Audi A6 Typ 4G: Wheel Bearing Housing Bonded Rubber Bushing, Replacing

Wheel Bearing Housing Bonded Rubber Bushing, Replacing, FWD Vehicles

Special tools and workshop equipment required

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Rod -VW408A-

- Press Piece - Rod -VW411-

- Shop Press -VAG1290A-

- Bearing Installer - Wheel Bearing Bushing -T40184-

Removing

- Remove wheel bearing housing. Refer to → Chapter "Wheel Bearing Housing, Removing and Installing, FWD Vehicles".

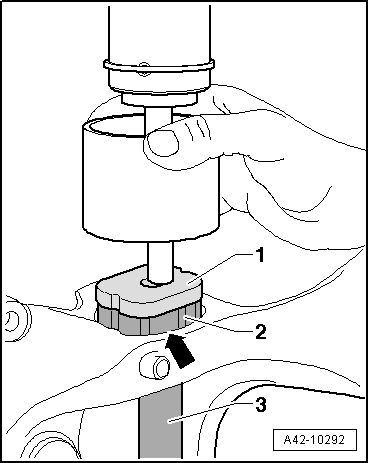

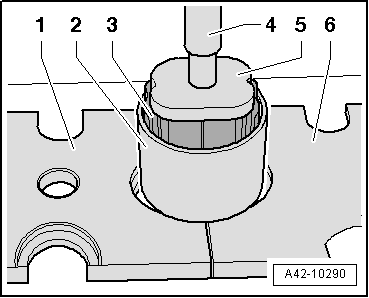

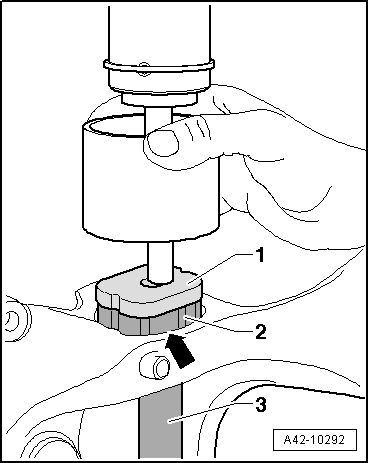

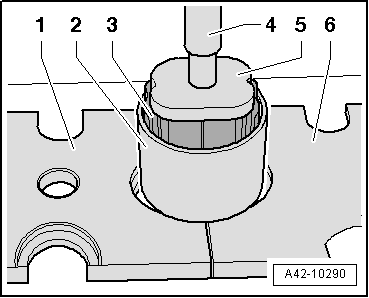

- In order to remove the front rubber bonded bushing, the Bearing Installer - Wheel Bearing Bushing - Pressure Plate -T40184/2--3- must be mounted on the front rubber bonded bushing in such a way so that the lugs -2- fit into the grooves -4-.

- Place the tools on the front bonded rubber bushing and the wheel bearing housing as illustrated.

Note

Note

When mounting the wheel bearing housing onto the Sleeve -T40184/1- be careful not to damage or push the rubber grommet on the rear rubber bonded bushing.

1 - Press Piece - Rod -VW411-

2 - Bearing Installer - Wheel Bearing Bushing - Pressure Plate -T40184/2-

3 - Wheel bearing housing

4 - Bearing Installer - Wheel Bearing Bushing - Sleeve -T40184/1-. The side with the groove must face the wheel bearing housing. On a bonded rubber bushing with a "positioning tab", this is in the groove on the Bearing Installer - Wheel Bearing Bushing - Sleeve -T40184/1-.

- Press out the front rubber bonded bushing.

