Audi A6 Typ 4G: Overview - Rear Brakes

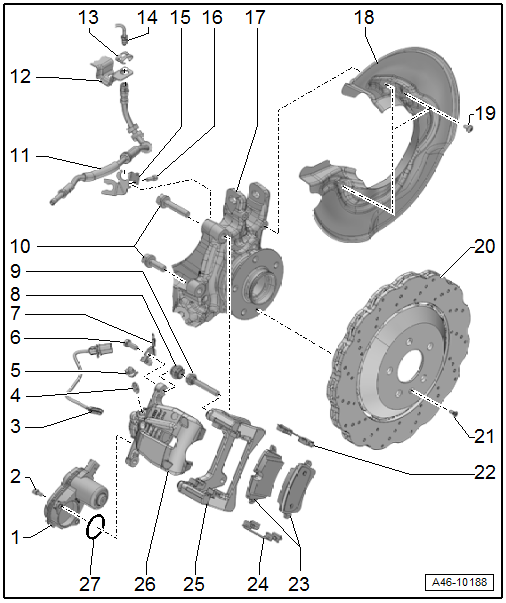

Overview - Rear Brakes, Steel Brakes

Note

Note

Applies to all steel rear brakes

1 - Electromechanical Parking Brake Motor

- Left Parking Brake Motor -V282-/Right Parking Brake Motor -V283-

- Left Parking Brake Motor -V282-/Right Parking Brake Motor -V283-, removing and installing. Refer to → Chapter "Left/Right Parking Brake Motor -V282-/-V283-, Removing and Installing".

- Electromechanical Parking Brake Control Module -J540-, removing and installing. Refer to → Chapter "Electromechanical Parking Brake Control Module -J540-, Removing and Installing".

2 - Bolts

- 12 Nm

3 - Brake Pad Wear Sensor

- Left Rear Brake Pad Wear Sensor -G36-/Right Rear Brake Pad Wear Sensor -G37-

- For inner brake pad

- Replace if damaged

- Cannot be removed without being damaged

- Removing and installing. Refer to → Chapter "Brake Pad Wear Indicator Wire, Removing and Installing, Steel Brakes".

4 - Bleed Screw

- 13 Nm

- Bleed the brake system. Refer to → Chapter "Hydraulic System, Standard Bleeding".

5 - Protective Cap

6 - Bolt

- 35 Nm

- Self-locking

- Replace after removing

- When loosening and tightening, counterhold at the guide pin

7 - Bracket

- For the connector

8 - Protective Cover

- For the guide pins

- Install the repair kit if the caps or guide pins are damaged. Use the supplied grease packet to lubricate guide pins

9 - Guide Pin

- Check ease of movement

- Install the repair kit if the caps or guide pins are damaged. Use the supplied grease packet to lubricate guide pins

10 - Bolt

- 100 Nm +90º

- With a washer

- Note the different bolt lengths. The long bolt sits above.

- Replace after removing

11 - Brake Hose

- Make sure the brake hose is routed correctly. Make sure the brake hose is not blocked, bent or rubbing against the vehicle.

- Replace if damaged

- Make sure that tabs are properly seated in the grooves on the bracket.

- 20 Nm (brake hose to brake caliper)

12 - Bracket

- For brake hose

- Welded onto the body

13 - Spring

- Replace if damaged

14 - Brake Line

- 14 Nm (brake line to brake hose)

15 - Bracket

- For brake hose and electrical wires

16 - Bolt

- 9 Nm

17 - Stub Axle Carrier

18 - Brake Shield

- Removing and installing. Refer to → Chapter "Brake Shield, Removing and Installing".

19 - Bolt

- 10 Nm

20 - Brake Rotor

- Allocation. Refer to the Parts Catalog.

- Wear limit. Refer to → Chapter "Technical Data, Brakes"

- Always replace on both sides of the axle

- Removing and installing. Refer to → Chapter "Brake Rotor, Removing and Installing, Steel Brakes".

21 - Bolt

- 10 Nm

22 - Brake Pad Spring

- Replace when pads are replaced

- Make sure it fits correctly in the brake carrier

23 - Brake Pads

- Allocation. Refer to the Parts Catalog.

- Checking pad thickness. Refer to → for the wear limit.

- Always replace on both sides of the axle

- Removing and installing. Refer to → Chapter "Brake Pads, Removing and Installing, Steel Brakes".

- Note installation position:

- Identification "BA" = outer brake pad

- Identification "BI" = inner brake pad with brake pad wear indicator mount

24 - Brake Pad Spring

- Replace when pads are replaced

- Make sure it fits correctly in the brake carrier

25 - Brake Carrier

- Delivered as an assembled replacement part with sufficient grease on the guide pins

- Install the repair kit if the caps or guide pins are damaged. Use the supplied grease packet to lubricate guide pins

26 - Brake Caliper

- Removing and installing. Refer to → Chapter "Brake Caliper, Removing and Installing, Steel Brakes".

- Replacing. Refer to → Chapter "Brake Caliper, Replacing, Steel Brakes".

- Servicing. Refer to → Chapter "Brake Caliper Piston, Removing and Installing".

