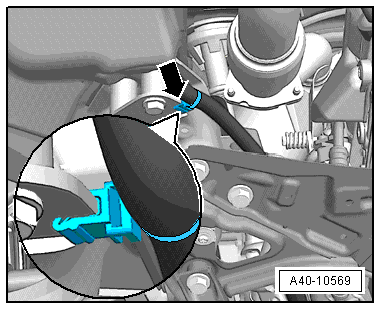

- Disconnect the left and right connector -1- from the vehicle level sensor (if equipped) and remove the clip -arrow-.

- Remove the right and left clamps for the vehicle level sensor wires from the subframe.

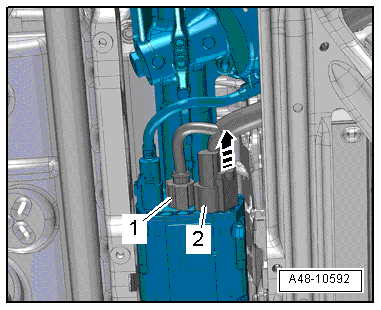

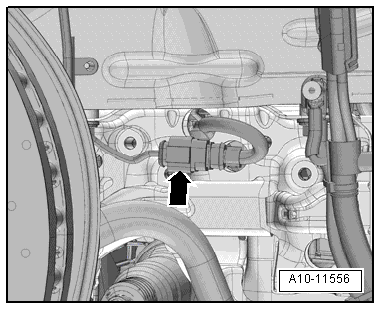

- Remove the connector -1- for the vehicle signals (CAN bus and terminal 15) from the Power Steering Control Module -J500-.

- Release the safety mechanism -arrow-, push the retainer downward and disconnect the connector -2- for the voltage (terminal 30) from the Power Steering Control Module -J500-.

- Free up the clip -arrow-, disconnect the connector -1- and free up the electric wire.

- Remove the remaining clips -arrows- on the crossbrace and free up the wiring harness.

Note

Note

Ignore Items -1 through 5-.

- Open the clip -arrow- on the left rear subframe and free up the wiring harness.

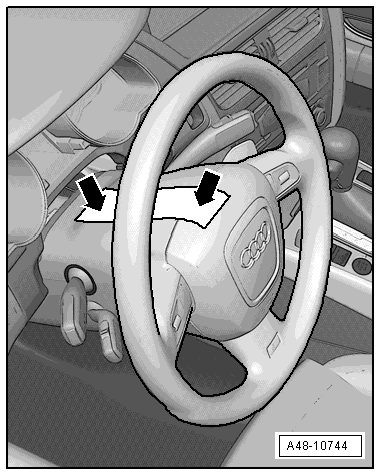

- Turn the steering wheel so that the wheels are in the straight-ahead position and then tape it secure -arrow- so that it cannot turn.

Note

Note

- Be sure to use tape that will not leave behind any residue when it is removed.

- Be careful not to turn the steering wheel during the repair because the Airbag Spiral Spring/Return Spring with Slip Ring -F138- can become damaged.

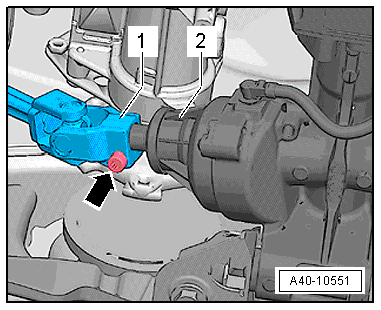

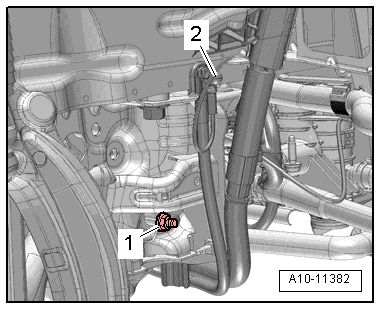

- Remove the bolt -arrow-.