Installing

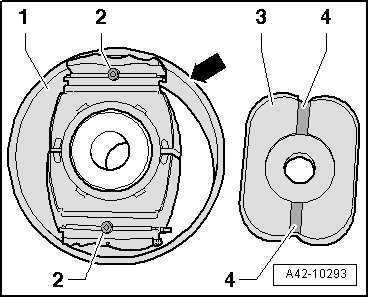

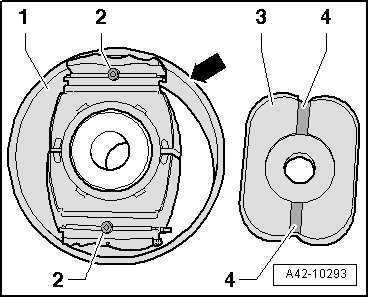

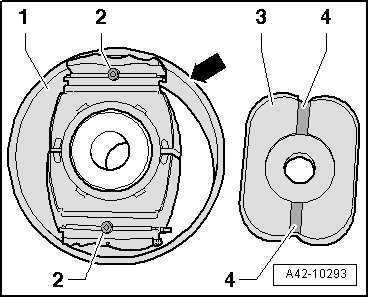

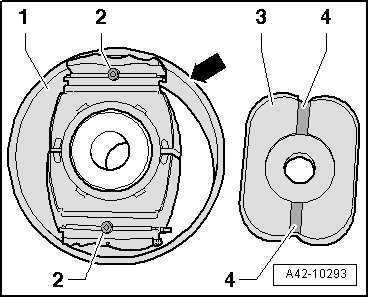

- Place the front bonded rubber bushing in the Bearing Installer - Wheel Bearing Bushing - Sleeve -T40184/3-. The "thin" collar -arrow- must face upward.

- In order to install the front rubber bonded bushing, the Bearing Installer - Wheel Bearing Bushing - Pressure Plate -T40184/2--3- must be mounted on the front rubber bonded bushing in such a way so that the lugs -2- fit into the grooves -4-.

- Press the front rubber bonded bushing all the way onto the thrust plates -1 and 6-.

1 - Press Plate -VW401-. Arrange as illustrated.

2 - Sleeve -T40184/3-

3 - Front bonded rubber bushing

4 - Press Piece - Rod -VW408A-

5 - Bearing Installer - Wheel Bearing Bushing - Pressure Plate -T40184/2-

6 - Press Plate -VW402-. Arrange as illustrated.

- Then slightly pull apart the thrust plates -1 and 6-.

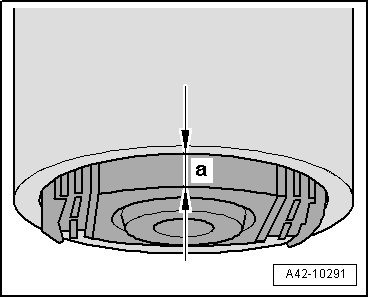

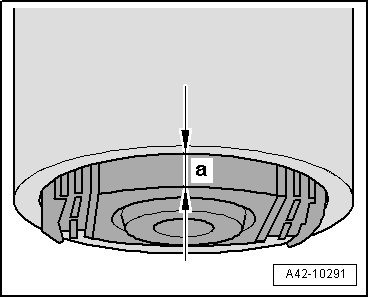

- Press the front rubber bonded bushing approximately 2 mm out of the Sleeve -T40184/3-.

a = 2 mm

- Remove the Press Piece - Rod -VW408A- and insert the Press Piece - Rod -VW411-.