27 - O-Ring

- Replace after removing

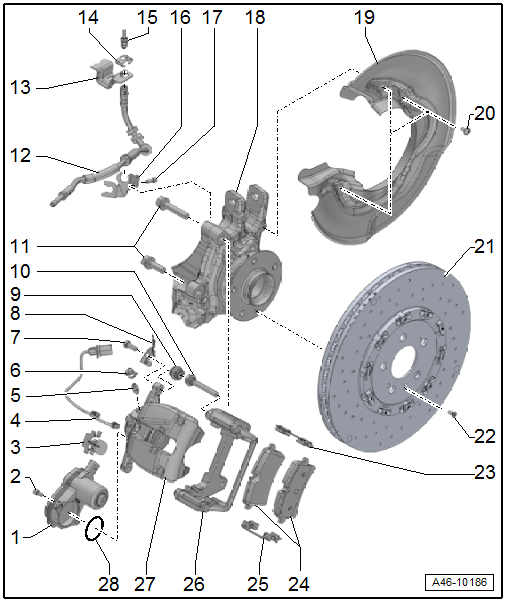

Overview - Rear Brakes, Ceramic Brakes

1 - Electromechanical Parking Brake Motor

- Left Parking Brake Motor -V282-/Right Parking Brake Motor -V283-

- Left Parking Brake Motor -V282-/Right Parking Brake Motor -V283-, removing and installing. Refer to → Chapter "Left/Right Parking Brake Motor -V282-/-V283-, Removing and Installing".

- Electromechanical Parking Brake Control Module -J540-, removing and installing. Refer to → Chapter "Electromechanical Parking Brake Control Module -J540-, Removing and Installing".

2 - Bolts

- 12 Nm

3 - Bracket

- For brake pad wear sensor electrical wire

4 - Brake Pad Wear Sensor

- Left Rear Brake Pad Wear Sensor -G36-/Right Rear Brake Pad Wear Sensor - G37-

- Replace if damaged

- Cannot be removed without damaging it

- Removing and installing. Refer to → Chapter "Brake Pad Wear Indicator Wire, Removing and Installing, Ceramic Brakes".

5 - Bleed Screw

- 13 Nm

- Bleed the brake system. Refer to → Chapter "Hydraulic System, Standard Bleeding".

6 - Protective Cap

7 - Bolt

- 35 Nm

- Self-locking

- Replace after removing

- When loosening and tightening, counter-holding the guide pin

8 - Bracket

- For the connector

9 - Protective Cover

- For the guide pins

- Install the repair kit if the caps or guide pins are damaged. Use the supplied grease packet to lubricate the guide pins.

10 - Guide Pin

- Check ease of movement

- Install the repair kit if the caps or guide pins are damaged. Use the supplied grease packet to lubricate the guide pins.

11 - Bolt

- 100 Nm +90º

- With a washer

- Note the different bolt lengths. The long bolt sits above.

- Replace after removing

- When loosening and tightening, counter-holding the guide pin

12 - Brake Hose

- Make sure the brake hose is routed correctly. Make sure the brake hose is not blocked, bent or rubbing against the vehicle.

- Replace if damaged

- Make sure that tabs are properly seated in the grooves on the bracket.

- 20 Nm (brake hose to brake caliper)

13 - Bracket

- For brake hose

- Welded onto the body

14 - Spring

- Replace if damaged

15 - Brake Line

- 14 Nm (brake line to brake hose)

16 - Bracket

- For brake hose and electrical wires

17 - Bolt

- 9 Nm

18 - Stub Axle Carrier

19 - Brake Shield

- Removing and installing. Refer to → Chapter "Brake Shield, Removing and Installing".

20 - Bolt

- 10 Nm

21 - Brake Rotor

- Allocation. Refer to the Parts Catalog.

- Brake Rotor Thickness. Refer to → Chapter "Ceramic Brake Rotor, Determining Wear".

- Additionally check for:

- Cracks in connection area. Refer to → Chapter "Cracks in Ceramic Brake Rotor Connection Area".

- Chamfer. Refer to → Chapter "Chamfer".

- Nicks. Refer to → Chapter "Nicks on Ceramic Brake Rotor".

- Crack in cooling channel. Refer to → Chapter "Crack in Cooling Channel".

- Brake Rotor Thickness. Refer to → Chapter "Ceramic Brake Rotor, Determining Wear".

- Always replace on both sides of the axle

- Removing and installing. Refer to → Chapter "Brake Rotor, Removing and Installing, Ceramic Brakes".

22 - Bolt

- 10 Nm

23 - Brake Pad Spring

- Replace when pads are replaced

- Make sure it fits correctly in the brake carrier

24 - Brake Pads

- Checking pad thickness. Refer to → for the wear limit.

- Always replace on both sides of the axle

- Allocation. Refer to the Parts Catalog.

- Removing and installing. Refer to → Chapter "Brake Pads, Removing and Installing, Ceramic Brakes".

25 - Brake Pad Spring

- Replace when pads are replaced.

- Make sure it fits correctly in the brake carrier.

26 - Brake Carrier

- Delivered as an assembled replacement part with sufficient grease on the guide pins

- Install the repair kit if the caps or guide pins are damaged. Use the supplied grease packet to lubricate guide pins

27 - Brake Caliper

- Removing and installing. Refer to → Chapter "Brake Caliper, Removing and Installing, Ceramic Brakes".

- Replacing. Refer to → Chapter "Brake Caliper, Replacing, Ceramic Brakes".

- Servicing. Refer to → Chapter "Brake Caliper Piston, Removing and Installing".

28 - O-Ring

- Replace after removing