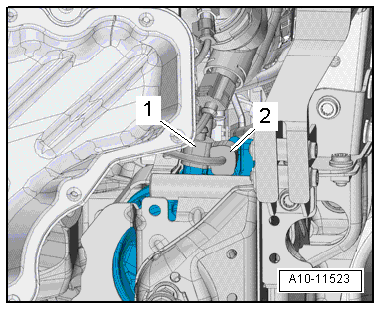

- Remove the universal joint -1- from the steering gear -2- and support the steering intermediate shaft so that it cannot fall.

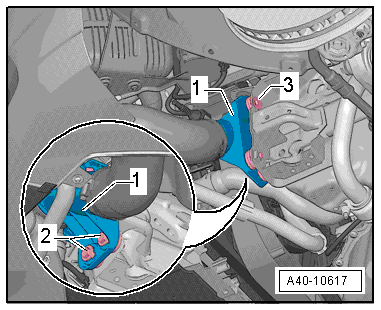

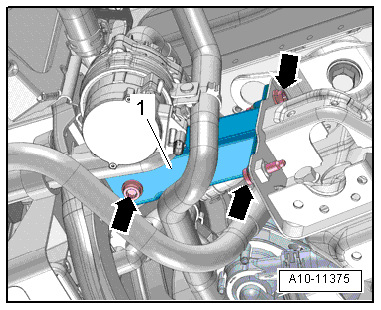

- Remove the right and left nuts -1- and bolts -2- and remove the heat shield upper section -3-.

- If equipped remove the Transmission Fluid Cooling Valve -N509-. Refer to → Engine Mechanical, Fuel Injection and Ignition; Rep. Gr.19; Coolant Pump/Thermostat; Coolant Valve, Removing and Installing.

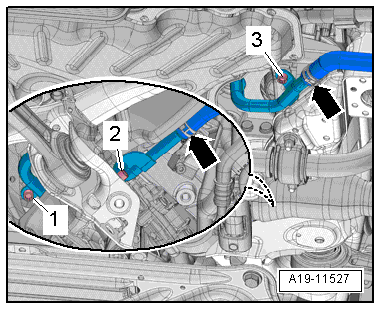

- For vehicles with an intermediate flange -1-, remove the bolts -2 and 3- and free up the intermediate flange with the hoses still connected.

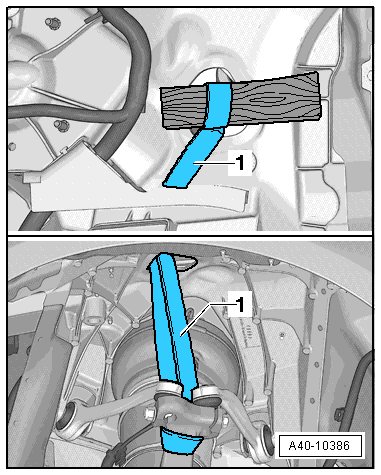

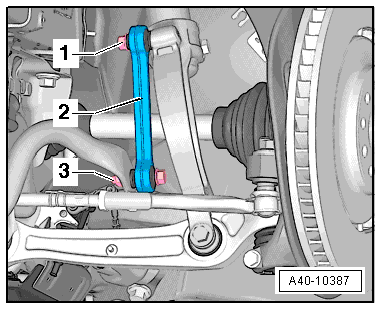

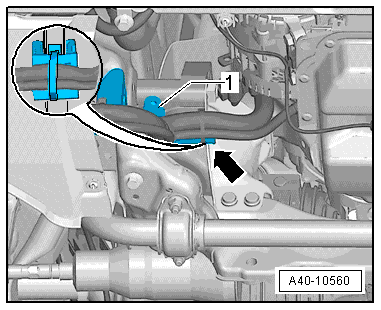

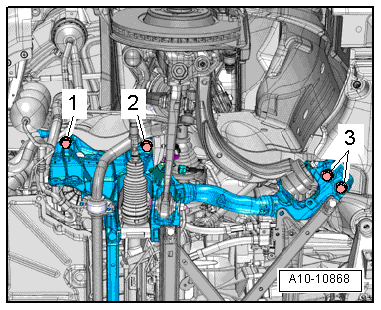

- Tie up the left and right wheel bearing housings using the Tensioning Strap -T10083--1-, as illustrated.

Note

Note

To prevent the joints on the upper control arm from being damaged, support the wheel bearing housing.