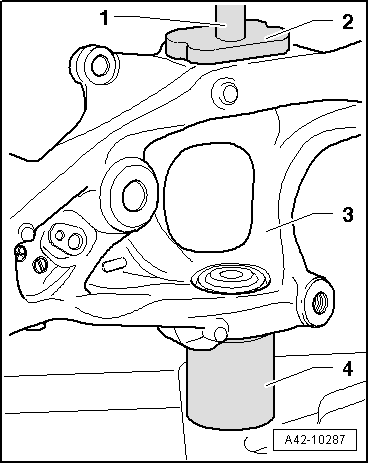

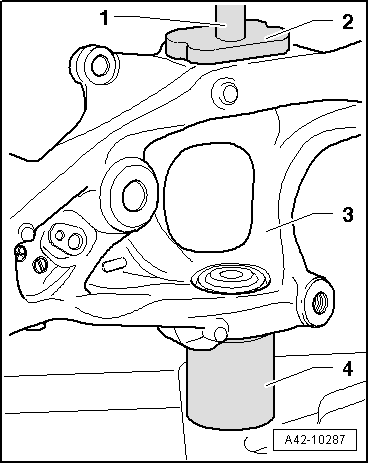

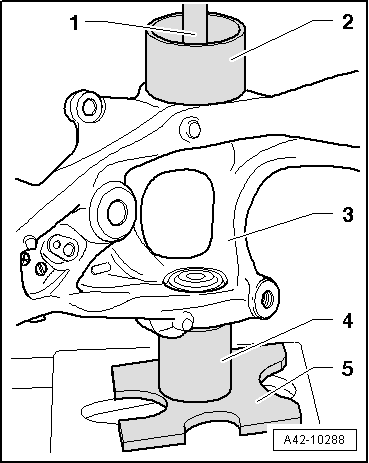

- Position the wheel bearing housing on the Shop Press -VAG1290A-.

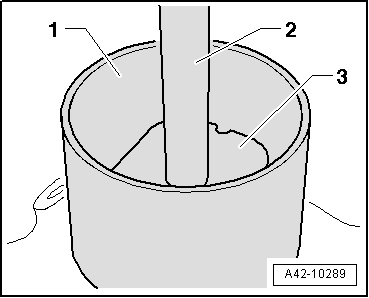

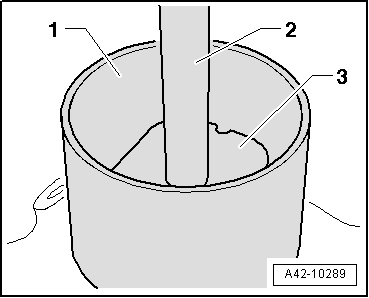

- Mount the front rubber bonded bushing (not shown in the illustration), the pressure plate -3- and the sleeve -1- on the wheel housing bearing.

1 - Sleeve -T40184/3-

2 - Press Piece - Rod -VW411-

3 - Bearing Installer - Wheel Bearing Bushing - Pressure Plate -T40184/2- Pay attention to the installation position of the front rubber bonded bushing.

- Place the tools on the front bonded rubber bushing and the wheel bearing housing -3- as illustrated.

Note

Note

When mounting the wheel bearing housing onto the Sleeve -T40184/1- be careful not to damage or push the rubber grommet on the rear rubber bonded bushing.

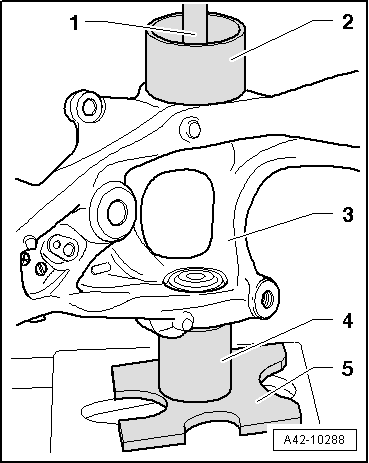

- Slowly press the front rubber bonded bushing in (not shown in the illustration) until the sleeve -2- can be pulled out at the top.

1 - Press Piece - Rod -VW411-

2 - Sleeve -T40184/3-

3 - Wheel bearing housing

4 - Bearing Installer - Wheel Bearing Bushing - Sleeve -T40184/1-. The side with the groove must face the wheel bearing housing. On a bonded rubber bushing with a "positioning tab", this is in the groove on the Bearing Installer - Wheel Bearing Bushing - Sleeve -T40184/1-.

5 - Press Plate -VW402-

- Slowly press the front rubber bonded bushing -2- so that it is even with the edge -arrow- of the wheel bearing housing.

Note

Note

Ignore Item -3-.

- Install the wheel bearing housing. Refer to → Chapter "Wheel Bearing Housing, Removing and Installing, FWD Vehicles".

Wheel Bearing Housing Bonded Rubber Bushing, Replacing, AWD Vehicles

Special tools and workshop equipment required

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Rod -VW408A-

- Press Piece - Rod -VW411-

- Shop Press -VAG1290A-

- Bearing Installer - Wheel Bearing Bushing -T40184-

Removing

- Remove wheel bearing housing. Refer to → Chapter "Wheel Bearing Housing, Removing and Installing, FWD Vehicles".