- Remove the left and right control arms. Refer to → Chapter "Control Arm, Removing and Installing".

- Remove the nut from the left and right guide link joint pins enough so it is flush with the joint pin threads. Counterhold the joint pins if necessary.

- Press the guide link joint pin off the conical seat using the Puller - Ball Joint -T40042-.

Note

Note

- Be careful not to damage CV boot in the process!

- Make sure that both puller lever arms are parallel to each other when using greatest force.

- Separate the left and right guide link from the wheel bearing housing. Be careful not to damage the CV boot on the guide link joint pin.

- Remove the threaded connector -1- for the right and left coupling rods on the shock absorber fork.

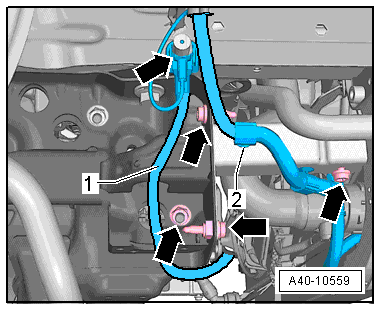

- Disconnect and free up the connectors -1- for the Right Electrohydraulic Engine Mount Solenoid Valve -N145- and -2- and for the Left Electrohydraulic Engine Mount Solenoid Valve -N144-.

Applies to Audi RS6

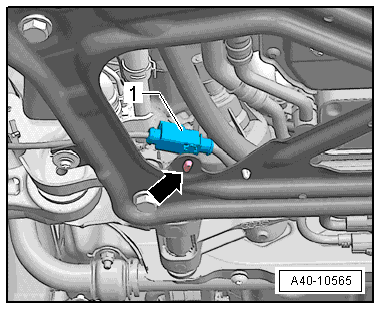

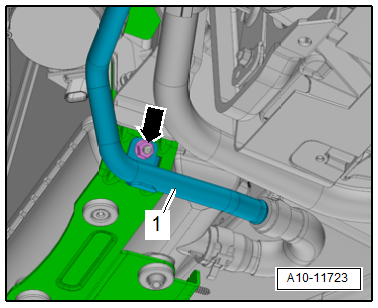

- Remove the nut -arrow-, free up the coolant pipe -1- and push it slightly to the side.

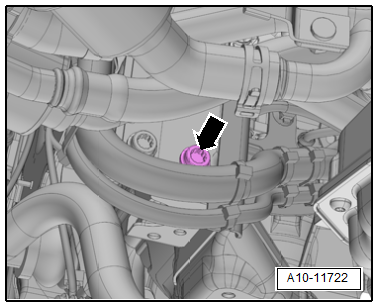

- Remove the bolt -arrow- and free up the wiring harness.

Applies to Vehicles with a 6- or 8-Cylinder Engine

- Remove the bolts -arrows- and the left lower front longitudinal member -1-.

- Remove the nuts and bolts -arrows- and free up the Ground (GND) cable -1- and the electric wire -2-.

- Remove the right lower front longitudinal member.

- Loosen the hose clamps -arrows-, then clamp off the coolant hoses with the Hose Clamps - Up To 25mm -3094- and remove the hoses.

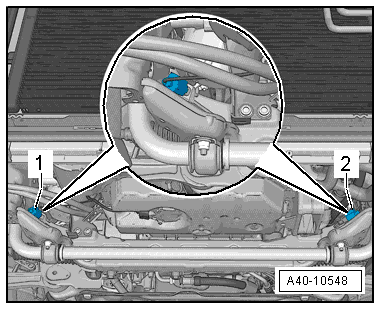

- Disconnect the left and right connectors -1 and 2-.

- Remove the connector -arrow- from the mount, disconnect it, and then guide it through the subframe.

Continuation for All

- Remove the nuts -1 and 2-, if necessary, and move the GND cable -arrow- to the side.

- Remove the right and left clip -arrow- from the engine mount bracket and free up the wires and the metal bracket -1-.

- There is also a wire attached to the rear engine bracket on the left, depending on the engine type.

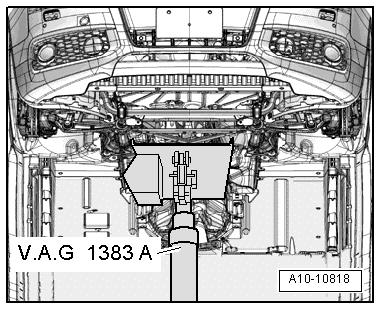

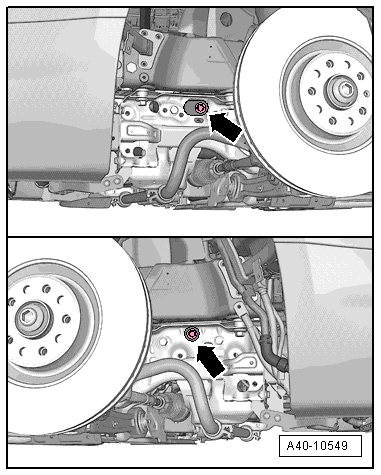

- Support the subframe using the Engine and Gearbox Jack -VAS6931- and a piece of hard wood, as shown.

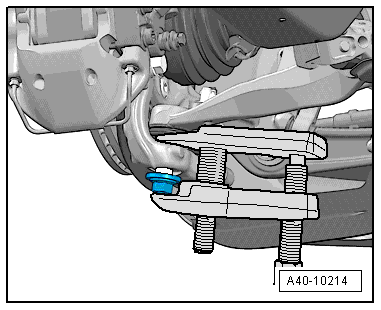

- Remove the bolt -arrow- for the left and right engine mounts.

- Mark the location of the subframe to the longitudinal members using a felt-tip pen.

- Remove the left and right bolts -1, 2 and 3- from the subframe diagonally and in steps.

- Lower the subframe using the Engine and Gearbox Jack -VAS6931-.

Note

Note

Make sure there is enough clearance for the electric lines when lowering the subframe.

- Replace the attachments later if necessary.

Installing

Install in reverse order of removal. Note the following:

WARNING

WARNING

Pull on the -Item 1- steering intermediate shaft to make sure it is installed correctly with the bolt installed. Tighten the bolt -Item 1-.

Note

Note

Perform a pre-adjustment on the subframe if it is being replaced or if it had to be removed in order to loosen the crossbrace.

Subframe Pre-Adjusting Procedure:

1 - Place the subframe over the head.

2 - Pre-install the steering gear and guide link (tighten the bolts hand-tight).

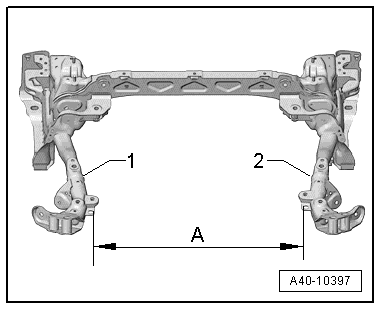

3 - Move the arms -1 and 2- to adjust dimension -A- (the inner edges of the holes must match up with each other).

4 - Mount the crossbrace and tighten it to the rear bolting points. The crossbrace is now pre-adjusted.

5 - Tighten the steering gear.

6 - Tighten the crossbrace at the front 2 attaching points.

Dimension -A- = 599 mm

Note

Note

- Bonded rubber bushings have a limited range of motion. Only tighten suspension bolts when vehicle is in curb weight or control position.

- Lift wheel bearing in control position. Refer to → Chapter "Wheel Bearing in Control Position, Lifting Vehicles with Air Suspension" or → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Position the subframe on the body at the location marked.

- Tighten the subframe bolts diagonally.

WARNING

WARNING

All bolts and nuts must be tightened properly before driving the vehicle!

- To determine if an axle alignment is required, see Table. Refer to → Chapter "Evaluating Need for Axle Alignment".

- On vehicles with automatic head lamp range control, perform headlamp basic setting. Refer to → Electrical Equipment; Rep. Gr.94; Headlamp; Headlamp, Adjusting.

- If the Level Control Sensor is removed or installed on a vehicle with air suspension or if the linkage was loosened, the control position must be programmed again by starting the correct program on the Vehicle Diagnostic Tester in Guided Functions.

- If the control position was reprogrammed on vehicles with lane assist, the Camera Control Module -J852- must be calibrated again. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".