- In order to remove the front rubber bonded bushing, the Bearing Installer - Wheel Bearing Bushing - Pressure Plate -T40184/2--3- must be mounted on the front rubber bonded bushing in such a way so that the lugs -2- fit into the grooves -4-.

- Place the tools on the front bonded rubber bushing and the wheel bearing housing as illustrated.

Note

Note

When mounting the wheel bearing housing onto the Sleeve -T40184/1- be careful not to damage or push the rubber grommet on the rear rubber bonded bushing.

1 - Press Piece - Rod -VW411-

2 - Bearing Installer - Wheel Bearing Bushing - Pressure Plate -T40184/2-

3 - Wheel bearing housing

4 - Bearing Installer - Wheel Bearing Bushing - Sleeve -T40184/1-. The side with the groove must face the wheel bearing housing. On a bonded rubber bushing with a "positioning tab", this is in the groove on the Bearing Installer - Wheel Bearing Bushing - Sleeve -T40184/1-.

- Press out the front rubber bonded bushing.

Installing

- Place the front bonded rubber bushing in the Bearing Installer - Wheel Bearing Bushing - Sleeve - T40184/3-. The "thin" collar -arrow- must face upward.

- In order to install the front rubber bonded bushing, the Bearing Installer - Wheel Bearing Bushing - Pressure Plate -T40184/2--3- must be mounted on the front rubber bonded bushing in such a way so that the lugs -2- fit into the grooves -4-.

- Press the front rubber bonded bushing all the way onto the thrust plates -1 and 6-.

1 - Press Plate -VW401-. Arrange as illustrated.

2 - Sleeve -T40184/3-

3 - Front bonded rubber bushing

4 - Press Piece - Rod -VW408A-

5 - Bearing Installer - Wheel Bearing Bushing - Pressure Plate -T40184/2-

6 - Press Plate -VW402-. Arrange as illustrated.

- Then slightly pull apart the thrust plates -1 and 6-.

- Press the front rubber bonded bushing approximately 2 mm out of the Sleeve -T40184/3-.

a = 2 mm

- Remove the Press Piece - Rod -VW408A- and insert the Press Piece - Rod -VW411-.

- Position the wheel bearing housing on the Shop Press -VAG1290A-.

- Mount the front rubber bonded bushing (not shown in the illustration), the pressure plate -3- and the sleeve -1- on the wheel housing bearing.

1 - Sleeve -T40184/3-

2 - Press Piece - Rod -VW411-

3 - Bearing Installer - Wheel Bearing Bushing - Pressure Plate -T40184/2- Pay attention to the installation position of the front rubber bonded bushing.

- Place the tools on the front bonded rubber bushing and the wheel bearing housing -3- as illustrated.

Note

Note

When mounting the wheel bearing housing onto the Sleeve -T40184/1- be careful not to damage or push the rubber grommet on the rear rubber bonded bushing.

- Slowly press the front rubber bonded bushing in (not shown in the illustration) until the sleeve -2- can be pulled out at the top.

1 - Press Piece - Rod -VW411-

2 - Sleeve -T40184/3-

3 - Wheel bearing housing

4 - Bearing Installer - Wheel Bearing Bushing - Sleeve -T40184/1-. The side with the groove must face the wheel bearing housing. On a bonded rubber bushing with a "positioning tab", this is in the groove on the Bearing Installer - Wheel Bearing Bushing - Sleeve -T40184/1-.

5 - Press Plate -VW402-

- Install the front bonded rubber bushing -2- using Bearing Installer - Wheel Bearing Bushing Pressure Plate -T40184/2--1- slowly until it is flush with the edge -arrow- of the wheel bearing housing.

Note

Note

Ignore Item -3-.

- Install the wheel bearing housing. Refer to → Chapter "Wheel Bearing Housing, Removing and Installing, FWD Vehicles".